IgY liposome spray and preparation method thereof

A liposome and lipid technology, applied in the directions of liposome delivery, antibodies, pharmaceutical formulations, etc., can solve the problems of destroying the immune system and resistance of patients, side effects of patients' health, and dependence of patients, so as to avoid inhibition. Effect, avoid enzyme damage, particle size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

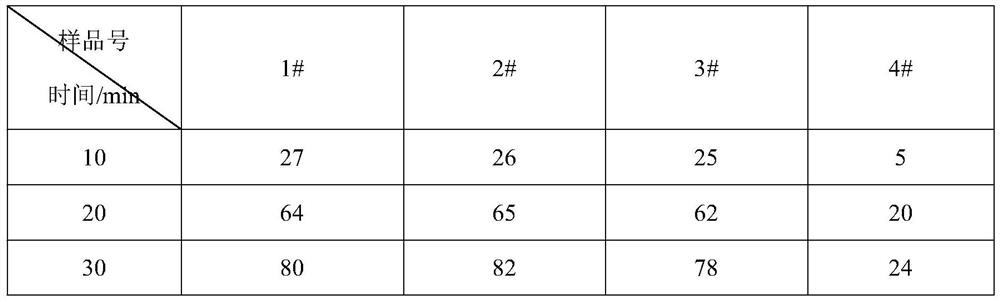

Examples

Embodiment 1

[0024] An IgY liposome spray comprises the following components in percentage by weight: 0.5% moisturizing agent, 0.5% preservative, 1% liposome lecithin, 0.5% stabilizer, 2% IgY antibody, and the rest is distilled water. Wherein, the humectant is trehalose, the preservative is 1,2 hexanediol, and the stabilizer is Tween 80.

[0025] The preparation process of liposomal lecithin is to dissolve egg yolk lecithin and cholesterol with hot ethanol to obtain a solution, wherein the concentration of egg yolk lecithin is 10 mg / mL, the concentration of cholesterol is 2 mg / mL, and the temperature of hot ethanol is 40 ° C. The solution was sheared and homogenized for 5 minutes, followed by high-pressure homogenization. The high-pressure homogenization pressure was 30 MPa, and the high-pressure homogenization time was 7 minutes to obtain liposomal lecithin. The average particle size was 88 nm, and the PDI was 0.25. ±0.09.

[0026] The preparation method of above-mentioned IgY liposome s...

Embodiment 2

[0033] An IgY liposome spray comprises the following components in weight percentage: 1% moisturizing agent, 1.5% preservative, 2% liposome lecithin, 0.8% stabilizer, 3% IgY antibody, and the rest is distilled water. Wherein, the moisturizing agent is trehalose, the preservative is hydroxyacetophenone, and the stabilizer is Tween 80.

[0034] The preparation process of liposomal lecithin is to dissolve egg yolk lecithin and cholesterol with hot ethanol to obtain a solution, wherein the concentration of egg yolk lecithin is 10 mg / mL, the concentration of cholesterol is 2 mg / mL, and the temperature of hot ethanol is 40 ° C. The solution was sheared and homogenized for 5 minutes, followed by high-pressure homogenization. The high-pressure homogenization pressure was 30 MPa, and the high-pressure homogenization time was 7 minutes to obtain liposomal lecithin. The average particle size was 90 nm, and the PDI was 0.21 ± 0.08.

[0035] The preparation method of above-mentioned IgY l...

Embodiment 3

[0042] An IgY liposome spray comprises the following components in percentage by weight: 1.5% moisturizing agent, 1% preservative, 2.5% liposome lecithin, 1% stabilizer, 4% IgY antibody, and the rest is distilled water. Wherein, the moisturizing agent is trehalose, the preservative is hydroxyacetophenone, and the stabilizer is Tween 80.

[0043] The preparation process of liposomal lecithin is to dissolve egg yolk lecithin and cholesterol with hot ethanol to obtain a solution, wherein the concentration of egg yolk lecithin is 10 mg / mL, the concentration of cholesterol is 2 mg / mL, and the temperature of hot ethanol is 40 ° C. The solution is sheared and homogenized, homogenized for 5min, then high-pressure homogenized, and the high-pressure homogenized pressure is 30MPa, and the high-pressure homogenized time is 7min, and the liposomal lecithin is obtained, and its particle diameter is that the average value is 90nm, and the PDI is 0.22±0.05.

[0044] The preparation method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com