High-power wrapping layer light stripper

A cladding light and stripper technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of inability to withstand high-power stripping, low mechanical strength of optical fibers, etc., to improve heat treatment capacity and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

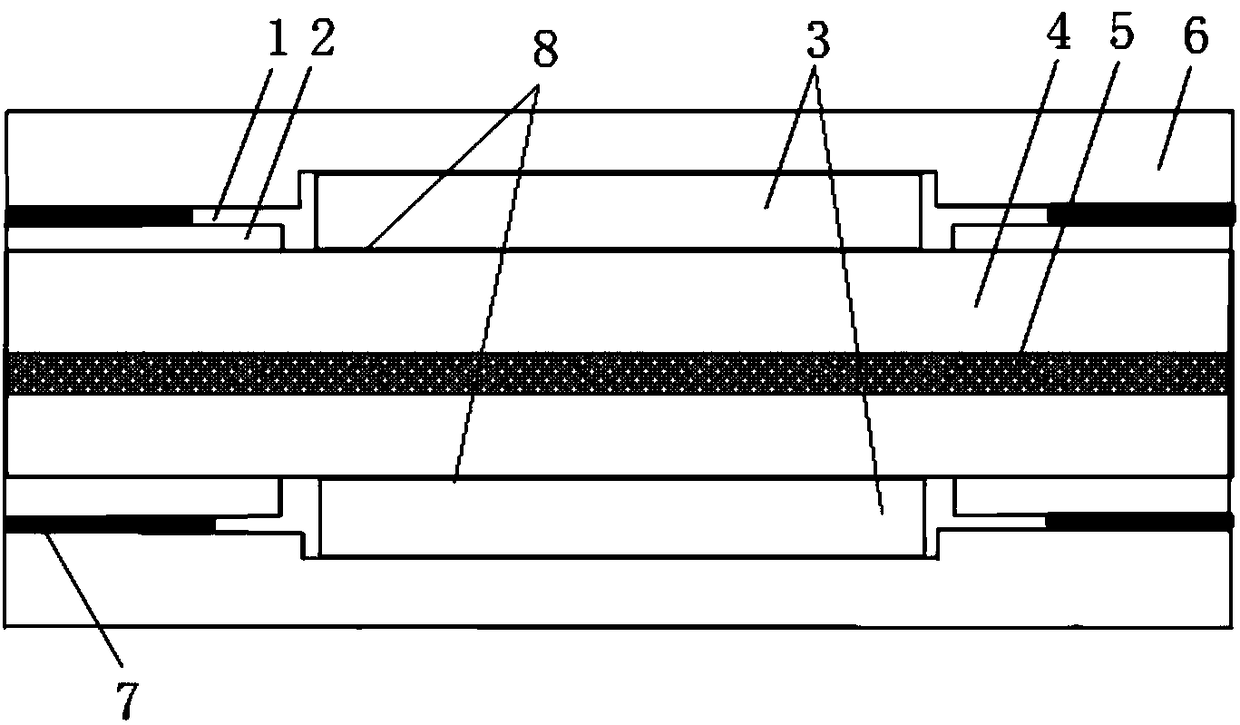

[0022] The existing cladding optical stripper device adopts the method of stripping the inner cladding of the optical fiber into a stepped form and coating high-refractive-index glue. This method reduces the mechanical strength of the optical fiber, and at the same time, due to the existence of high-refractive-index optical glue, it cannot withstand high power stripping.

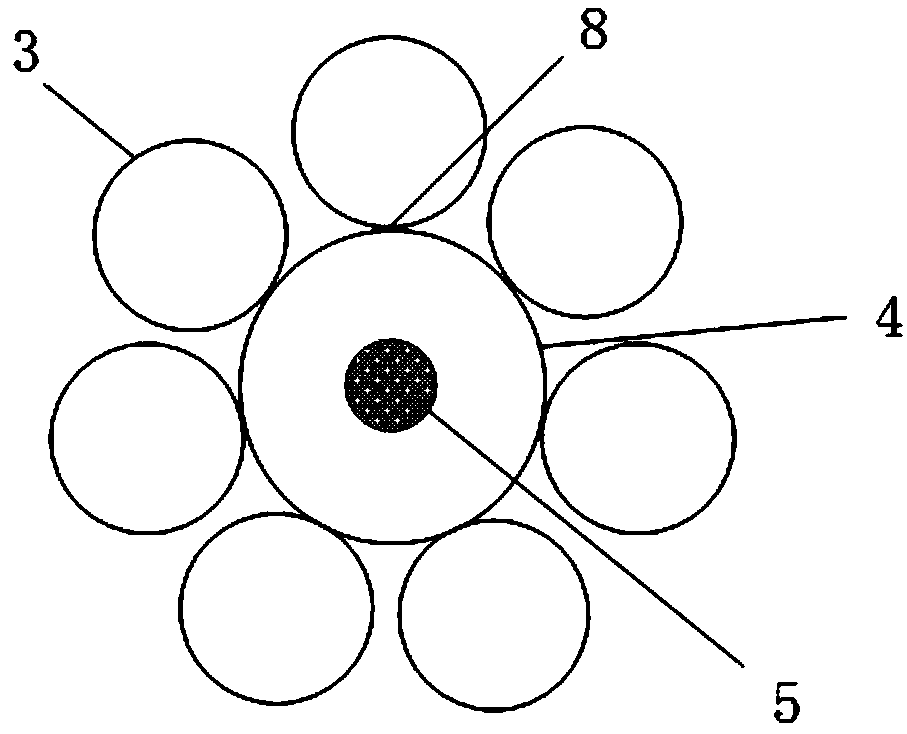

[0023] For this reason, the present invention provides a kind of high-power cladding light stripper, realizes cladding light stripping by destroying the waveguide structure on the surface of the optical fiber, then connects the quartz glass rod on the surface of the optical fiber to reduce the heat density of the optical fiber, realizes the high Power CPS.

[0024] The invention realizes light energy transfer by connecting the optical fiber cladding with the quartz glass rod, reduces the light energy density on the quartz rod, and then contacts the package shell through the quartz rod; this structure can rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com