Aluminium alloy foil material for container and method for producing the same

A technology of aluminum alloy foil and manufacturing method, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of poor deep drawing performance, poor appearance quality, high cost, etc., and achieve improved elongation and increased elongation , Improve the effect of deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

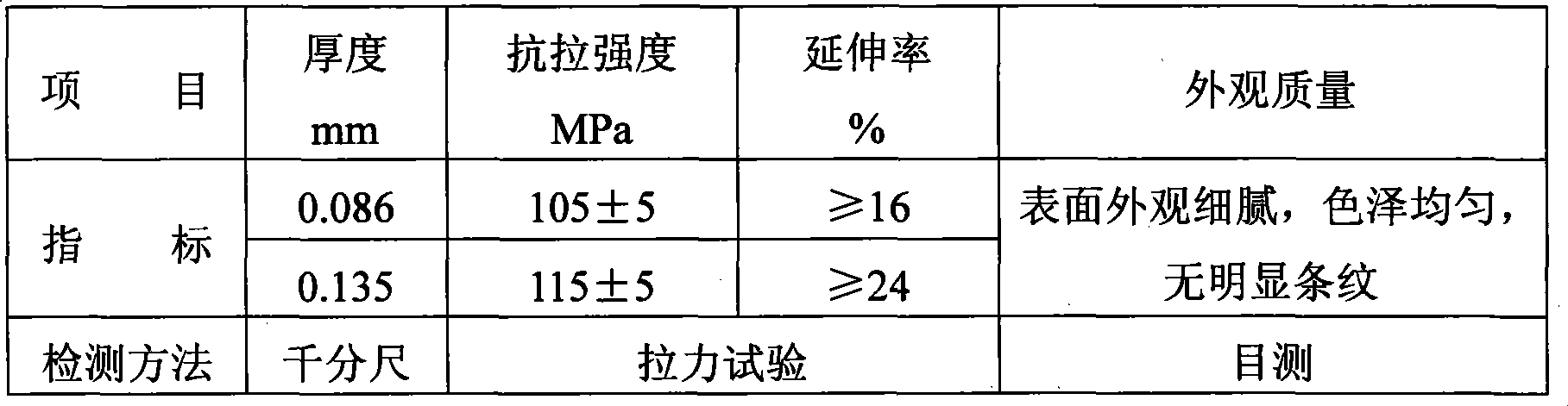

Image

Examples

Embodiment 1

[0026] Embodiment 1: the chemical composition ratio of material is:

[0027] Component iron silicon copper manganese titanium aluminum Weight ratio 0.42 0.08 0.10 1.1 0.020 the remaining

[0028] The method of making the aluminum alloy foil for the container is:

[0029] 1) Casting and rolling of slabs: put the industrially pure aluminum ingots for remelting, aluminum-iron master alloy ingots, aluminum-silicon master alloy ingots, aluminum-copper master alloy ingots and aluminum-manganese master alloy ingots prepared in the above ratio into the melting furnace Melting and heating up to 700°C, after refining, slag removal, stirring, analysis and adjustment of components, it enters the static furnace, where static, refining, degassing, and slag removal are carried out; in order to improve the microstructure and The distribution shape and structure of the second phase particles, after the aluminum liquid is exported to the static furnace, the...

Embodiment 2

[0036] Embodiment 2: the chemical composition ratio of material is:

[0037] Component iron silicon copper manganese titanium aluminum Weight ratio 0.45 0.05 0.08 1.2 0.022 the remaining

[0038] The method of making the aluminum alloy foil for the container is:

[0039] 1) Casting and rolling of slabs: put the industrially pure aluminum ingots for remelting, aluminum-iron master alloy ingots, aluminum-silicon master alloy ingots, aluminum-copper master alloy ingots and aluminum-manganese master alloy ingots prepared in the above ratio into the melting furnace Melt and heat up to 710°C, after refining, slag removal, stirring, analysis and adjustment of components, enter the static furnace, and carry out static, refining, degassing and slag removal in the static furnace; in order to improve the microstructure and The distribution shape and structure of the second phase particles, after the aluminum liquid is exported to the static furnace, ...

Embodiment 3

[0046] Embodiment 3: the chemical composition ratio of material is:

[0047] Component iron silicon copper manganese titanium aluminum Weight ratio 0.46 0.10 0.04 1.3 0.025 the remaining

[0048] The method of making the aluminum alloy foil for the container is:

[0049] 1) Casting and rolling of slabs: put the industrially pure aluminum ingots for remelting, aluminum-iron master alloy ingots, aluminum-silicon master alloy ingots, aluminum-copper master alloy ingots and aluminum-manganese master alloy ingots prepared in the above ratio into the melting furnace Melt and heat up to 720°C, after refining, slag removal, stirring, analysis and adjustment of components, enter the static furnace, and carry out static, refining, degassing and slag removal in the static furnace; in order to improve the microstructure and The distribution shape and structure of the second phase particles, after the aluminum liquid is exported to the static furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com