Patents

Literature

32results about How to "Synergistic flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

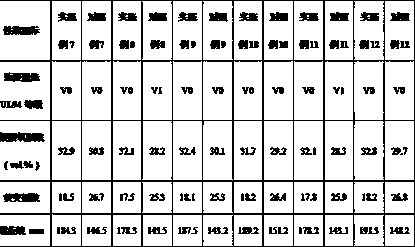

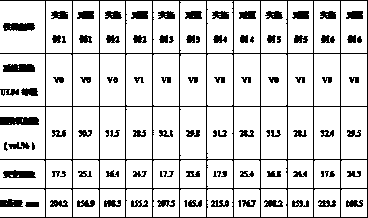

Special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and preparation method of halogen-free flame-retardant synergistic masterbatch

ActiveCN110591341AEffective protectionImprove thermal protection performanceAcrylonitrilePolytetrafluoroethylene

The invention relates to the technical field of modification and processing of plastics, in particular to special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and a preparation method of the halogen-free flame-retardant synergistic masterbatch. Multiple-compounded coated aluminum diethylphosphinate is adopted as a phosphorous-based flame retardant of the functional masterbatch, and the functional masterbatch comprises the compositions: in percent by mass, 55.0-65.0% of multiple-compounded coated aluminum diethylphosphinate, 20.0-30.0% of anhydrous zinc borate, 8.0-10.0% of nylon 6 resin, 3.0-5.0% of star-shaped nylon, 0.5-1.0% of styrene-acrylonitrile copolymer-coated polytetrafluoroethylene, 0.5-1.0% of a dispersant and 0.3-0.5% of a lubricant. Whenthe prepared functional masterbatch is compared with traditional flame-retardant functional masterbatch, the heat resistance and thermal stability of aluminum diethylphosphinate are improved significantly, aluminum diethylphosphinate is adaptive to a high processing temperature of nylon resin, so that the flame retardant effect of aluminum diethylphophinate on nylon resin is improved more effectively.

Owner:江苏万纳普新材料科技有限公司

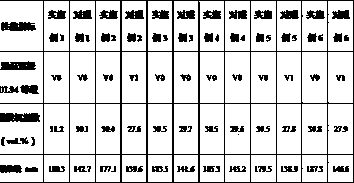

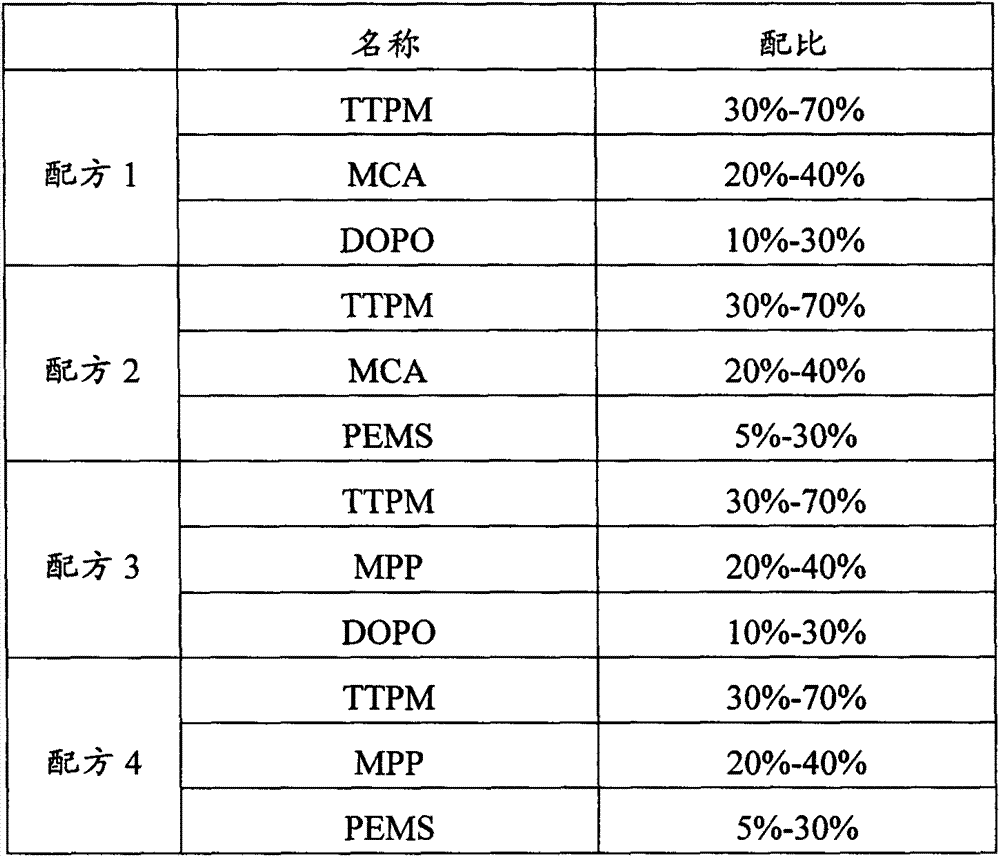

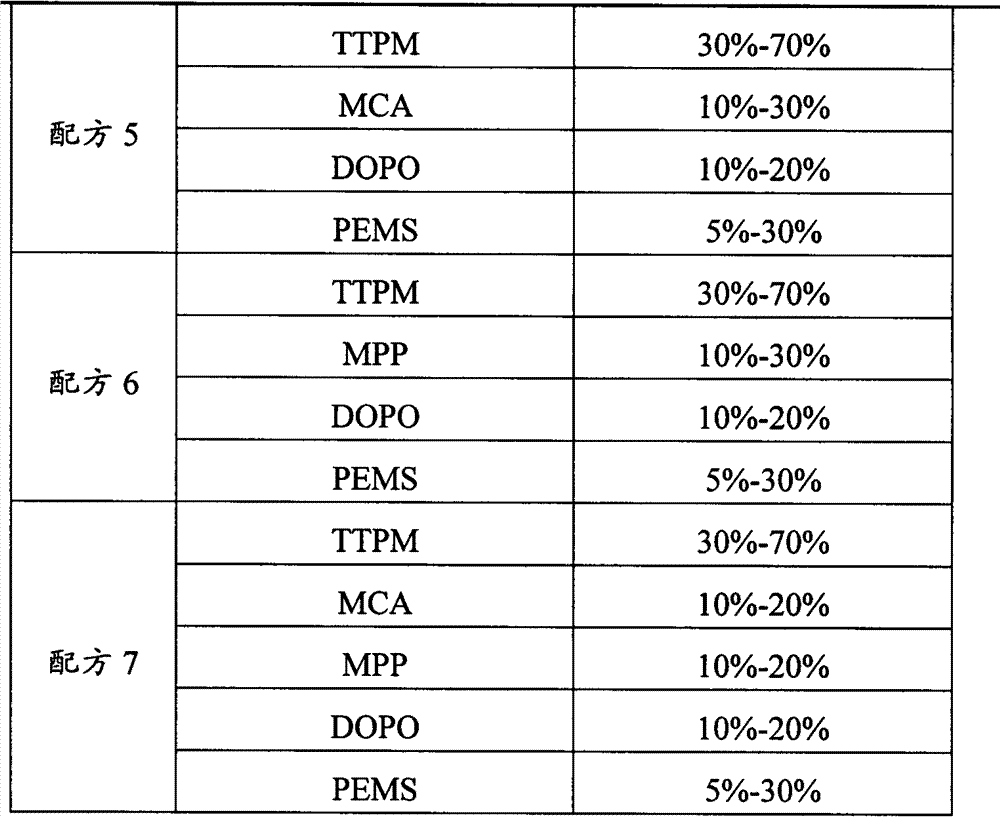

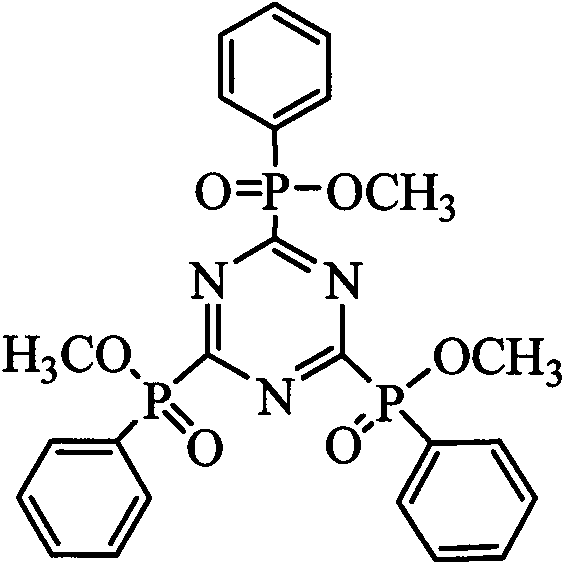

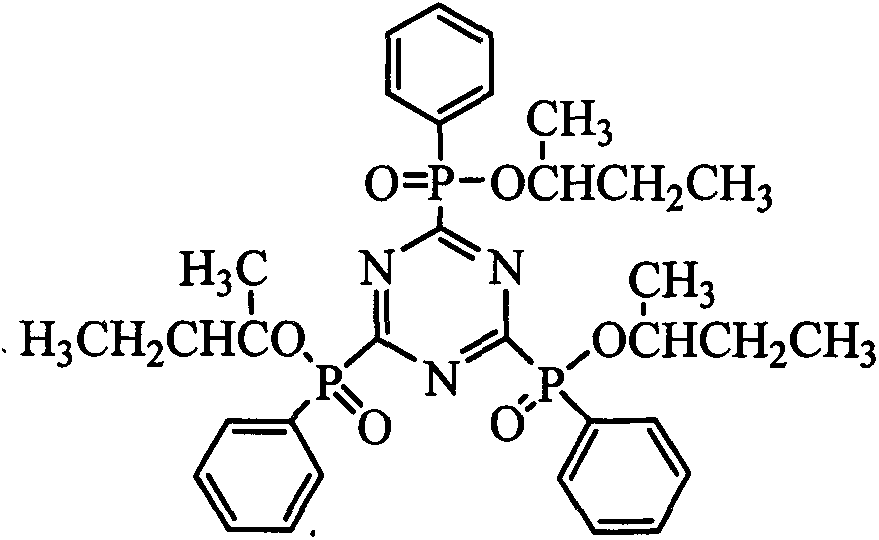

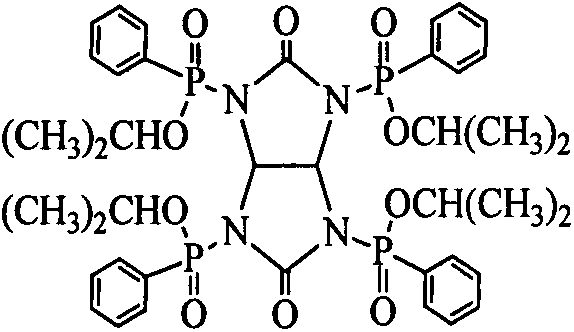

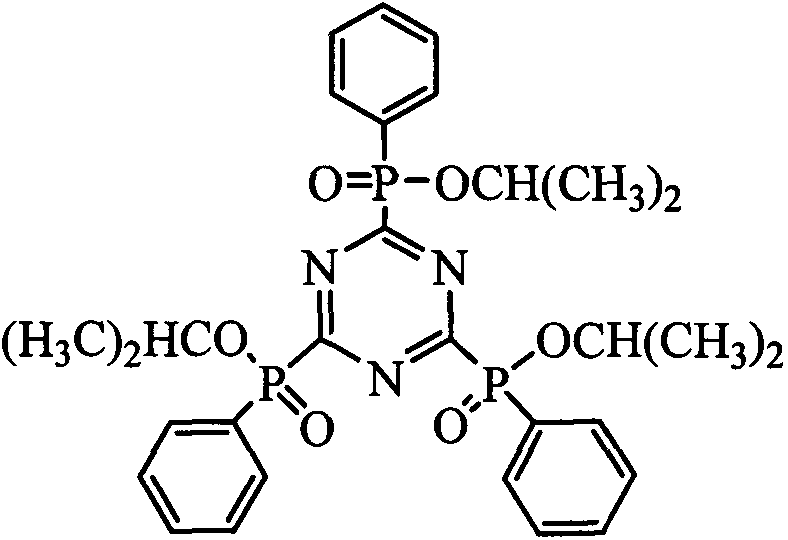

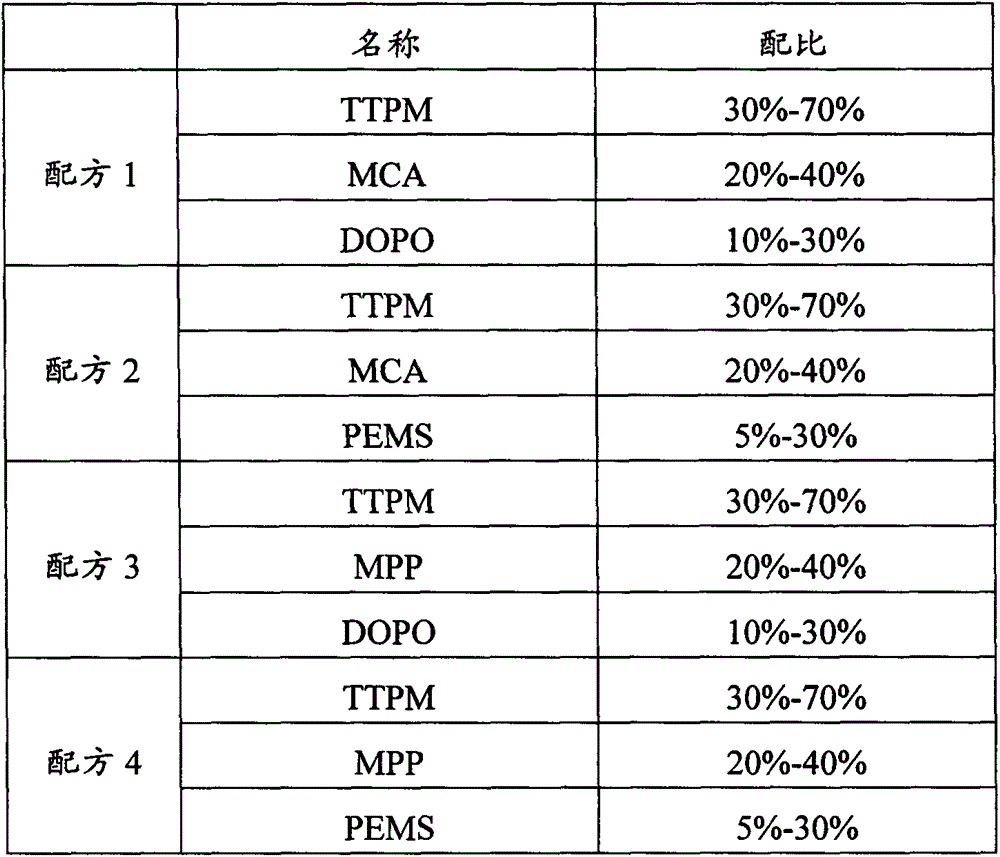

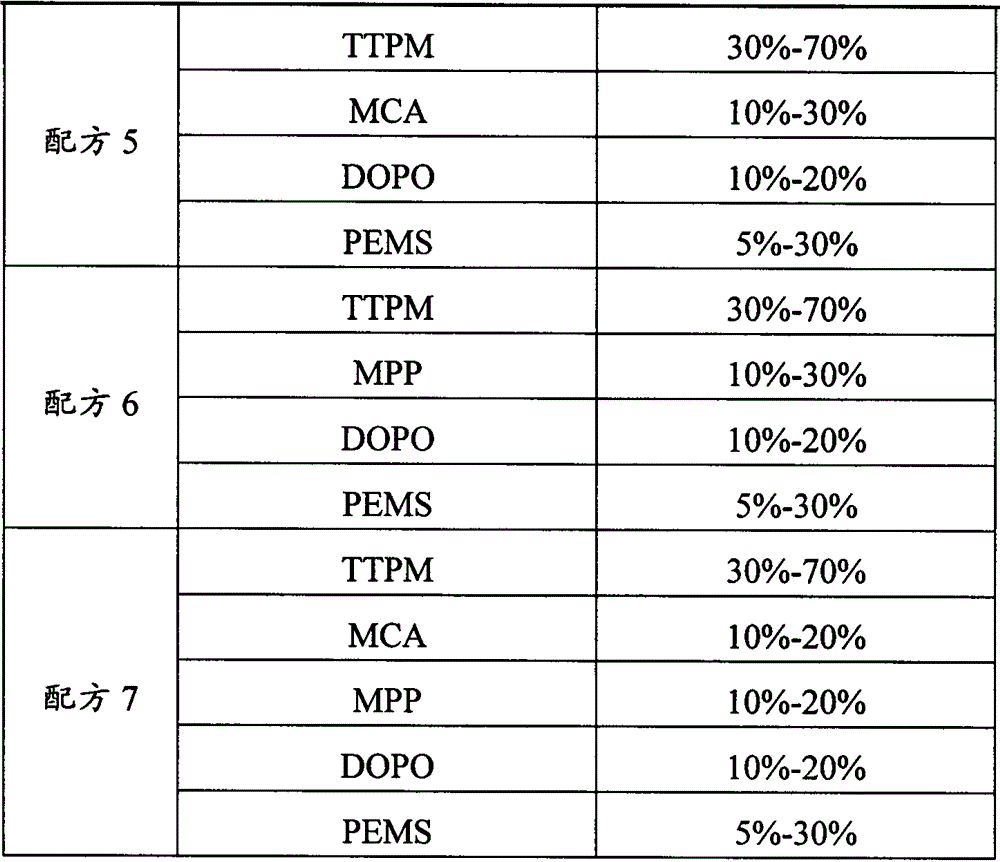

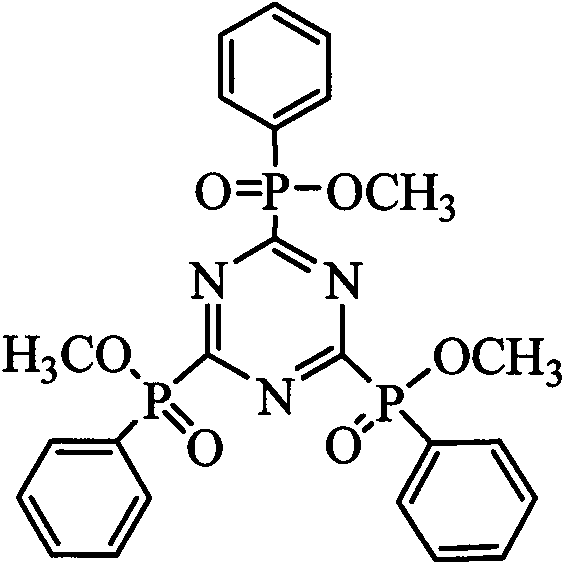

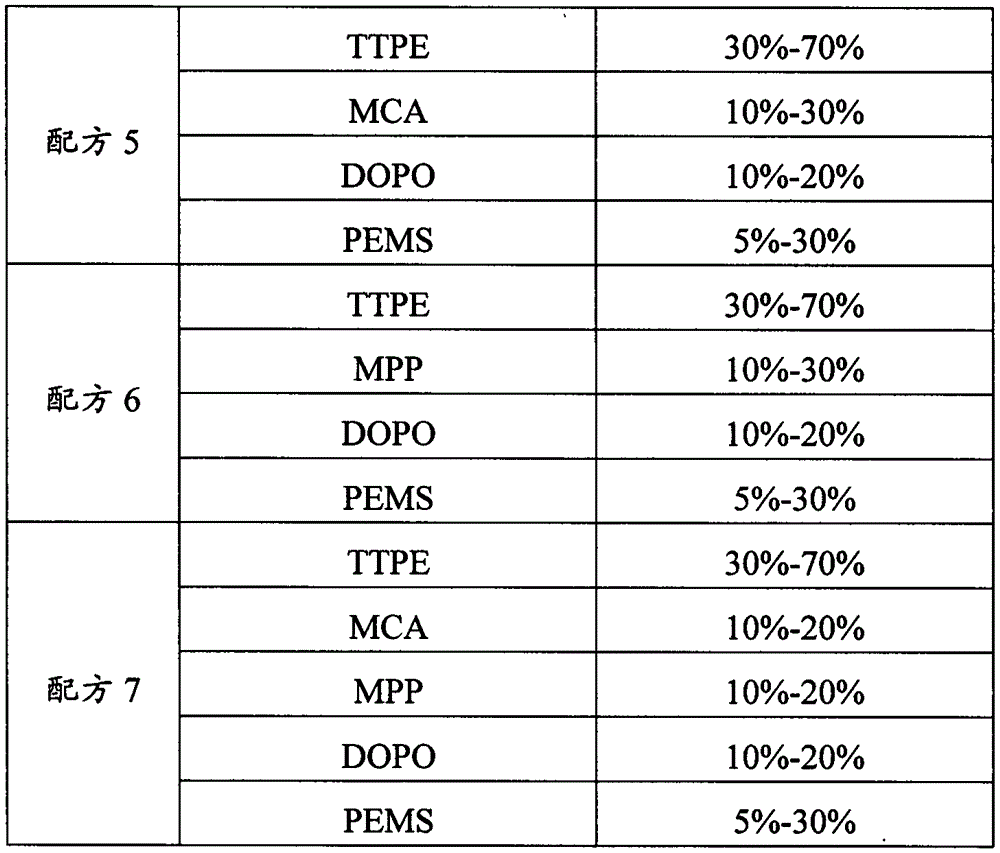

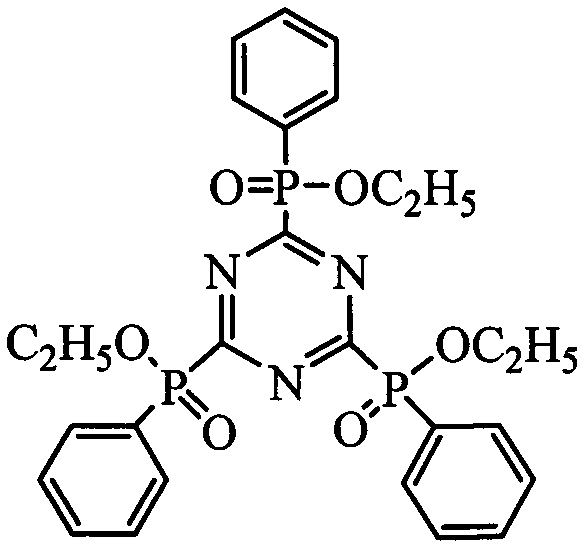

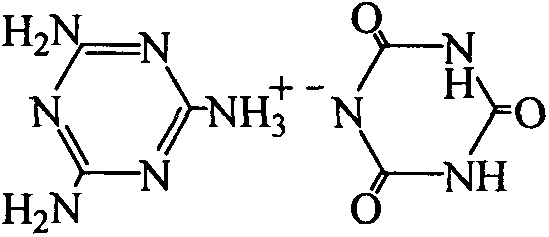

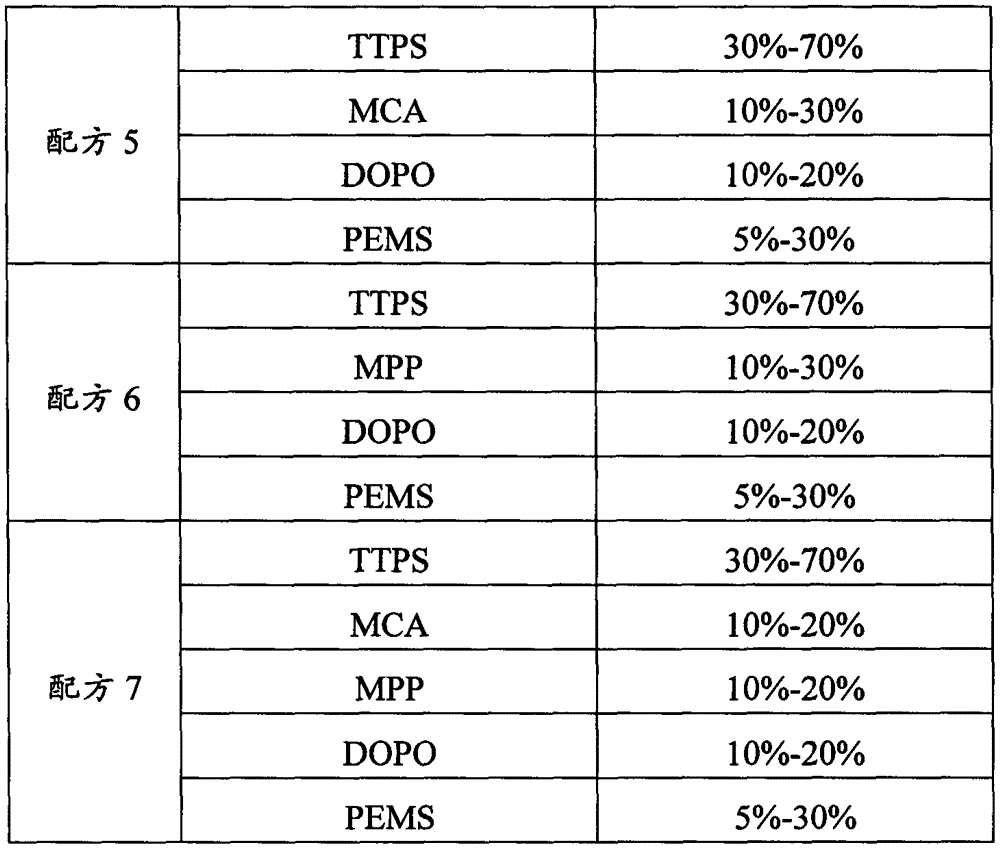

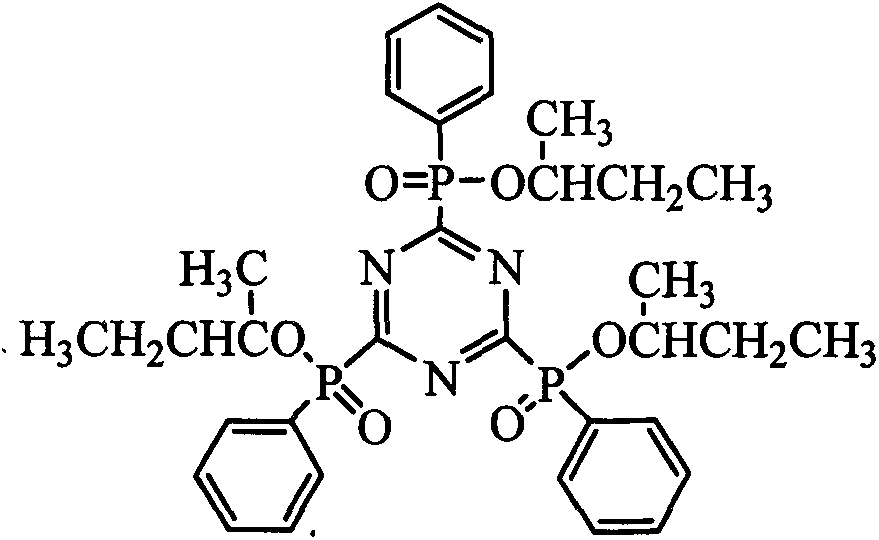

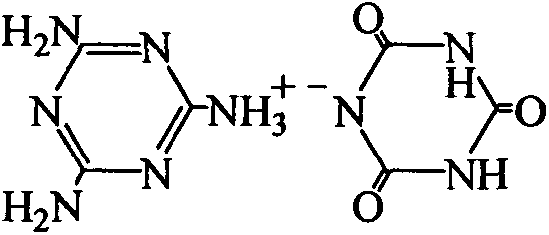

Triazine triphenyl phosphinic acid methyl ester flame retardant composition and application method thereof

The invention relates to a triazine triphenyl phosphinic acid methyl ester flame retardant composition and an application method thereof. The flame retardant composition is prepared by compounding and uniformly mixing any two, three or four of melamine cyanurate (MCA), melamine pyrophosphate (MPP), 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and pentaerythritol methyl silicate (PEMS) with triazine triphenyl phosphinic acid methyl ester (TTPM) at any proportion, wherein the weight part of the TTPM is greater than zero. The flame retardant composition provided by the invention has the advantages of multi-element synergic effect, good flame retardancy, good compatibility with materials, low cost, zero halogen, environmental protection and the like, can be used as a flame retardant for polyester PET, polyester PBT, polyurethane, polypropylene, epoxy resin and other materials, and has excellent application and popularization prospects.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

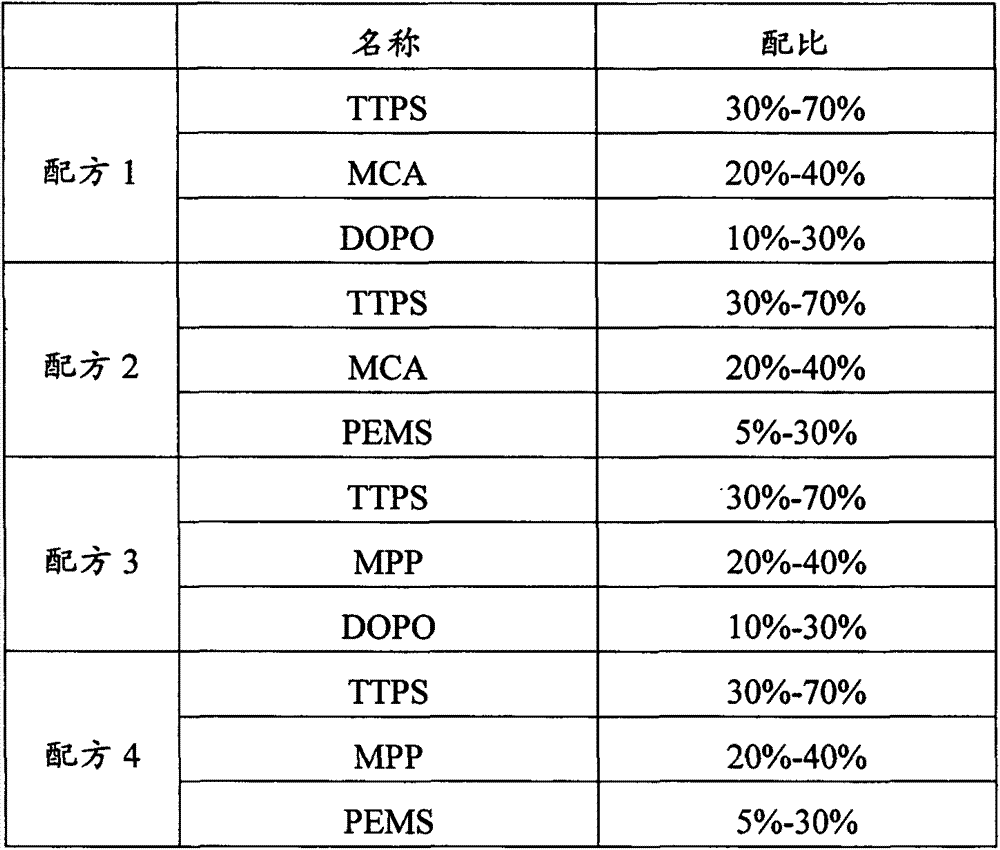

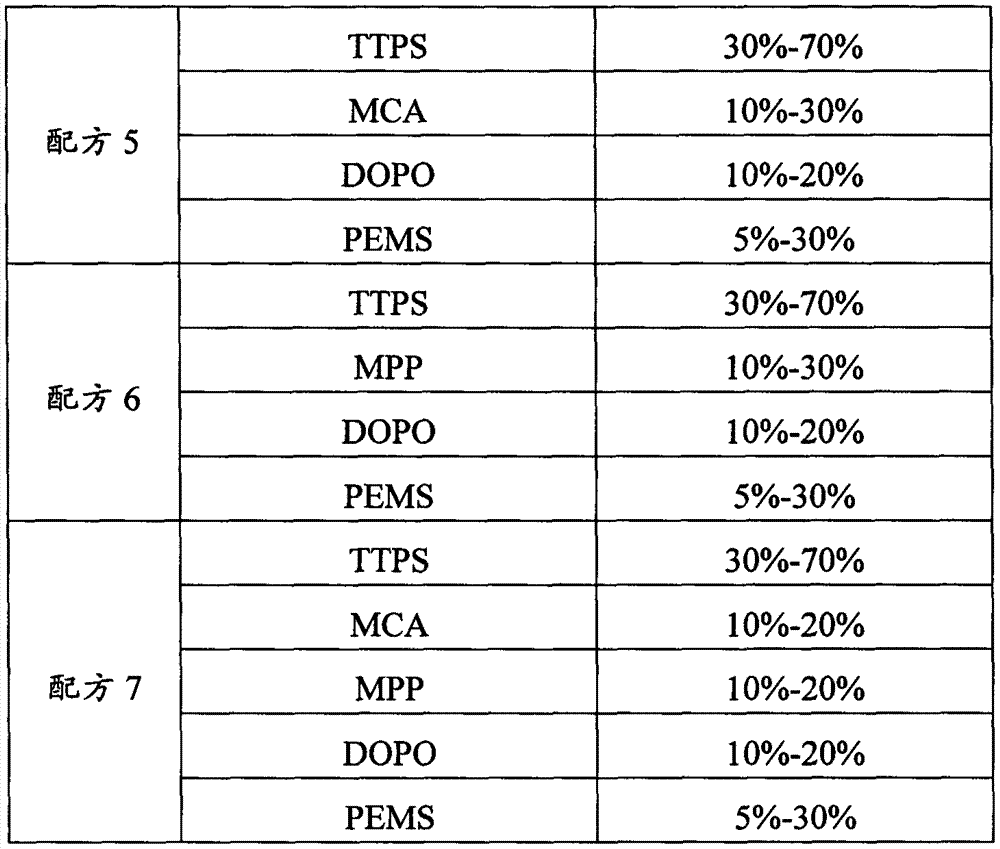

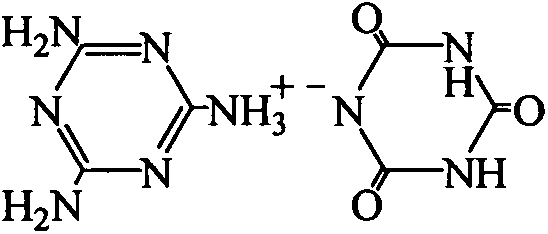

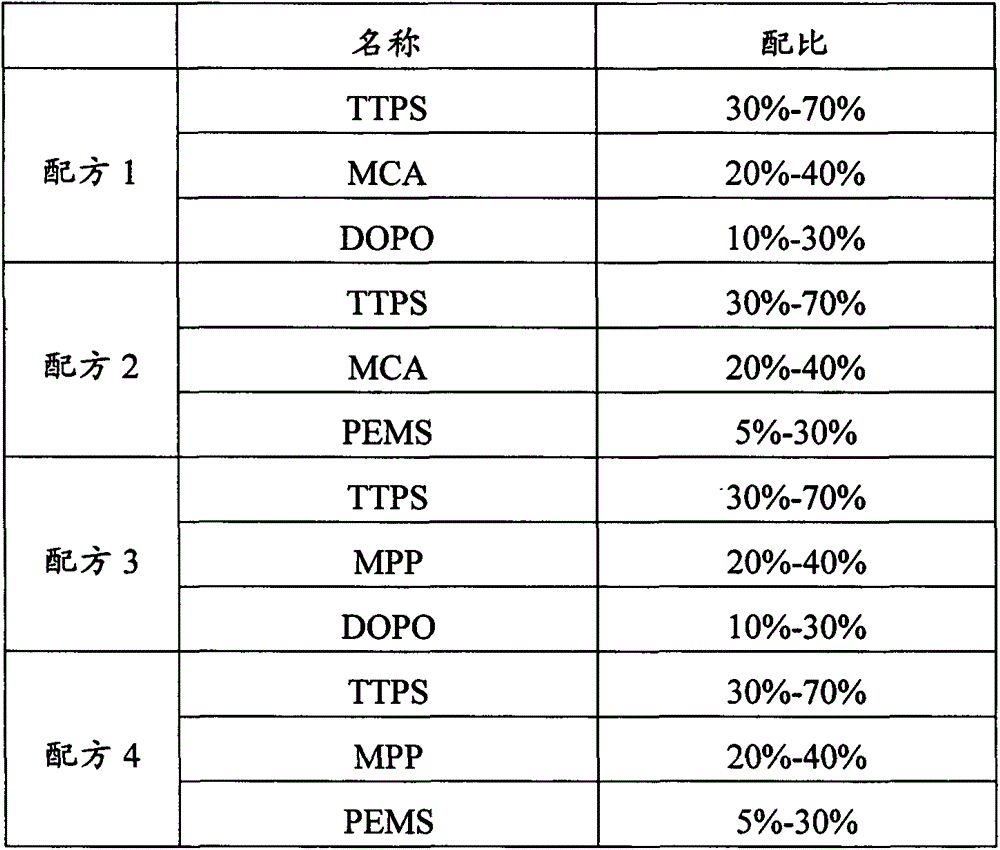

Triazine triphenyl phosphinic acid sec-butyl ester flame retardant composition and application method thereof

The invention relates to a triazine triphenyl phosphinic acid sec-butyl ester flame retardant composition and an application method thereof. The flame retardant composition is prepared by compounding and uniformly mixing any two, three or four of melamine cyanurate (MCA), melamine pyrophosphate (MPP), 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and pentaerythritol methyl silicate (PEMS) with triazine triphenyl phosphinic acid sec-butyl ester (TTPS) at any proportion, wherein the weight part of the TTPS is greater than zero. The flame retardant composition provided by the invention has the advantages of multielement synergic effect, good flame retardancy, good compatibility with materials, low cost, zero halogen, environmental protection and the like, can be used as a flame retardant for polyester PET, polyester PBT, polyurethane, polypropylene, epoxy resin and other materials, and has excellent application and popularization prospects.

Owner:RES INST OF XIANGCHENG SUZHOU UNIV OF SCI & TECH

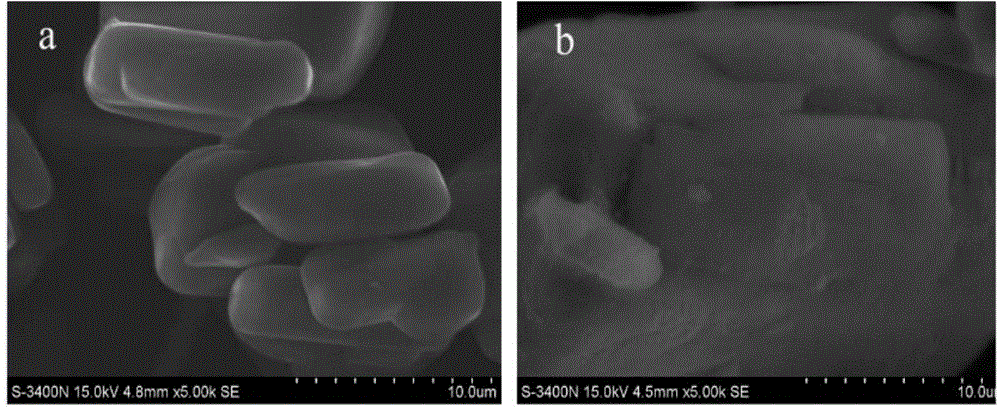

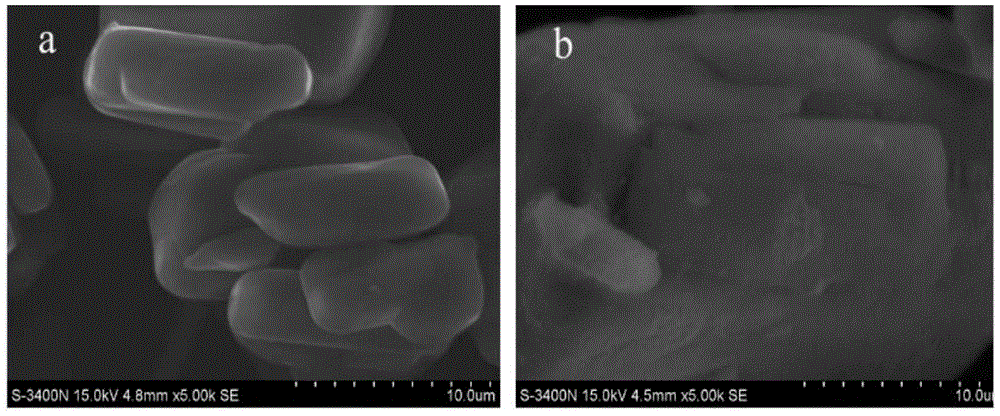

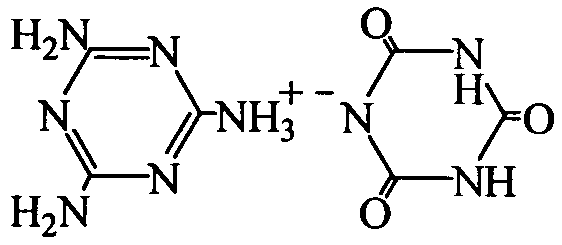

Waterproof core-shell structure flame retardant and application of flame retardant to preparation of polyurethane composite

ActiveCN104817676AImprove the disadvantage of being easily soluble in waterEfficient Flame RetardancyMelamine formaldehydeFilter paper

The invention belongs to the field of materials and discloses a waterproof core-shell structure flame retardant and application of the flame retardant to preparation of a polyurethane composite. The flame retardant forms a core-shell structure by taking ammonium polyphosphate as a capsule core and taking a copolymer of melamine formaldehyde prepolymer and multiamino polyether as a capsule wall material. Since a shell of the system is hydrophobic resin, water resistance is highly improved as compared with that uncoated flame retardant particles, loss rate of ammonium polyphosphate particles sealed with filter paper reaches 98.0%, loss rate of the prepared waterproof flame retardant particles under the same conditions is lower than 8.50%, and the polyurethane composite prepared from the waterproof core-shell structure flame retardant has good flame retardant effect and can still keep efficient flame retardance under the condition of long-time water soaking.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Special nylon resin modification flame-retardant synergetic functional master batch and preparation method thereof

InactiveCN110591243AImprove thermal stabilityImprove thermal protection performanceAcrylonitrilePolystyrene

The invention relates to the technical field of plastic modification processing and in particular discloses a special nylon resin modification flame-retardant synergetic functional master batch and apreparation method thereof. The functional master batch adopts multiple composite coated brominated polystyrene as main body flame retardant, and comprises the following components in percentage by mass: 55.0-70.0wt.% of multiple composite coated brominated polystyrene, 15.0-30.0wt.% of anhydrous zinc borate, 8.0-10.0wt.% of nylon 6 resin, 2.0-3.0wt.% of starlike nylon, 0.5-1.0wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0wt.% of a dispersant and 0.3-0.5wt.% of a lubricant. Compared with a conventional plastic flame-retardant functional master batch, the flame-retardant synergetic functional master batch disclosed by the invention is capable of improving the thermal stability and the flowing dispersibility of domestic brominated flame retardant, so that theflame retardance efficiency can be improved, a flame retardance effect identical to that of a conventional flame-retardant functional master batch can be achieved with a less master batch addition amount, and in addition, the mechanical performance loss of a modified high-temperature-resistant nylon resin composite material can be effectively reduced.

Owner:江苏万纳普新材料科技有限公司

Special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and preparation method thereof

The invention relates to the technical field of plastic modification processing, in particular to special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and a preparation method thereof. According to the functional masterbatch, multiple composite coated ammonium polyphosphate is used as a phosphorus-based flame retardant; the functional masterbatch is prepared from the following components in percentage by mass: 55.0-65.0 wt.% of the multiple composite coated ammonium polyphosphate, 25.0-35.0 wt.% of a nitrogen flame retardant, 7.0-11.0 wt.% of carrier resin, 0.5-1.0 wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0 wt.% of a dispersing agent and 0.3-0.5 wt.% of a lubricating agent. Compared with the traditional flame-retardant functional masterbatch, the functional masterbatch prepared by the invention has the advantages that the thermal stability of ammonium polyphosphate is remarkably improved, and thewater resistance of the ammonium polyphosphate is enhanced, so that the flame-retardant effect of the ammonium polyphosphate on polyolefin resin is more effectively improved.

Owner:江苏万纳普新材料科技有限公司

Non-halogen flame retardant hard polyurethane foam material and preparation method thereof

The invention provides a non-halogen flame retardant hard polyurethane foam material and a preparation method thereof. The material is composed of a component A and a component B, and the weight ratio of the component A to the component B is 1:(1-1.5), wherein the component A comprises, by weight, 6-20 parts of phenolic resin, 60-80 parts of polyether polyol, 5-10 parts of expansible graphite, 1-4 parts of catalysts, 16-30 parts of compounded flame retardant, 1-3 parts of polysiloxane foam stabilizers and 15-30 parts of foaming agent, the component B is isocyanate, and the compounded flame retardant is made of magnesium hydrate, water glass, an silane coupling agent and nano montmorillonite. The foam material improves the flame retardant property, lowers the influence of the flame retardant on the mechanical property of the foam material and further improves the foaming property.

Owner:合肥广能新材料科技有限公司

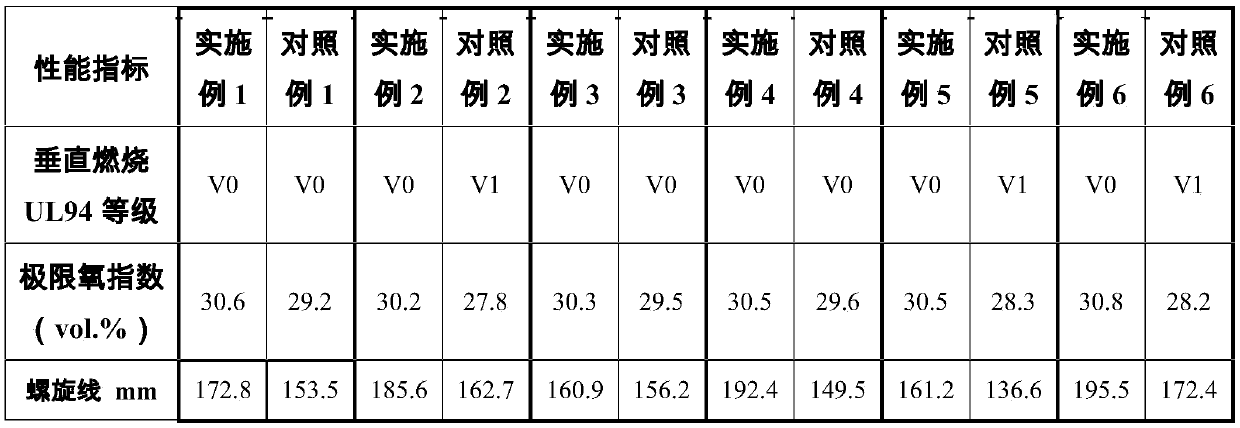

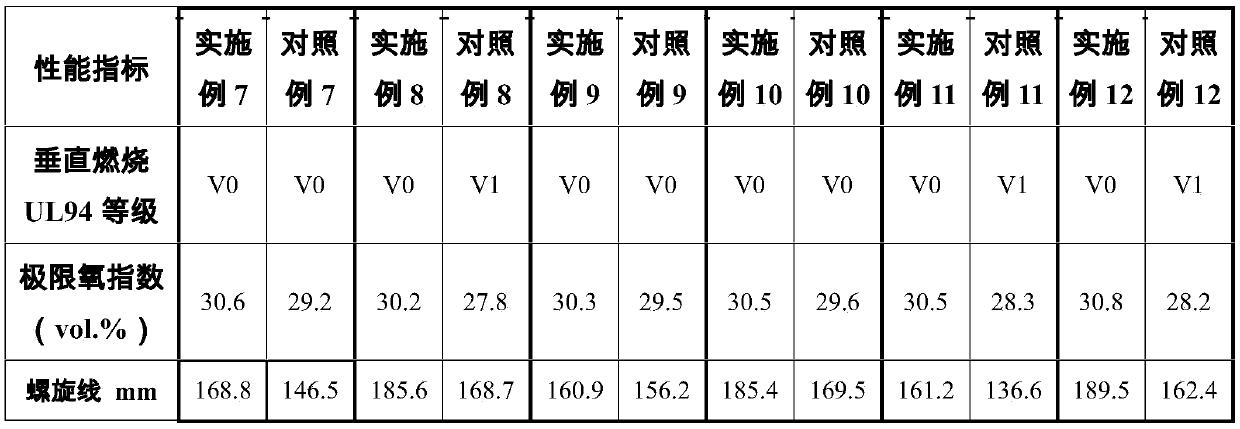

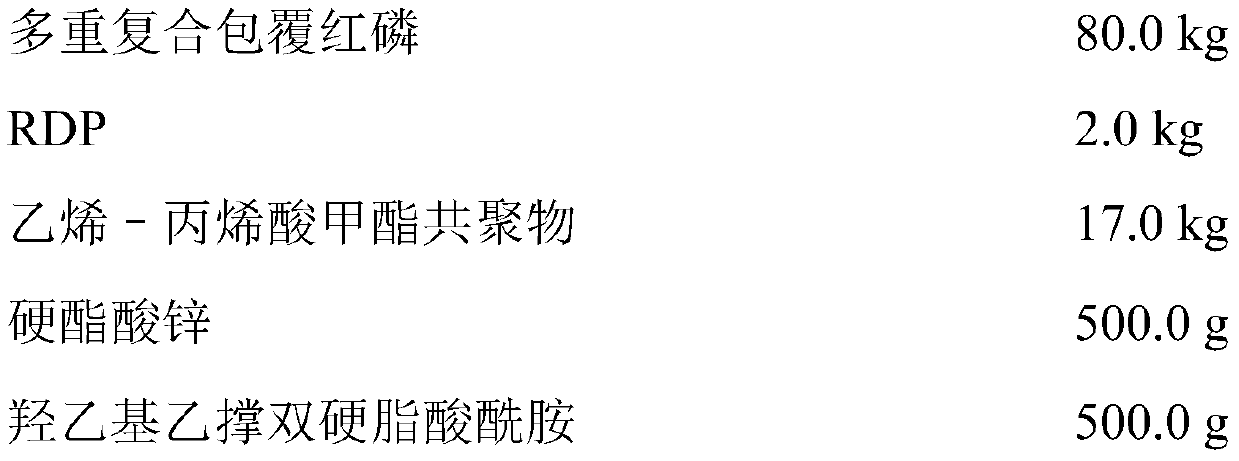

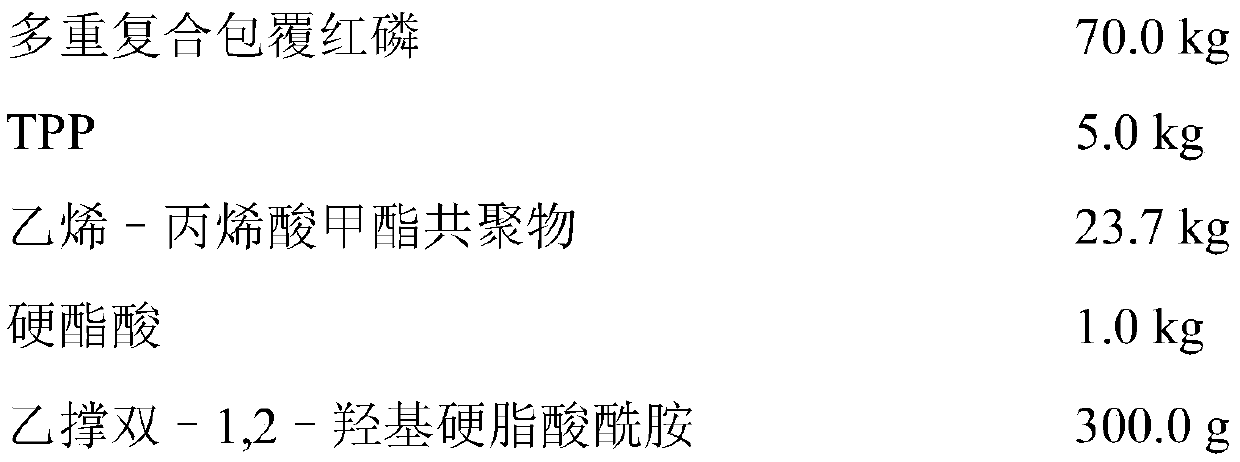

Halogen-free flame-retardant synergistic functional masterbatch special for polyphenyl ether modification and preparation method thereof

ActiveCN110615937AEnhanced compactness and structural stabilityImprove flame retardant performanceCorrosionPhosphate

The invention relates to the technical field of plastic modification processing, in particular to halogen-free flame-retardant synergistic functional masterbatch special for polyphenyl ether modification and a preparation method thereof. According to the functional masterbatch, multiply composited coated red phosphorus is used as a phosphorus flame retardant; and the functional masterbatch is prepared from the following components in percentage by mass: 70.0 wt.%-80.0 wt.% of the multiply composited coated red phosphorus, 3.0 wt.%-5.0 wt.% of organic phosphate, 17.0 wt.%-25.0 wt.% of an ethylene-methyl acrylate copolymer, 0.5 wt.%-1.0 wt.% of a dispersing agent and 0.3 wt.%-0.5 wt.% of a lubricating agent. Compared with the traditional flame-retardant functional masterbatch, the functionalmasterbatch prepared by the method has the advantages that thermal stability and water resistance of red phosphorus are remarkably enhanced, the activity of red phosphorus and the corrosion of red phosphorus to a base material are reduced, and the compatibility with a resin matrix is improved, so that the flame-retardant effect of red phosphorus to polyphenyl ether is more effectively improved.

Owner:江苏万纳普新材料科技有限公司

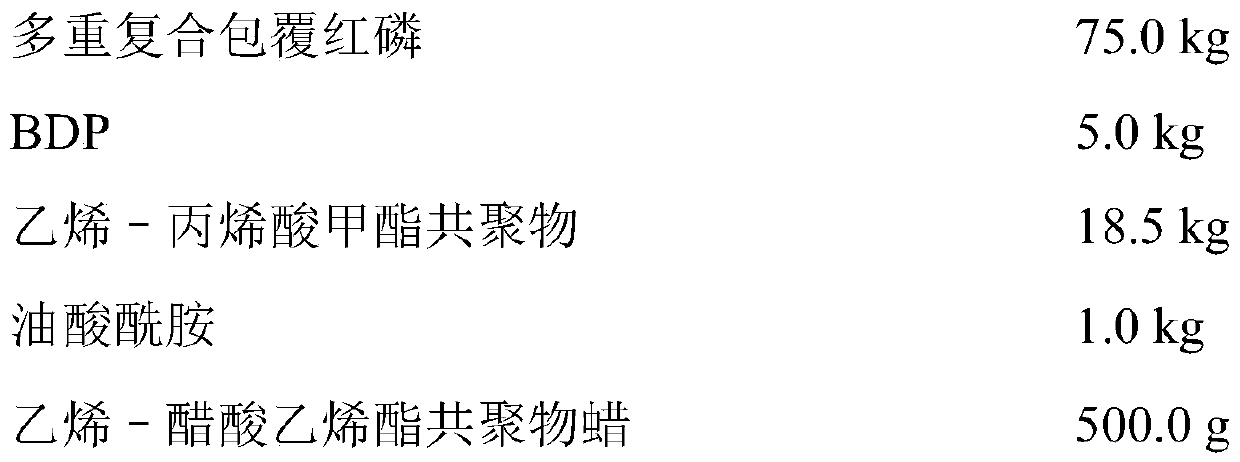

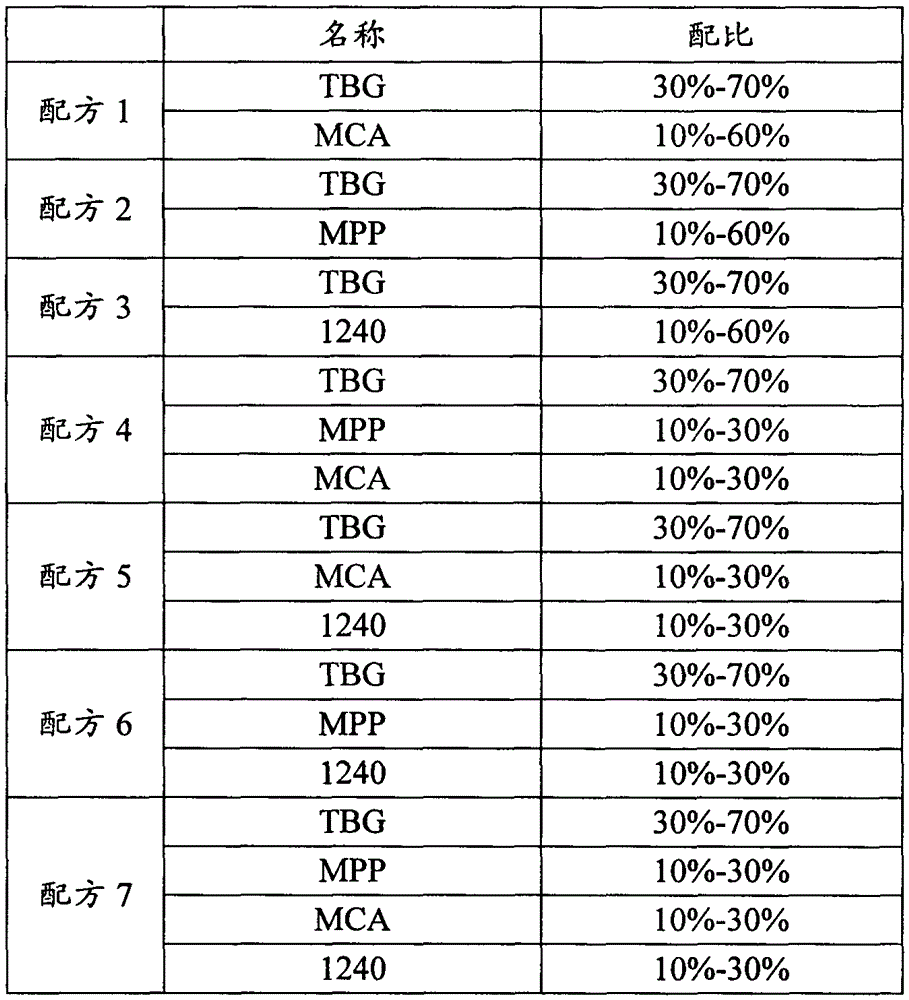

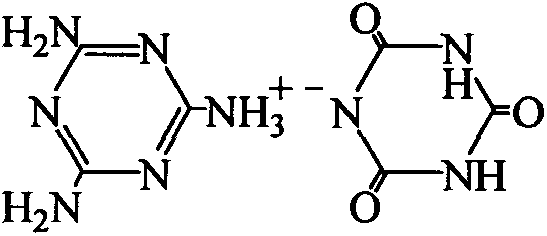

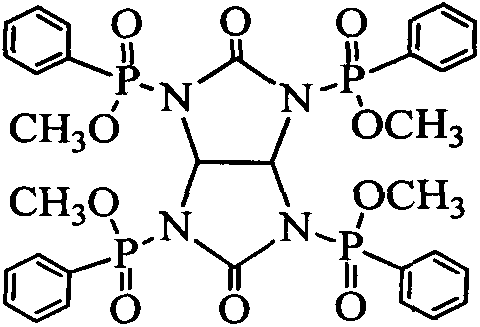

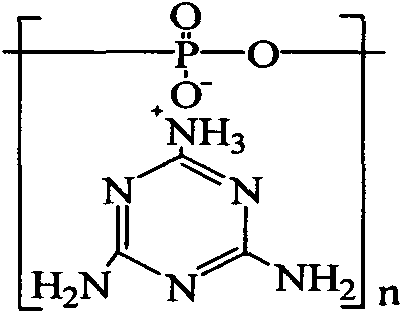

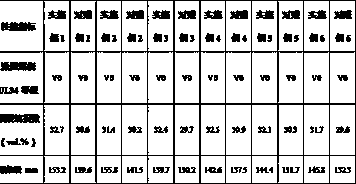

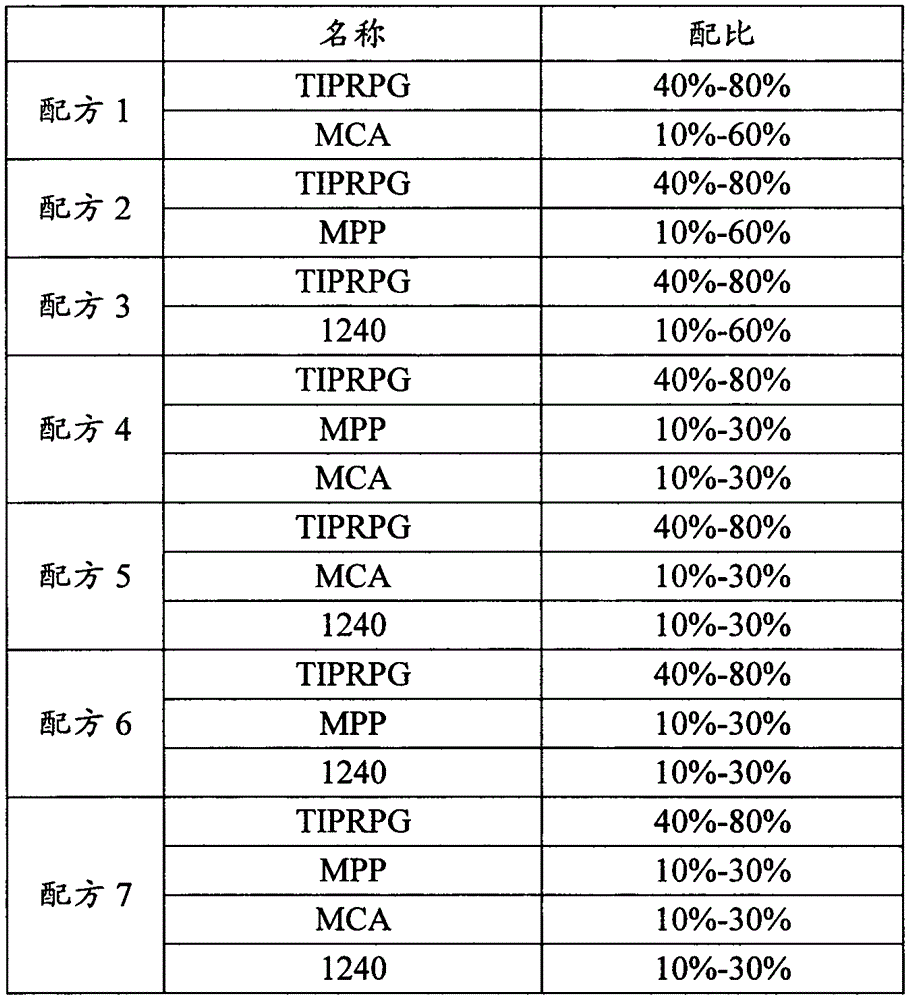

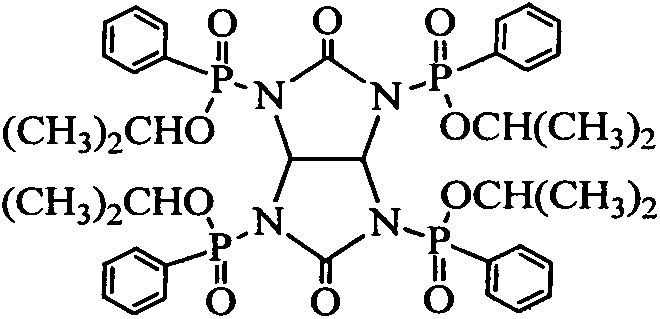

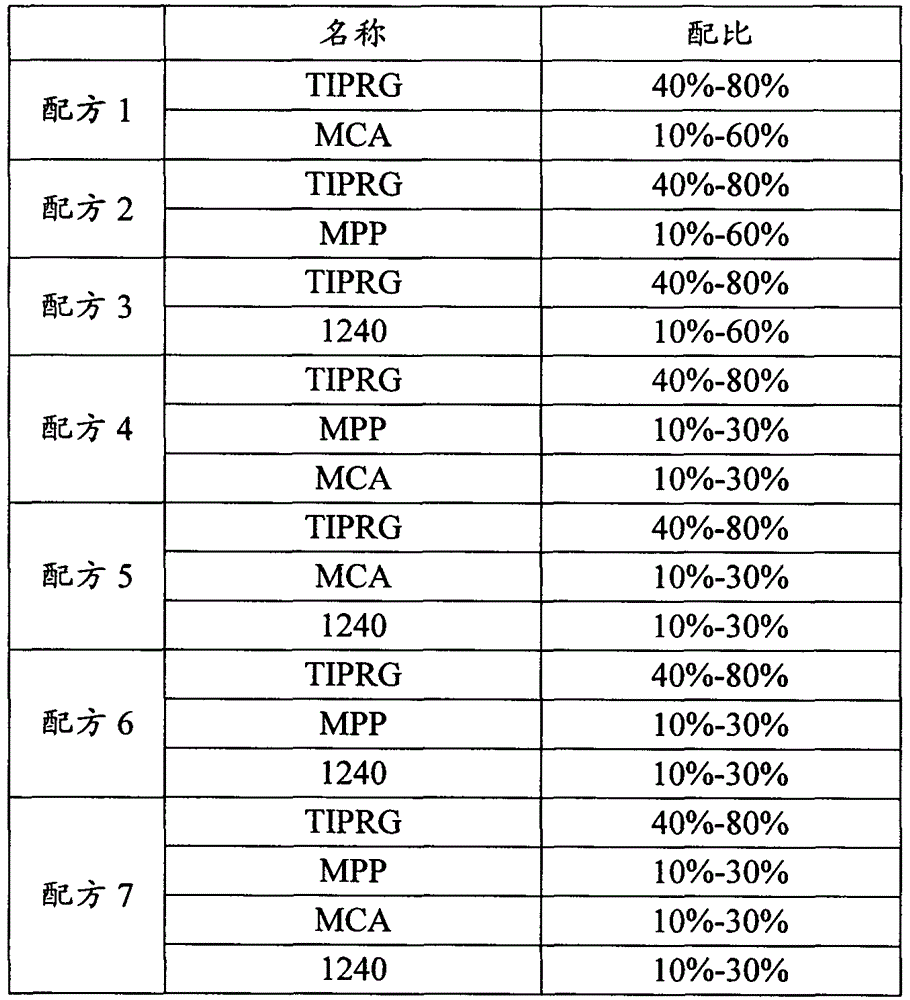

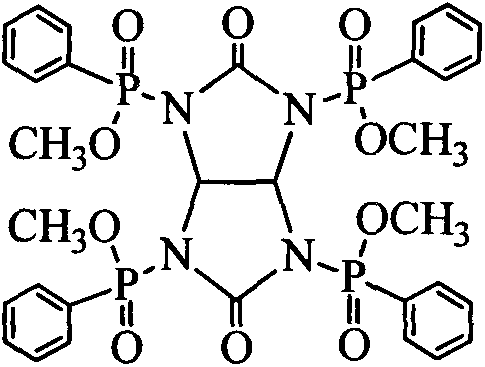

Tetra(0-isopropyl-phenylphosphinyl)glycoluril (TIPRPG) flame retardant composition and application method thereof

The invention relates to a tetra(0-isopropyl-phenylphosphinyl)glycoluril (TIPRPG) flame retardant composition. The flame retardant composition is prepared from tetra(0-isopropyl-phenylphosphinyl)glycoluril and any one or two or three of melamine cyanurate (MCA), melamine polyphosphate (MPP) and diethyl aluminum phosphinate (1240) through compounding according to any weight ratio and uniformly mixing, wherein the weight fraction of TIPRPG in the flame retardant composition is greater than 0. The flame retardant composition disclosed by the invention has the advantages that multiple elements are synergic, the material compatibility is good, the flame retardance is high, the flame retardant composition is halogen-free and environment-friendly, the application cost can be reduced and the like, so that the flame retardant composition can be applied to flame retardants of polyester, polyamide and the like.

Owner:苏州艾科迪新材料科技有限公司

Special thermoplastic polyurethane modification flame-retardant synergetic functional master batch and preparation method thereof

ActiveCN110591336AGood heat protectionHigh thermal decomposition temperatureBromineBrominated flame retardant

The invention relates to the technical field of plastic modification processing and in particular to a special thermoplastic polyurethane modification flame-retardant synergetic functional master batch and a preparation method thereof. The functional master batch adopts multiple composite coated ethylene di(tetrabromo phthalic diamide) as main body flame retardant, and comprises the following components in percentage by mass: 60.0-75.0wt.% of multiple composite coated ethylene di(tetrabromo phthalic diamide), 10.0-25.0wt.% of zinc phosphate, 9.0-13.0wt.% of thermoplastic polyurethane, 1.0-2.0wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0wt.% of a dispersant and 0.3-0.5wt.% of a lubricant. Compared with a conventional flame-retardant functional master batch,the functional master batch disclosed by the invention is capable of remarkably improving the thermal stability of brominated flame retardant, a material yellowing phenomenon in a thermal mechanicalprocessing process can be effectively reduced, and the flame retardant effect of domestic brominated flame retardant on the thermoplastic polyurethane can be improved.

Owner:江苏万纳普新材料科技有限公司

Special polypropylene modified flame-retardant synergetic functional master batch and preparation method thereof

PendingCN110591228AImprove thermal protection performanceEffective protectionPolymer scienceTetrabromobisphenol A

The invention relates to the technical field of plastic modification processing and in particular relates to a special polypropylene modified flame-retardant synergetic functional master batch and a preparation method thereof. The functional master batch adopts tetrabromobisphenol A di(2,3-dibromopropyl) ether in multiple composite coating as main body flame retardant, and comprises the followingcomponents in percentage by mass: 55.0-70.0wt.% of tetrabromobisphenol A di(2,3-dibromopropyl) ether in multiple composite coating, 15.0-30.0wt.% of antimonous oxide, 7.0-10.0wt.% of high-flowabilitypolypropylene, 2.0-4.0wt.% of atactic polypropylene, 1.0-2.0wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0wt.% of a dispersant and 0.3-0.5wt.% of a lubricant. Comparedwith a conventional flame-retardant functional master batch, the functional master batch provided by the invention is capable of remarkably improving the thermal stability of brominated flame retardant, effectively reducing material yellowing phenomena in the thermal mechanical processing process, and improving the flame retardance effect of domestic brominated flame retardant on polypropylene.

Owner:江苏万纳普新材料科技有限公司

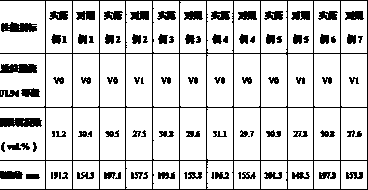

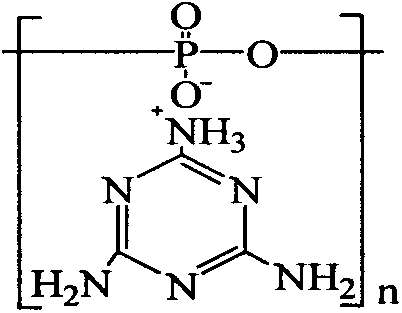

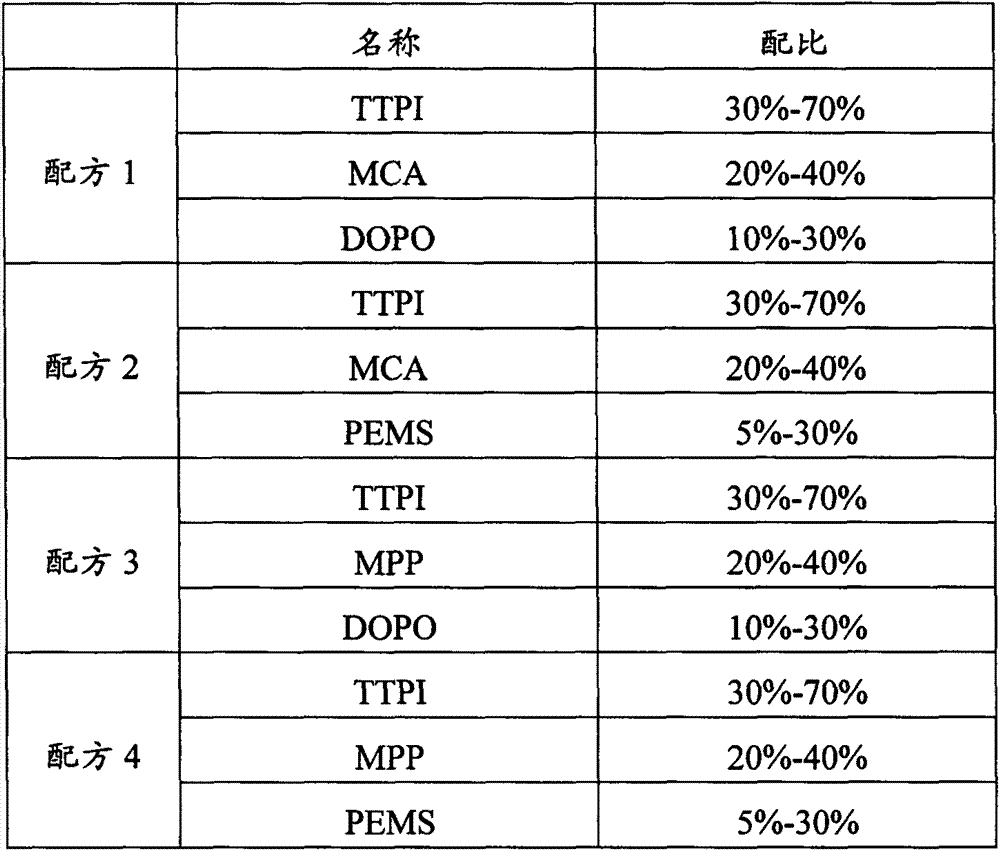

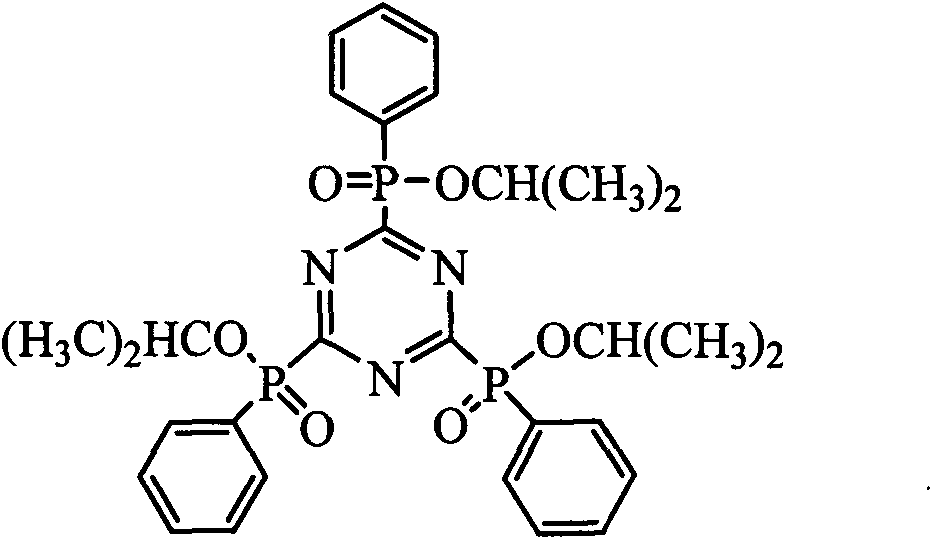

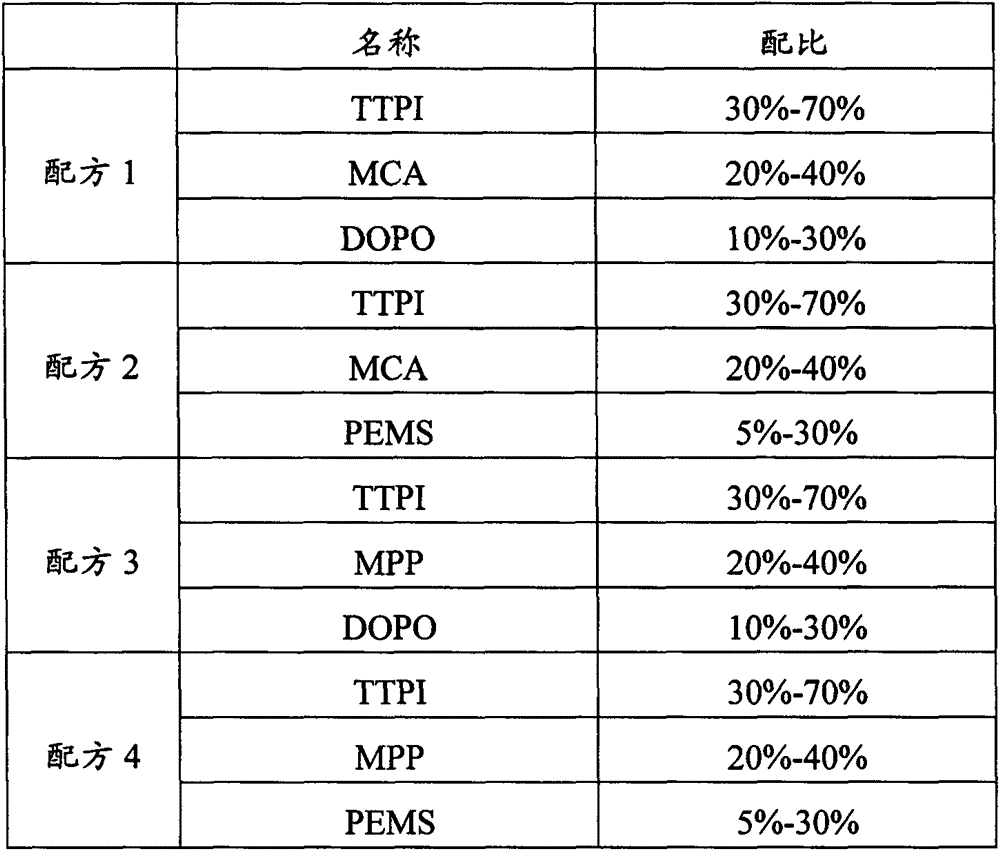

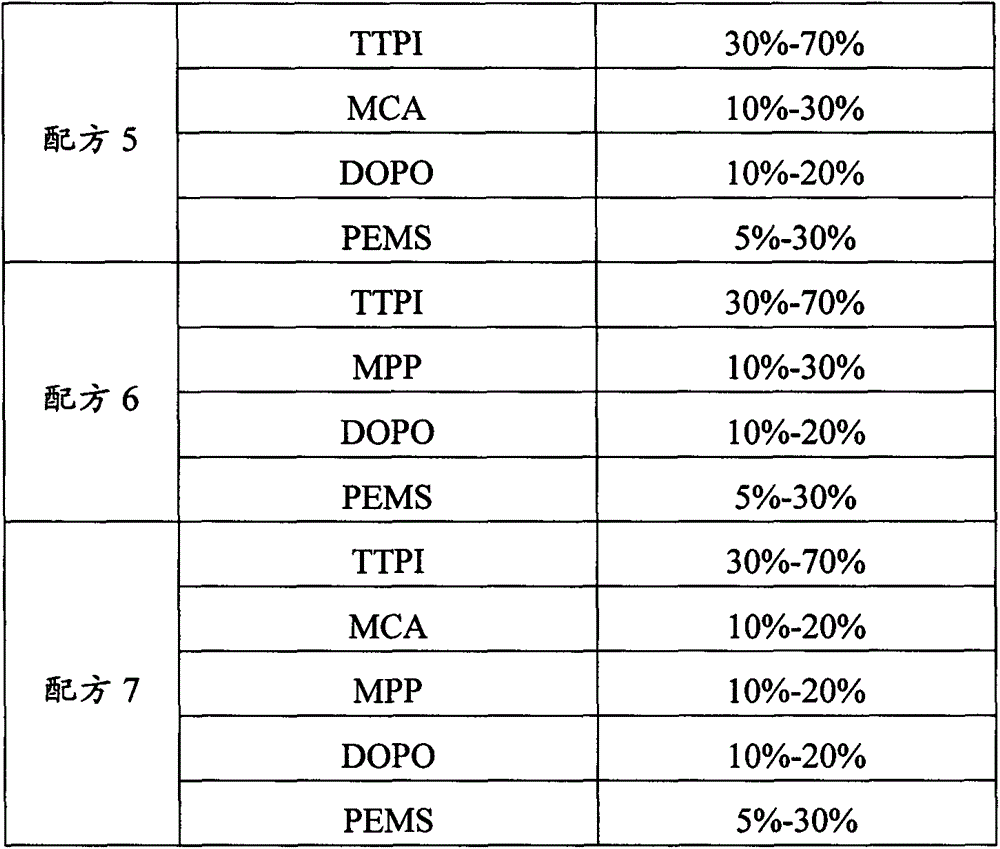

Triazine triphenyl phosphinic acid isopropyl ester flame retardant composition and application method thereof

The invention relates to a triazine triphenyl phosphinic acid isopropyl ester flame retardant composition and an application method thereof. The flame retardant composition is prepared by compounding and uniformly mixing any two, three or four of melamine cyanurate (MCA), melamine pyrophosphate (MPP), 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and pentaerythritol methyl silicate (PEMS) with triazine triphenyl phosphinic acid isopropyl ester (TTPI) at any proportion, wherein the weight part of the TTPI is greater than zero. The flame retardant composition provided by the invention has the advantages of multielement synergic effect, good flame retardancy, good compatibility with materials, low cost, zero halogen, environmental protection and the like, can be used as a flame retardant for polyester PET, polyester PBT, polyurethane, polypropylene, epoxy resin and other materials, and has excellent application and popularization prospects.

Owner:RES INST OF XIANGCHENG SUZHOU UNIV OF SCI & TECH

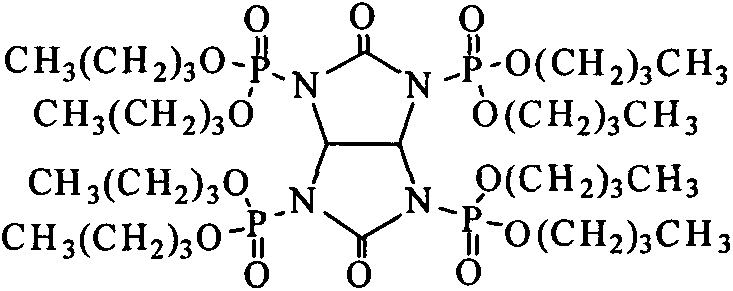

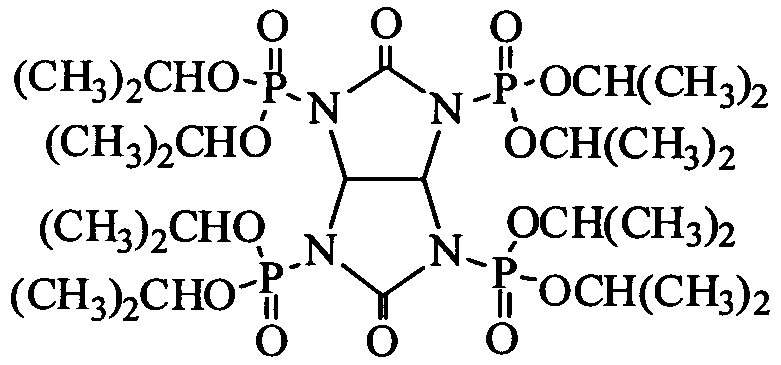

Tetra(o,o-dibutylphosphoryl) glycoluril flame retardant composition and application method thereof

ActiveCN104151794BImprove flame retardant performanceNo reduction in mechanical strengthEnvironmental resistanceGlycoluril

The invention relates to a 4(0,0-dibutyl phosphoryl)glycoluril flame retardant composition. The flame retardant composition is prepared by compounding and uniformly mixing 4(0,0-dibutyl phosphoryl)glycoluril (TBG) with any one, two or three of melamine cyanurate (MCA), melamine pyrophosphate (MPP) and aluminum diethylphosphinate (1240), wherein the weight fraction of the 4(0,0-dibutyl phosphoryl)glycoluril in the flame retardant composition is larger than zero. The flame retardant composition disclosed by the invention has the advantages of multi-element synergistic interaction, high material compatibility, high flame resistance, freeness from halogen, environmental friendliness, reduction in the application cost and the like, and can be applied to flame retardants such as polyester and polyamide.

Owner:苏州瑞纳新材料科技有限公司

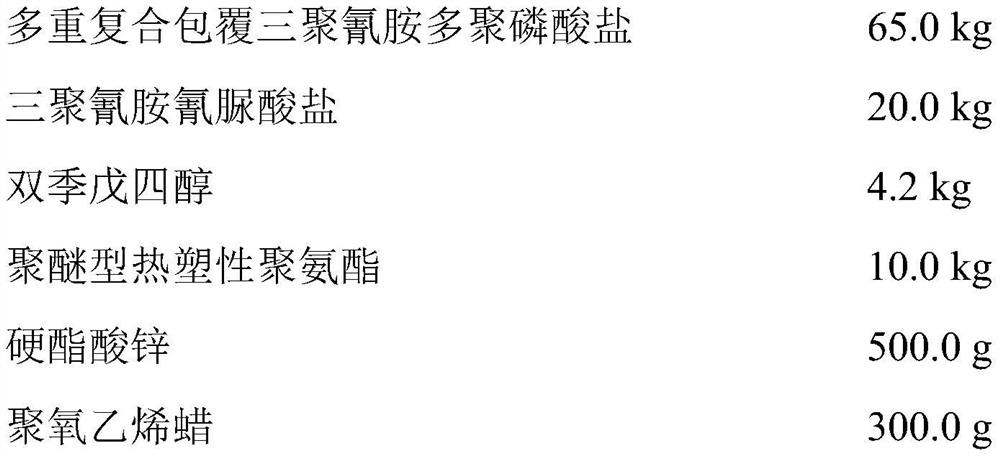

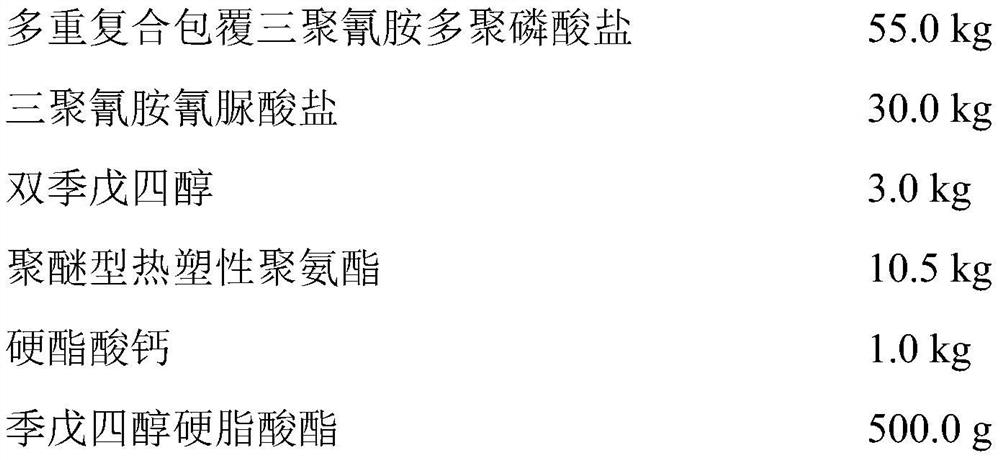

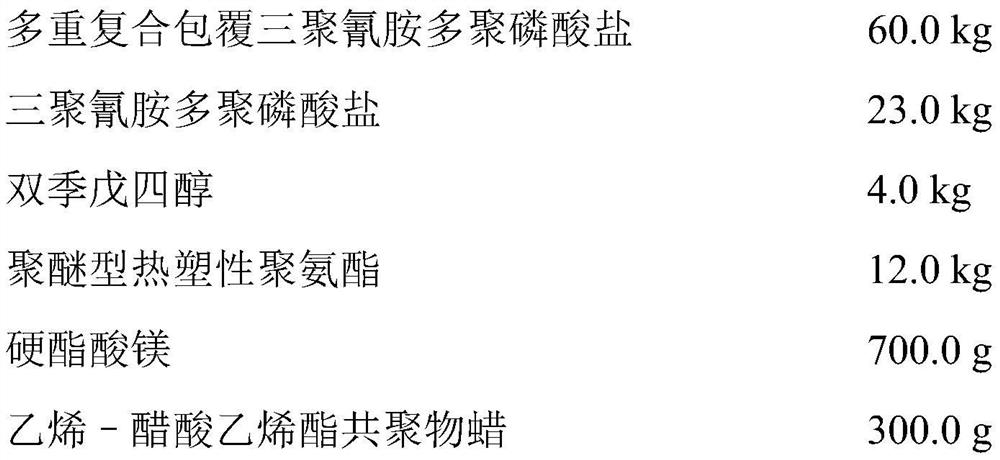

A special halogen-free flame retardant and synergistic functional masterbatch for polyoxymethylene modification and preparation method thereof

The invention relates to the technical field of plastic modification processing, in particular to a special halogen-free flame-retardant synergistic functional masterbatch for polyoxymethylene modification and a preparation method thereof; It is a flame retardant, and the mass percentage composition of the functional masterbatch is as follows: multiple composite coating melamine polyphosphate 55.0-65.0 wt.%, nitrogen-based flame retardant 20.0-30.0 wt.%, dipentaerythritol 3.0-5.0 wt .%, thermoplastic polyurethane 10.0~12.0 wt.%, dispersant 0.5~1.0 wt.%, lubricant 0.3~0.5 wt.%; compared with the traditional flame retardant functional masterbatch, the functional masterbatch prepared by the present invention significantly improves Improve the thermal stability of melamine polyphosphate, enhance its water resistance, thus more effectively improve the flame retardant effect of melamine polyphosphate on polyoxymethylene.

Owner:江苏勒诚技术研发有限公司

Isopropyl triazine triphenylphosphinate flame retardant composition and application method thereof

The invention relates to a triazine triphenyl phosphinic acid isopropyl ester flame retardant composition and an application method thereof. The flame retardant composition is prepared by compounding and uniformly mixing any two, three or four of melamine cyanurate (MCA), melamine pyrophosphate (MPP), 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and pentaerythritol methyl silicate (PEMS) with triazine triphenyl phosphinic acid isopropyl ester (TTPI) at any proportion, wherein the weight part of the TTPI is greater than zero. The flame retardant composition provided by the invention has the advantages of multielement synergic effect, good flame retardancy, good compatibility with materials, low cost, zero halogen, environmental protection and the like, can be used as a flame retardant for polyester PET, polyester PBT, polyurethane, polypropylene, epoxy resin and other materials, and has excellent application and popularization prospects.

Owner:RES INST OF XIANGCHENG SUZHOU UNIV OF SCI & TECH

Methyl triazine triphenylphosphinate flame retardant composition and application method thereof

The invention relates to a triazine triphenyl phosphinic acid methyl ester flame retardant composition and an application method thereof. The flame retardant composition is prepared by compounding and uniformly mixing any two, three or four of melamine cyanurate (MCA), melamine pyrophosphate (MPP), 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and pentaerythritol methyl silicate (PEMS) with triazine triphenyl phosphinic acid methyl ester (TTPM) at any proportion, wherein the weight part of the TTPM is greater than zero. The flame retardant composition provided by the invention has the advantages of multi-element synergic effect, good flame retardancy, good compatibility with materials, low cost, zero halogen, environmental protection and the like, can be used as a flame retardant for polyester PET, polyester PBT, polyurethane, polypropylene, epoxy resin and other materials, and has excellent application and popularization prospects.

Owner:山东产研中科高端化工产业技术研究院有限公司

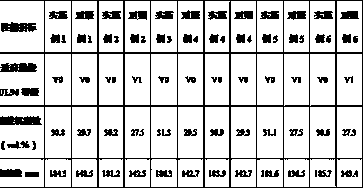

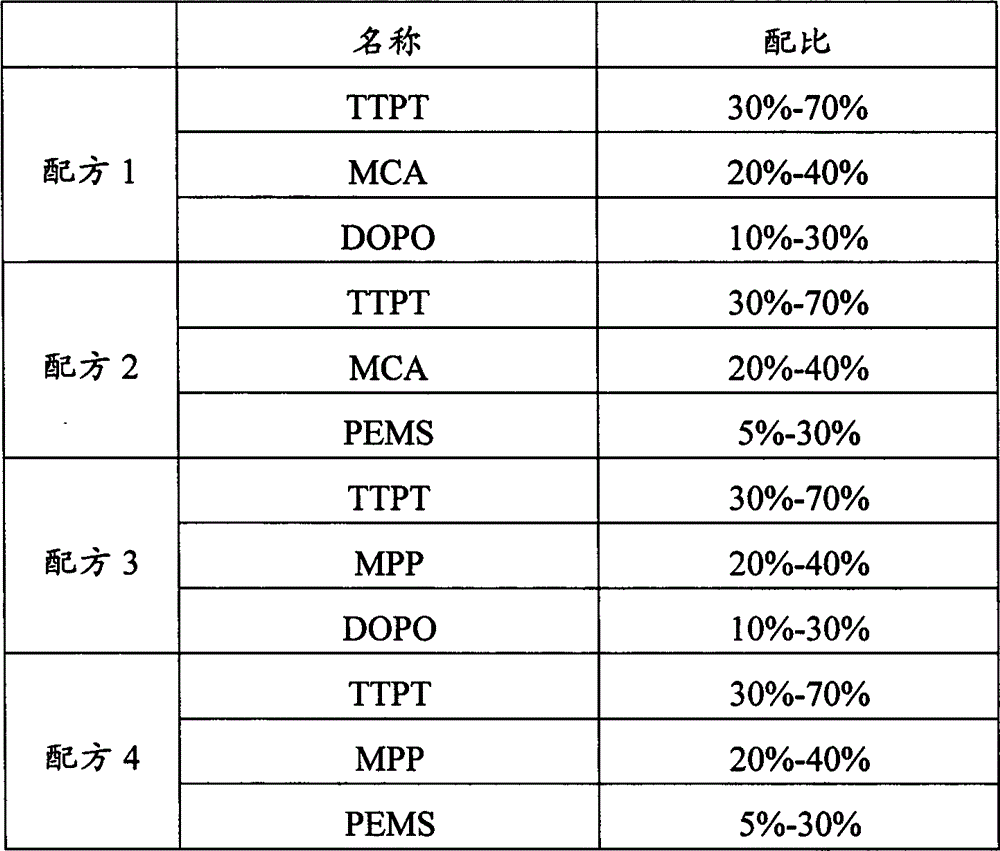

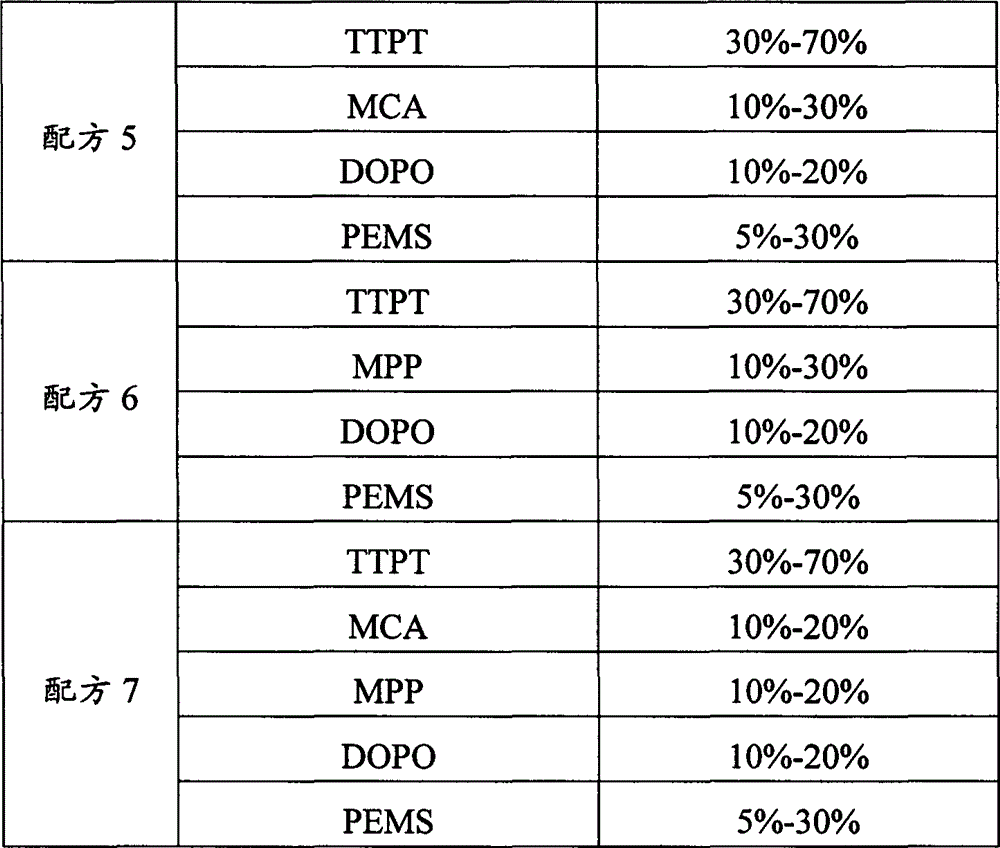

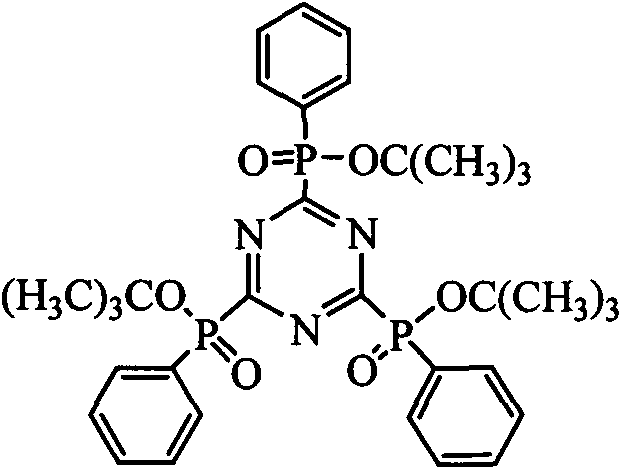

Triazine triphenyl phosphinate tert-butyl flame retardant composition and application method thereof

The invention relates to a triazine triphenyl phosphinic acid tert-butyl ester flame retardant composition and an application method thereof. The flame retardant composition is prepared by compounding and uniformly mixing any two, three or four of melamine cyanurate (MCA), melamine pyrophosphate (MPP), 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and pentaerythritol methyl silicate (PEMS) with triazine triphenyl phosphinic acid tert-butyl ester (TTPT) at any proportion, wherein the weight part of the TTPT is greater than zero. The flame retardant composition provided by the invention has the advantages of multielement synergic effect, good flame retardancy, good compatibility with materials, low cost, zero halogen, environmental protection and the like, can be used as a flame retardant for polyester PET, polyester PBT, polyurethane, polypropylene, epoxy resin and other materials, and has excellent application and popularization prospects.

Owner:RES INST OF XIANGCHENG SUZHOU UNIV OF SCI & TECH

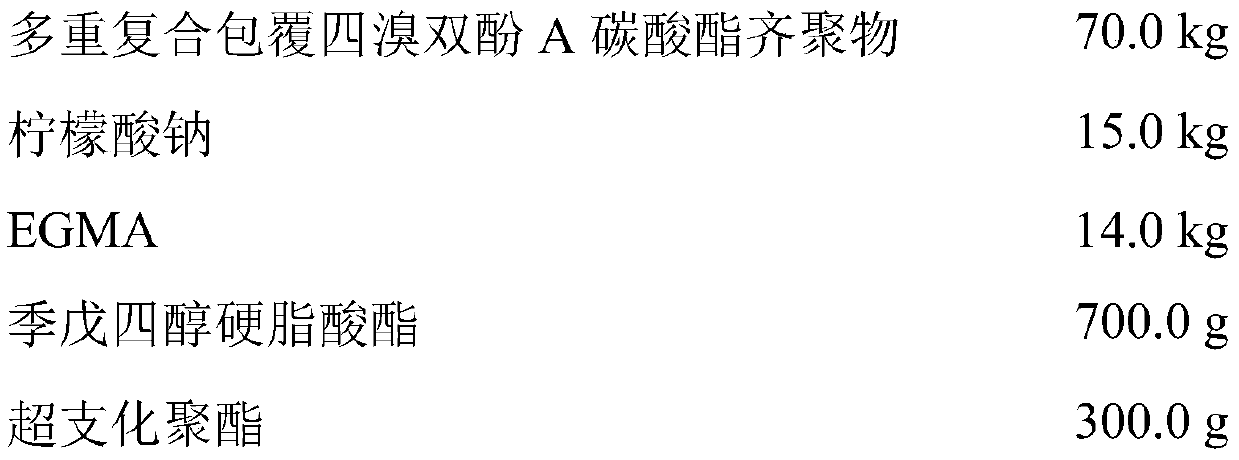

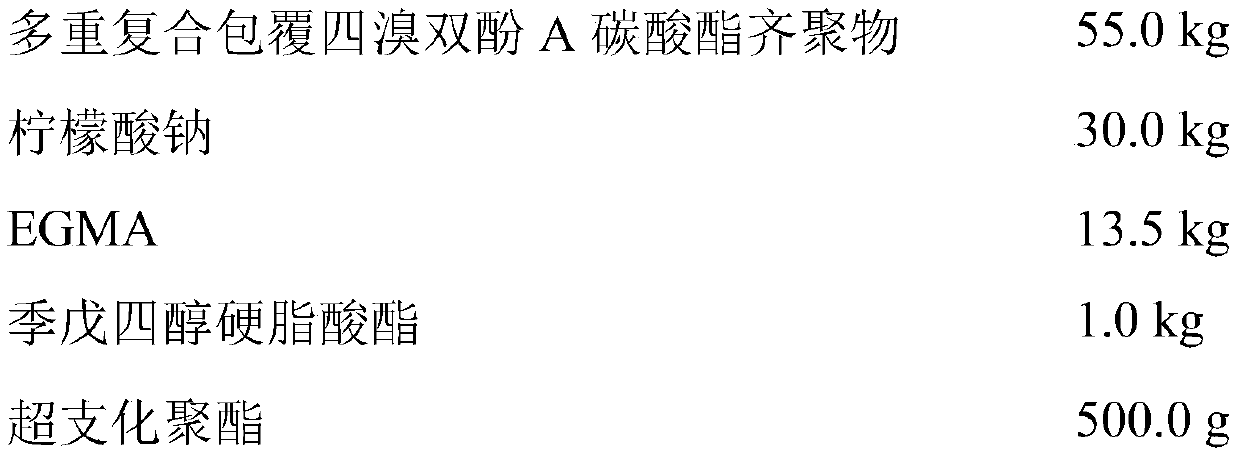

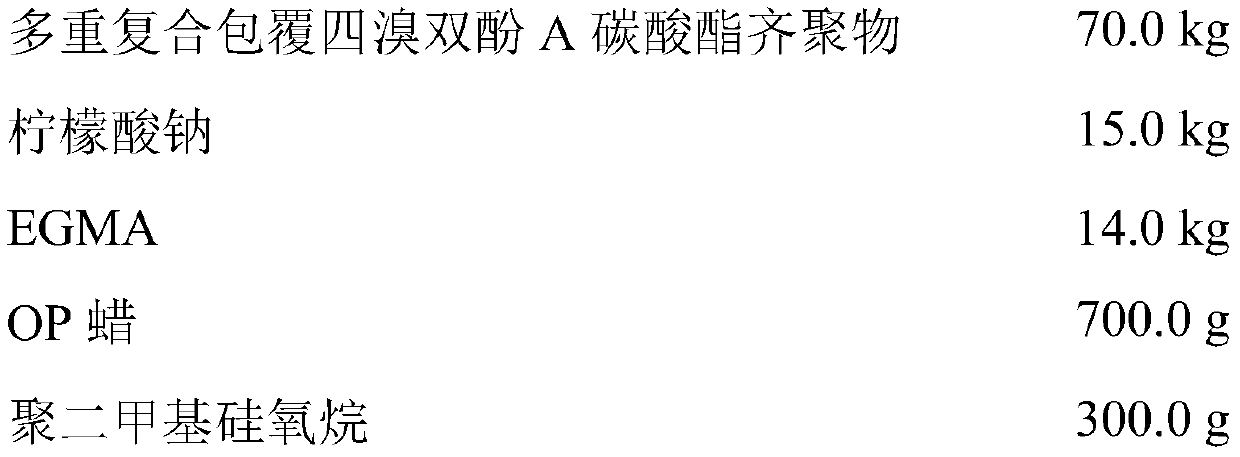

Polycarbonate and polycarbonate alloy modification special flame-retardant synergistic functional master batch, and preparation method thereof

ActiveCN110669281AImproved resistance to repeated thermomechanical processingImprove flame retardant performancePolymer sciencePolycarbonate

The invention relates to the technical field of plastic modification processing, in particular to a polycarbonate and polycarbonate alloy modification special flame-retardant synergistic functional master batch, and a preparation method thereof. According to the polycarbonate and polycarbonate alloy modification special flame-retardant synergistic functional master batch, a multi-composite coatedtetrabromo bisphenol A carbonate oligomer is used as a main body flame retardant; the polycarbonate and polycarbonate alloy modification special flame-retardant synergistic functional master batch comprises the following components in percentage by mass : 55.0-70.0wt% of the multi-composite coated tetrabromo bisphenol A carbonate oligomer, 15.0-30.0wt% of sodium citrate, 10.0- 14.0wt% of ethylene-glycidyl acrylate copolymer, 0.0-4.0wt% of an aliphatic copolyester, 0.0-0.5wt% of a hyperbranched polyester, 0.5-1.0wt% of a dispersant and 0.3-0.5wt% of a lubricant. Compared with a traditional plastic flame-retardant functional master batch, the flame-retardant synergistic functional master batch disclosed by the invention has the advantages that the thermal stability and the flow dispersity ofthree above domestic brominated flame retardants are improved,so that the flame-retardant effect is improved; the flame retardant effect which is the same as that of the traditional flame retardant functional master batch can be obtained at a less master batch addition amount, and the mechanical property loss of flame retardant compounds of modified polycarbonate and polycarbonate alloy thereof can be effectively reduced.

Owner:江苏万纳普新材料科技有限公司

Novel flame-retardant sheath for display wire bundle

InactiveCN108586949AImprove heat and aging resistanceGood compatibilityRubber insulatorsVegetal fibresRed mudPolyvinyl chloride

The invention discloses a novel flame-retardant sheath for a display wire bundle. The novel flame-retardant sheath is prepared from the following raw materials in parts by weight: 65 to 75 parts of ethylene-propylene-diene monomer rubber, 25 to 35 parts of polyvinyl chloride, 6 to 13 parts of flame-retardant compound, 5 to 8 parts of fly ash, 12 to 17 parts of tailing with high content of magnesium and phosphor, 3 to 7 parts of red mud, 4 to 12 parts of carbon black, 3 to 6 parts of lithium porcelain stone, 2 to 4.5 parts of magnesium laurate, 1 to 5 parts of aramid pulp, 0.5 to 3 parts of active aluminum oxide, 1 to 2.5 parts of alpha-lipoic acid, and 0.5 to 1.5 parts of dioctyl azelate. The novel flame-retardant sheath has an excellent flame-retardant property.

Owner:ANHUI FUYUEDA ELECTRONICS CO LTD

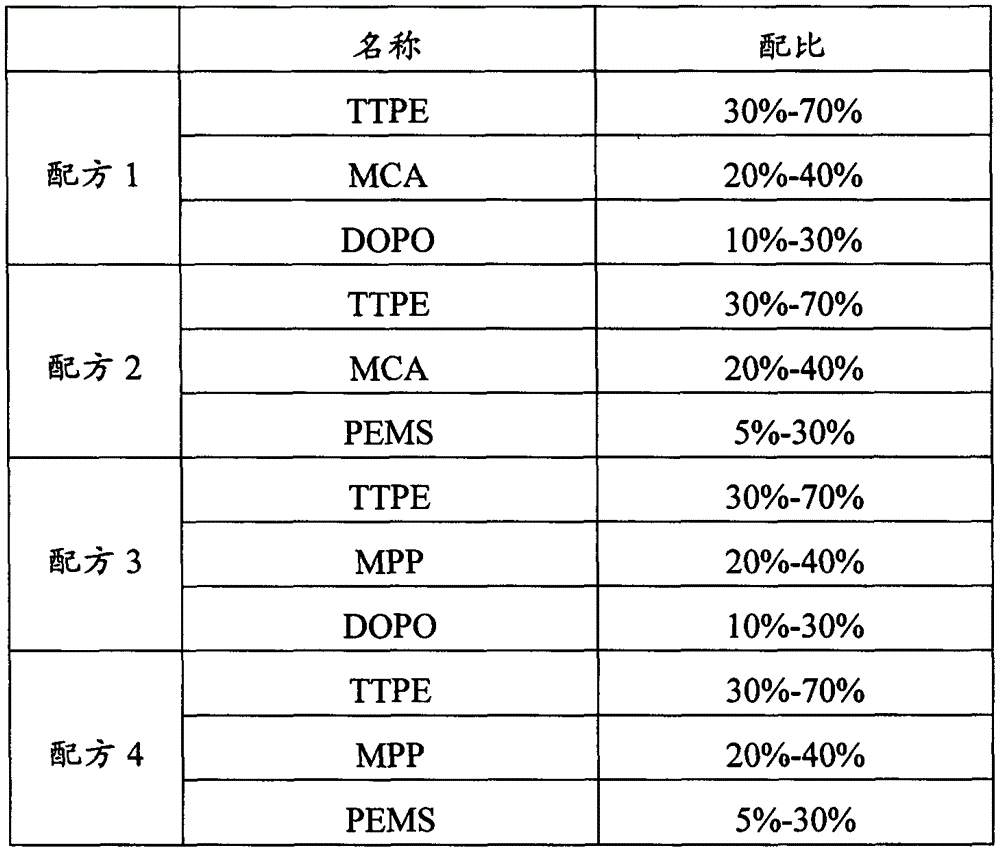

Ethyl triazine triphenylphosphinate flame retardant composition and application method thereof

The invention relates to a triazine triphenyl phosphinic acid ethyl ester flame retardant composition and an application method thereof. The flame retardant composition is prepared by compounding and uniformly mixing any two, three or four of melamine cyanurate (MCA), melamine pyrophosphate (MPP), 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and pentaerythritol methyl silicate (PEMS) with triazine triphenyl phosphinic acid ethyl ester (TTPE) at any proportion, wherein the weight part of the TTPE is greater than zero. The flame retardant composition provided by the invention has the advantages of multielement synergic effect, good flame retardancy, good compatibility with materials, low cost, zero halogen, environmental protection and the like, can be used as a flame retardant for polyester PET, polyester PBT, polyurethane, polypropylene, epoxy resin and other materials, and has excellent application and popularization prospects.

Owner:山东产研中科高端化工产业技术研究院有限公司

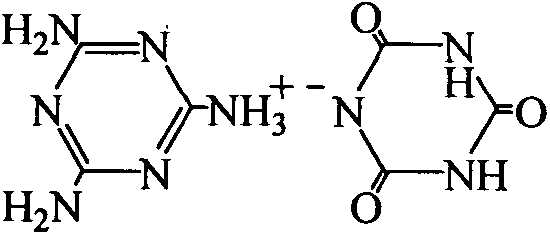

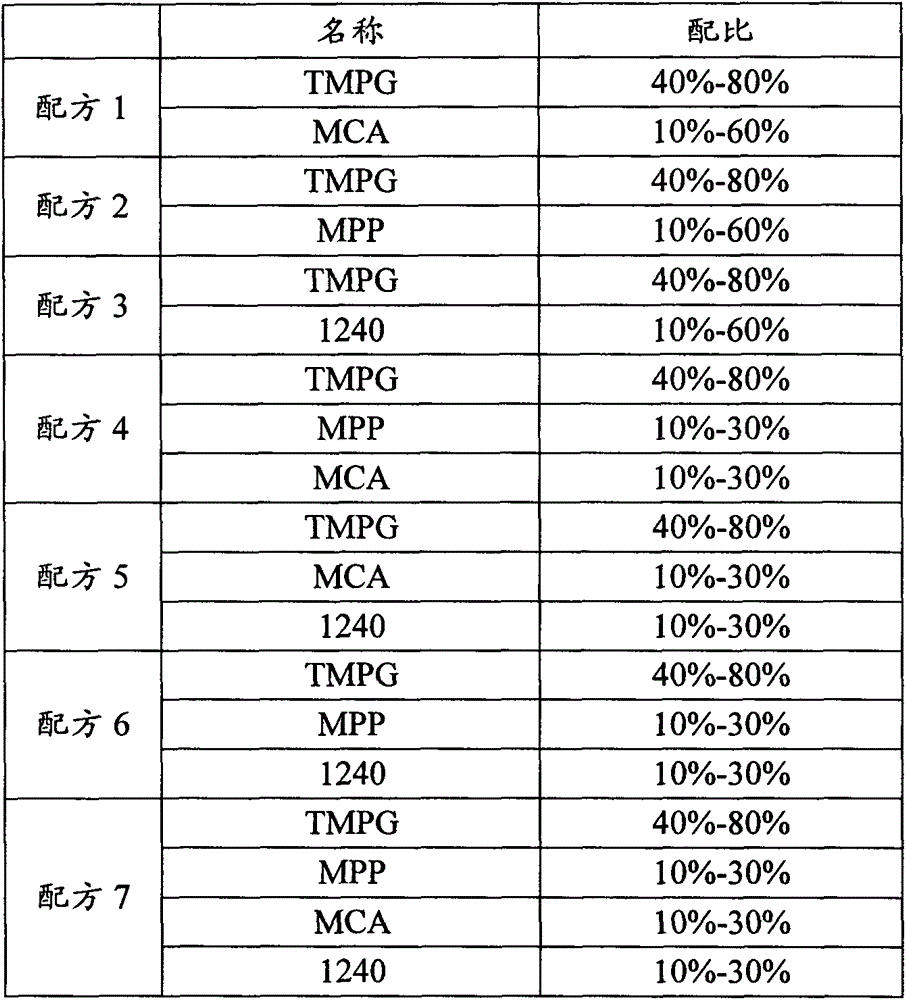

Tetra(0-methyl-phenylphosphinyl)glycoluril (TMPG) flame retardant composition and application method thereof

ActiveCN104194041AImprove flame retardant performanceNo reduction in mechanical strengthGlycolurilPolyester

The invention relates to a tetra(0-methyl-phenylphosphinyl)glycoluril (TMPG) flame retardant composition. The flame retardant composition is prepared from TMPG and any one or two or three of melamine cyanurate (MCA), melamine polyphosphate (MPP) and diethyl aluminum phosphinate (1240) through compounding according to any weight ratio and uniformly mixing, wherein the weight fraction of TMPG in the flame retardant composition is greater than 0. The flame retardant composition disclosed by the invention has the advantages that multiple elements are synergic, the material compatibility is good, the flame retardance is high, the flame retardant composition is halogen-free and environment-friendly, the application cost can be reduced and the like, so that the flame retardant composition can be applied to flame retardants of polyester, polyamide and the like.

Owner:苏州艾科迪新材料科技有限公司

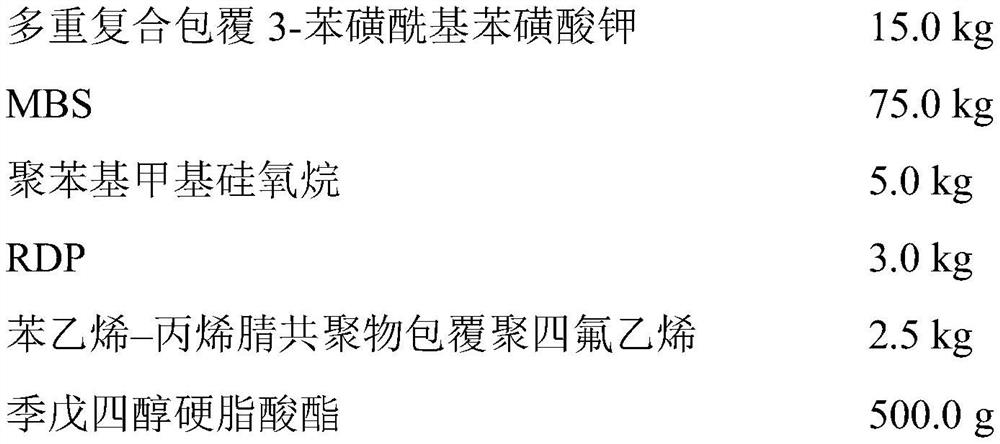

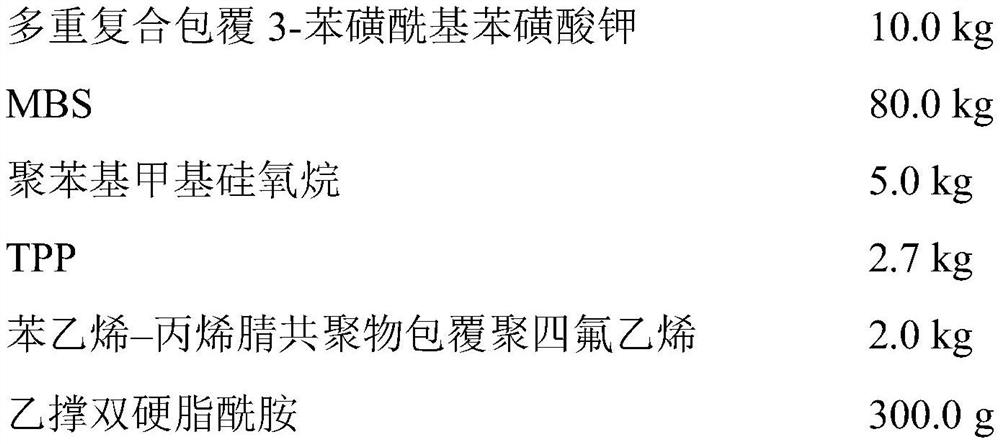

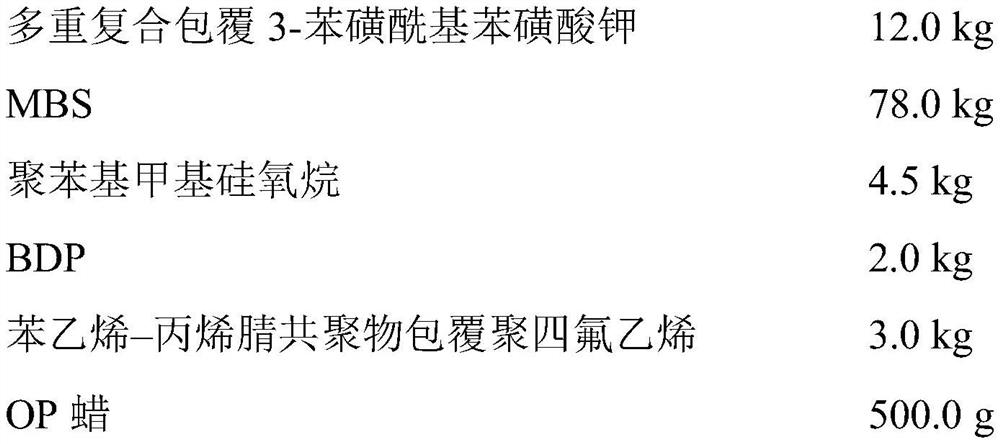

Special halogen-free flame-retardant synergistic masterbatch for modification of polycarbonate resin and preparation method of halogen-free flame-retardant synergistic masterbatch

The invention relates to the technical field of modification and processing of plastics, in particular to special halogen-free flame-retardant synergistic masterbatch for modification of polycarbonateresin and a preparation method of the halogen-free flame-retardant synergistic masterbatch. Multiple-compounded coated potassium aluminum 3-benzenesulfonylbenzenesulfonate is adopted as an inorganicflame retardant, and the halogen-free flame-retardant synergistic masterbatch comprises the compositions: in percent by mass, 10.0-15.0% of multiple-compounded coated potassium aluminum 3-benzenesulfonylbenzenesulfonate, 75.0-80.0% of methyl methacrylate-butadiene-styrene terpolymer (MBS), 3.0-5.0% of polyphenylmethylsiloxane, 2.0-3.0% of organic phosphate, 2.0-3.0% of styrene-acrylonitrile copolymer-coated polytetrafluoroethylene and 0.3-0.5% of a lubricant. When the prepared functional masterbatch is compared with traditional flame-retardant functional masterbatch, the heat resistance and thermal stability of potassium aluminum 3-benzenesulfonylbenzenesulfonate are improved significantly, benzenesulfonic acid functional groups for development of flame retardancy of potassium aluminum 3-benzenesulfonylbenzenesulfonate is protected effectively, and potassium aluminum 3-benzenesulfonylbenzenesulfonate is adaptive to a high processing temperature of polycarbonate resin, so that the flameretardant effect of potassium aluminum 3-benzenesulfonylbenzenesulfonate on the polycarbonate resin is improved more effectively.

Owner:江苏万纳普新材料科技有限公司

Tetrakis (o-isopropyl-phenylphosphinoyl) glycoluril flame retardant composition and application method thereof

ActiveCN104194040BImprove flame retardant performanceNo reduction in mechanical strengthPolyesterGlycoluril

The invention relates to a tetra(0-isopropyl-phenylphosphinyl)glycoluril (TIPRPG) flame retardant composition. The flame retardant composition is prepared from tetra(0-isopropyl-phenylphosphinyl)glycoluril and any one or two or three of melamine cyanurate (MCA), melamine polyphosphate (MPP) and diethyl aluminum phosphinate (1240) through compounding according to any weight ratio and uniformly mixing, wherein the weight fraction of TIPRPG in the flame retardant composition is greater than 0. The flame retardant composition disclosed by the invention has the advantages that multiple elements are synergic, the material compatibility is good, the flame retardance is high, the flame retardant composition is halogen-free and environment-friendly, the application cost can be reduced and the like, so that the flame retardant composition can be applied to flame retardants of polyester, polyamide and the like.

Owner:苏州艾科迪新材料科技有限公司

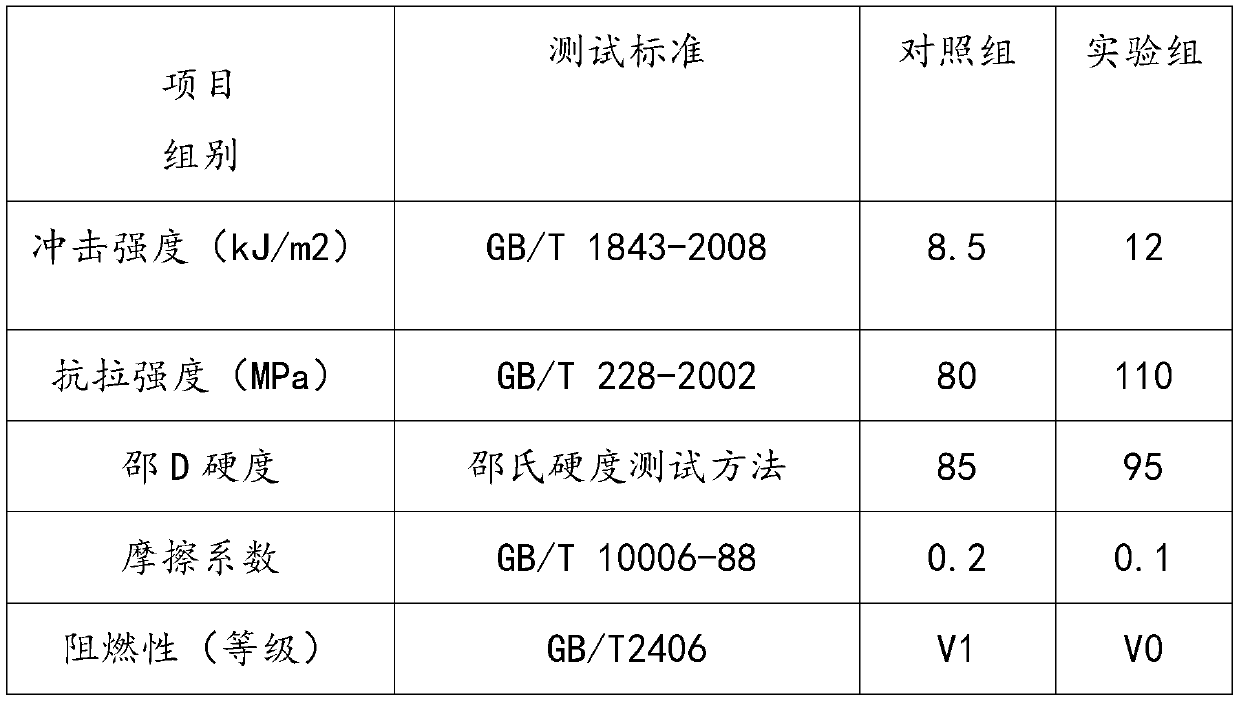

High-strength wear-resistance ceramic-plastic gear and preparation method thereof

The invention discloses a high-strength wear-resistance ceramic-plastic gear. The high-strength wear-resistance ceramic-plastic gear is prepared from materials including modified polyether-ether-ketone, ceramic fiber, polyformaldehyde, polyamide, lanthanum dodecoxyborate, glycol, thermotropic liquid crystal polyester, polyethylene terephthalate, nanometer aluminum oxide, 2, 6-tert-butyl-4-methylphenol, tri-octyl ester, diisononyl phthalate, polyborosiloxane, ammonium polyphosphate and 4'-methoxyacetoacetanilide, wherein the modified polyether-ether-ketone and the ceramic fiber interact to endow the high-strength wear-resistance ceramic-plastic gear with plastic and ceramic properties; the lanthanum dodecoxyborate can form a protective membrane on the surface to effective reduce friction and wearing; the glycol, the nanometer aluminum oxide and the polyethylene terephthalate synergize to improve the chemical properties of heat resistance and chemical resistance as well as impact strength and wear resistance; the polyborosiloxane and the ammonium polyphosphate can promote each other to form a silicon-containing carbonized protective layer to achieve synergistic flame-retardant effects.

Owner:漳州优普激光科技有限公司

Triazine triphenyl phosphinate sec-butyl flame retardant composition and application method thereof

The invention relates to a triazine triphenyl phosphinic acid sec-butyl ester flame retardant composition and an application method thereof. The flame retardant composition is prepared by compounding and uniformly mixing any two, three or four of melamine cyanurate (MCA), melamine pyrophosphate (MPP), 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and pentaerythritol methyl silicate (PEMS) with triazine triphenyl phosphinic acid sec-butyl ester (TTPS) at any proportion, wherein the weight part of the TTPS is greater than zero. The flame retardant composition provided by the invention has the advantages of multielement synergic effect, good flame retardancy, good compatibility with materials, low cost, zero halogen, environmental protection and the like, can be used as a flame retardant for polyester PET, polyester PBT, polyurethane, polypropylene, epoxy resin and other materials, and has excellent application and popularization prospects.

Owner:RES INST OF XIANGCHENG SUZHOU UNIV OF SCI & TECH

Water-resistant core-shell flame retardant and its application in the preparation of polyurethane composites

ActiveCN104817676BImprove the disadvantage of being easily soluble in waterEfficient Flame RetardancyMelamine formaldehydeWater resistant

The invention belongs to the field of materials and discloses a waterproof core-shell structure flame retardant and application of the flame retardant to preparation of a polyurethane composite. The flame retardant forms a core-shell structure by taking ammonium polyphosphate as a capsule core and taking a copolymer of melamine formaldehyde prepolymer and multiamino polyether as a capsule wall material. Since a shell of the system is hydrophobic resin, water resistance is highly improved as compared with that uncoated flame retardant particles, loss rate of ammonium polyphosphate particles sealed with filter paper reaches 98.0%, loss rate of the prepared waterproof flame retardant particles under the same conditions is lower than 8.50%, and the polyurethane composite prepared from the waterproof core-shell structure flame retardant has good flame retardant effect and can still keep efficient flame retardance under the condition of long-time water soaking.

Owner:国科广化(南雄)新材料研究院有限公司 +1

A special halogen-free flame retardant synergistic functional masterbatch for polycarbonate resin modification and its preparation method

Owner:江苏万纳普新材料科技有限公司

Tetrakis (o, o-diisopropylphosphoryl) glycoluril flame retardant composition and application method thereof

ActiveCN104177652BImprove flame retardant performanceNo reduction in mechanical strengthPolyesterGlycoluril

The invention relates to a tetrakis (0,0-diisopropylphosphoryl) glycoluril flame retardant composition. The flame retardant composition is composed of tetrakis (0,0-diisopropylphosphoryl) glycoluril (TIPRG) and melamine cyanurate (MCA), melamine polyphosphate (MPP) and diethylphosphinic acid Any one, two or three kinds of aluminum (1240) are compounded and uniformly mixed in any weight ratio, and tetrakis (0,0-diisopropylphosphoryl) glycoluril is added to the flame retardant composition The weight fraction in is greater than zero. The flame retardant composition of the present invention has the advantages of multi-element synergy, good compatibility with materials, high flame retardancy, halogen-free environmental protection, and can reduce application costs, etc., and can be used for flame retardancy of polyester, polyamide, etc. agent.

Owner:苏州艾科迪新材料科技有限公司

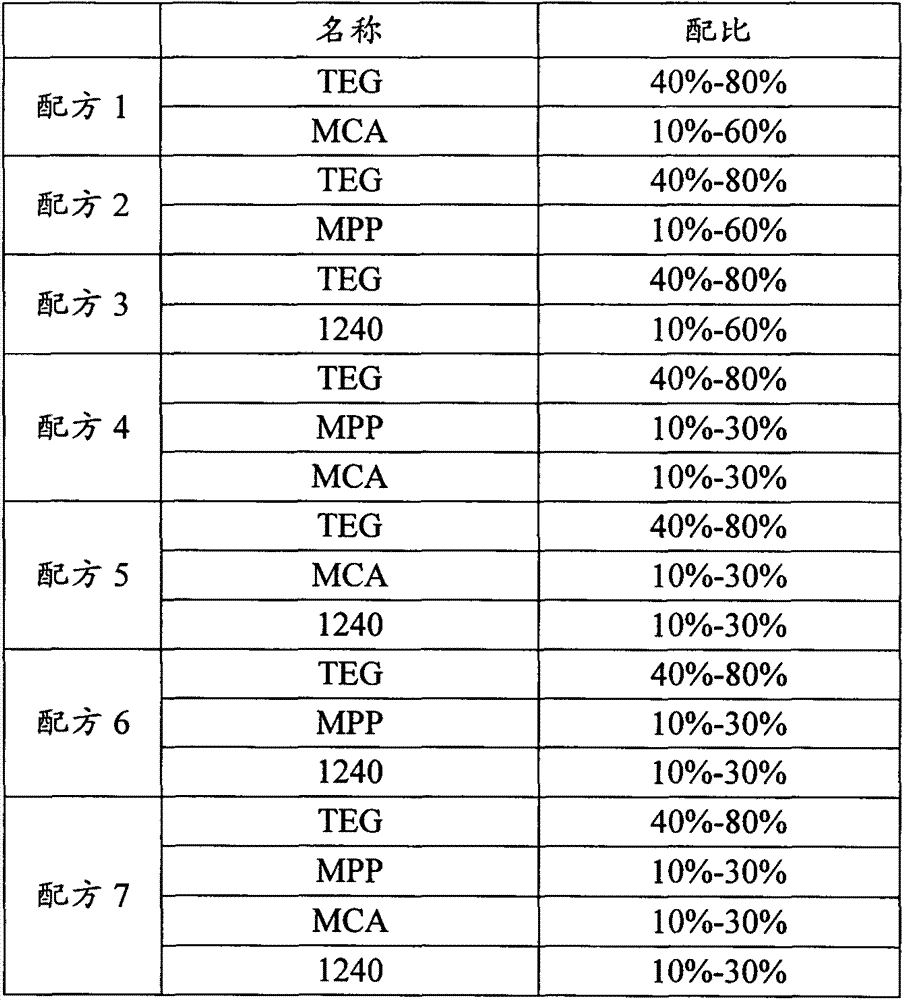

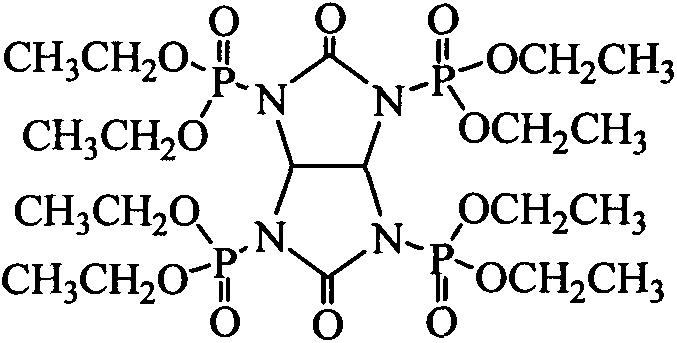

Tetrakis (0,0-diethylphosphoryl) glycoluril flame retardant composition and application method thereof

ActiveCN104151795BImprove flame retardant performanceNo reduction in mechanical strengthGlycolurilPolyester

The invention relates to a 4(0,0-diethyl phosphoryl)glycoluril flame retardant composition. The flame retardant composition is prepared by compounding and uniformly mixing 4(0,0-diethyl phosphoryl)glycoluril (TEG) with any one, two or three of melamine cyanurate (MCA), melamine pyrophosphate (MPP) and aluminum diethylphosphinate (1240), wherein the weight fraction of the 4(0,0-diethyl phosphoryl)glycoluril in the flame retardant composition is larger than zero. The flame retardant composition disclosed by the invention has the advantages of multi-element synergistic interaction, high material compatibility, high flame resistance, freeness from halogen, environmental friendliness, reduction in the application cost and the like, and can be applied to flame retardants such as polyester and polyamide.

Owner:苏州科立盈胶粘材料有限公司

Tetrakis (o-methyl-phenylphosphinoyl) glycoluril flame retardant composition and application method thereof

ActiveCN104194041BImprove flame retardant performanceNo reduction in mechanical strengthPolyesterGlycoluril

The invention relates to a tetrakis (0-methyl-phenylphosphinoyl) glycoluril flame retardant composition. The flame retardant composition is composed of tetrakis (0-methyl-phenylphosphinoyl) glycoluril (TMPG) and melamine cyanurate (MCA), melamine polyphosphate (MPP) and diethylphosphinic acid Any one, two or three kinds of aluminum (1240) are compounded and uniformly mixed in any weight ratio, and tetrakis (0-methyl-phenylphosphinyl) glycoluril is added to the flame retardant composition The weight fraction in is greater than zero. The flame retardant composition of the present invention has the advantages of multi-element synergy, good compatibility with materials, high flame retardant performance, halogen-free environmental protection, and can reduce application costs, etc., and can be used for flame retardant of polyester, polyamide, etc. agent.

Owner:苏州艾科迪新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com