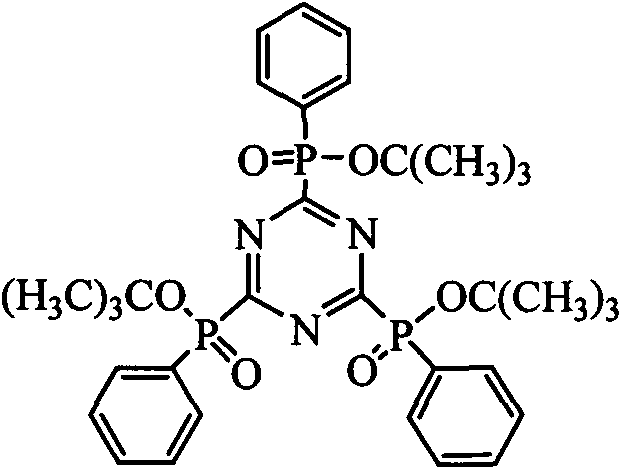

Triazine triphenyl phosphinate tert-butyl flame retardant composition and application method thereof

A technology of triazine triphenyl phosphine and tert-butyl acid, which is applied in the field of triazine triphenyl phosphinate tert-butyl ester flame retardant composition, achieves good application development prospect, simple preparation method and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

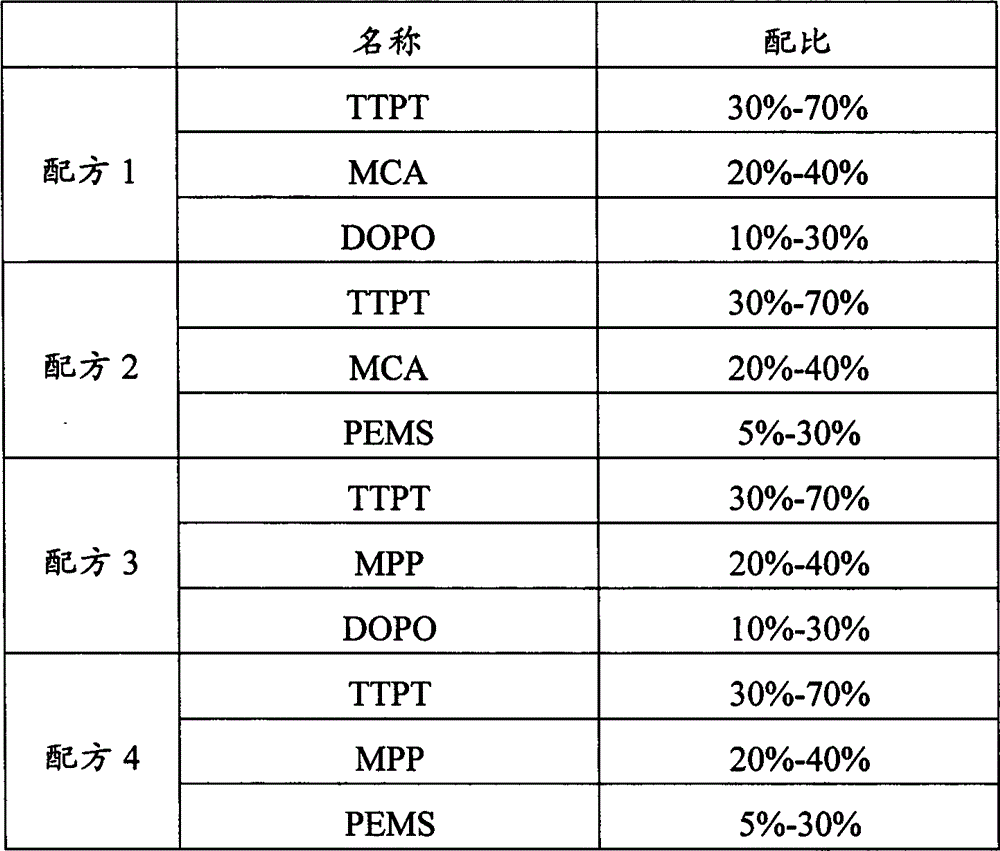

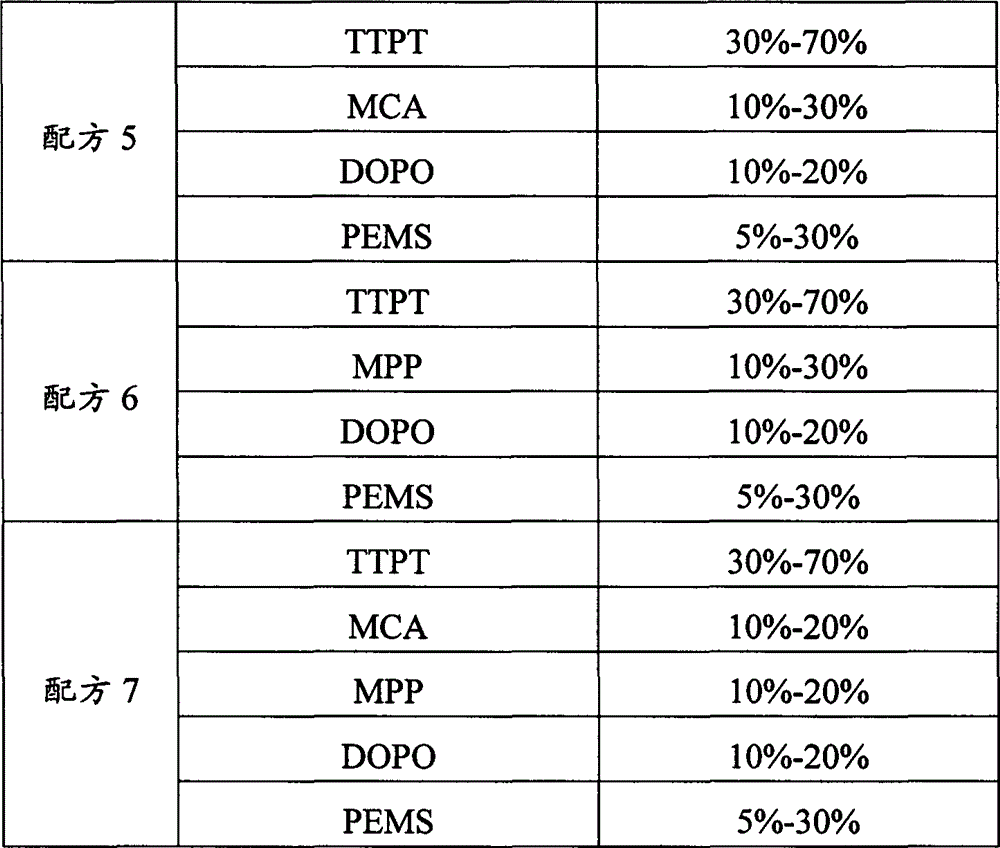

[0029] Example 1 Add different proportions of TTPT, MCA and DOPO to polyester PET, stir evenly, use XJ-01 type extruder to extrude a sample with a diameter of about 3 mm at melting temperature, and use HC900-2 type oxygen index to measure The limiting oxygen index was measured by the instrument, and the results are shown in Table 2.

[0030] Table 2 Flame retardant data of TTPT combined with MCA and DOPO for PET

[0031]

Embodiment 2

[0032] Example 2 Add different proportions of TTPT, MCA and PEMS to polyester PET, stir evenly, use XJ-01 type extruder to extrude a sample with a diameter of about 3 mm at melting temperature, and use HC900-2 type oxygen index to measure The limiting oxygen index was measured by the instrument, and the results are shown in Table 3.

[0033] Table 3 Flame retardant data of TTPT combined with MCA and PEMS for PET

[0034]

Embodiment 3

[0035] Example 3 Add different proportions of TTPT, MPP and DOPO to polyester PET, stir evenly, use XJ-01 type extruder to extrude a sample with a diameter of about 3mm at melting temperature, and use HC900-2 type oxygen index to measure The limiting oxygen index was measured by an instrument, and the results are shown in Table 4.

[0036] Table 4 Flame retardant data of TTPT combined with MPP and DOPO for PET

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com