Internal-stress-free floor producing method

A production method and technology of internal stress, applied in the direction of wood processing appliances, manufacturing tools, etc., can solve problems such as inability to solve the internal stress of the floor, difficult maintenance of solid wood floors, damage to solid wood floors, etc., and achieve no reduction in mechanical strength, light weight, and increase in The effect of resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for producing a floor without internal stress, comprising the following steps:

[0032] A. Polish the upper layer of the floor substrate made of solid wood to ensure that the upper layer of the floor substrate is flat;

[0033] B. Cut the floor substrate after the upper layer is polished to ensure that the floor substrate is cut to the specified length and width, and at the same time cut the side layer of the floor substrate flat;

[0034] C. The flattened floor substrate is divided into two times for groove and groove processing. First, cut the groove and groove of the two long sides, and then change the other end and cut the groove and groove of the two short sides;

[0035] D. Grinding the floor base material after groove-and-groove processing to remove the burrs generated during the groove-and-groove process, and obtain a semi-finished floor;

[0036] E. Apply multiple primers to the semi-finished floor, and dry them separately;

[0037] F. Polish the sur...

Embodiment 2

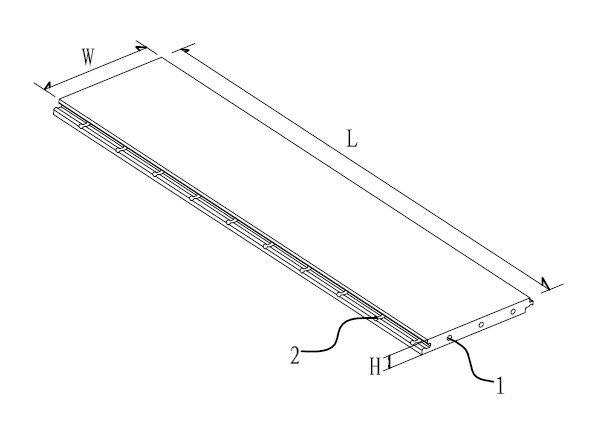

[0043] The difference from Embodiment 1 is that there are eight short through holes 2 and two long through holes 1 in total, the length L of the floor is 910mm, the width W of the floor is 125mm, the thickness H of the floor is 18mm, the long through holes 1 and The diameter of the cross section of the short through hole 2 is 5mm, the distance between the long through hole 1 and the short through hole 2 and the bottom surface of the floor is 8mm, the distance between the central axes of the adjacent long through holes 1 is 50mm, and the distance between the adjacent short through holes 2 The distance between the central axes is 100mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com