Surface coating method of zirconia ceramic implant material and application thereof

A zirconia ceramic and surface coating technology, applied in the field of surface treatment of implant materials, can solve the problems of easy falling off of micron-scale coatings, achieve good biological activity and osteogenic performance, improve biological characteristics, and improve biological activity The effect of the agent on osteogenic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

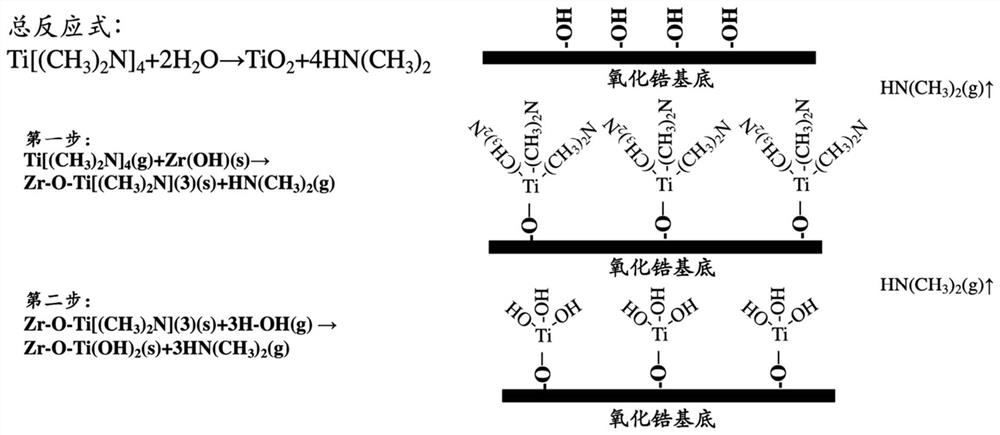

[0056] This embodiment provides a preparation method for forming a metal oxide film on the surface of a zirconia ceramic substrate by ALD technology. The reaction principle is as follows: figure 1 shown, including the following steps:

[0057] (1) Introduce the precursor A tetradimethylaminotitanium into the reaction chamber, and perform the first surface reaction with the reaction sites on the zirconia ceramic substrate;

[0058] (2) purging with an inert gas to remove unreacted precursor A and volatile by-product dimethylamine in the reaction chamber;

[0059] (3) Precursor B water is introduced into the reaction chamber, and the second surface reaction is carried out with the site after the surface reaction in step (1), at this time, the surface is converted back to the initial surface with the same reaction site;

[0060] (4) purging with inert gas again, that is, completing a cycle process, depositing a titanium oxide film;

[0061] (5) Repeat the above steps (1)-(4), u...

Embodiment 2

[0073] This embodiment provides a method for preparing a functional gradient coating that forms a titanium oxide film layer-magnesia film layer on the surface of a zirconia ceramic substrate by ALD technology, and the steps are as follows:

[0074] Steps (1)-(6) are the same as in Example 1;

[0075] Step (7) introduces the corresponding precursor, and repeats steps (1)-(4) to obtain a magnesium oxide film with a target thickness;

[0076] In step (8), the obtained implant material is heated and tempered to obtain a magnesium oxide film with an amorphous structure.

[0077] The obtained implant material was tested, and the test results of its biological activity, osteogenic performance, bonding performance and wear resistance were comparable to those of Example 1.

Embodiment 3

[0079] This embodiment provides a method for preparing a functional gradient coating that forms a titanium oxide film layer-magnesia film layer on the surface of a zirconia ceramic substrate by ALD technology, and the steps are as follows:

[0080] Steps (1)-(6) are the same as in Example 1;

[0081] Step (7) introduces the corresponding precursor, and repeats steps (1)-(4) to obtain a silicon oxide film with a target thickness;

[0082] In step (8), the implant material obtained in step (7) is heated and tempered to obtain a silicon oxide film with an amorphous structure.

[0083] Step (9) introduces the corresponding precursor, and repeats steps (1)-(4) to obtain a magnesium oxide film with a target thickness;

[0084] In step (10), the obtained implant material is heated and tempered to obtain a magnesium oxide film with an amorphous structure.

[0085] The obtained implant material was tested, and the test results of its biological activity, osteogenic performance, bondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com