Antibacterial and anti-sticking agent for gum dipping process and preparation method of antibacterial and anti-sticking agent

The technology of anti-sticking agent and anti-bacterial agent is applied in the field of anti-sticking anti-sticking agent for dipping process and its preparation, which can solve the problems of erosion of dipped paper and limited application, and achieve good antibacterial performance, good antibacterial activity, and inhibit bacteria. effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

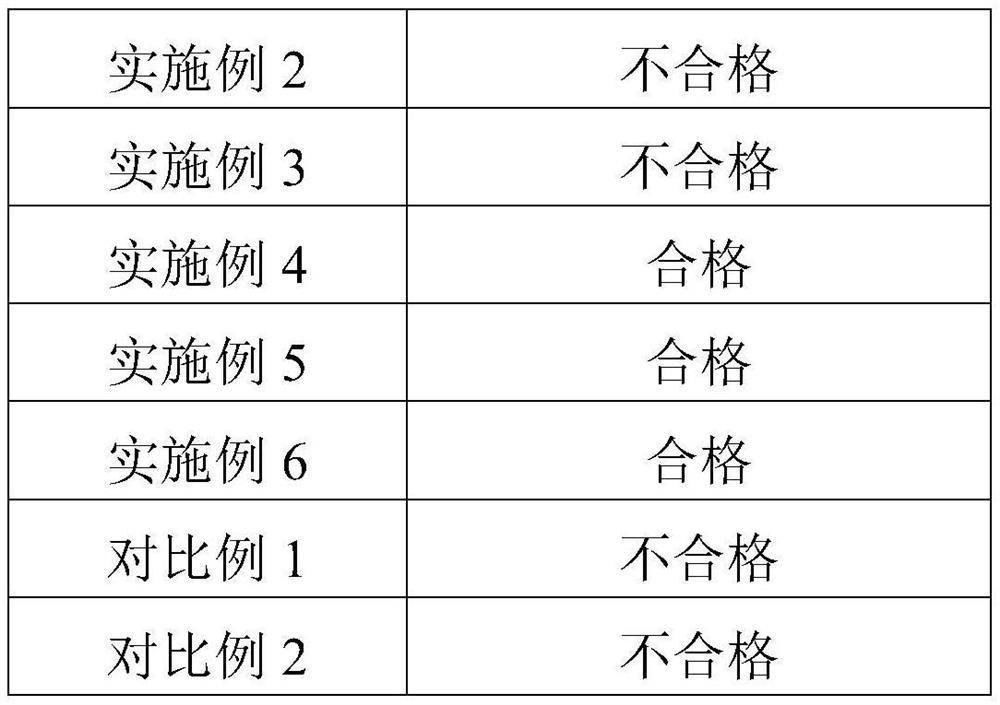

Embodiment 1

[0038] A method for preparing an anti-sticking agent, comprising the following steps: in parts by mass, heating 25 parts of beeswax to 70°C to melt, then adding 6 parts of emulsifier and mixing, stirring at a speed of 180r / min for 6 minutes to obtain the anti-sticking agent .

[0039] The emulsifier is prepared by mixing Tween 80 and polyacrylamide at a mass ratio of 2:1.

Embodiment 2

[0041] A preparation method of an anti-sticking agent, comprising the following steps:

[0042] (1) In terms of parts by mass, take 35 parts of cactus and peel the skin, homogenize its meat quality with a speed of 6000r / min for 4min, then add 55 parts of absolute ethanol, stir with a speed of 300r / min for 30min, filter to obtain a cactus ethanol solution;

[0043] (2) In terms of parts by mass, heat 25 parts of beeswax to 70° C. to melt, then add 35 parts of cactus ethanol solution and 6 parts of emulsifier, mix, and stir at 180 r / min for 6 minutes to obtain the anti-sticking agent.

[0044] The emulsifier is prepared by mixing Tween 80 and polyacrylamide at a mass ratio of 2:1.

Embodiment 3

[0046] A preparation method of an anti-sticking agent, comprising the following steps:

[0047] (1) In terms of parts by mass, take 35 parts of cactus and peel the skin, homogenize its meat quality with a speed of 6000r / min for 4min, then add 55 parts of absolute ethanol, stir with a speed of 300r / min for 30min, filter to obtain a cactus ethanol solution;

[0048] (2) In parts by mass, heat 25 parts of beeswax to 70°C, then add 35 parts of cactus ethanol solution and 6 parts of emulsifier, keep stirring at 180r / min for 6min at 70°C, and finally add 1.4 parts of pH regulator, continue Stir at 180r / min for 6min, and cool to room temperature to obtain the anti-sticking agent.

[0049] The emulsifier is prepared by mixing Tween 80 and polyacrylamide at a mass ratio of 2:1.

[0050] The pH regulator is oxalic acid-sodium oxalate buffer solution with pH=6.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com