Preparation method of wearable friction generator based on flexible PU/PVDF composite nanofiber yarn

A composite nanofiber and friction generator technology, which is applied in the field of friction generator preparation and nanofiber materials, can solve the problems of small capacity, large volume, heavy quality, etc., and achieve high surface charge density, high specific surface area, and reliable principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

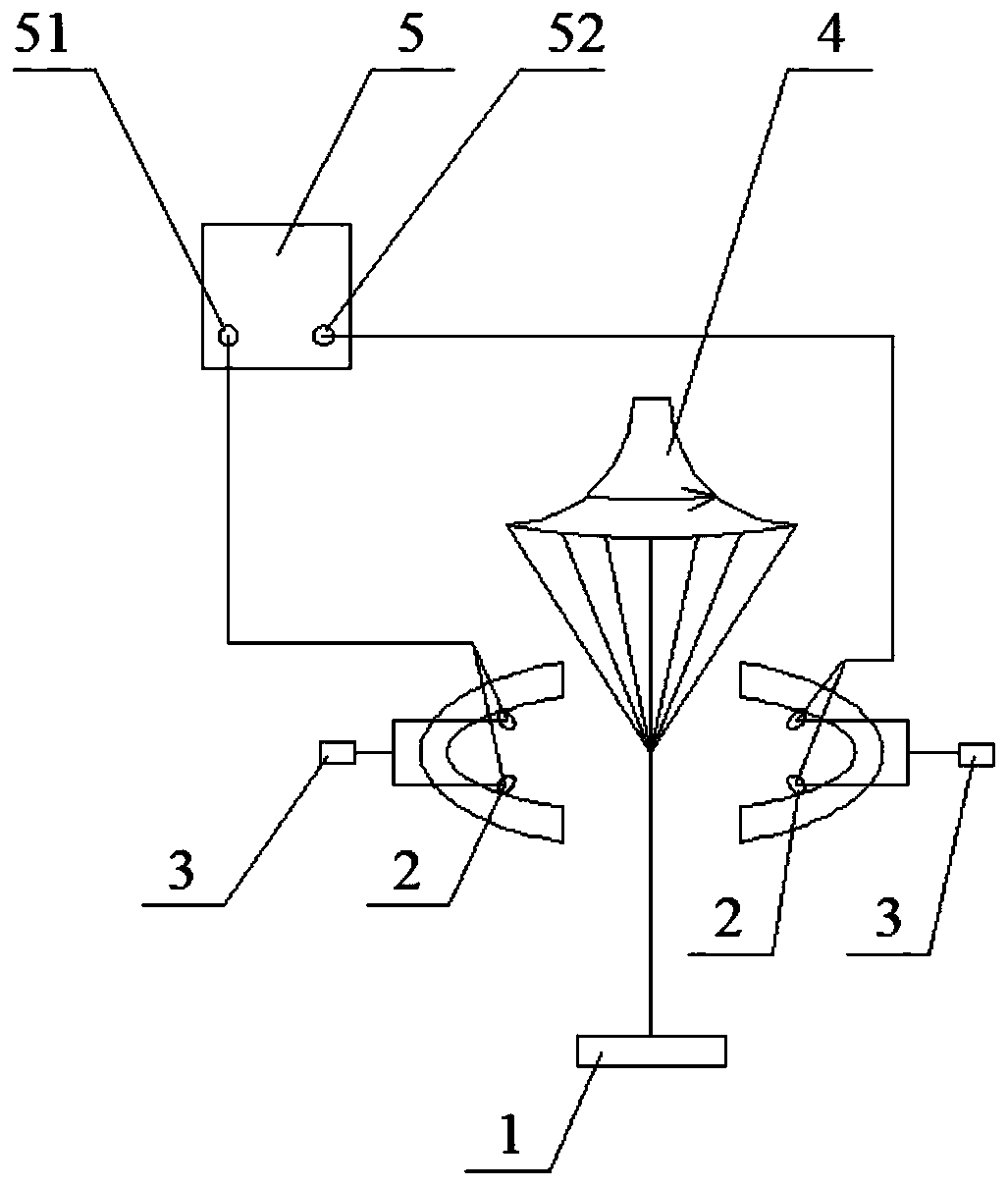

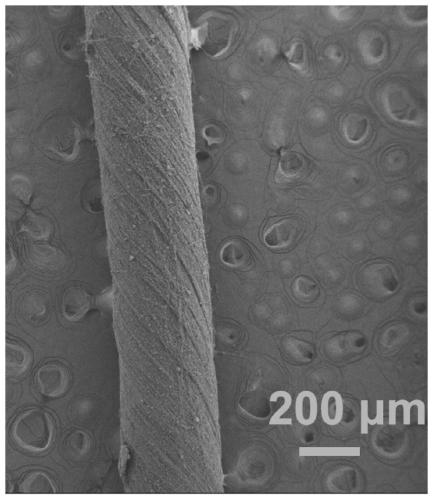

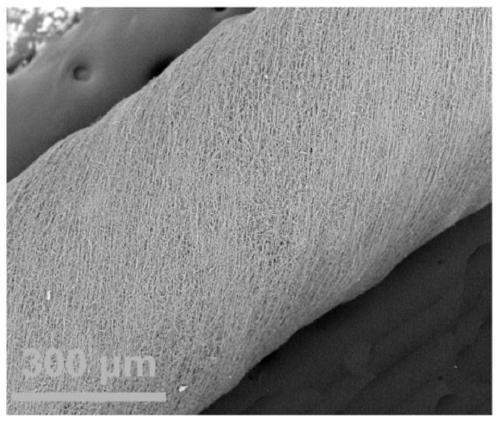

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the friction generator of the flexible PU / PVDF composite nanofiber yarn of the present embodiment is as follows:

[0039] (1) Put the elastic filament into the DT-03S low-temperature plasma treatment apparatus and carry out surface modification treatment for 45 minutes under the condition of discharge power of 150W to make it have a rough surface microstructure, and to coat the conductive solution for the next step prepare.

[0040] (2) Add the CNT powder into the toluene solvent, and carry out strong ultrasonic treatment under normal temperature and sealed conditions to obtain a uniformly dispersed CNT dispersion; then add the elastic polymer Parafilm film, and magnetically stir at 60°C for 6 hours to obtain a uniform CNT / Elastic polymer conductive dispersion; the solute (CNT and elastic polymer) accounts for 7% of the total mass of the solution, and CNT accounts for 15% of the solute mass.

[0041] (3) Using the method of physical coating, ...

Embodiment 2

[0052] The preparation method of the friction generator of the flexible PU / PVDF composite nanofiber yarn of the present embodiment is as follows:

[0053] (1) Put the elastic filament into the DT-03S low-temperature plasma treatment apparatus and perform surface modification treatment for 50 minutes under the discharge power of 160W to make it have a rough surface microstructure, which is used for coating the conductive solution in the next step prepare.

[0054] (2) Add the CNT powder into the toluene solvent, and perform a strong ultrasonic treatment under normal temperature and sealed conditions to obtain a uniformly dispersed CNT dispersion; then add elastic polymer polyurethane and magnetically stir at 70°C for 5 hours to obtain a uniform CNT / elastic Conductive polymer dispersion; the solute (CNT and elastic polymer) accounts for 8% of the total mass of the solution, and the CNT accounts for 20% of the solute mass.

[0055] (3) Using the method of physical coating, the s...

Embodiment 3

[0065] The preparation method of the friction generator of the flexible PU / PVDF composite nanofiber yarn of the present embodiment is as follows:

[0066] (1) Put the elastic filament into the DT-03S low-temperature plasma treatment apparatus and carry out surface modification treatment under the condition of discharge power of 170W for 60 minutes to make it have a rough surface microstructure, and to coat the conductive solution for the next step prepare.

[0067] (2) Add the CNT powder to the toluene solvent, and perform a strong ultrasonic treatment under normal temperature and sealed conditions to obtain a uniformly dispersed CNT dispersion; then add the elastic polymer polyurethane and magnetically stir at 75°C for 6 hours to obtain a uniform CNT / elastic Conductive polymer dispersion; the solute (CNT and elastic polymer) accounts for 9% of the total mass of the solution, and the CNT accounts for 25% of the solute mass.

[0068] (3) Using the method of physical coating, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com