A special halogen-free flame retardant and synergistic functional masterbatch for polyoxymethylene modification and preparation method thereof

A functional masterbatch, flame retardant and synergistic technology, applied in the field of plastic modification processing, can solve the problems of poor thermal stability, weak interface adhesion, large loss of flame retardant performance, etc., to achieve enhanced compactness and structural stability, Improve thermal decomposition temperature and synergistic flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

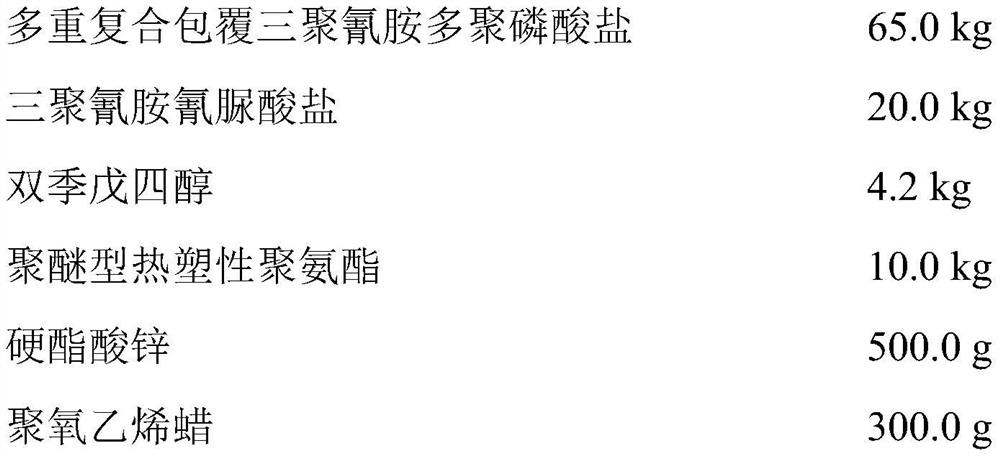

[0034] A special halogen-free flame retardant synergistic functional masterbatch for polyoxymethylene modification, the quality ratio of raw materials is as follows:

[0035]

[0036] The preparation method of the multi-compound coated melamine polyphosphate used in the above-mentioned polyoxymethylene modified special-purpose halogen-free flame-retardant synergistic functional masterbatch is as follows:

[0037] Add 230L of absolute ethanol, 120kg of melamine polyphosphate, 7kg of aluminum sol, and 1kg of zinc oxide sol into the enamel reaction kettle with a stirring and temperature control device, stir evenly and add to 40°C, then add the mass percentage content dropwise at an even speed 10.0wt.% ammonia water, and the pH value of the reaction solution is controlled at 7.5 to 8.5 to promote the sol-gel reaction between the aluminum sol and the zinc oxide sol. After the addition is completed, continue to stir for 3.5 hours to end the reaction; Washing, filtering, and dryin...

Embodiment 2

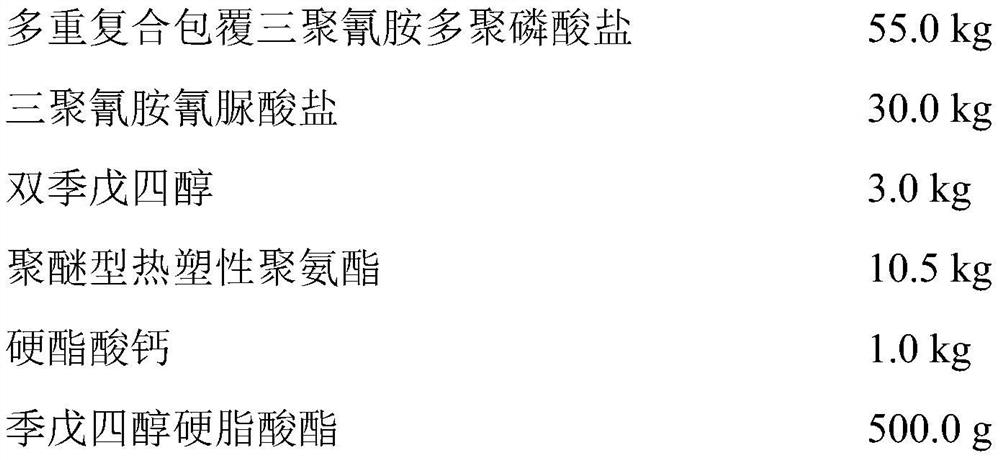

[0040] A special halogen-free flame retardant synergistic functional masterbatch for polyoxymethylene modification, the quality ratio of raw materials is as follows:

[0041]

[0042] The preparation method of the multi-compound coated melamine polyphosphate used in the above-mentioned polyoxymethylene modified special-purpose halogen-free flame-retardant synergistic functional masterbatch is as follows:

[0043] Add 230L of absolute ethanol, 120kg of melamine polyphosphate, 8kg of aluminum sol, and 1.5kg of zinc oxide sol into the enamel reaction kettle with a stirring and temperature control device, stir evenly and add to 35°C, then add the mass percentage dropwise at an even speed Ammonia water with a content of 11.5wt.%, and the pH value of the reaction solution is controlled at 7.5 to 8.5 to promote the sol-gel reaction between the aluminum sol and the zinc oxide sol. After the addition is completed, continue to stir for 4 hours to end the reaction; Washing, filtering,...

Embodiment 3

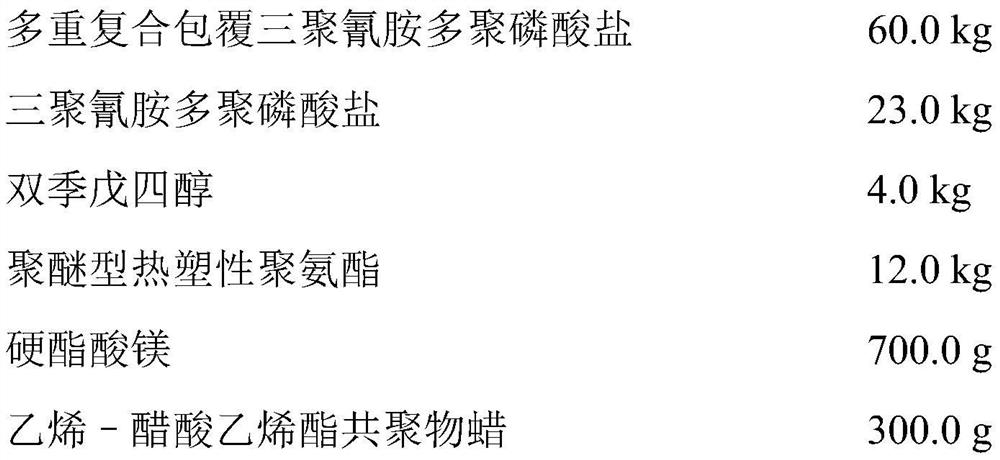

[0046] A special halogen-free flame retardant synergistic functional masterbatch for polyoxymethylene modification, the preparation method of the multiple compound coated melamine polyphosphate used in it is as follows:

[0047] Add 230L of absolute ethanol, 120kg of melamine polyphosphate, 7.5kg of aluminum sol, and 2kg of zinc oxide sol into the enamel reaction kettle with a stirring and temperature control device, stir evenly and add to 37°C, then add the mass percentage dropwise at an even speed Ammonia water with a content of 12.5wt.%, and the pH value of the reaction solution is controlled at 7.5 to 8.5 to promote the sol-gel reaction between the aluminum sol and the zinc oxide sol. After the addition is completed, continue to stir for 4 hours to end the reaction; Wash, filter, and dry in an oven at 125°C for 8 hours to obtain zinc ion-doped aluminum hydroxide-coated melamine polyphosphate. In another glass container, 3kg of phytic acid was dissolved in 6L of deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com