Stretching wrapping film and preparation method thereof

A technology for stretching and wrapping films and raw materials, applied in chemical instruments and methods, sustainable manufacturing/processing, flexible coverings, etc., can solve problems such as high environmental pollution and refractory film degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

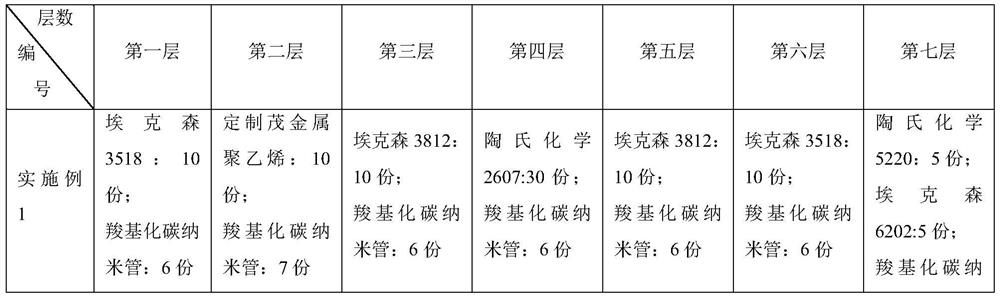

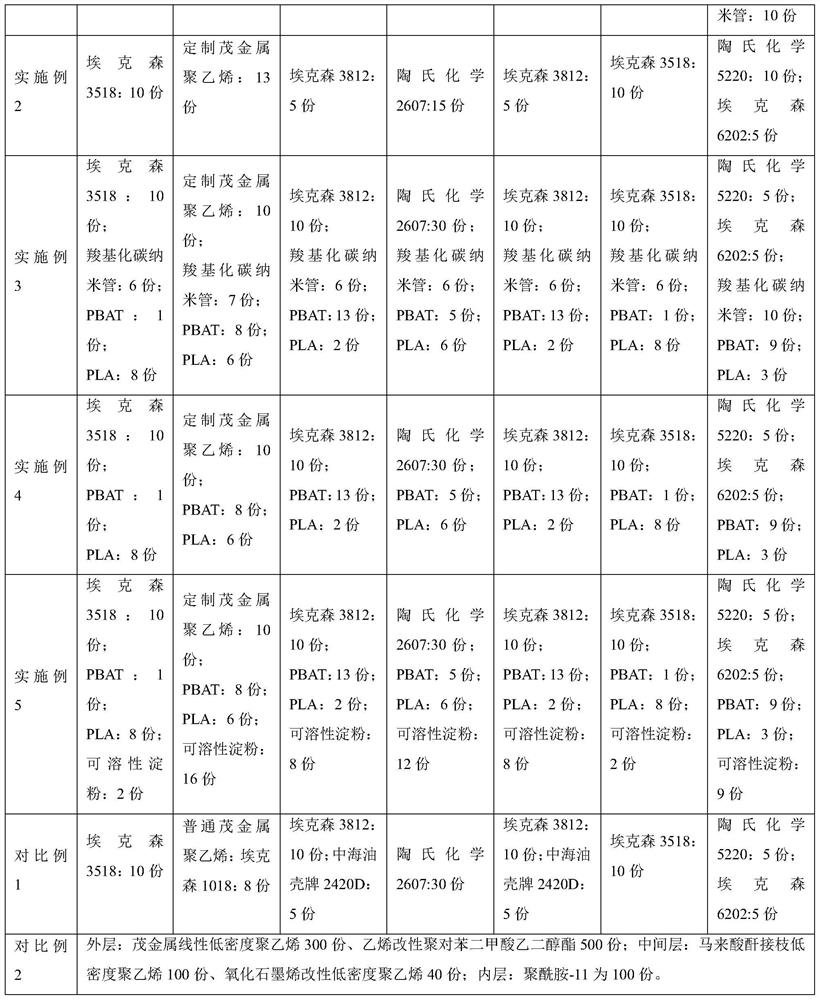

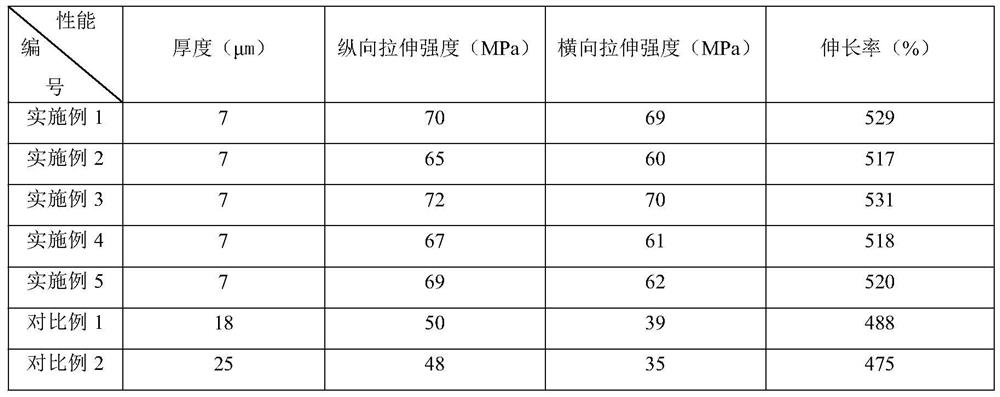

[0039] A kind of stretch wrapping film, is made up of 7 layers of materials, carries out the preparation of stretch wrapping film according to following steps:

[0040] (1) Melt blending of raw materials: Weigh the raw materials according to the ratio of the raw materials of each layer in Table 1, and add the raw materials of each layer into the corresponding screw extruder for melt blending to obtain a uniform melt; then the raw materials The melt is extruded into the distributor through the screw, and the distributor distributes the melt according to the mass ratio of each layer;

[0041]The length ratio among the feed section, compression section and homogenization section in the screw extruder is 1:1.22:1.11. Specifically: for a traditional screw extruder, the length of the feeding section, the compression section and the homogenization section are the same. In this embodiment, the compression section is lengthened by 10%, and the feeding section is correspondingly reduced...

Embodiment 2

[0049] According to the proportioning of each layer of raw materials in Table 1, the raw materials are weighed, similar to the preparation method of Example 1, the difference from Example 1 in the specific preparation steps is:

[0050] (1) The mass ratio of the raw material melts from the first layer to the seventh layer distributed by the distributor is 1:1.2:0.5:0.4:0.3:1:1.2;

[0051] (2) The length ratio between the feeding section, compression section and homogenization section in the screw extruder is 1:1.22:1.11;

[0052] (3) The temperature of the extrusion die of the screw extruder is 230°C, and the extrusion pressure is 15MPa;

[0053] (4) The speed ratio of forming roll, cooling roll, traction roll and winding roll is 1: 1.006: 1.011: 0.998.

Embodiment 3

[0055] According to the proportioning of each layer of raw materials in Table 1, the raw materials are weighed, similar to the preparation method of Example 1, the difference from Example 1 in the specific preparation steps is:

[0056] (1) The mass ratio of the raw material melts from the first layer to the seventh layer distributed by the distributor is 1:0.8:0.9:0.6:0.7:1:1.7;

[0057] (2) The length ratio between the feeding section, compression section and homogenization section in the screw extruder is 1:1.15:1.08;

[0058] (3) The temperature of the extrusion die of the screw extruder is 280°C, and the extrusion pressure is 8MPa;

[0059] (4) The speed ratio of forming roll, cooling roll, traction roll and winding roll is 1: 1.053: 1.125: 0.925.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com