Flame-retardant synergistic functional master batch special for polyethylene modification and preparation method thereof

A polyethylene modification and functional masterbatch technology, applied in the field of plastic modification processing, can solve the problems of poor thermal stability of decabromodiphenylethane, damaged flame retardant effect, uneven dispersion, etc., and achieve good recycling and reprocessing. , good flame retardant effect, the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

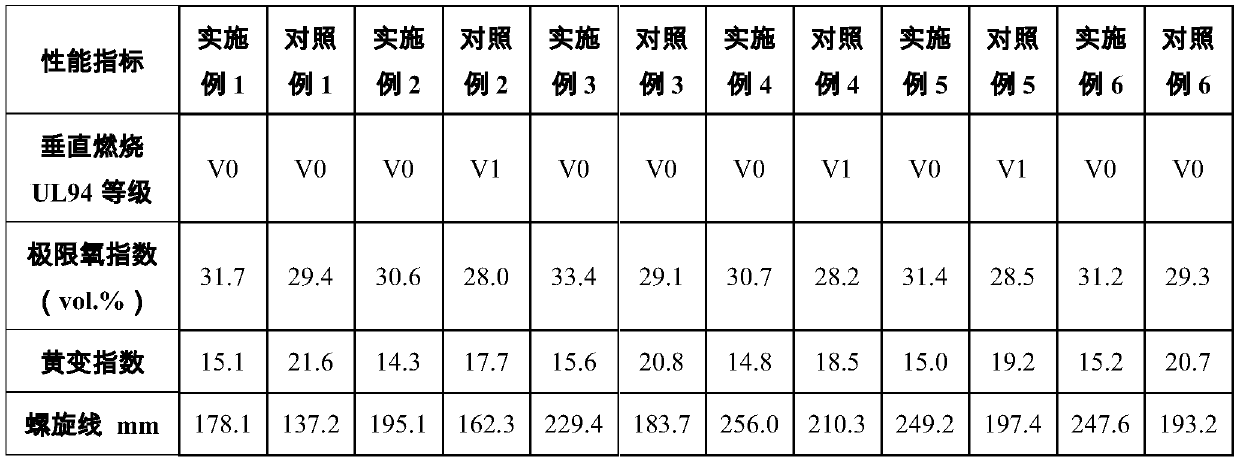

Examples

Embodiment 1

[0033] Multiple compound coated decabromodiphenylethane 70.0 kg Antimony trioxide 15.0 kg POE 13.0kg Styrene-acrylonitrile copolymer coated PTFE 1.0 kg stearic acid 700.0 g Ethylene bis stearamide 300.0 g

[0034] The preparation method of the above-mentioned functional masterbatch is as follows: Weigh all the raw materials according to the above-mentioned mass ratio requirements, put them into a high-speed mixer and mix them evenly, and then transfer them to the internal mixer for thermal mixing. The mixing temperature of the internal mixer is The temperature is 125°C, the mixing time is 16 minutes, and then the resulting dough blend is fed into a single-screw extruder through a conical feeder, melted and extruded and pelletized to obtain the flame retardant High-efficiency masterbatch; the screw speed of the single-screw extruder is 170 rpm, and the barrel temperature is controlled at 150-160°C in sections.

[0035] The prepara...

Embodiment 2

[0038] Multiple compound coated decabromodiphenylethane 55.0 kg Antimony trioxide 30.0 kg POE 11.5 kg Styrene-acrylonitrile copolymer coated PTFE 2.0 kg Oleamide 1.0 kg polyethylene wax 500.0 g

[0039] The preparation method of the above-mentioned functional masterbatch is as follows: Weigh all the raw materials according to the above-mentioned mass ratio requirements, put them into a high-speed mixer and mix them evenly, and then transfer them to the internal mixer for thermal mixing. The mixing temperature of the internal mixer is The temperature is 110°C, the mixing time is 20 minutes, and then the resulting dough blend is fed into a single-screw extruder through a conical feeder, melted and extruded and pelletized to obtain the flame retardant High-efficiency masterbatch; the screw speed of the single-screw extruder is 160 rpm, and the temperature of the barrel is controlled at 150-160°C in sections.

[0040] The preparatio...

Embodiment 3

[0043] Multiple compound coated decabromodiphenylethane 70.0 kg Antimony trioxide 15.0 kg POE 12.5kg Styrene-acrylonitrile copolymer coated PTFE 1.5 kg Zinc stearate 700.0 g Polydimethylsiloxane 300.0 g

[0044] The preparation method of the above-mentioned functional masterbatch is as follows: Weigh all the raw materials according to the above-mentioned mass ratio requirements, put them into a high-speed mixer and mix them evenly, then transfer them to the internal mixer for thermal mixing. The mixing temperature of the internal mixer is 100°C, the mixing time is 20 minutes, and then the resulting dough blend is fed into a single-screw extruder through a conical feeder, melted and extruded and pelletized to obtain the flame retardant synergistic Functional masterbatch; the screw speed of the single-screw extruder is 150 rpm, and the barrel temperature is controlled at 150-160°C in stages.

[0045] The preparation method of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com