Aluminium alloy foil material for container and method for producing the same

A technology of aluminum alloy foil and manufacturing method, applied in metal rolling, manufacturing tools, metal rolling and other directions, can solve the problems of poor deep drawing performance, high cost, poor appearance quality, etc., to improve the distribution shape and structure, The effect of improving deformation resistance and elongation

Active Publication Date: 2010-08-18

JIANGSU ALCHA ALUMINUM CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

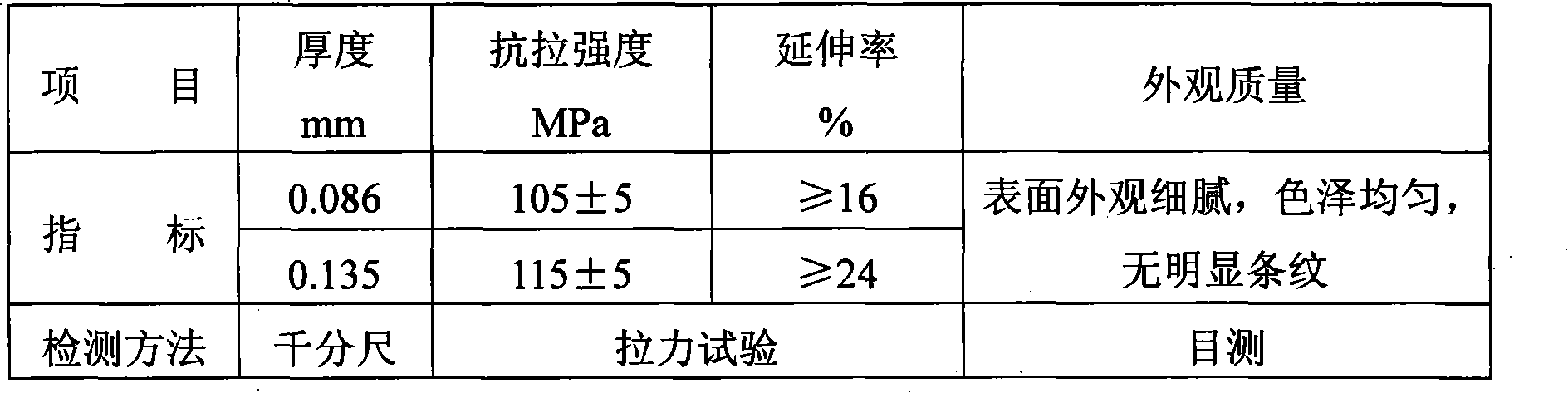

Purpose of the invention: the purpose of the present invention is to solve the disadvantages of the prior art that the aluminum foil often adopts hot rolling technology, the cost is too high, the casting and rolling technology has poor deep drawing performance, and the appearance quality is poor, and proposes an aluminum alloy foil for containers. The material has high tensile strength and elongation, and has good deep drawability, formability, and stiffness, and the appearance and color are uniform and beautiful without defects, which meets the needs of users

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an aluminum alloy foil used for containers, which is characterized in that: the components and the weight ratios are: 0.42 to 0.52 percent of iron, 0.05 to 0.20 percent of silicon, 0.04 to 0.13 percent of copper, 1.10 to 1.30 percent of manganese, 0.020-0.040 percent of titanium and the residual quantity of aluminum. The manufacturing method of the aluminum alloy foil usedfor containers comprises slab casting and rolling, pre-annealing, plank cold rolling, intermediate annealing, cold rolling, finished product annealing, greasing and cutting. Compared with the prior art, the aluminum alloy foil has the remarkable advantages: higher tensile strength and elongation; good deep-drawing performance, formability and stiff and smooth degree, beautiful appearance, uniformcolor and luster without defect, thus meeting the requirement of the users.

Description

technical field The invention relates to an aluminum alloy foil material for containers, and also provides a manufacturing method of the aluminum alloy foil material. Background technique Because aluminum foil has the advantages of easy forming, beautiful appearance, easy disinfection, low cost, and convenient recycling, aluminum foil containers of deep-processed products are widely used, and can be made into containers for fruits and other foods, plates, lunch boxes, and lunch boxes on airplanes , refrigerator boxes, cold storage containers, etc. Aluminum foil for containers is required to have high tensile strength and elongation, good deep drawability, formability, and stiffness, and the appearance and color are uniform and beautiful without defects. At present, this kind of aluminum foil is often produced by hot rolling technology, and the cost is relatively high. However, when casting and rolling technology is used for production, there are generally defects such as p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C21/00C22F1/04B21B37/16

Inventor 张敏达章建华张建军何献忠彭晓彤吴永新

Owner JIANGSU ALCHA ALUMINUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com