Flame retardant having reactivity and adopting core-shell structure as well as preparation method and application of flame retardant

A technology of core-shell structure and reactivity, which is applied in the field of materials to achieve the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

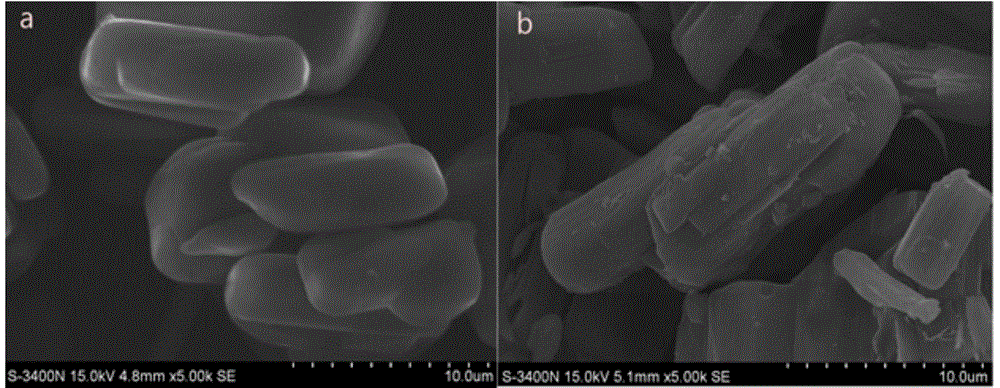

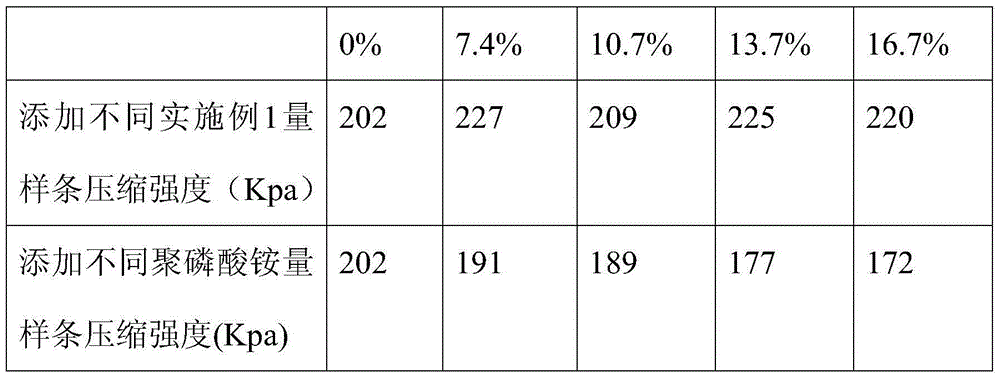

Embodiment 1

[0025] Add 60g of ammonium polyphosphate (APP) powder into a three-neck flask containing 180ml of toluene at room temperature, stir and raise the temperature to 50°C, keep stirring and add 7ml of methyl methacrylate and 3ml of hydroxyethyl acrylate mixture dropwise; keep stirring at 50°C for 10 Minutes, heat up to 70°C, add dropwise benzoyl peroxide (BPO) solution (prepared by dissolving 0.10g benzoyl peroxide in 10ml methyl ethyl ketone); heat up to 80°C, keep stirring for 4 hours, and filter with suction 1. Washing with toluene, suction filtration, and drying to constant weight, the obtained white powder is the reactive core-shell structure flame retardant.

Embodiment 2

[0027] Add 60g of ammonium polyphosphate (APP) powder into a three-neck flask containing 210ml of toluene at room temperature, stir and raise the temperature to 55°C, keep stirring and add 7ml of methyl methacrylate and 3ml of hydroxyethyl acrylate mixture dropwise; keep stirring at 50°C for 10 Minutes, heat up to 70°C, add dropwise benzoyl peroxide (BPO) solution (prepared by dissolving 0.10g benzoyl peroxide in 10ml methyl ethyl ketone); heat up to 80°C, keep stirring for 4 hours, and filter with suction 1. Washing with toluene, suction filtration, and drying to constant weight, the obtained white powder is the reactive core-shell structure flame retardant.

Embodiment 3

[0029] Add 60g of ammonium polyphosphate (APP) powder into a three-neck flask containing 240ml of toluene at room temperature, stir and heat up to 60°C, keep stirring and add 7ml of methyl methacrylate and 3ml of hydroxyethyl acrylate mixture dropwise; keep stirring at 50°C for 10 Minutes, heat up to 70°C, add dropwise benzoyl peroxide (BPO) solution (prepared by dissolving 0.10g benzoyl peroxide in 10ml methyl ethyl ketone); heat up to 80°C, keep stirring for 4 hours, and filter with suction 1. Washing with toluene, suction filtration, and drying to constant weight, the obtained white powder is the reactive core-shell structure flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com