Waterproof core-shell structure flame retardant and application of flame retardant to preparation of polyurethane composite

A technology of core-shell structure and composite materials, which is applied in the field of flame retardant materials, can solve the problems of loss of effective flame retardants and decline of flame retardant performance, and achieve the effect of maintaining flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

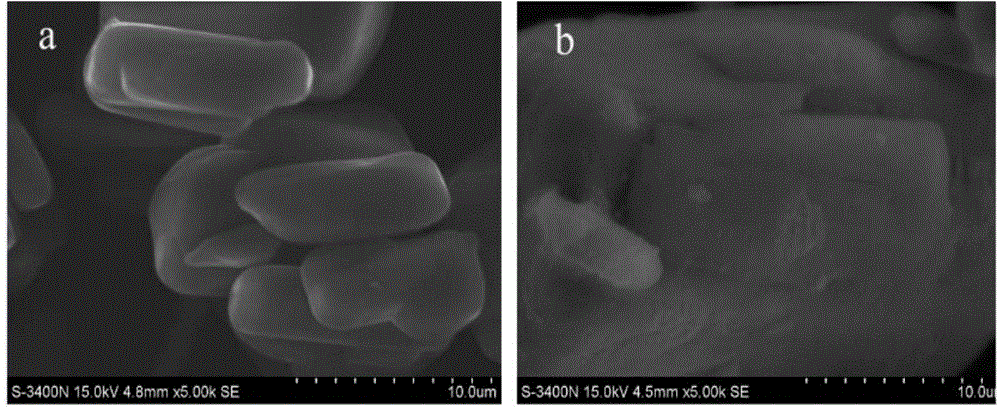

Image

Examples

Embodiment 1

[0026] (1) Preparation of water-resistant core-shell structure flame retardant:

[0027] Add ammonium polyphosphate (APP) powder to 100mL of absolute ethanol at room temperature, stir and heat up to 50°C, add 12g of melamine-formaldehyde prepolymer, raise the temperature to 60°C, adjust the pH to acidic, and then add 2g of polyether Amine, kept stirring for 0.5 hours, then automatically cooled, suction filtered, washed, dried, and the resulting white powder was a water-resistant core-shell flame retardant.

[0028] (2) Preparation of polyurethane composite material:

[0029] Take the water-resistant core-shell structure flame retardant prepared in 3.2 quality step (1), add 3 parts by mass of n-pentane, place it in an ice-water bath, and the flame retardant is infiltrated by n-pentane; then add 10 parts by mass of polyether multi-component Alcohol, 0.12 parts by mass of catalyst, stirred evenly, and made into material A; take 10 parts by mass of diphenylmethane diisocyanate (M...

Embodiment 2

[0031] (1) Preparation of water-resistant core-shell structure flame retardant:

[0032] Add ammonium polyphosphate (APP) powder to 120mL of absolute ethanol at room temperature, stir and heat up to 50°C, add 15g of melamine-formaldehyde prepolymer, raise the temperature to 70°C, adjust the pH to be acidic, and then add 2g of polyether Amine, keep stirring for 2 hours; then automatic cooling, suction filtration, washing, drying, the obtained white powder is the water-resistant core-shell structure flame retardant.

[0033] (2) Preparation of polyurethane composite material:

[0034] Take the water-resistant core-shell structure flame retardant prepared in 3.2 quality step (1), add 3 parts by mass of n-pentane, place it in an ice-water bath, and the flame retardant is infiltrated by n-pentane; then add 10 parts by mass of polyether multi-component Alcohol, 0.12 parts by mass of catalyst, stirred evenly, and made into material A; take 10 parts by mass of diphenylmethane diisocy...

Embodiment 3

[0036] (1) Preparation of water-resistant core-shell structure flame retardant:

[0037] Add ammonium polyphosphate (APP) powder to 150mL of absolute ethanol at room temperature, stir and heat up to 60°C, add 15g of melamine-formaldehyde prepolymer, raise the temperature to 80°C, adjust the pH to be acidic, and then add 2g of polyether Amine, keep stirring for 4 hours; then automatic cooling, suction filtration, washing, drying, the obtained white powder is the water-resistant core-shell structure flame retardant.

[0038] (2) Preparation of polyurethane composite material:

[0039] Take the water-resistant core-shell structure flame retardant prepared in 3.2 quality step (1), add 3 parts by mass of n-pentane, place it in an ice-water bath, and the flame retardant is infiltrated by n-pentane; then add 10 parts by mass of polyether multi-component Alcohol, 0.12 parts by mass of catalyst, stirred evenly, and made into material A; take 10 parts by mass of diphenylmethane diisocy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com