Patents

Literature

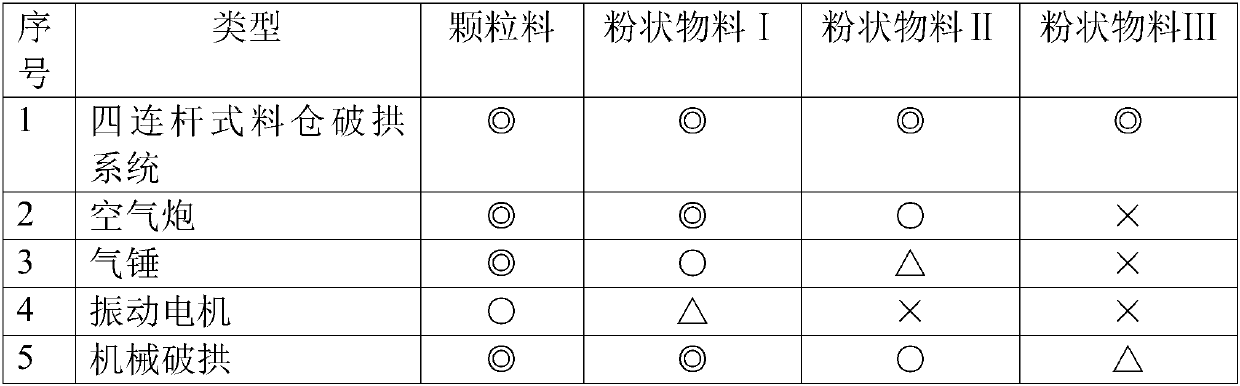

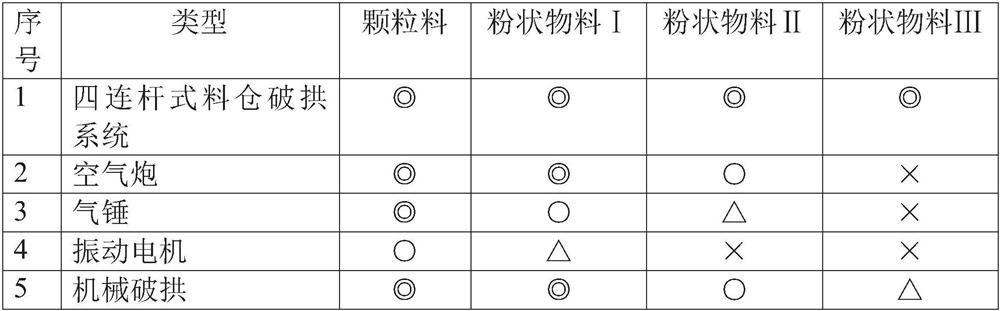

30results about How to "Reduce arching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

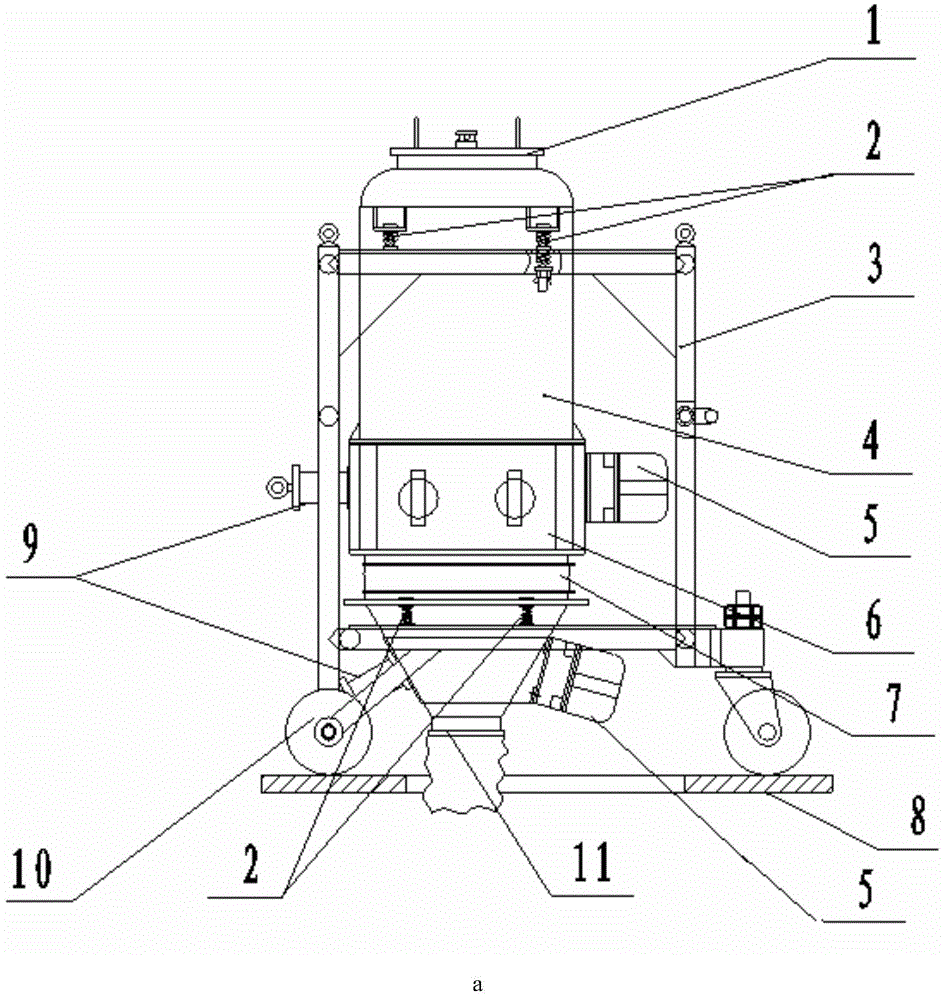

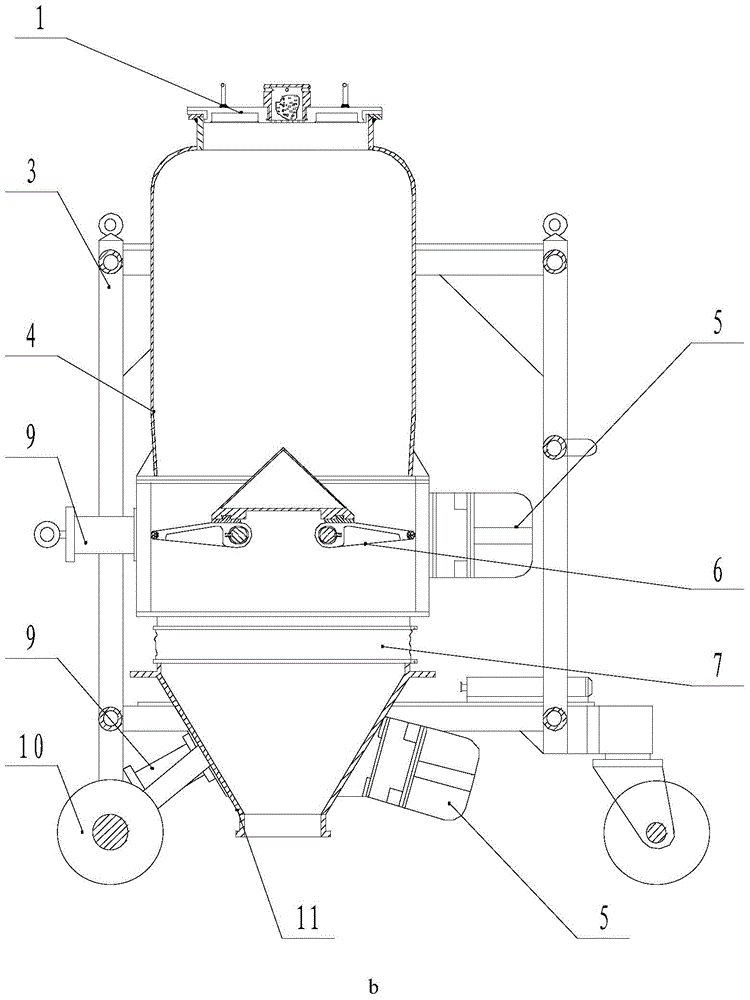

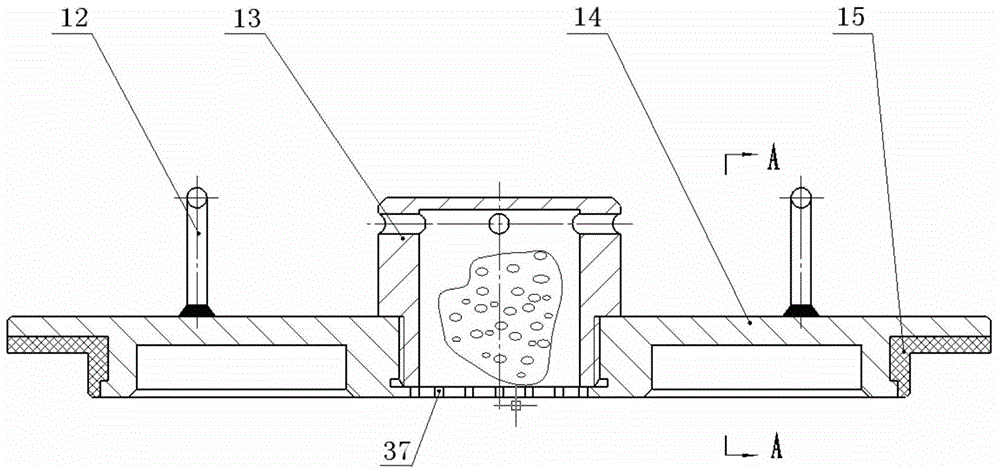

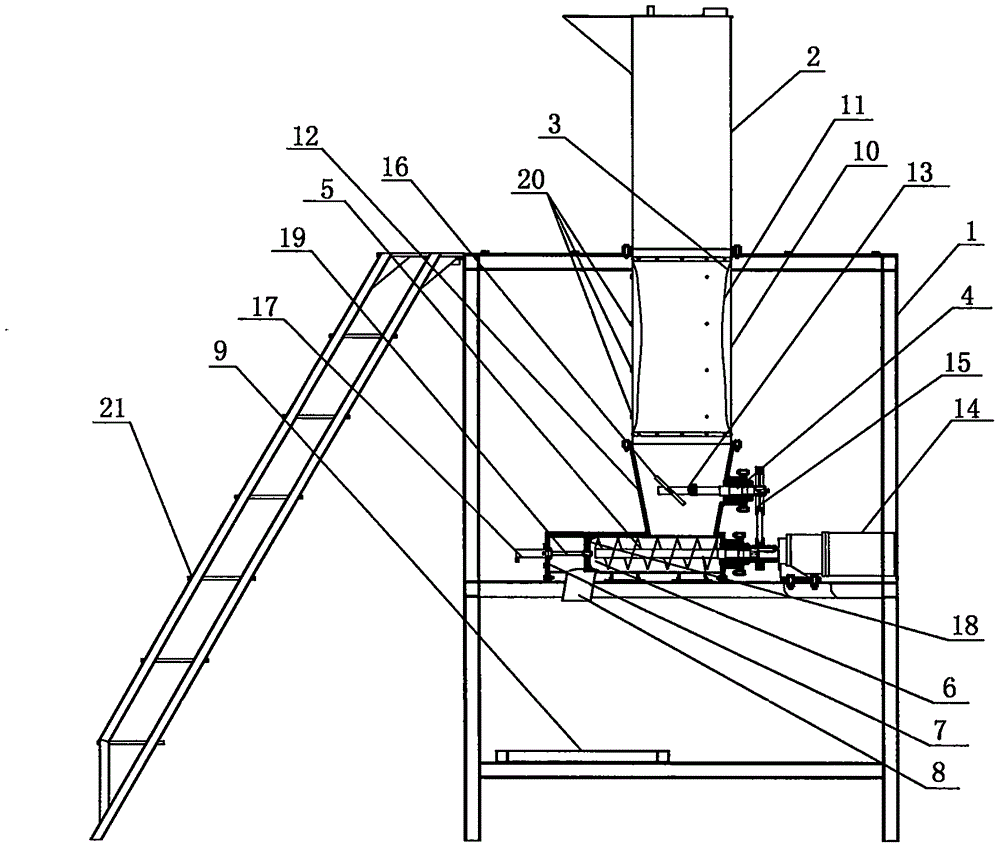

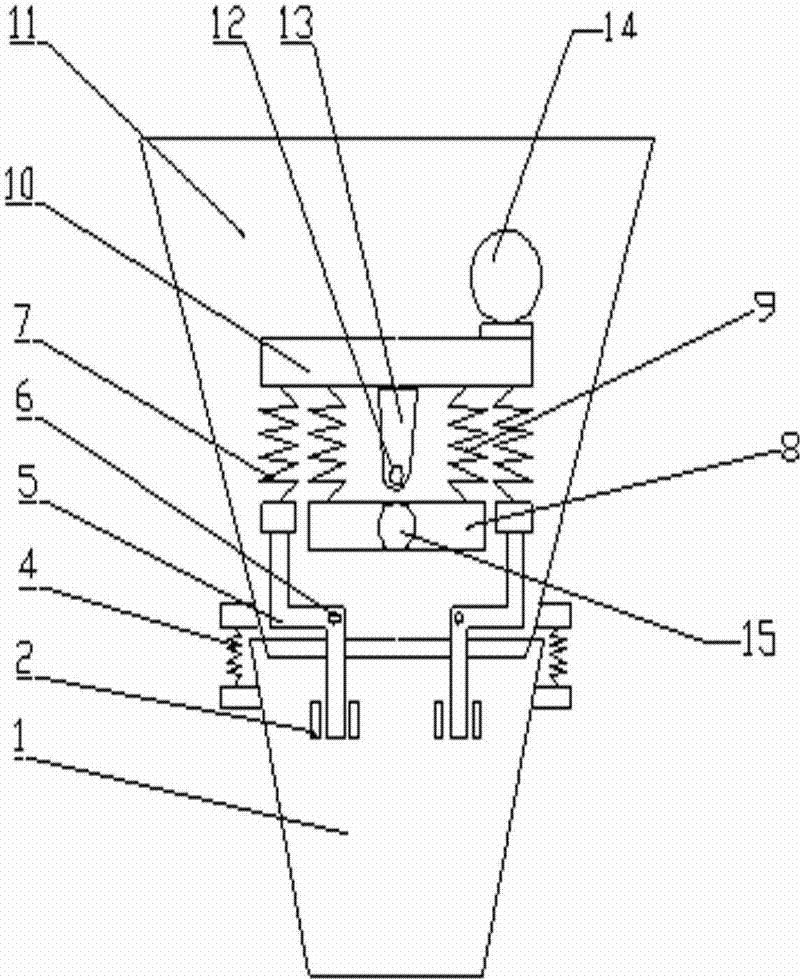

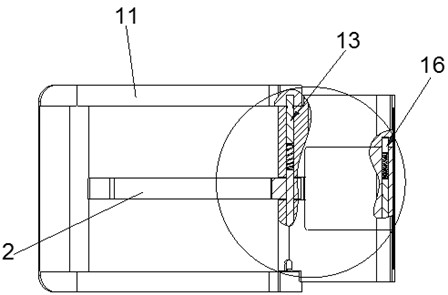

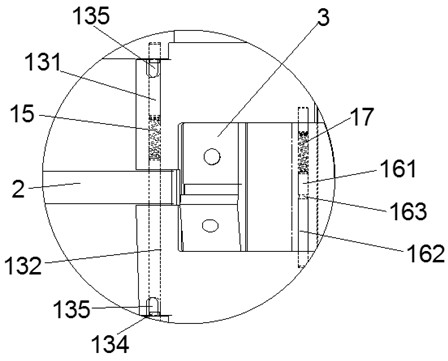

Powder storage device with quantitative discharging function

ActiveCN104309956APrevent blocking phenomenonUniform feedingLarge containersMechanical engineeringEngineering

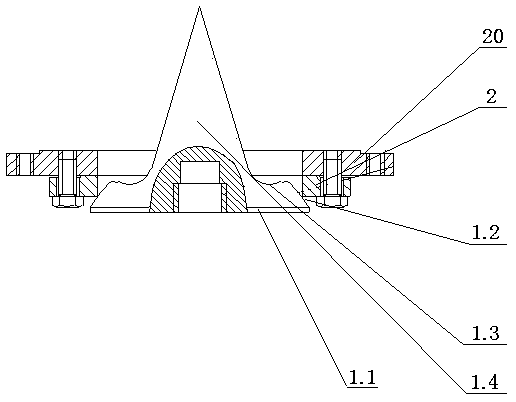

The invention relates to a powder storage device with a quantitative discharging function. The powder storage device is characterized in that a material containing barrel is mounted on an upper cross beam of a frame through a flexible connector; a quantitative discharging device is fixedly arranged below the material containing barrel; a discharging hopper is fixedly arranged below the quantitative discharging device; a dustproof cover is arranged on the discharging hopper in a sleeving way; the number of explosion-proof electromagnetic vibrators is two, the two explosion-proof electromagnetic vibrators are respectively mounted on a supporting base of the quantitative discharging device and a connecting base of the discharging hopper; the number of air hammers is two, one of the air hammers is mounted on the supporting base of the quantitative discharging device, and the other air hammer is mounted on a connecting plate of the discharging hopper. The powder storage device has the benefits that the powder storage device can be used for automatic quantitative discharging, transportation and storage of a lot of power stored; through the design of the structure and the adjustment of the vibration frequency of the explosion-proof electromagnetic vibrators, the arching and agglomeration phenomenon of the powder in the blanking process can be greatly reduced, so that smooth blanking is ensured; the power quantitative discharging is realized through real-time monitoring of power weight in the discharging process.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

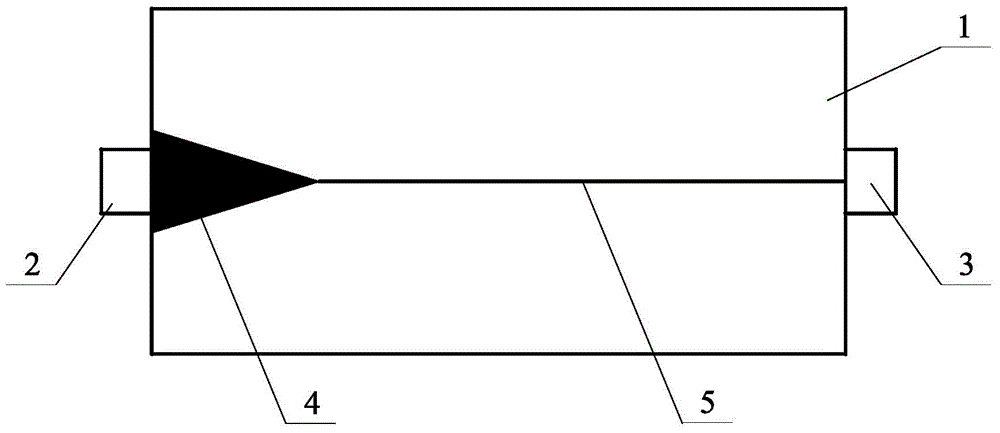

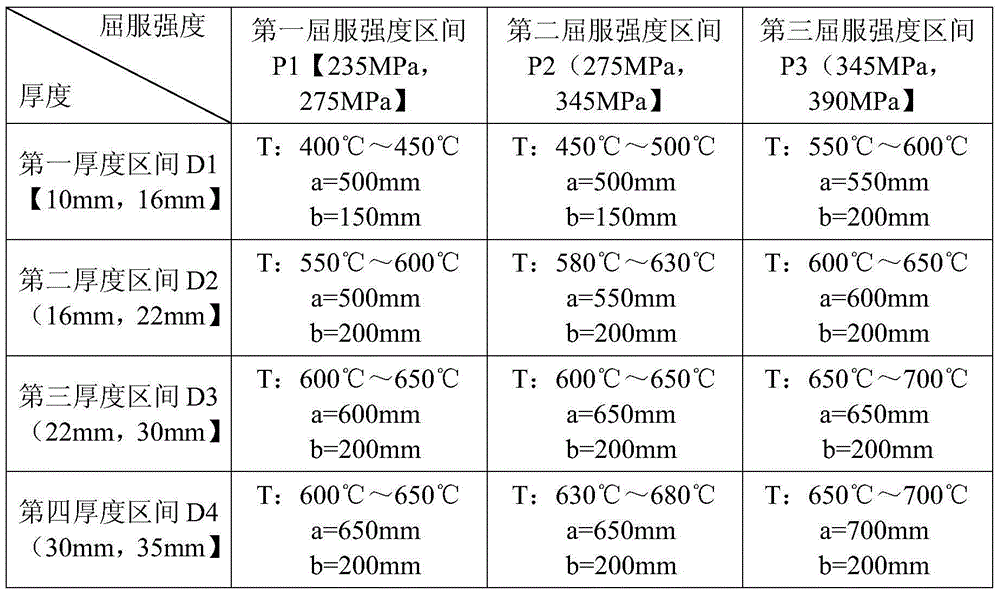

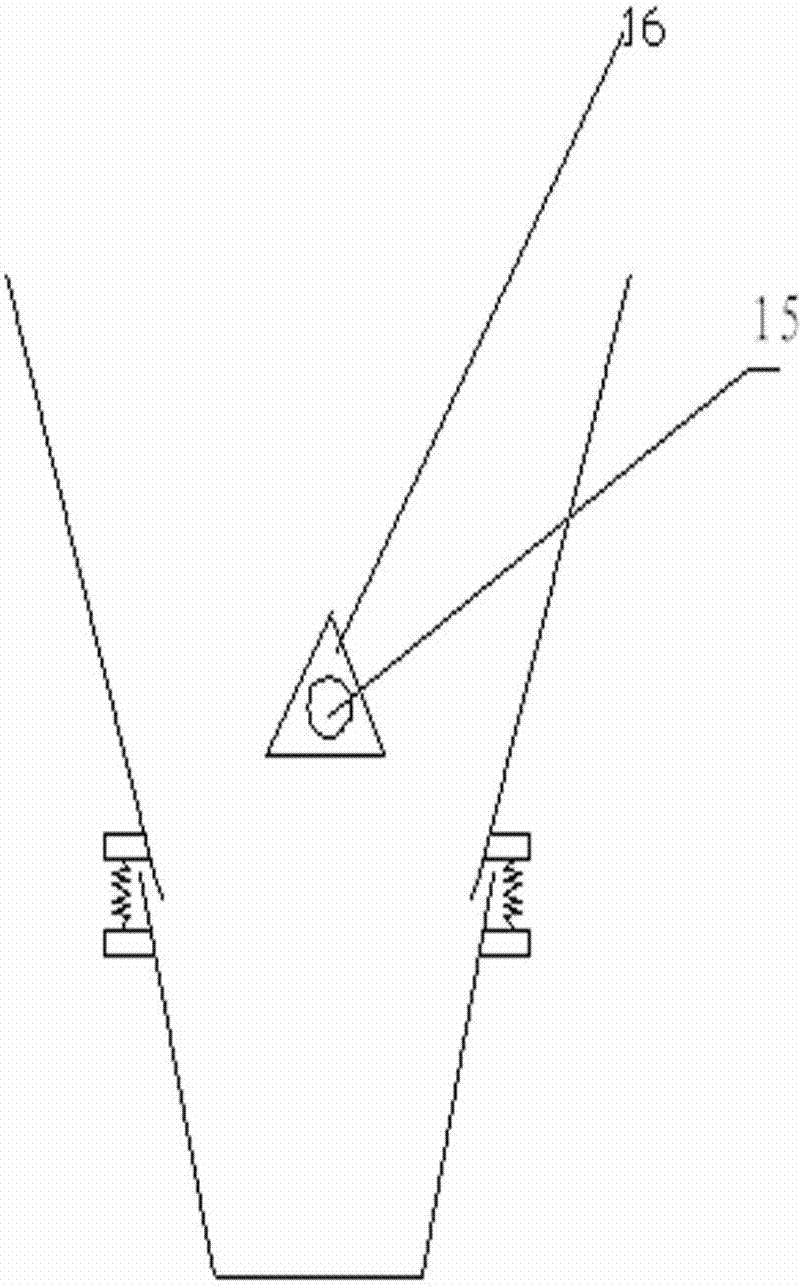

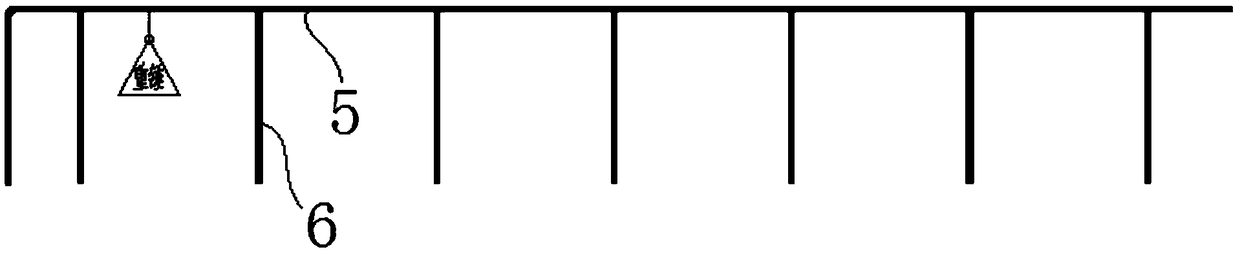

Finishing end heating method capable of preventing finishing end cracks from being generated in PCB welding

ActiveCN103706917AReduce thermal stressImprove welding qualityMetal working apparatusWelding accessoriesTemperature controlEngineering

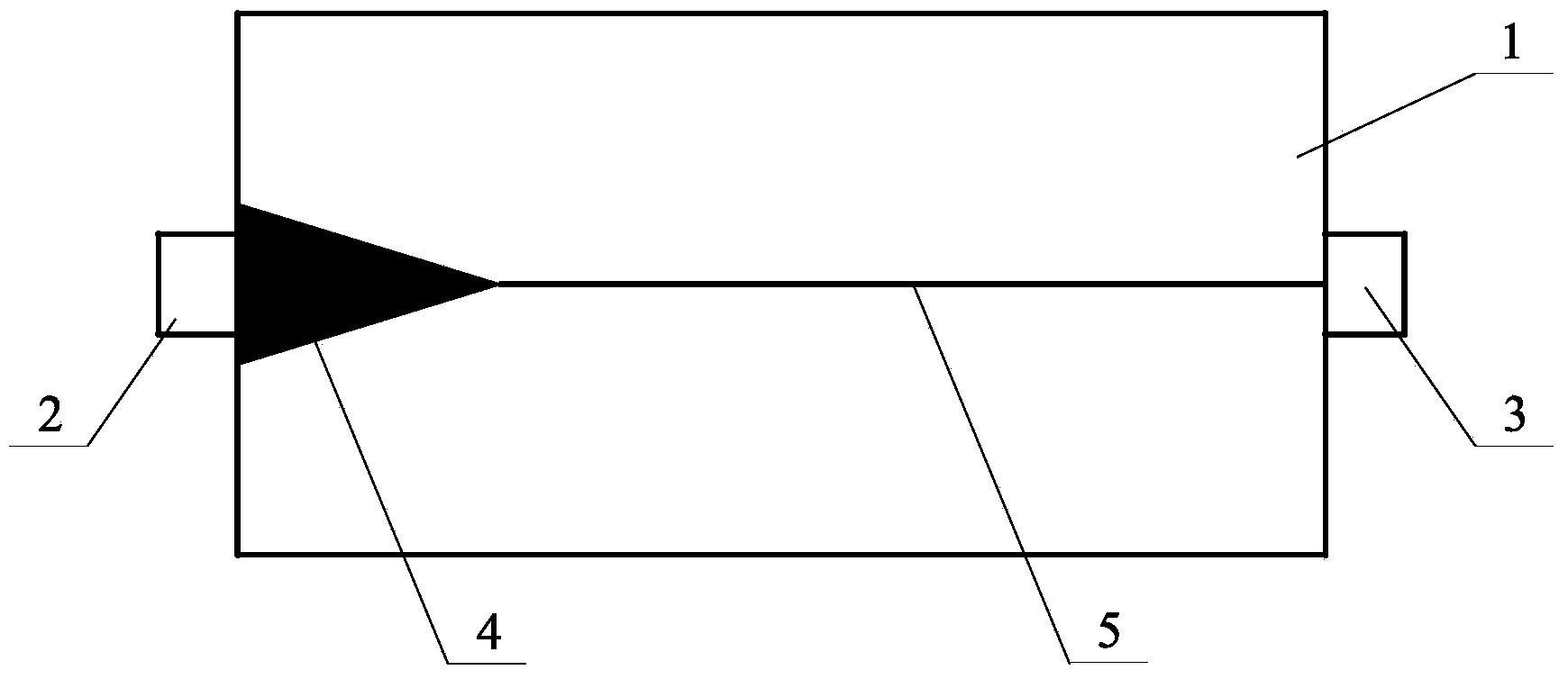

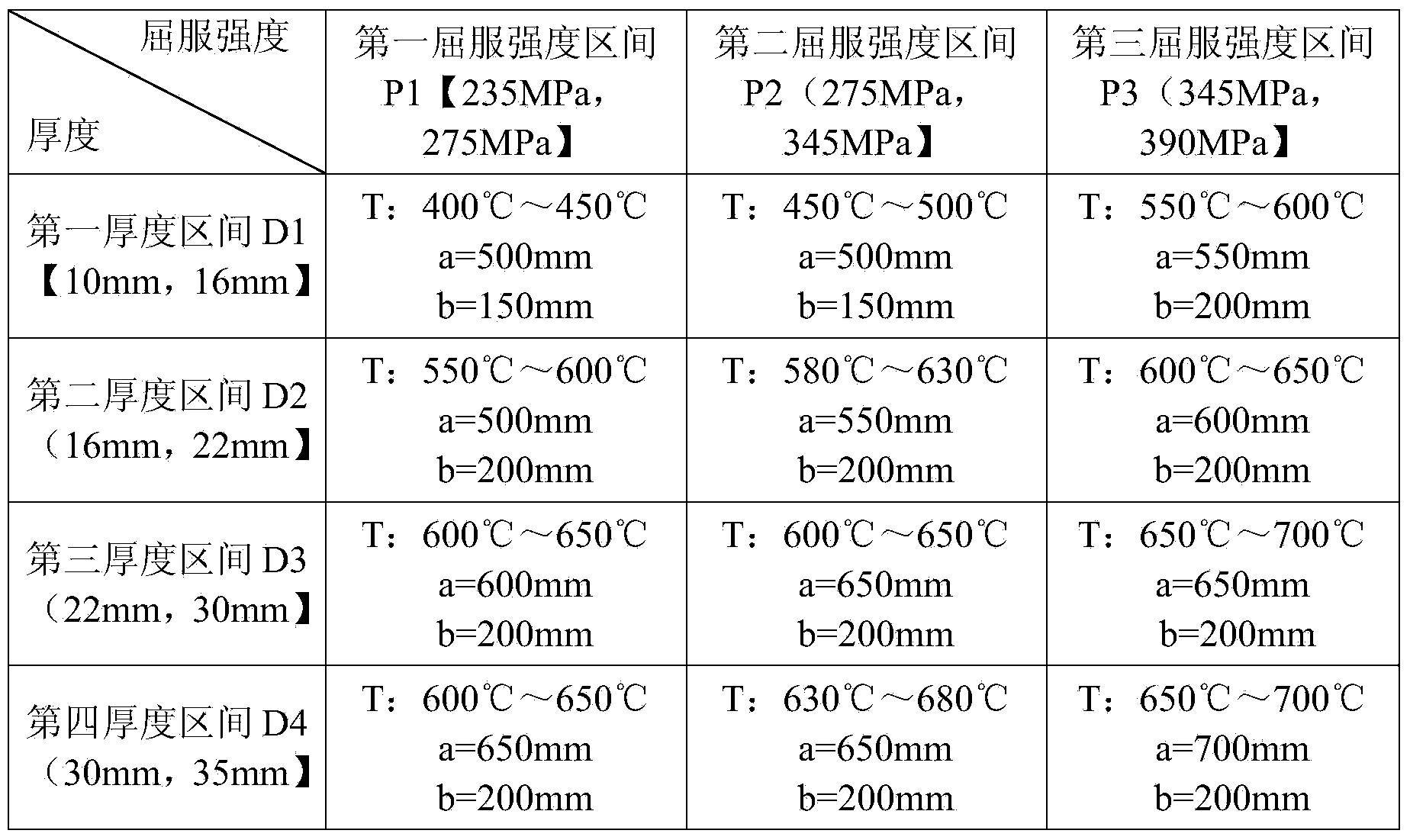

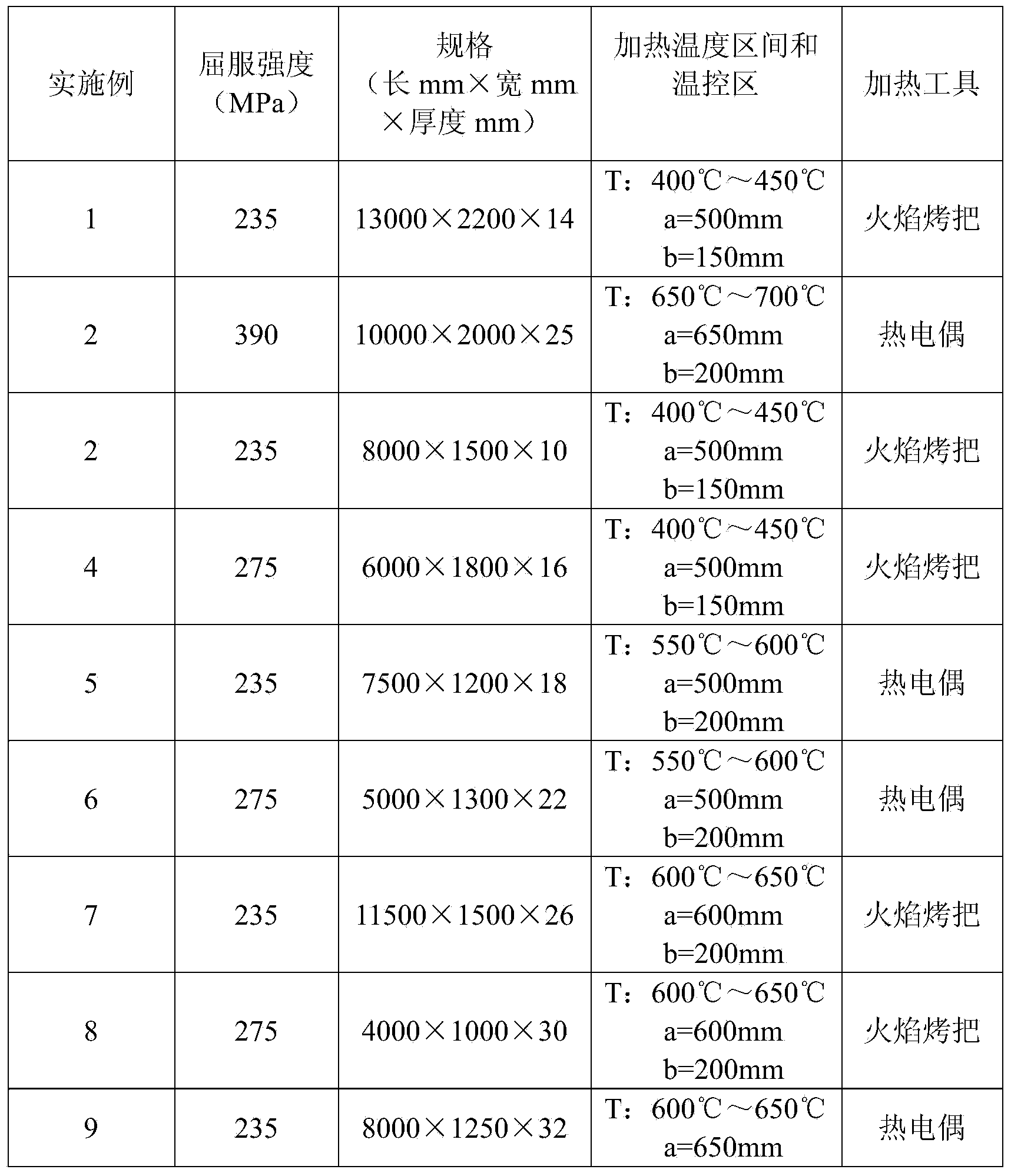

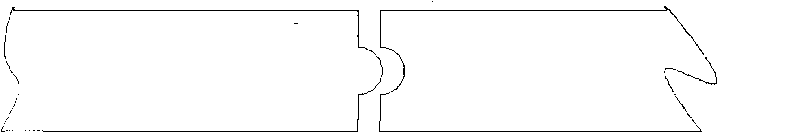

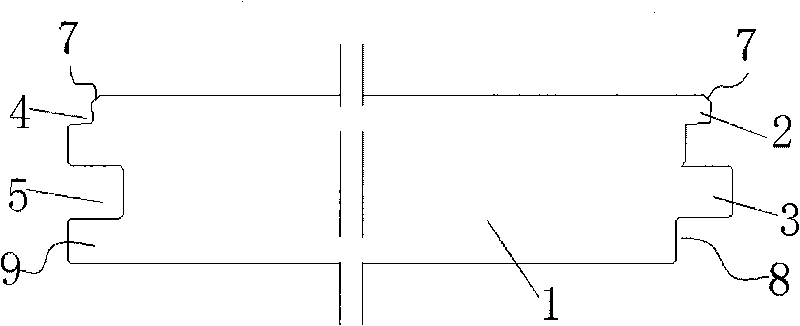

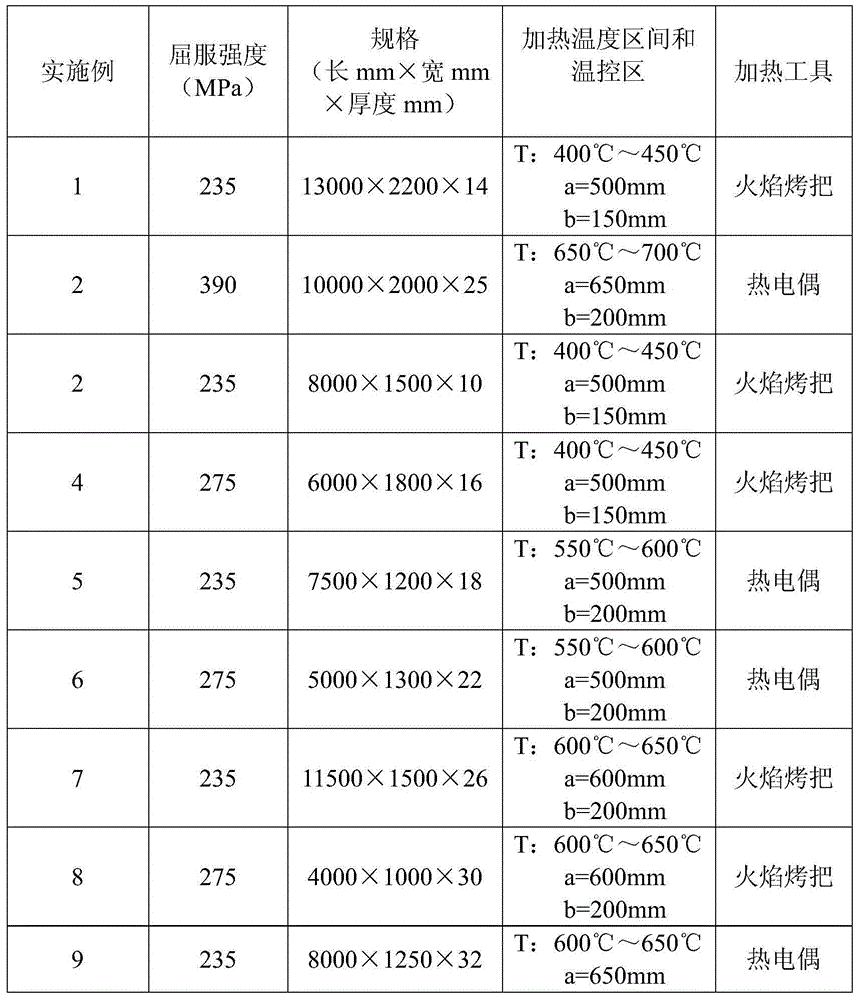

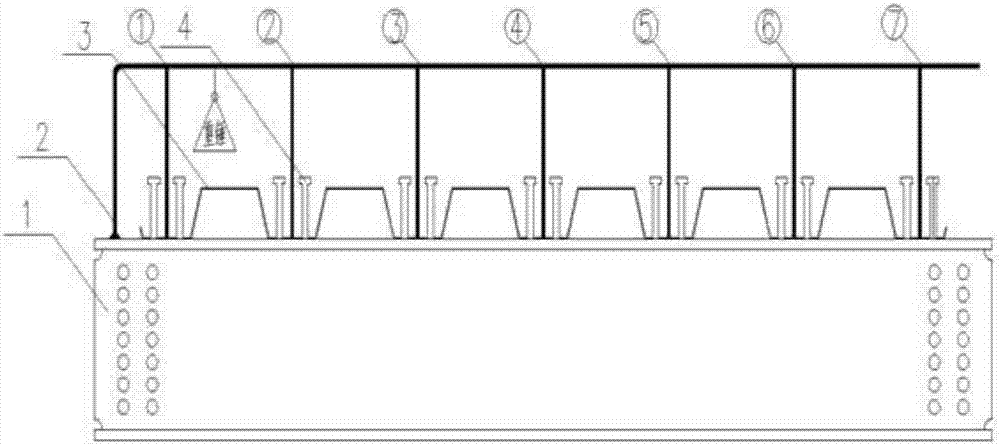

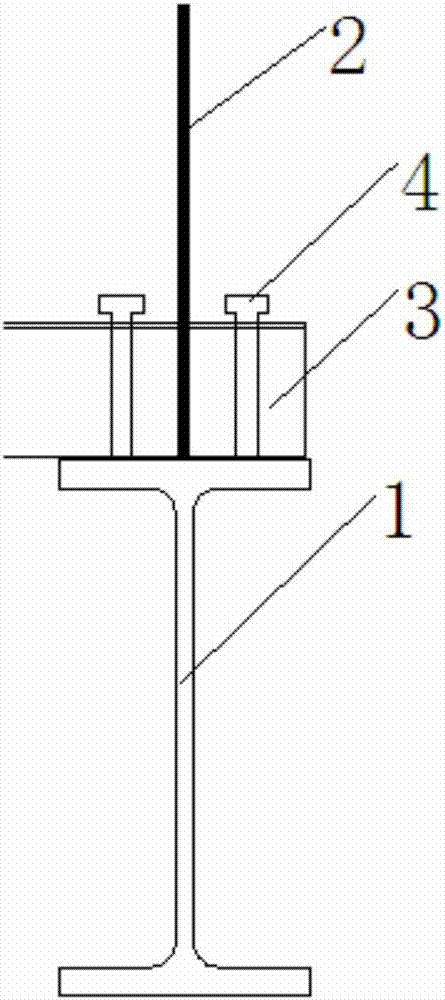

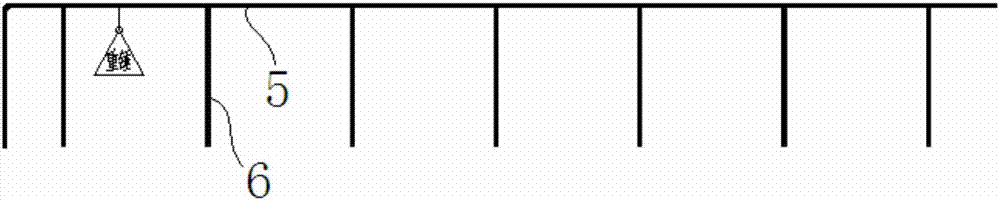

The invention discloses a finishing end heating method capable of preventing finishing end cracks from being generated in FCB welding, and relates to the field of material forming and control. The finishing end heating method capable of preventing the finishing end cracks from being generated in the FCB welding comprises the steps that a temperature control area in an isosceles triangle is preset in a welding finishing end area, the vertex of the isosceles triangle is located on a longitudinal welding seam, the bottom side of the isosceles triangle is perpendicular to the longitudinal welding seam, the length of the height of the isosceles triangle is a, and the length of the bottom side of the isosceles triangle is 2b; three yield strength sections and four thickness sections of a steel plate to be welded are defined; the a, the b and a temperature range T of the temperature control area are preset according to the yield strength section where the yield strength p of the steel plate 1 to be welded is located and the thickness section where the thickness d of the steel plate 1 to be welded is located; the temperature control area is heated, the longitudinal welding seam is welded, and the temperature in the temperature control area reaches T when welding is reaches the vertex of the isosceles triangle from the initial welding end of the longitudinal welding seam; heating is stopped, and welding is stopped when welding reaches the welding finishing end of the longitudinal welding seam; cooling is carried out, and a welded steel plate sample is formed. According to the finishing end heating method capable of preventing the finishing end cracks from being generated in the FCB welding, the probability of generating cracks at the finishing end of the welding can be reduced, the phenomenon of arch cambers on a plate surface can be controlled, deformation can be reduced, and the technology can be simplified.

Owner:QINGDAO WUCHUAN HEAVY IND CO LTD

Decorative board

InactiveCN101713243AEasy to splice and installSimple structureCovering/liningsEngineeringUltimate tensile strength

Owner:GUANGDONG YINGRAN WOOD IND

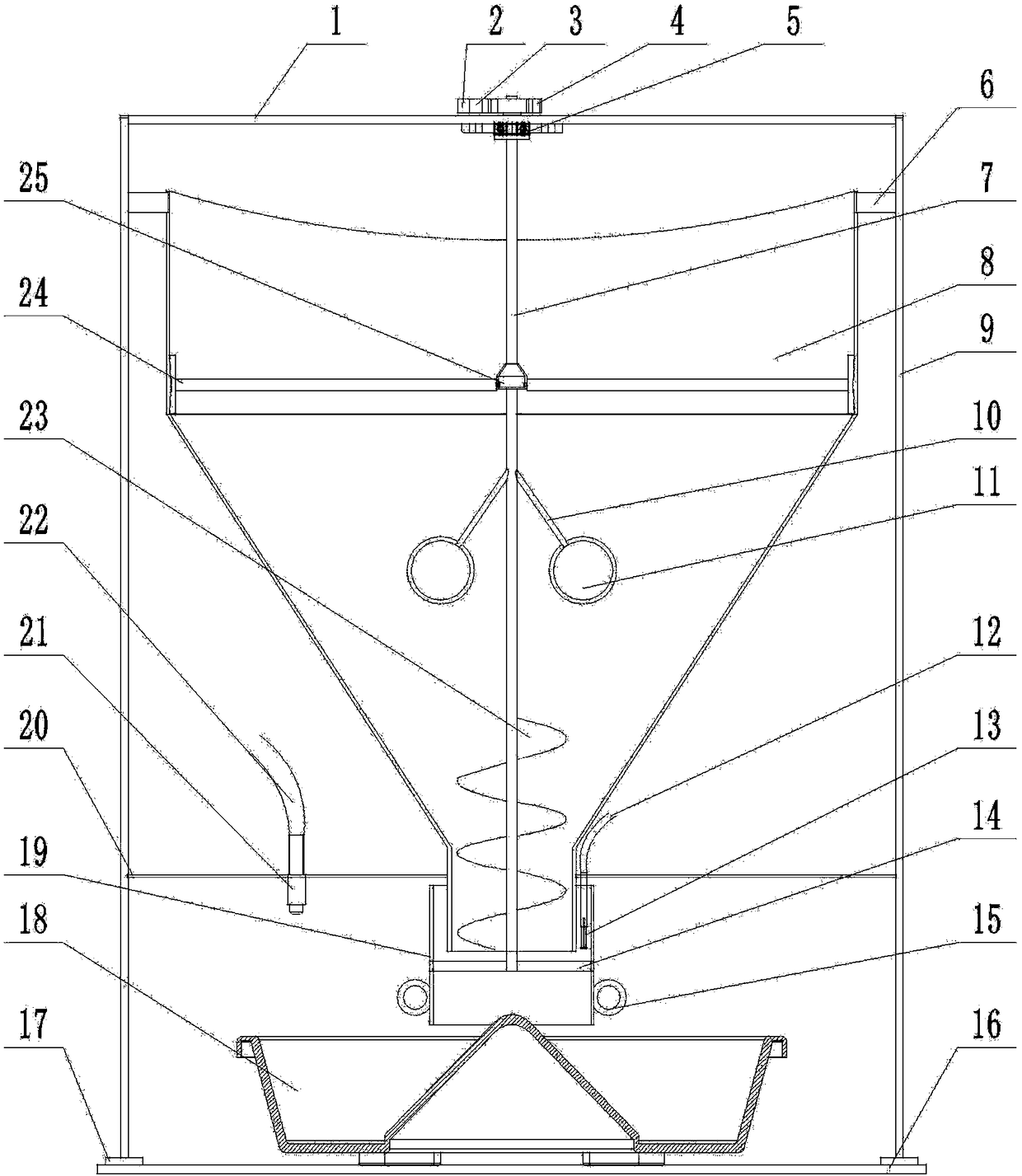

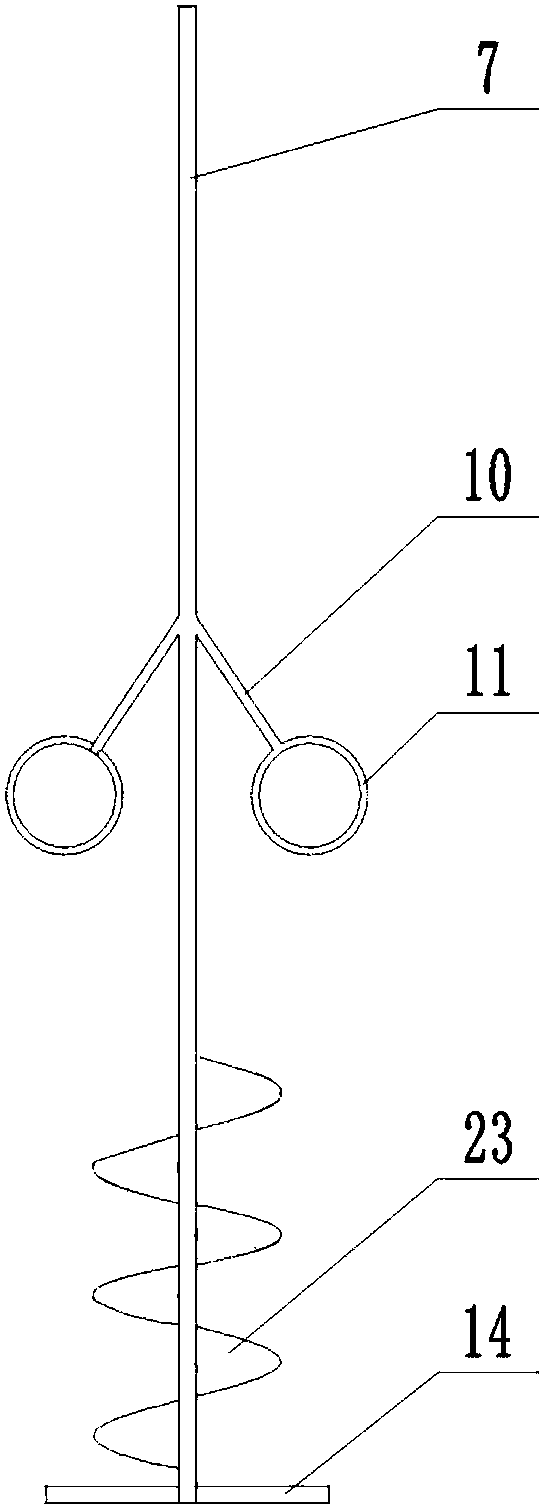

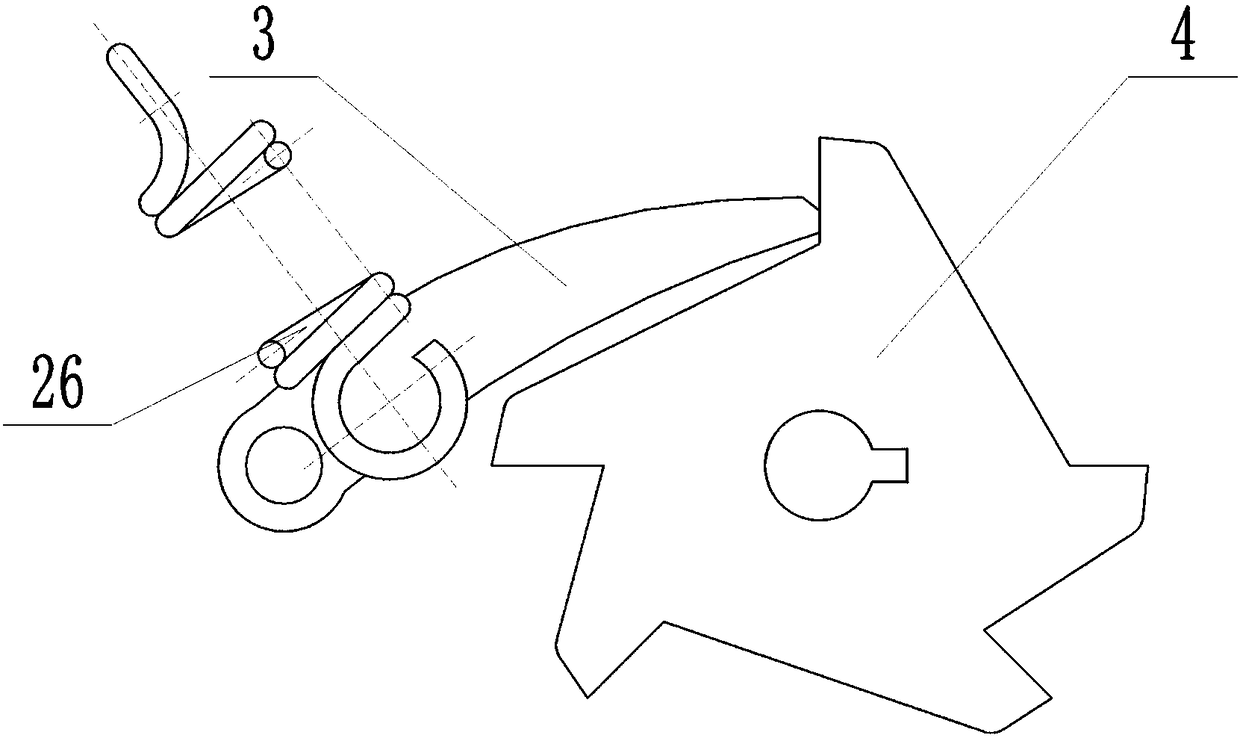

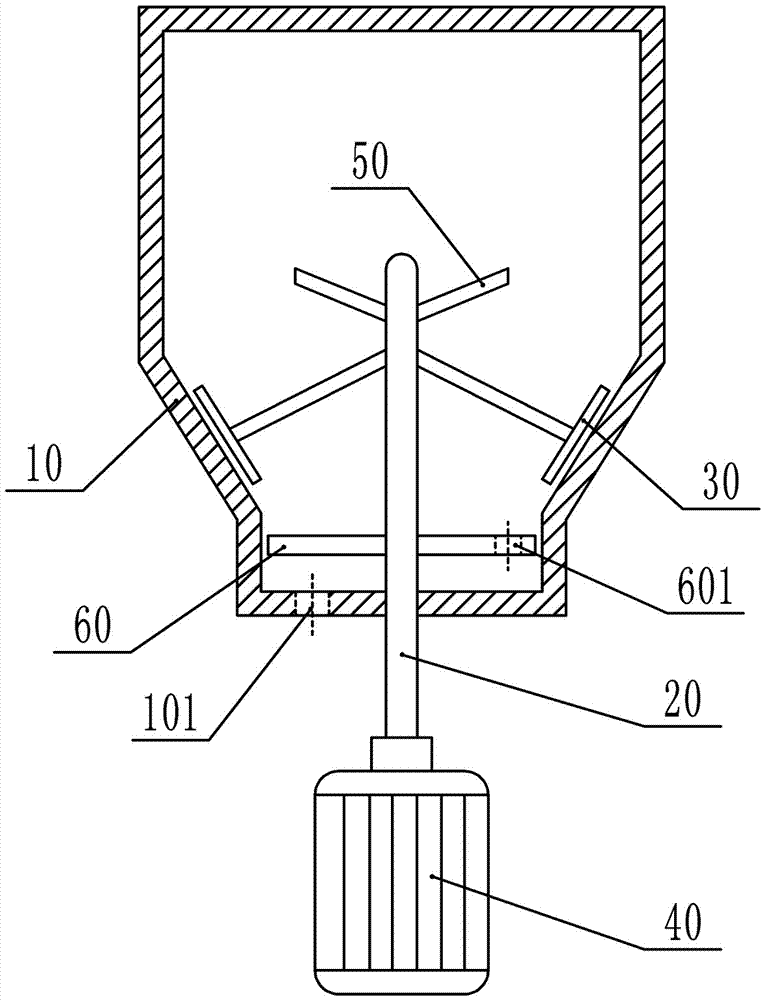

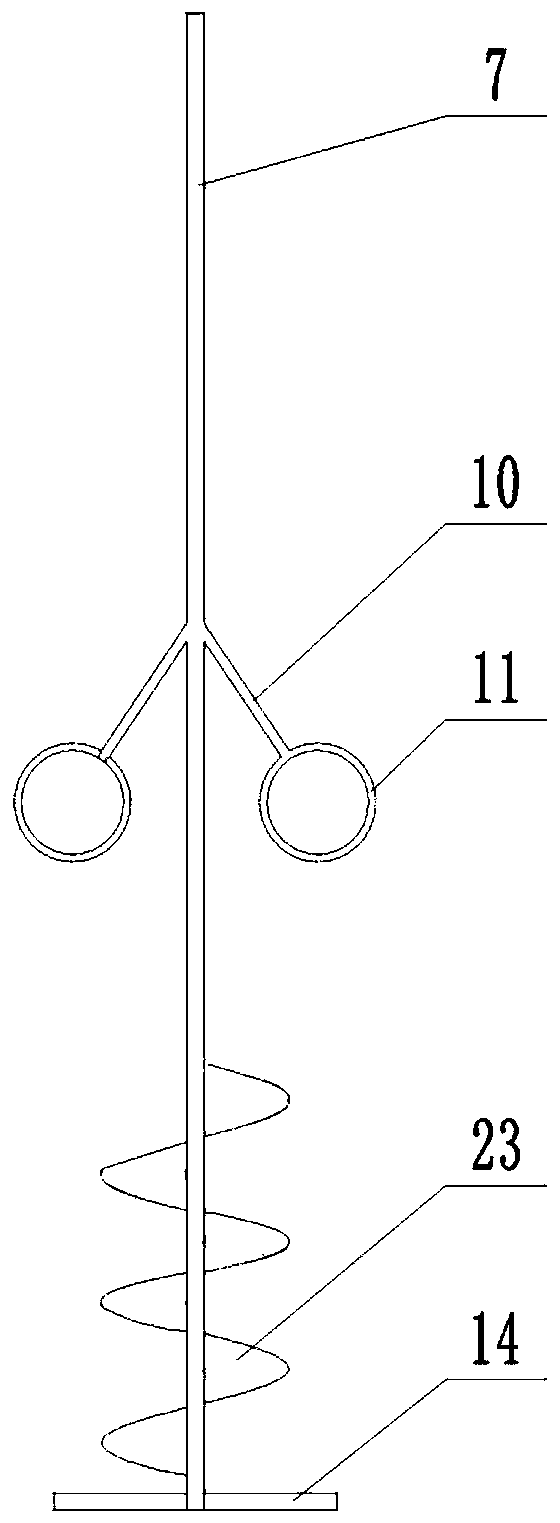

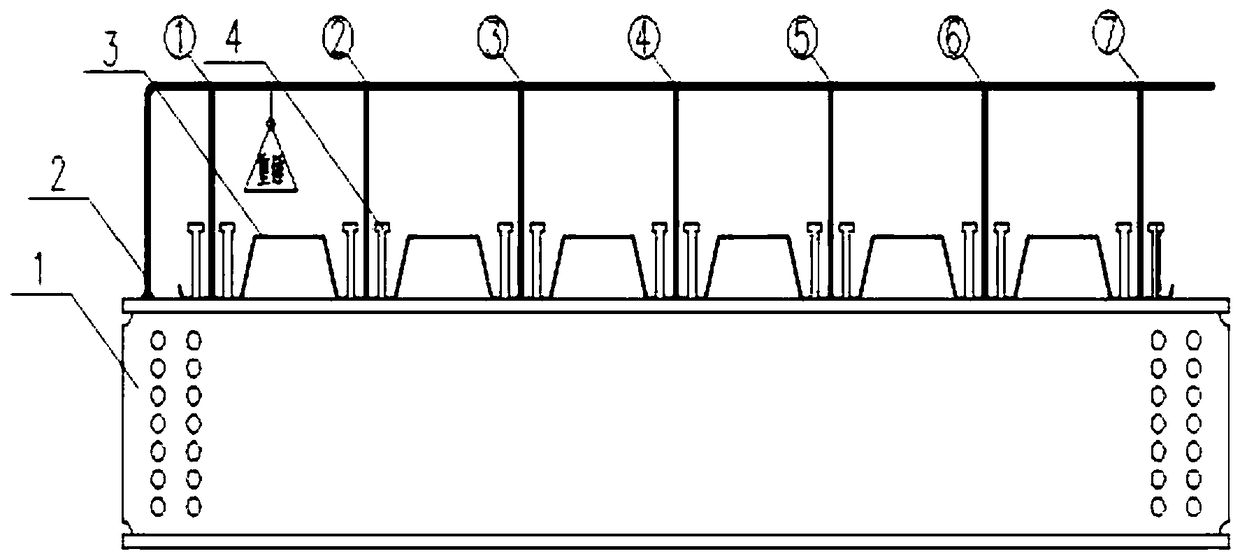

Slow-type feeding device

InactiveCN108651308AGrow fastPrevent archingAnimal feeding devicesAgricultural engineeringOccurrence probability

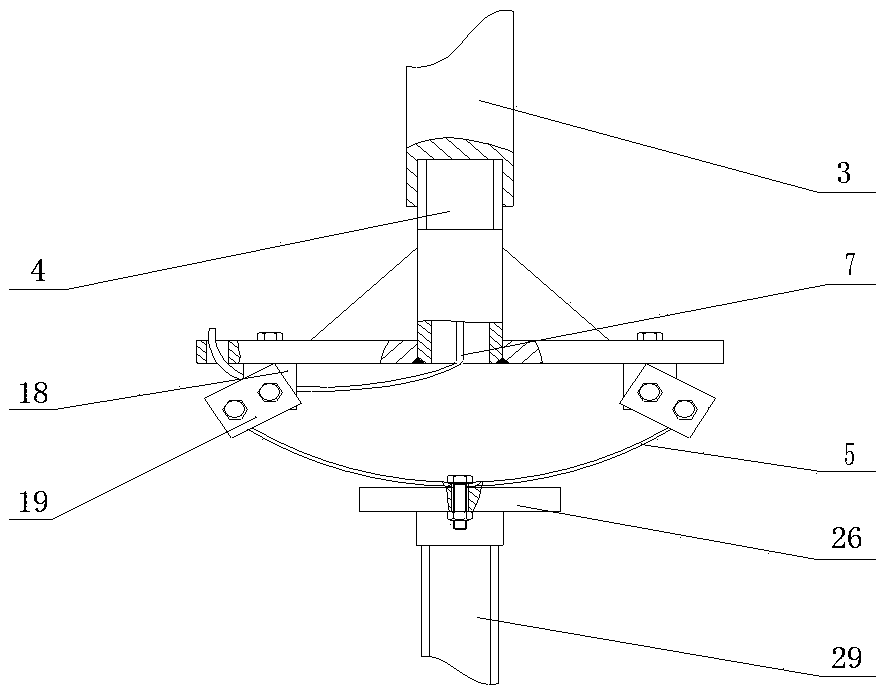

The invention discloses a slow-type feeding device, which is mainly used for restricted and delayed feeding for pigs. The slow-type feeding device mainly comprises a charging barrel, a main shaft, a ratchet wheel mechanism, a collision-type discharging device, a spraying device, a feeding trough and a drinking device. The charging barrel is arranged in the middle between left and right supports, the ratchet wheel mechanism is arranged at the center part of a crossbeam, the main shaft is positioned through the center of the ratchet wheel mechanism and the charging barrel, the collision-type discharging device is positioned through two ends of a cross bar at the lower part of the main shaft, three spraying devices are successively arranged at a discharging outlet in the lower part of the charging barrel at intervals of 120 degrees with the axis of the main shaft as the center, the feeding trough is arranged on a base plate, and the drinking device is arranged on the left side of a lowerconnecting link. According to the invention, on-demand feeding is realized through the cooperation of the ratchet wheel structure and a set of spiral blade at the lower part of the main shaft, thus reducing the loss and waste of feed; spray-like water drops can increase the moisture content of the feed and reduce the occurrence probability of respiratory diseases in pigs. The slow-type feeding device is simple and reasonable in structure design, convenient in operation and strong in applicability.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

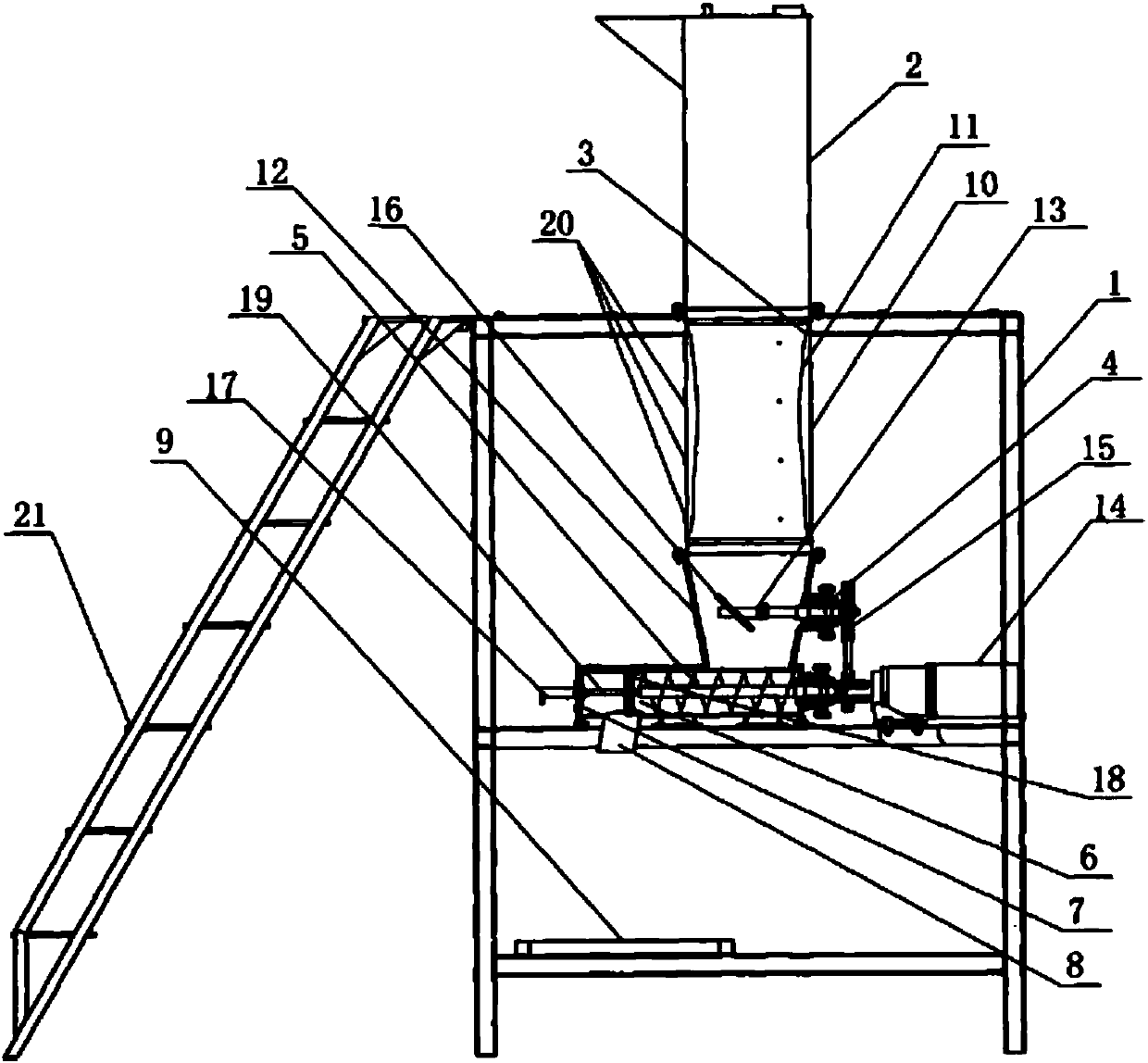

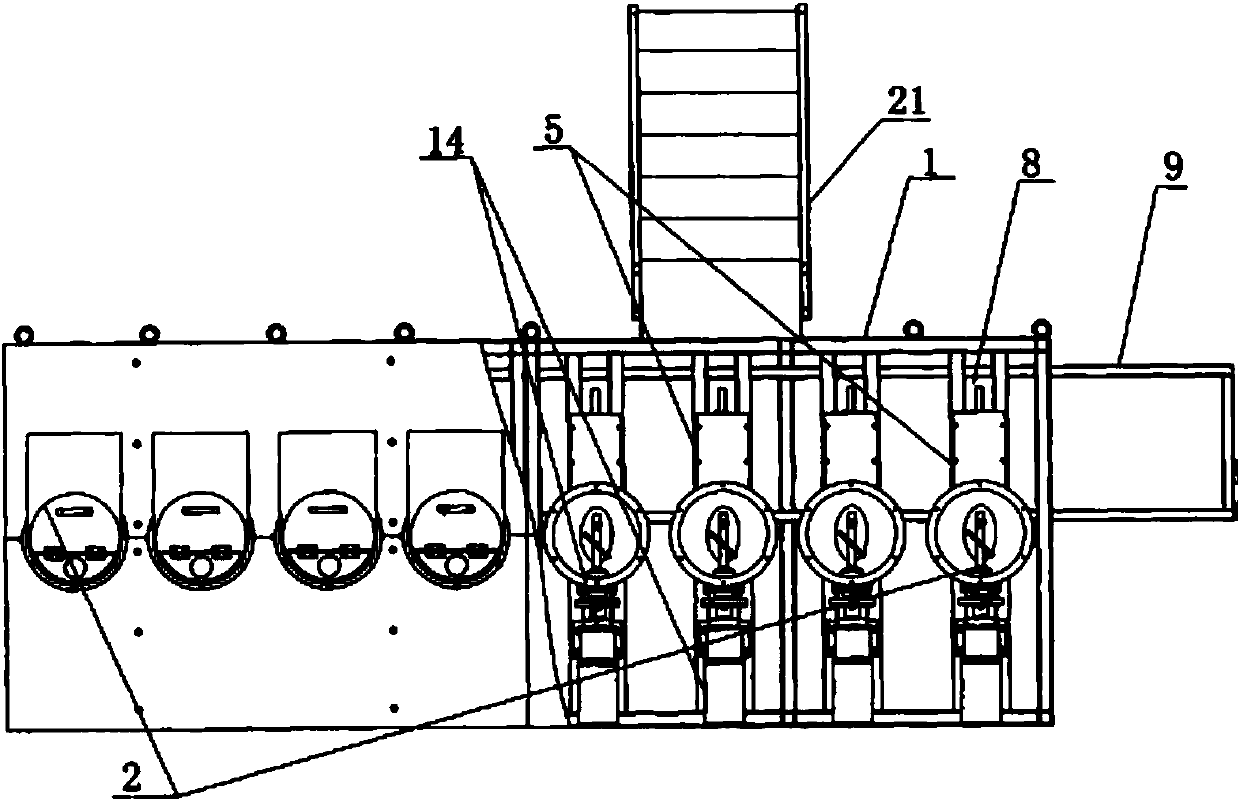

Dispensing equipment

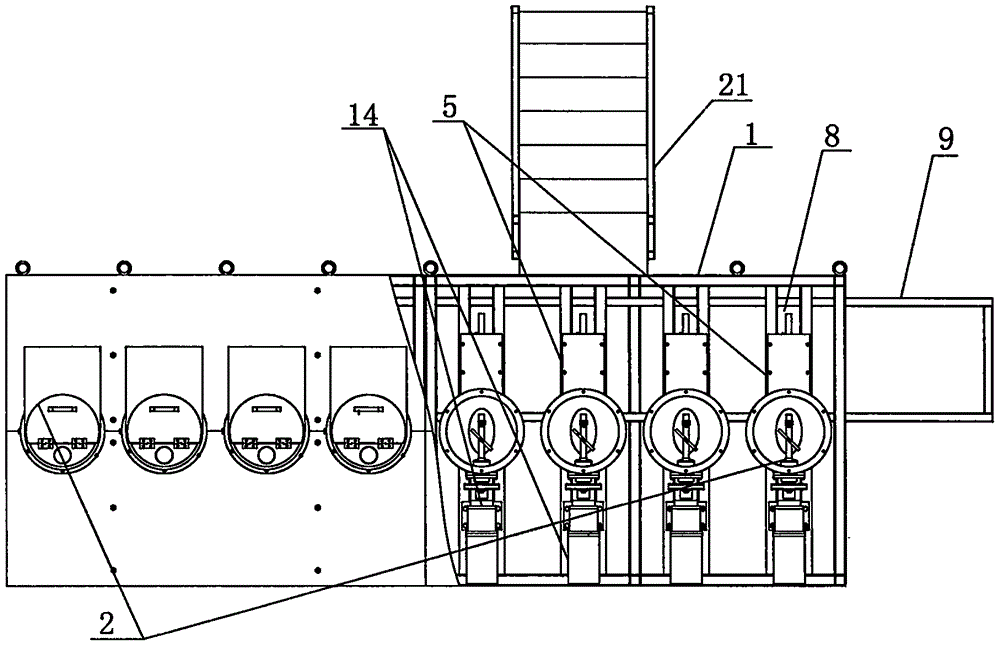

InactiveCN106364930AReduce archingReduce labor intensityLarge containersLoading/unloadingControl systemEngineering

The invention discloses dispensing equipment, which comprises a machine frame and a control system for controlling operation of the dispensing equipment, wherein at least two rows of stock bins are arranged on the machine frame; each row of stock bins comprise at least four stock bins; a cloth bag type pneumatic arch breaking structure for preventing raw materials from being arched is arranged on the middle part of each stock bin; a crushing and stirring structure is arranged on the lower part of each stock bin; a spiral feeder is arranged at the bottom of each stock bin; each spiral feeder is arranged vertical to the stock bin; a pneumatic valve is arranged on the front part of an outlet of each spiral feeder; a discharging port for leading out the raw materials is formed below the outlet of each spiral feeder; rails are arranged on the machine; the number of the rails is matched with that of one row of stock bins; a material vehicle matched with the stock bins and capable of moving along the rails is arranged on the rails; a vehicle hopper is arranged on the material vehicle; and an electronic scale is arranged between the vehicle hopper and the material vehicle. The dispensing equipment reduces the material arching phenomenon, enables the material proportion to be more accurate, improves the production efficiency and reduces the labor intensity of workers.

Owner:石中山

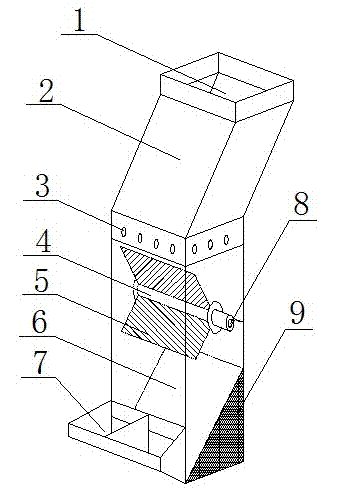

Garbage feeding device

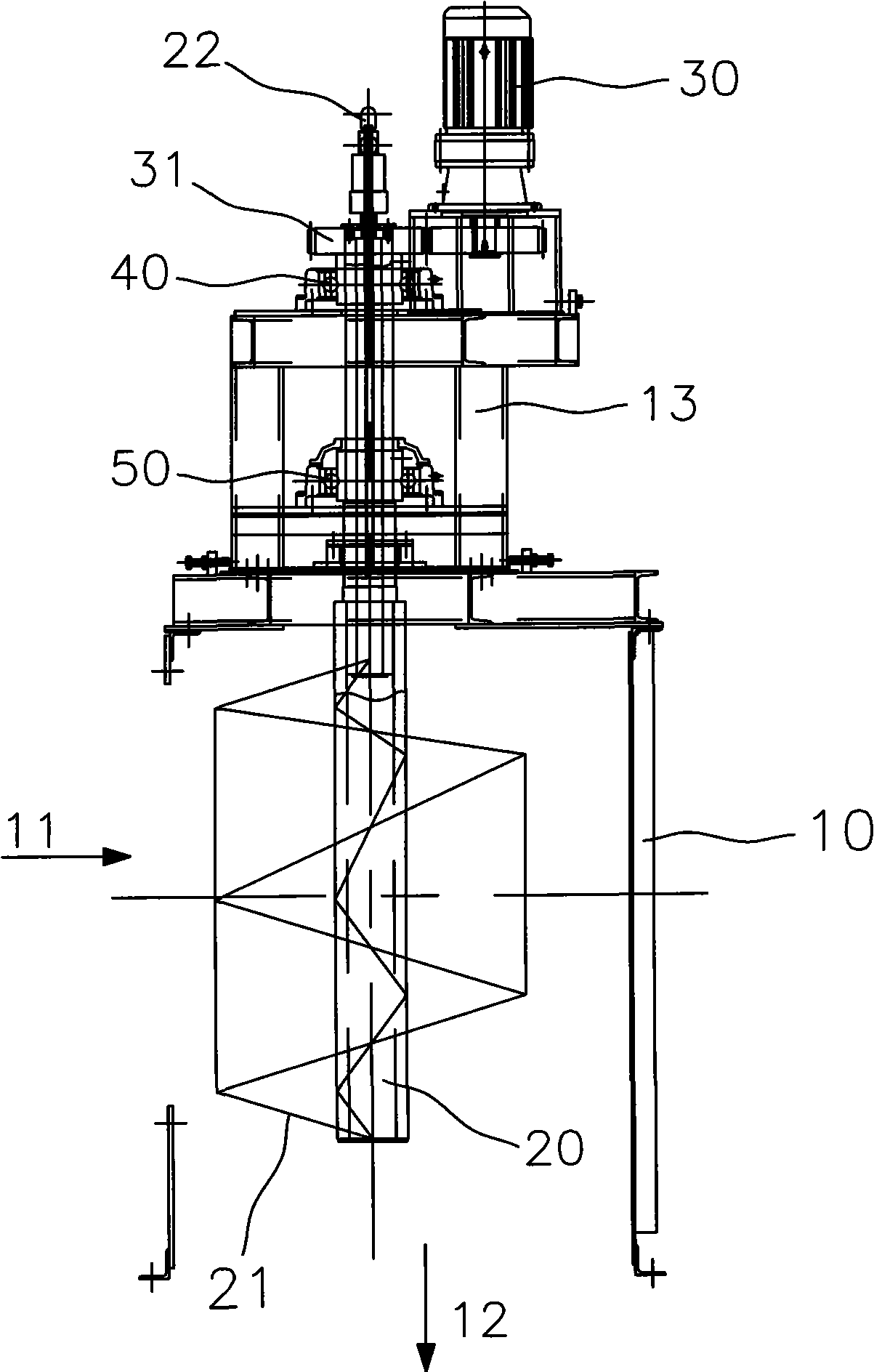

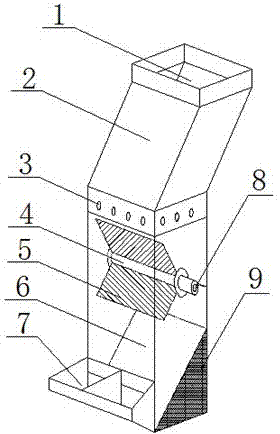

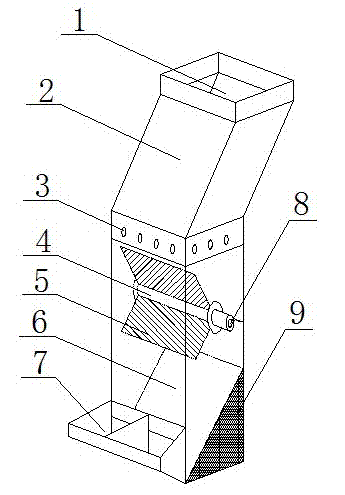

The invention relates to a garbage feeding device for feeding garbage into a garbage incinerator. The garbage feeding device comprises a shell, wherein a cavity is arranged inside the shell; a feeding hole is formed on the upper part of the outer side face of the shell; a discharge hole is formed on the lower part of the shell; a garbage crushing conveying mechanism is arranged in the cavity of the shell; and the garbage crushing conveying mechanism is connected with a power mechanism on the shell. From the above, in the garbage feeding device, the garbage crushing conveying mechanism is arranged in the shell, so that after materials are fed into the shell, the materials are scattered and crushed while being conveyed into the garbage incinerator, thereby greatly reducing and even eliminating a blocking or arching phenomenon of the garbage during a conveying process, and ensuring the stable running of a whole garbage treating system.

Owner:ANHUI CONCH KAWASAKI ENERGY CONSERVATION EQUIP +1

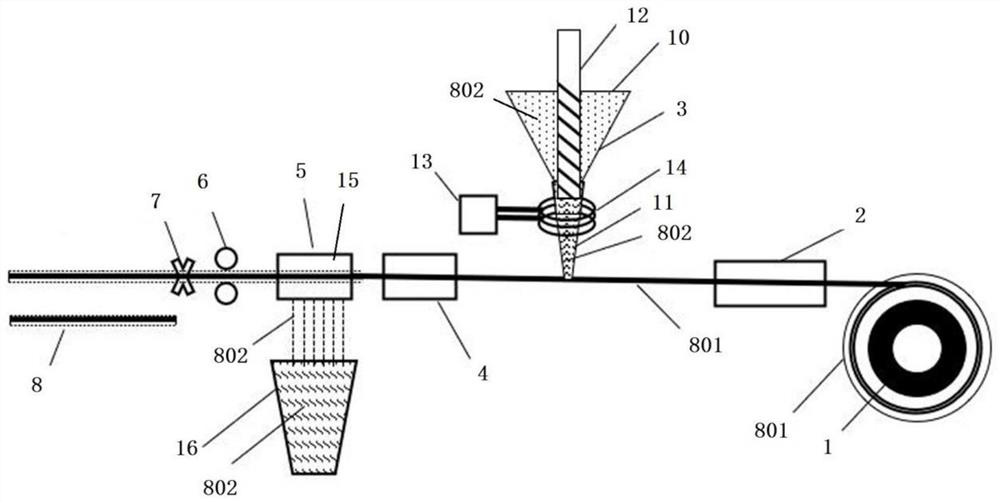

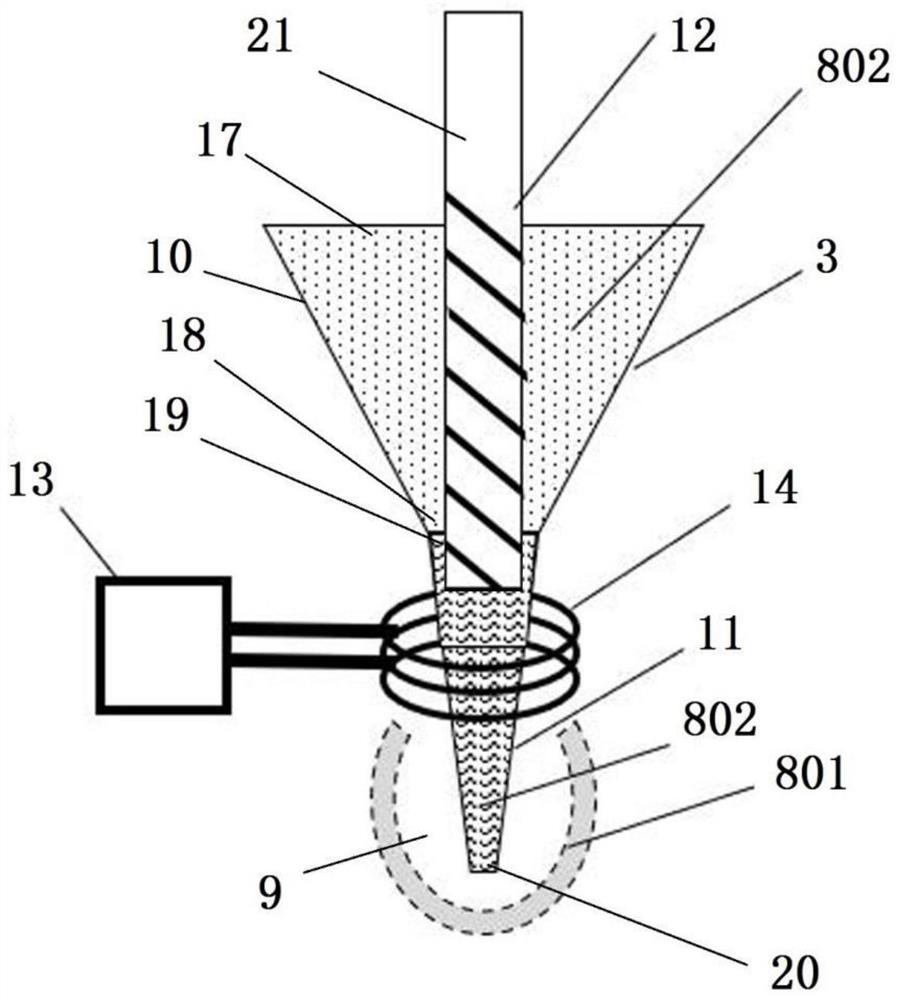

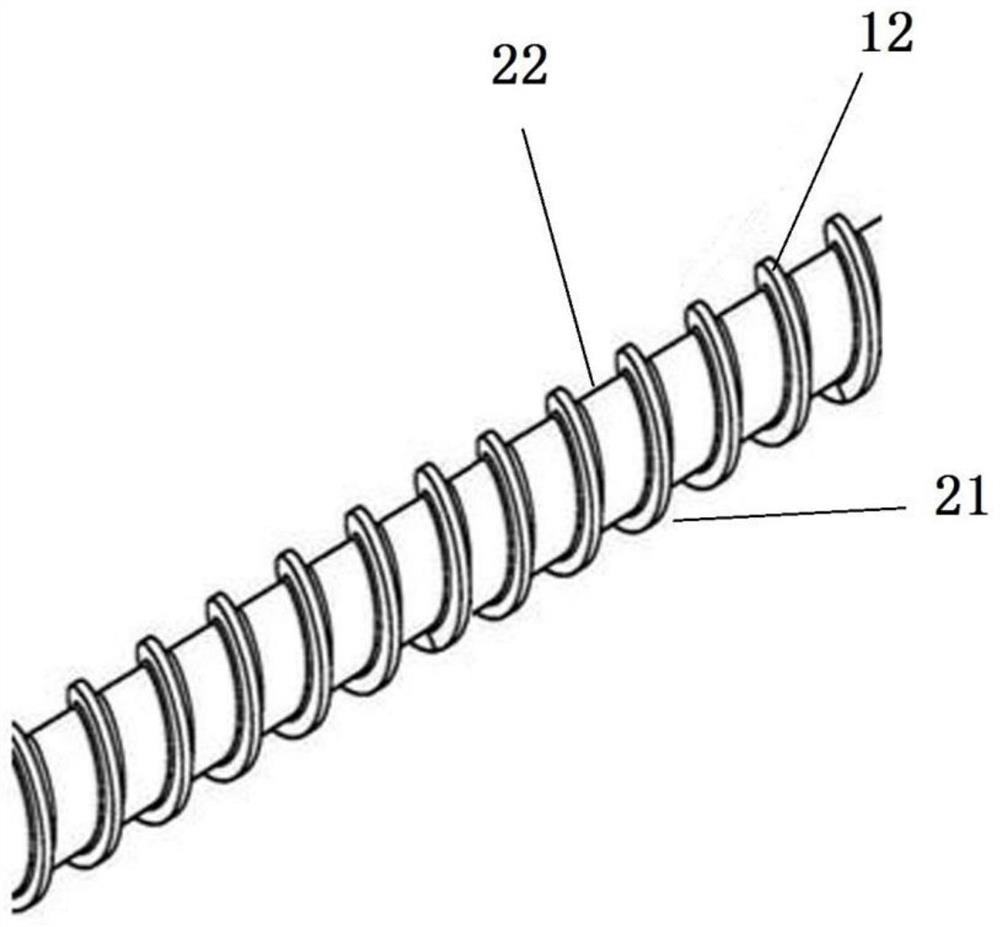

Soldering flux melting injection device and preparation method and preparation equipment of flux-cored welding rod

PendingCN114211155AWon't happenTechnical issues to avoid damageWelding/cutting media/materialsSoldering mediaAdhesiveSoldering

The invention relates to the field of flux-cored electrodes, in particular to a preparation method and device of a flux-cored electrode. The invention aims to protect a brazing flux melting injection device and a preparation method and preparation equipment of a flux-cored welding rod. The soldering flux melting injection device comprises a soldering flux container, a spiral conveying piece and an injection pipe, the injection pipe is provided with an injection pipe inlet and an injection pipe outlet, and the soldering flux container is provided with a container inlet and a container outlet; a spiral channel is arranged on the spiral conveying piece, and the spiral conveying piece extends into the injection tube and / or the brazing flux container; the soldering flux melting and injecting device further comprises a conveying part driving mechanism and a heating device for heating and melting the soldering flux in the injection pipe, and the spiral conveying part applies acting force to the soldering flux through rotation so that the soldering flux can be conveyed to an outlet of the injection pipe, and the melted soldering flux can be extruded out of the outlet of the injection pipe. When the brazing flux melting injection device is used, no organic adhesive is used, and the technical problem that the organic adhesive is prone to causing damage to the body health of production personnel is solved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

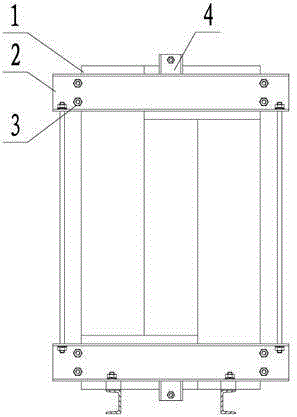

Small-sized transformer

InactiveCN105405604AReduce archingAvoid shocking situationsTransformers/inductances magnetic coresTransformerEngineering

The invention discloses a small-sized transformer. The small-sized transformer comprises an iron core, an upper pair of clamping elements and a lower pair of clamping elements, wherein the upper pair of clamping elements and the lower part of clamping elements are used for clamping the iron core, each pair of clamping elements is connected via a dual-head bolt, a steel channel is welded at the middle of each clamping element, one end of the steel channel is connected with the side end surface of the clamping element, the other end of the steel channel extends to the outer side of the iron core, and the other ends of each pair of steel channels are also connected through a dual-head bolt.

Owner:TONGLING RUIBO ELECTRONICS TECH CO LTD

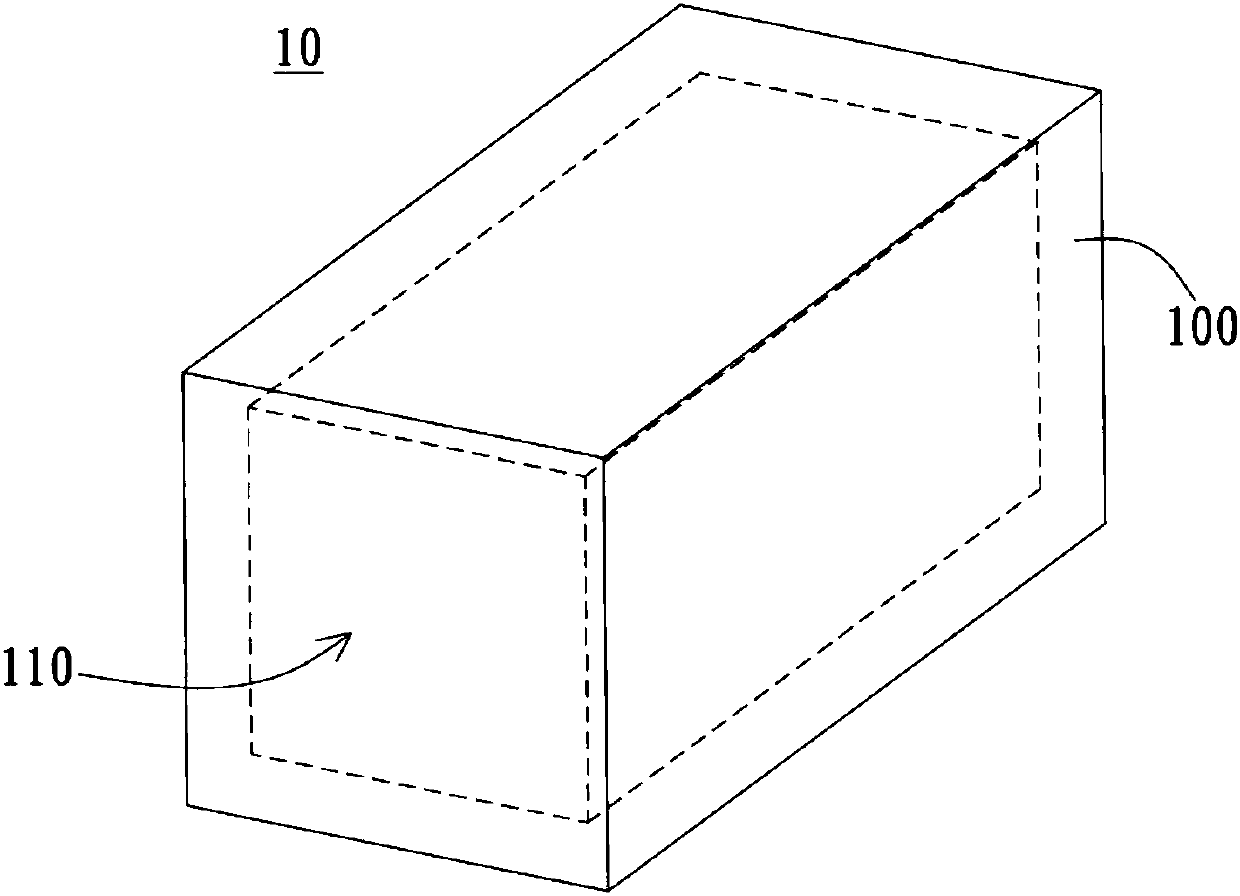

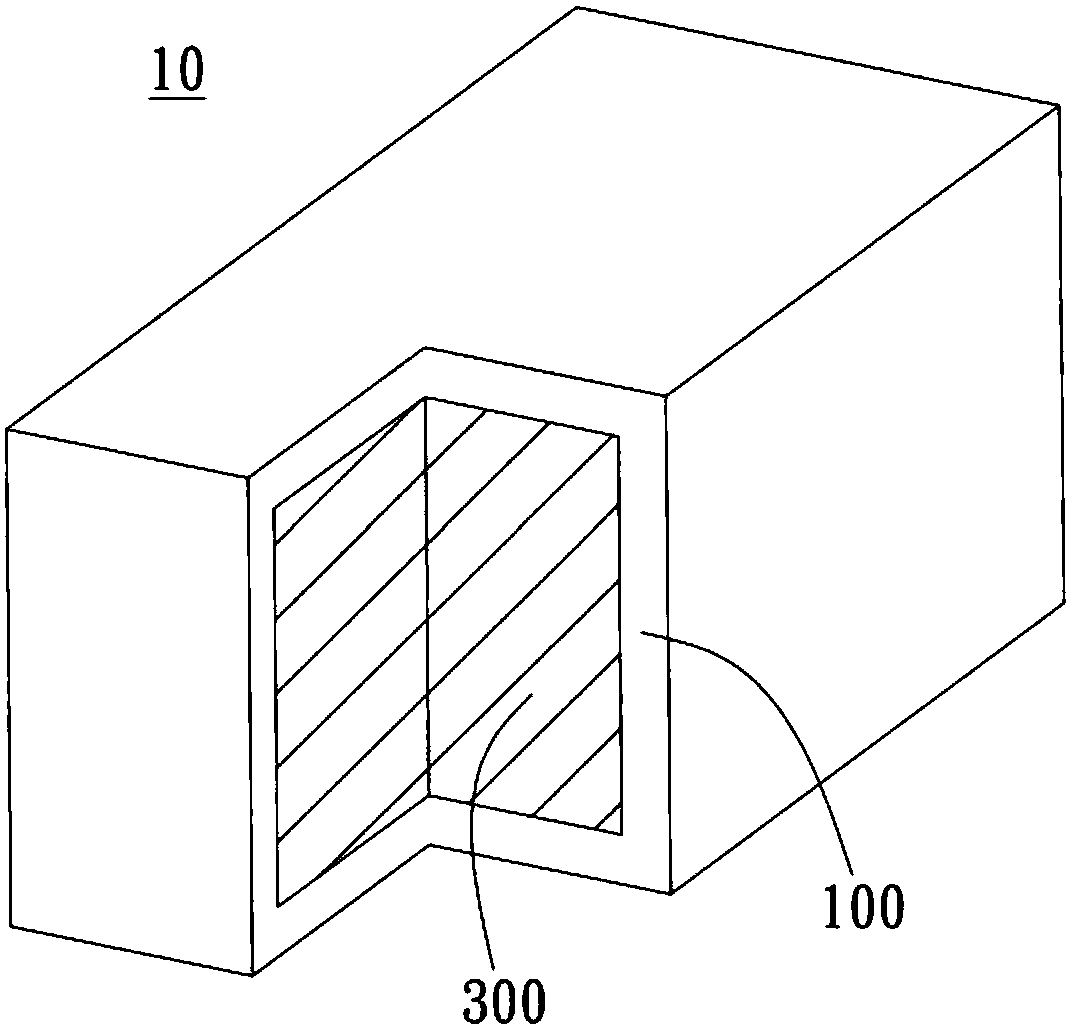

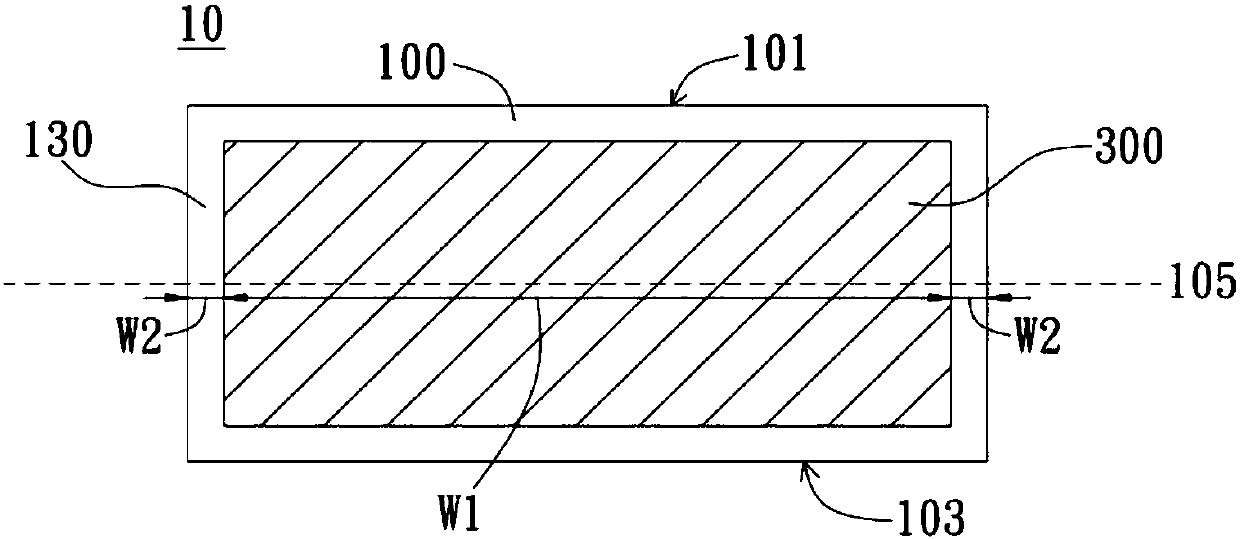

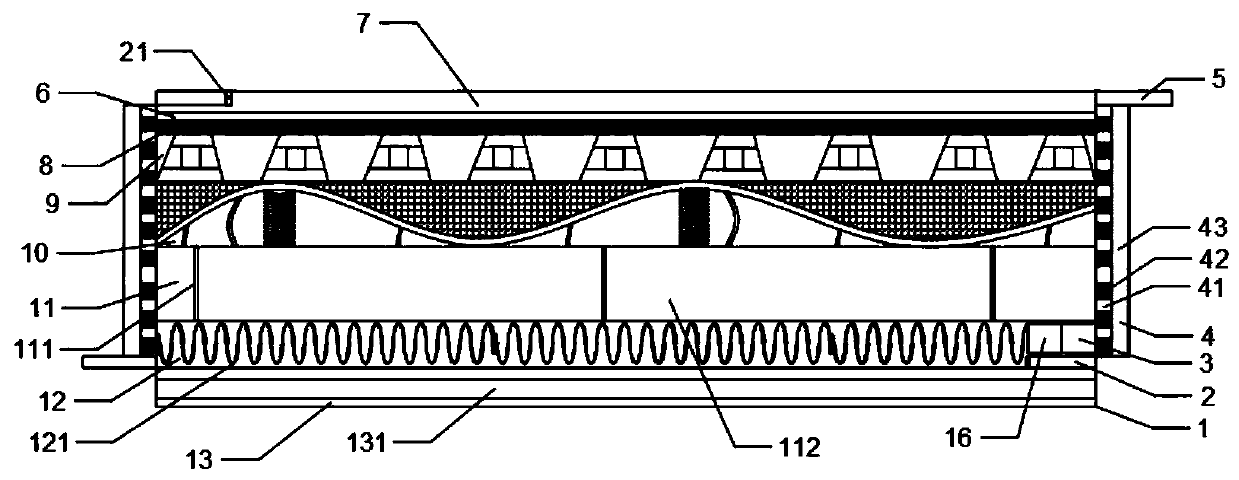

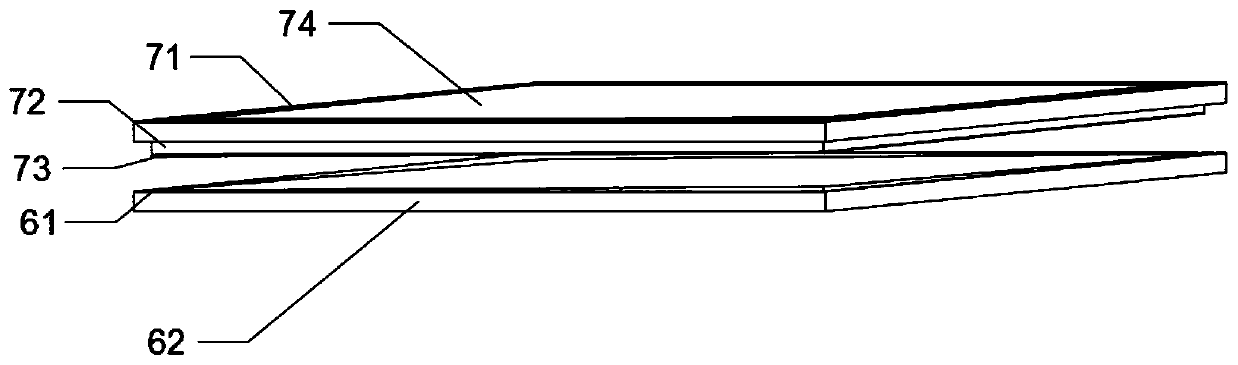

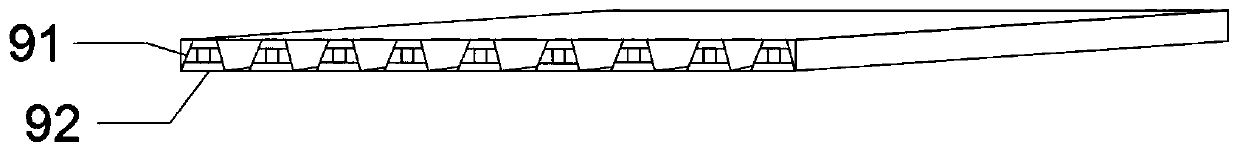

Block with phase change material, backlight module using the same and display equipment

ActiveCN108107629AReduce archingReduce bendingOptical light guidesNon-linear opticsComputer moduleEngineering

The invention provides a block, a backlight module using the same and display equipment. The block contains an outer bag and phase change material. The outer bag surrounds the block so that an accommodation cavity is formed in the interior. However, the phase change material is accommodated into the accommodation cavity. At least a part of the outer bag is made of elastic material while the melting point of the phase change material is lower than that of the elastic material. The backlight module contains an optical diaphragm, a frame body and the above block. The frame body at least partiallysurrounds the side edge of the optical diaphragm while the block is arranged between the optical diaphragm and the frame body. The display equipment comprises a display panel, the frame body and theabove block. The frame body has an accommodation area used for accommodating a display panel while the block is arranged between the display panel and the frame body.

Owner:AU OPTRONICS CORP

Feed storage bin

The invention belongs to an equipment device specially used for preparing livestock feed, and particularly discloses a feed storage bin which comprises a storage box with a discharge hole. The feed storage bin is characterized by further comprising a motor, a rotary shaft, a scraper plate and a baffle plate, wherein the lower part of the storage box is in the shape of a funnel; the rotary shaft is coaxially connected to an output shaft of the motor; the scraper plate is fixed to the rotary shaft, and is in clearance fit with the inner wall of the storage box; the baffle plate is positioned in the storage box, and is fixed to the output shaft; and a discharge opening corresponding to the discharge hole is formed in the baffle plate. When the scraper plate rotates, the feed can be effectively promoted to flow, so that arching phenomena are reduced. Meanwhile, even a few arching phenomena exist, the arches can be scraped off when the scraper plate rotates, and the feed is uniformly re-mixed under the driving of the rotary shaft.

Owner:CHONGQING CHANGYUAN FEED CO LTD

Burdening device capable of increasing efficiency

InactiveCN107774159AHigh precisionReduce archingRotary stirring mixersTransportation and packagingControl systemPneumatic valve

The invention relates to material delivery apparatuses and discloses a burdening device capable of increasing efficiency, which comprises a machine frame and a control system controlling operation ofthe burdening device. At least two rows of material bins are arranged on the machine frame, each row at least including four material bins. A cloth bag type pneumatic arch-breaking structure for preventing arch forming of raw materials is arranged in the middle of each material bin. A crushing and stirring mechanism is arranged on the lower part of the material bin. At least two spiral feeders arearranged on the bottoms of the material bins and are vertical to the material bins. A pneumatic valve is arranged on the front part of an outlet of each spiral feeder. A material outlet for discharging the raw material is arranged under the outlets of the spiral feeders. The machine frame is provided with rails, of which the number is matched with the number of material bins in each row. A material trolley capable of moving on the rail and being matched with the material bins is disposed on each rail. The burdening device reduces problem of arch forming of the materials and increases accuracyof material ratio, thus improving production efficiency and reducing labor intensity of workers.

Owner:慈溪市舒润卫浴实业有限公司

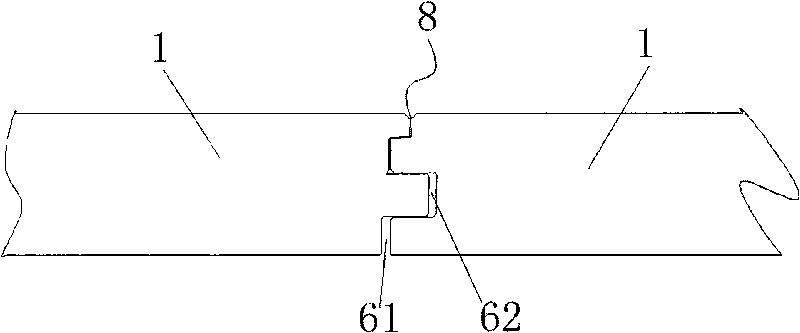

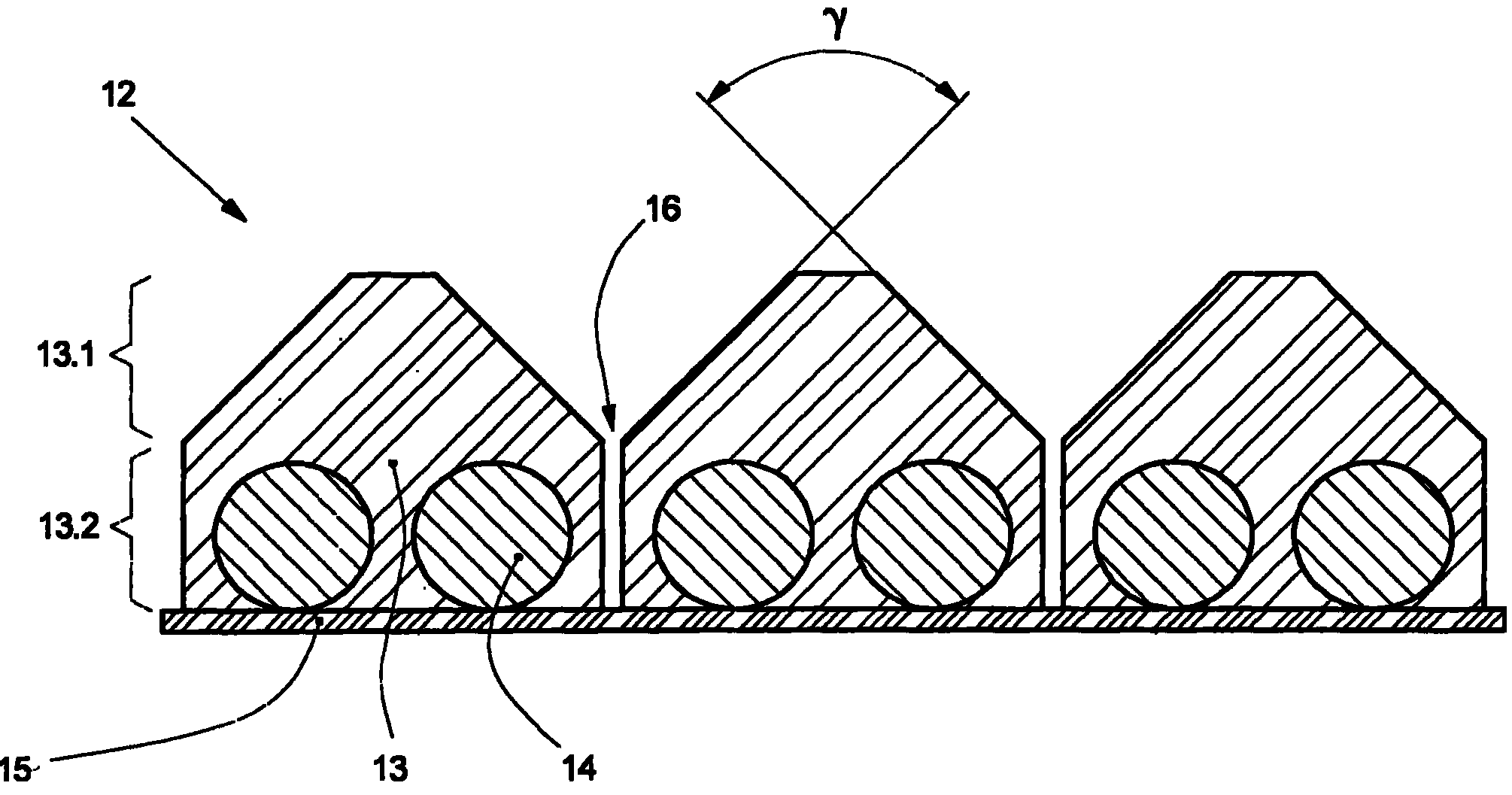

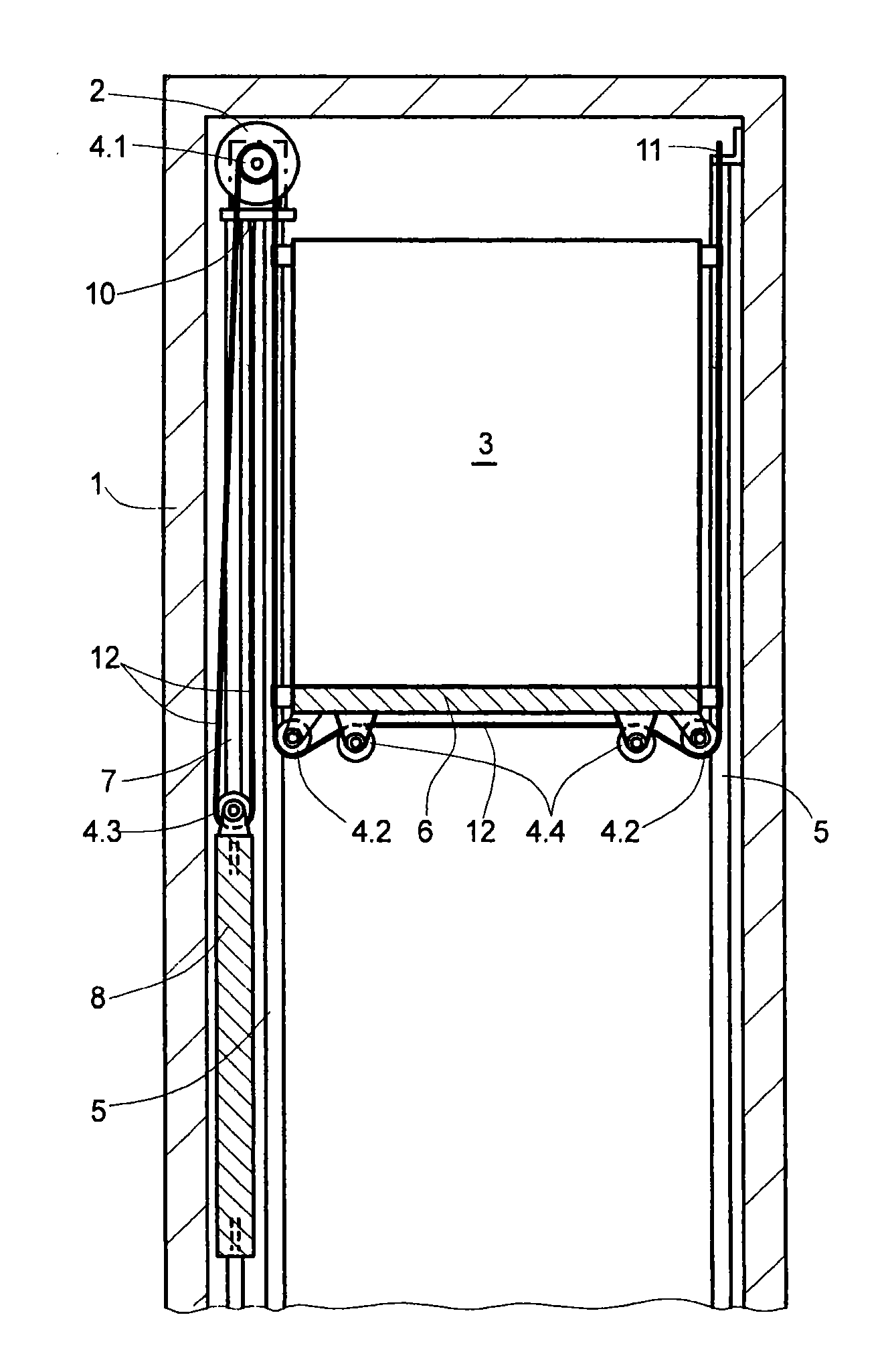

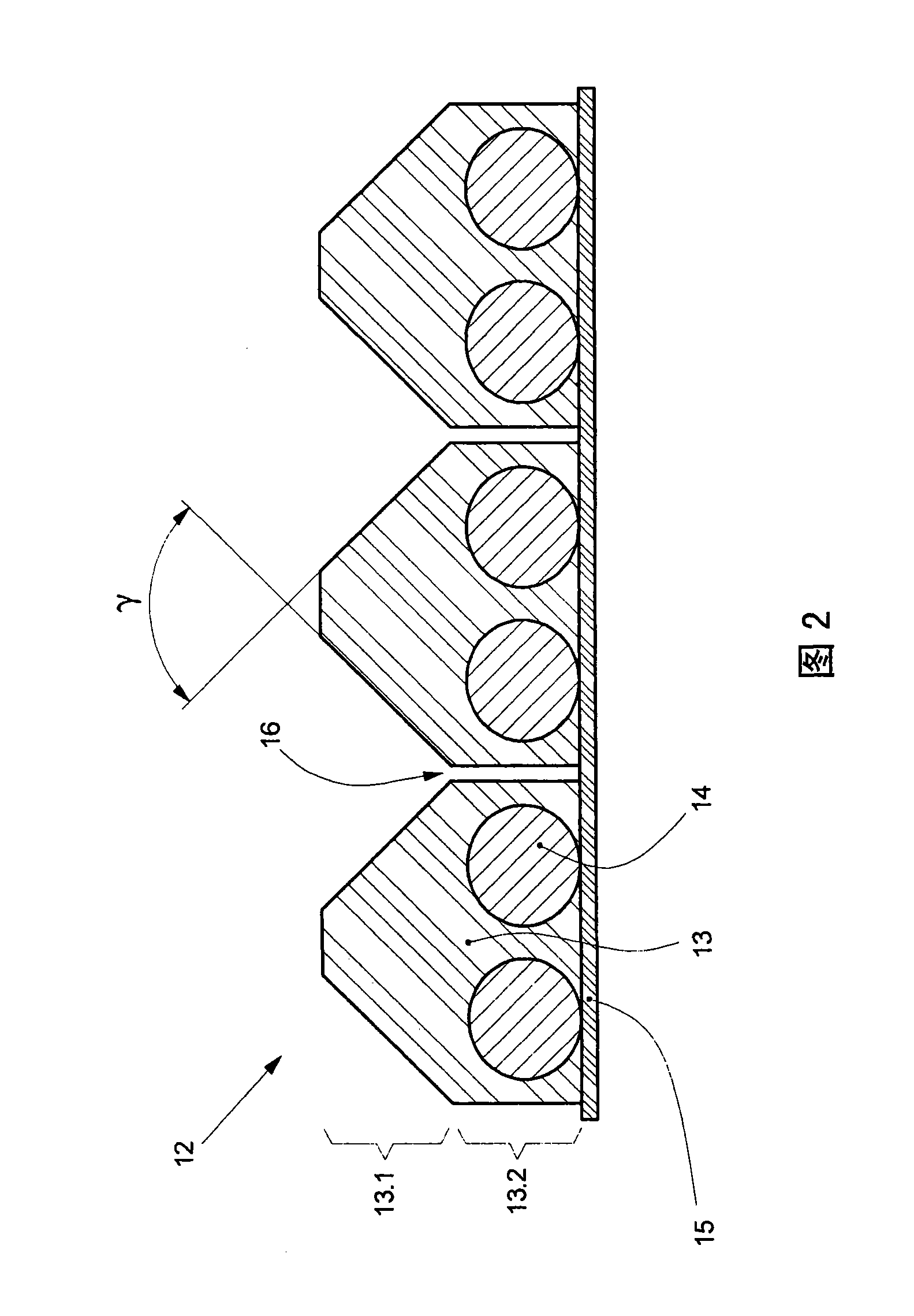

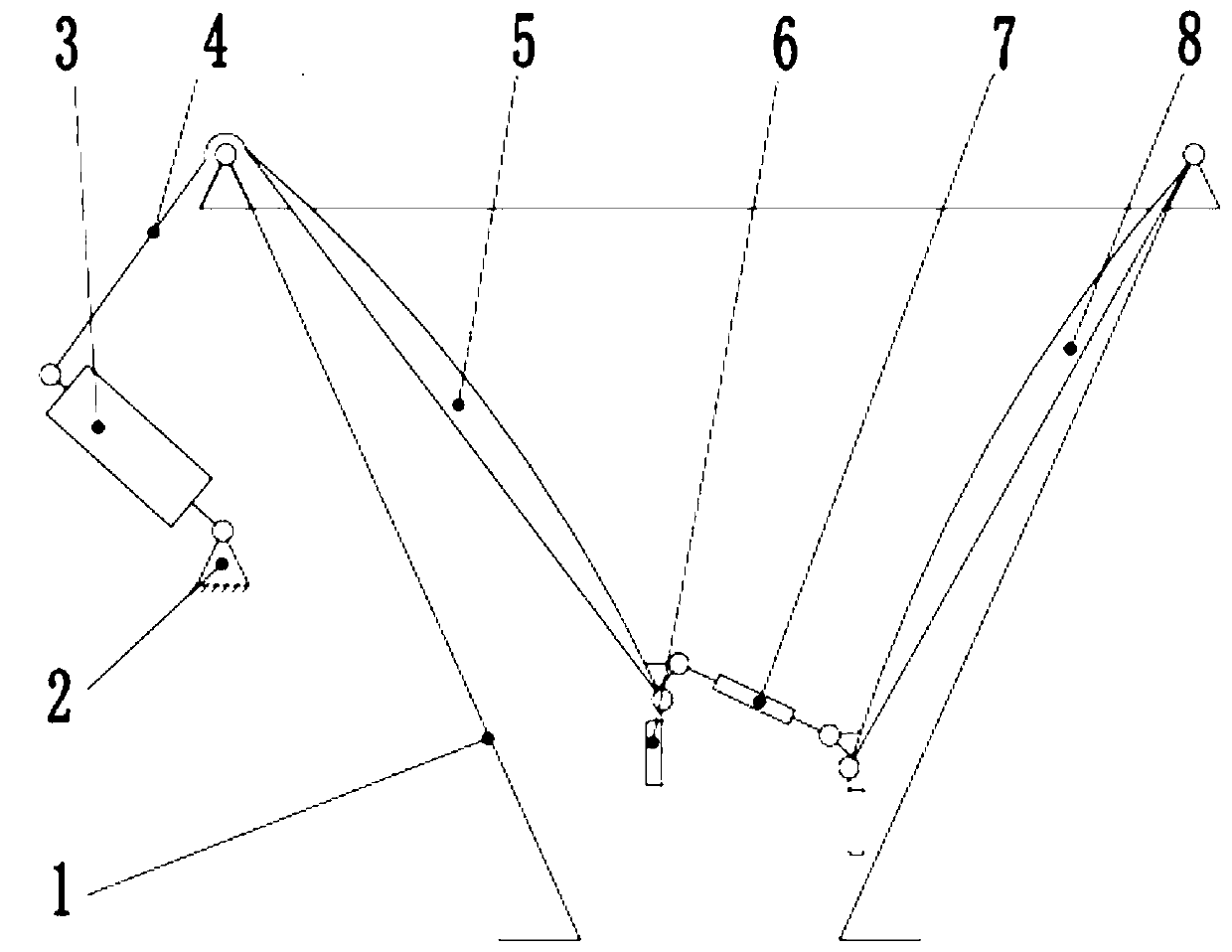

Lift system, load-bearing mechanism for such a lift system and method for assembly of such a load-bearing mechanism

InactiveCN101121488BReduced bending stiffnessImprove bending rigidityBeltsElevatorsPolyesterDrive wheel

A lift belt (12) for a lift installation comprises a wedge rib arrangement (15) with at least two wedge ribs (15.1) which extend in longitudinal direction of the lift belt an d form a contact side for engagement with a drive wheel (4.1) of the lift installation, a tensile carrier arrangement (14) with at least two tensile carriers (14.1, 14.2) arranged in two mutually adjacent wedge ribs of the wedge rib arrangement, and a back layer (13) whic h forms a rear side, which is opposite the contact side, of the lift belt. The back layer has a profile with at least one web (13.1) projecting into the wedge rib arrangement towar ds the contact side. <SDOCL LA=EN> 13 Claims 1. Lift belt (12) for a lift installation, with a wedge rib arrangement (15) with at least two wedge ribs (15.1) which extendin longitudinal direction of the lift bel t and which form a contact side for engagement with a drive wheel (4.1) of the lift installatio n, a tensile carrier arrangement (14) with at least two tensile carriers (14.1, 14.2) arranged in two mutually adjacent wedge ribs of the wedge rib arrangement, and a back layer (13) whic h forms a rear side, which is opposite the contact side, of the lift belt(12), characterised in that the back layer (13) forms a flat profile with at least one web (13.1) projecting into the wedge rib arrangement (15) towards the contact side. 2. Lift belt according to claim 1, characterised in that the back layer (13) is produced from a thermoplastic synthetic material, particularly from polyamide (PA), polyethylene (PE), polyester, particularly polyethyleneterephthalate (PET), polycarbonate (PC), polypropylene (PP), polybutyleneterephthalate (PBT), polyethersulfone (PES), polytetrafluorethylene (PTFE), polyvinylchloride (PVC) or from polyblend and / or a fabric ofsuch a thermoplastic synthetic material. 3. Lift belt according to any one of the preceding claims.

Owner:INVENTIO AG

A terminal heating method for preventing terminal cracks from fcb welding

ActiveCN103706917BReduce thermal stressImprove welding qualityMetal working apparatusWelding accessoriesTemperature controlComputer terminal

The invention discloses a finishing end heating method capable of preventing finishing end cracks from being generated in FCB welding, and relates to the field of material forming and control. The finishing end heating method capable of preventing the finishing end cracks from being generated in the FCB welding comprises the steps that a temperature control area in an isosceles triangle is preset in a welding finishing end area, the vertex of the isosceles triangle is located on a longitudinal welding seam, the bottom side of the isosceles triangle is perpendicular to the longitudinal welding seam, the length of the height of the isosceles triangle is a, and the length of the bottom side of the isosceles triangle is 2b; three yield strength sections and four thickness sections of a steel plate to be welded are defined; the a, the b and a temperature range T of the temperature control area are preset according to the yield strength section where the yield strength p of the steel plate 1 to be welded is located and the thickness section where the thickness d of the steel plate 1 to be welded is located; the temperature control area is heated, the longitudinal welding seam is welded, and the temperature in the temperature control area reaches T when welding is reaches the vertex of the isosceles triangle from the initial welding end of the longitudinal welding seam; heating is stopped, and welding is stopped when welding reaches the welding finishing end of the longitudinal welding seam; cooling is carried out, and a welded steel plate sample is formed. According to the finishing end heating method capable of preventing the finishing end cracks from being generated in the FCB welding, the probability of generating cracks at the finishing end of the welding can be reduced, the phenomenon of arch cambers on a plate surface can be controlled, deformation can be reduced, and the technology can be simplified.

Owner:QINGDAO WUCHUAN HEAVY IND CO LTD

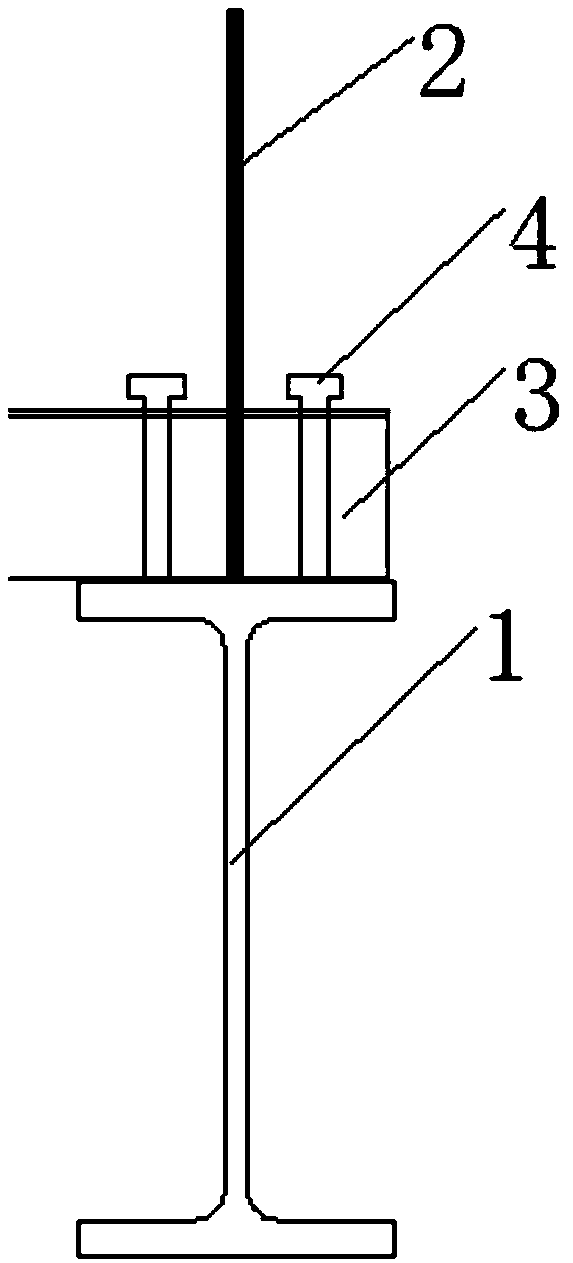

Floor board tightly attached mounting method

The invention relates to a floor board tightly attached mounting method. The floor board tightly attached mounting method comprises the steps that a component is provided at the lap joint of a floor board and a platform steel beam and comprises a cross rod located above the floor board and vertical rods distributed and fixed along the cross rod; the bottom end of the vertical rod located at one end of the cross rod is perpendicularly fixed to the top face of the platform steel beam, and the other vertical rods are perpendicularly jacked at a concave position of the top face of the floor board in sequence; then all welded studs are sequentially fixed; and finally, the component is dismantled. By adoption of the floor board tightly attached mounting method, the position of the component does not need to be adjusted, aloft operation is facilitated, efficiency is high, and recyclability is achieved.

Owner:CHINA FIRST METALLURGICAL GROUP

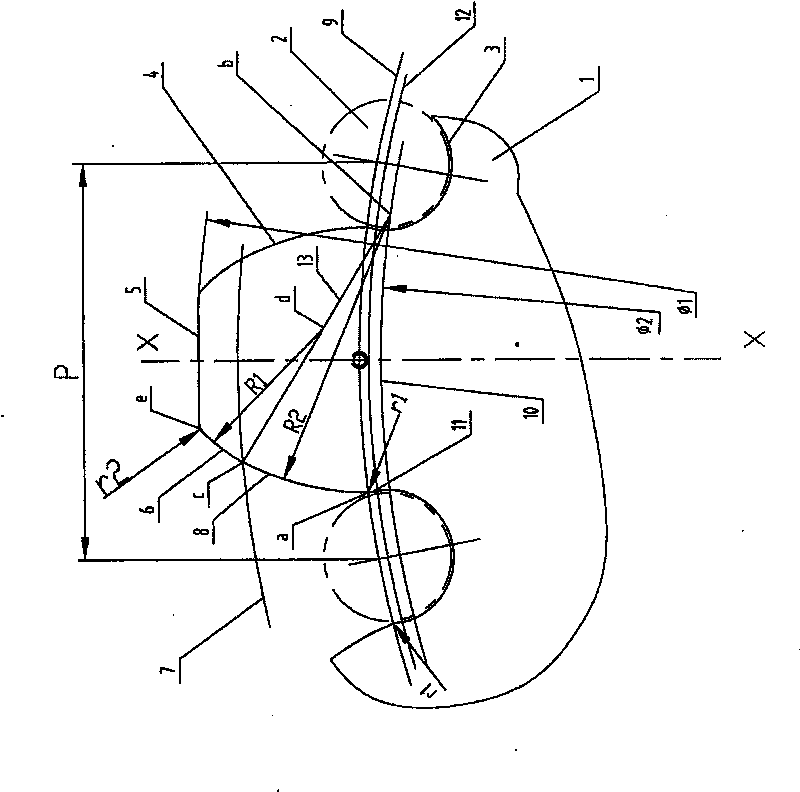

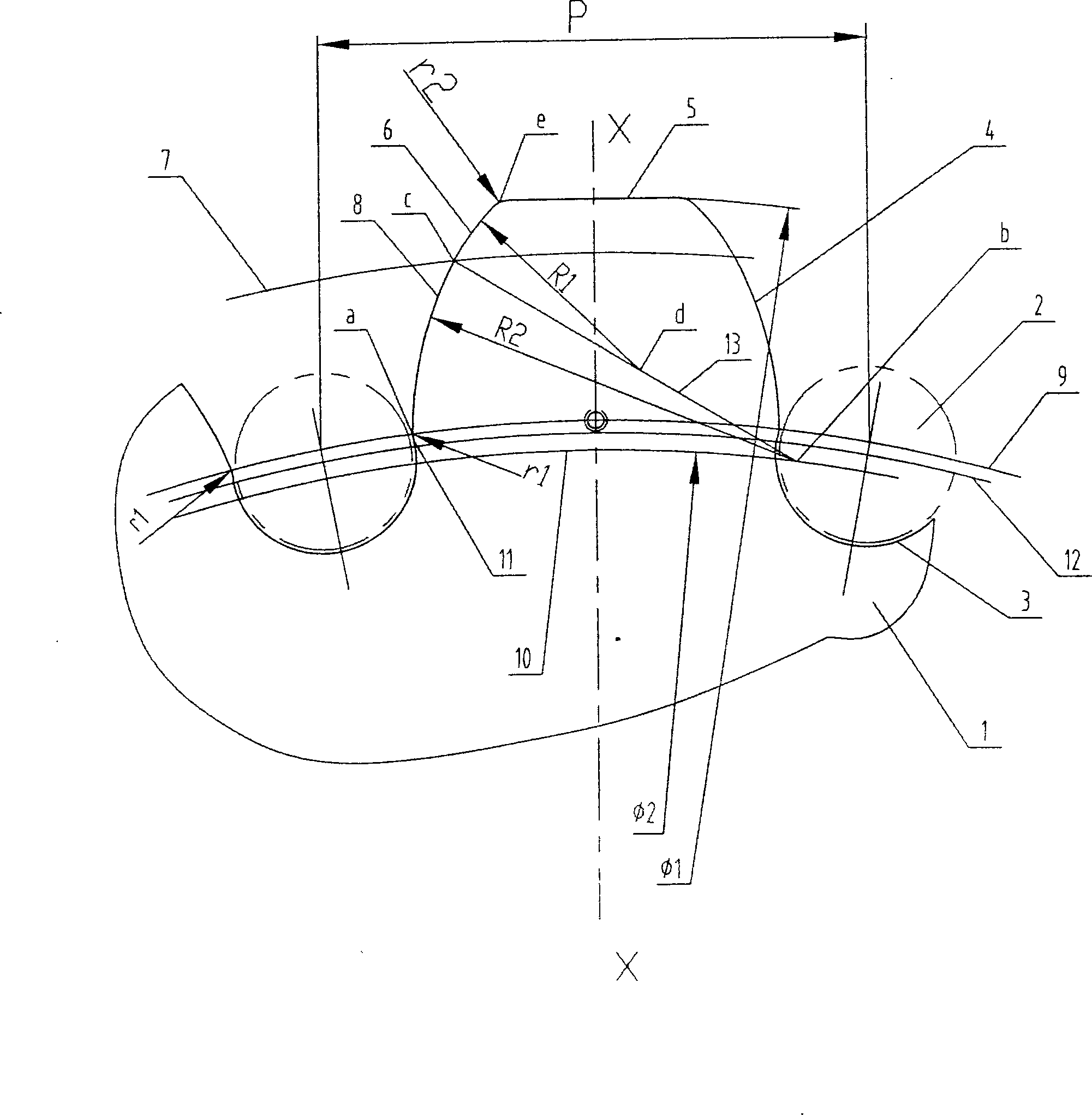

Method for correcting star wheel dental plate rack circle curve

ActiveCN101191547BReduce archingEliminate camberPortable liftingFurnace typesEngineeringMechanical engineering

The invention discloses a correction method for a star wheel toothed plate curve and a star wheel toothed arc curve, wherein, on the basis of the prior star wheel toothed plate with three pitch diameters, diameters of three concentric circles of a division circle, a pitch circle and a clamping wheel circle are not changed; the diameter 1 of an excircle on the star wheel toothed plate is adequatelydecreased; an auxiliary circle the diameter 2 of which is smaller than that of the pitch circle is produced; the radius R1 of the toothed arc curve is adequately decreased and the radius R2 of the toothed arc curve is adequately increased; the radius r1 of a transition curve is adequately decreased and the radius r2 of the transition curve is adequately increased; the circle center of the radiusR2of the toothed arc curve is arranged on the auxiliary circle and the circle center of the radius R1 of the toothed arc curve is arranged on the connecting line of the intersection point of the divisi on circle and the toothed plate curve and the circle center of the R2 of the toothed arc curve. Compared with the prior star wheel toothed plate, the star wheel toothed plate corrected and processedaccording to the invention looks small and the arc camber phenomenon of a loop wheel machine is obviously reduced when the star wheel toothed plate is arranged on the operating tail of the loop wheelmachine.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

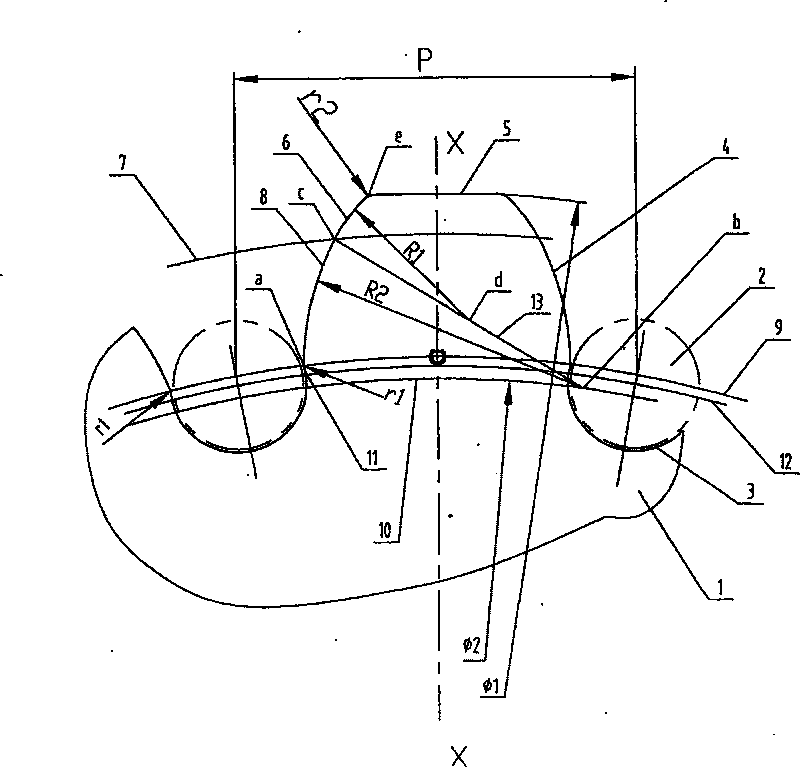

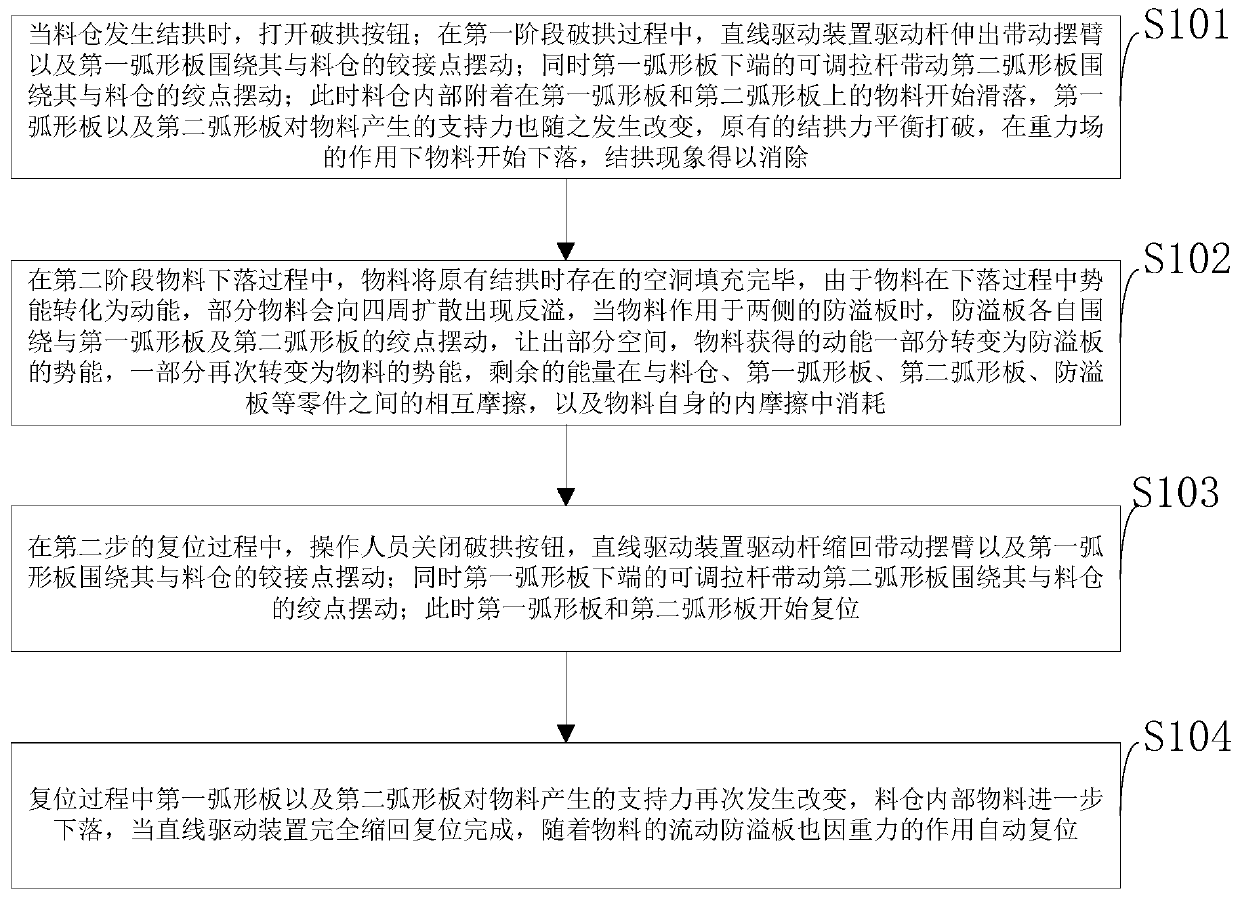

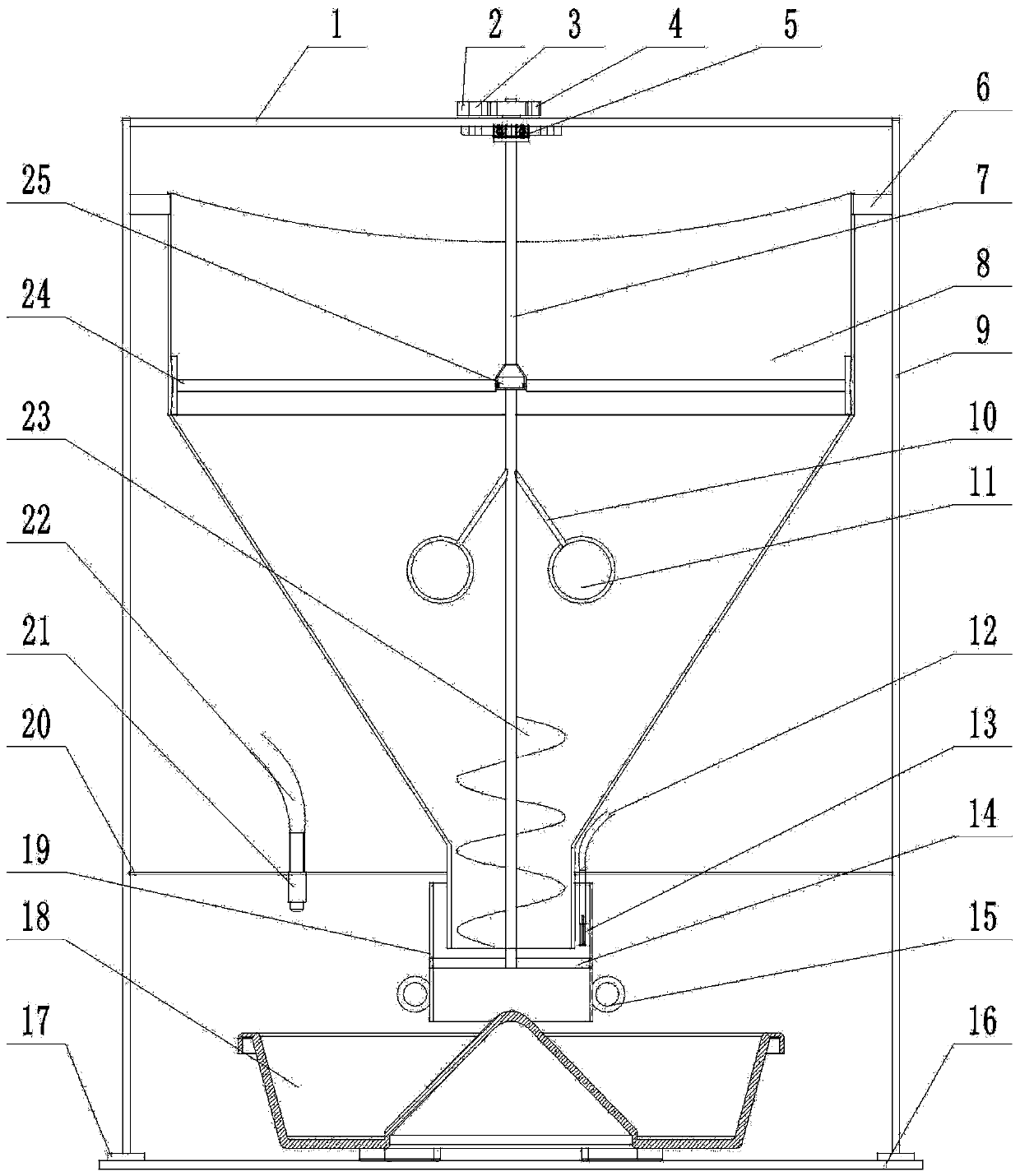

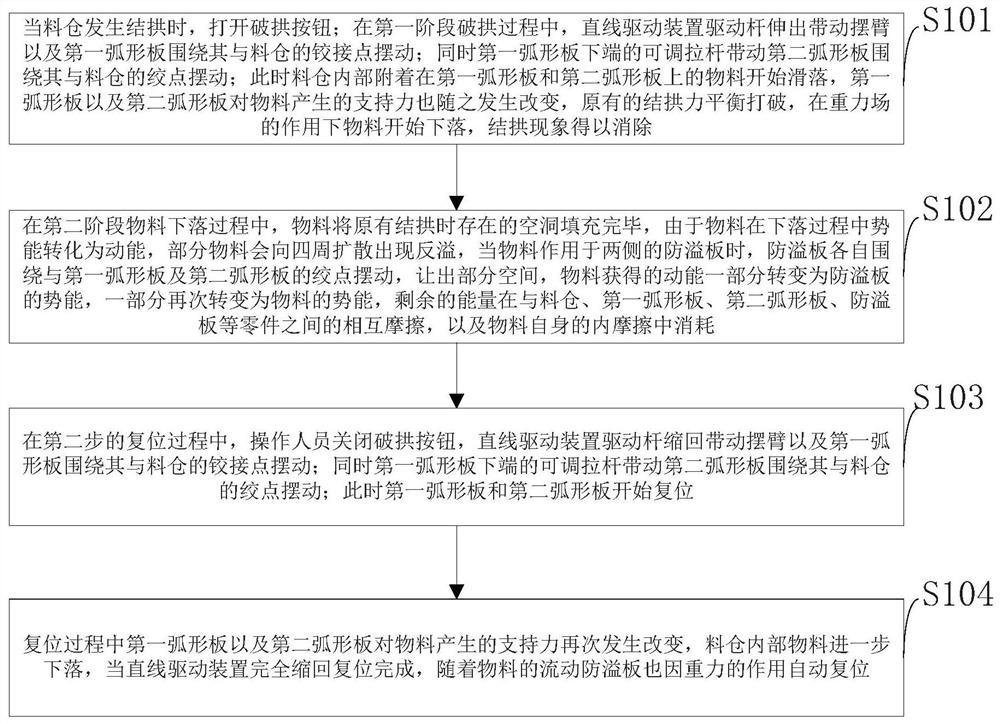

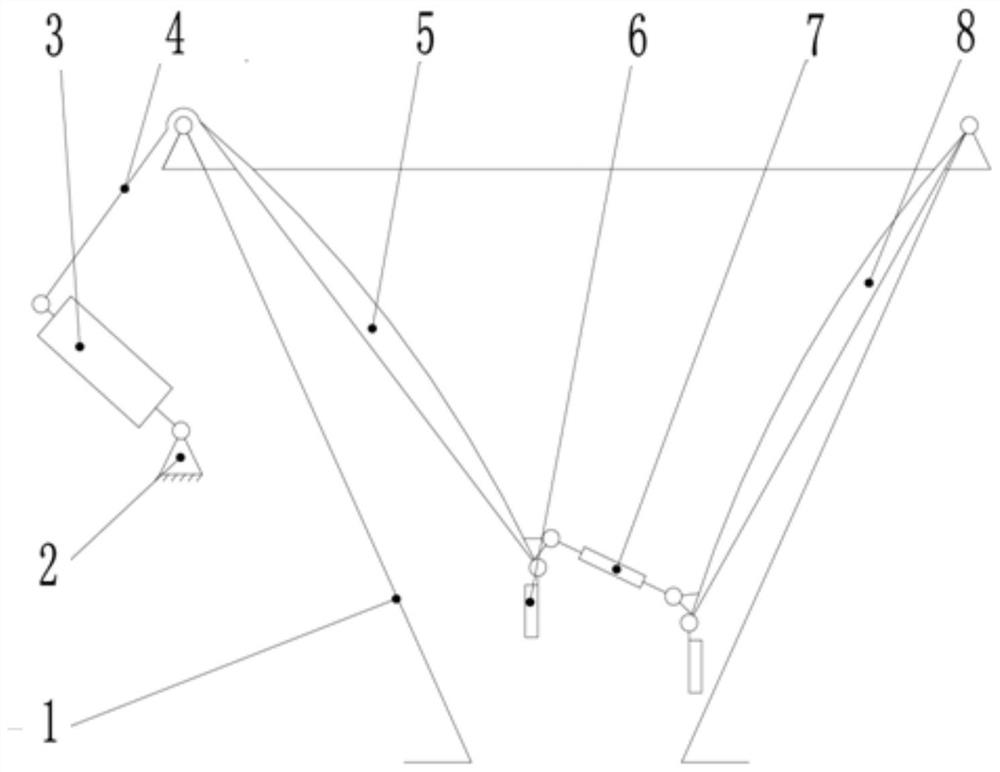

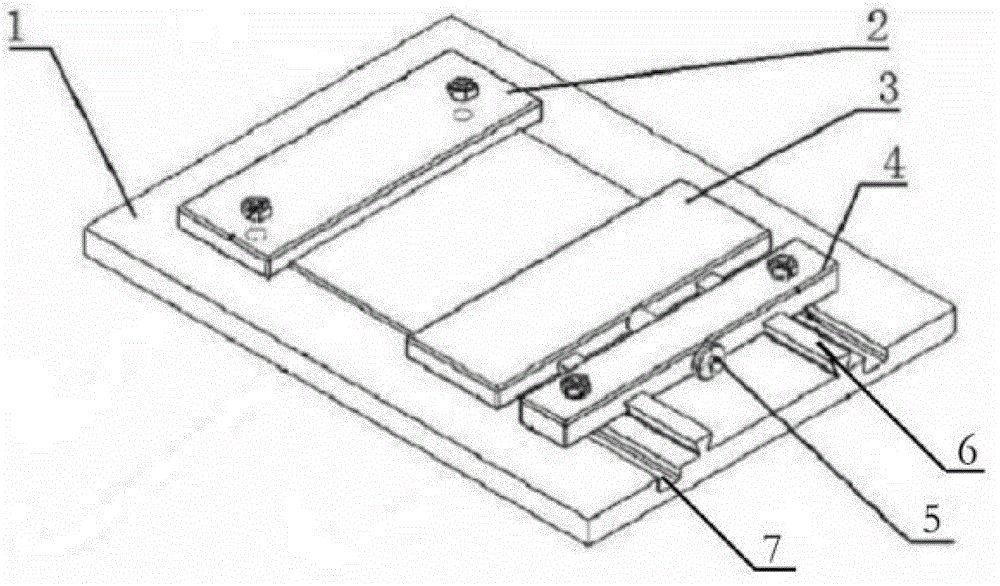

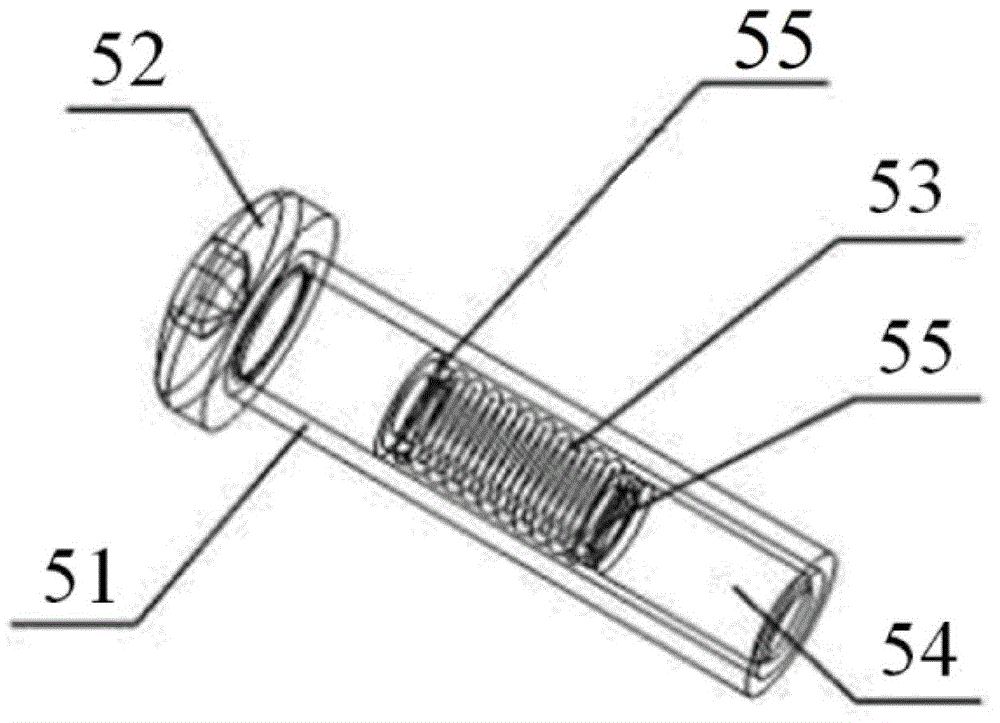

Four-link type bin arch breaking system and method and application of four-link type bin arch breaking method

ActiveCN111301877AGuaranteed reliabilityPrevent backflowLarge containersEngineeringStructural engineering

The invention belongs to the technical field of material conveying instruments, and discloses a four-link type bin arch breaking system and method and application of the four-link type bin arch breaking method. During the arch breaking process in the first stage, a linear driving device driving rod stretches out to drive a swinging arm and a first arc-shaped plate to swing around hinge points of the swinging arm and the first arc-shaped plate with a storage bin; meanwhile, an adjustable pull rod at the lower end of the first arc-shaped plate drives a second arc-shaped plate to swing around a hinge point of the second arc-shaped plate with the storage bin; materials start to fall down, and the arching phenomenon is eliminated; during the falling process of the materials in the second stage,existing cavities are filled with the materials, and when the materials act on overflow prevention plates on the two sides, the overflow prevention plates respectively swing around hinge points withthe first arc-shaped plate and the second arc-shaped plate, so that a partial space is reserved; and the linear driving device driving rod retracts to drive the swinging arm and the first arc-shaped plate to swing around the hinge points of the swinging arm and the first arc-shaped plate with the storage bin to start resetting. According to the four-link type bin arch breaking system and method and the application of the four-link type bin arch breaking method, the arch breaking of granular materials, powdery materials and wet-bonded materials with high water content can be rapidly completed.

Owner:陕西省农业机械研究所有限公司

Mixer on feeding equipment and use method thereof

Owner:QINGDAO ZHONGTAI POULTRY IND PROFESSIONAL COOP

Method for correcting star wheel dental plate rack circle curve

ActiveCN101191547AReduce archingEliminate camberPortable liftingFurnace typesCorrection methodMechanical engineering

The invention discloses a correction method for a star wheel toothed plate curve and a star wheel toothed arc curve, wherein, on the basis of the prior star wheel toothed plate with three pitch diameters, diameters of three concentric circles of a division circle, a pitch circle and a clamping wheel circle are not changed; the diameter 1 of an excircle on the star wheel toothed plate is adequately decreased; an auxiliary circle the diameter 2 of which is smaller than that of the pitch circle is produced; the radius R1 of the toothed arc curve is adequately decreased and the radius R2 of the toothed arc curve is adequately increased; the radius r1 of a transition curve is adequately decreased and the radius r2 of the transition curve is adequately increased; the circle center of the radius R2 of the toothed arc curve is arranged on the auxiliary circle and the circle center of the radius R1 of the toothed arc curve is arranged on the connecting line of the intersection point of the division circle and the toothed plate curve and the circle center of the R2 of the toothed arc curve. Compared with the prior star wheel toothed plate, the star wheel toothed plate corrected and processed according to the invention looks small and the arc camber phenomenon of a loop wheel machine is obviously reduced when the star wheel toothed plate is arranged on the operating tail of the loop wheel machine.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

a slow feeder

InactiveCN108651308BGrow fastPrevent archingAnimal feeding devicesSpiral bladeAgricultural engineering

The invention discloses a slow-type feeding device, which is mainly used for restricted and delayed feeding for pigs. The slow-type feeding device mainly comprises a charging barrel, a main shaft, a ratchet wheel mechanism, a collision-type discharging device, a spraying device, a feeding trough and a drinking device. The charging barrel is arranged in the middle between left and right supports, the ratchet wheel mechanism is arranged at the center part of a crossbeam, the main shaft is positioned through the center of the ratchet wheel mechanism and the charging barrel, the collision-type discharging device is positioned through two ends of a cross bar at the lower part of the main shaft, three spraying devices are successively arranged at a discharging outlet in the lower part of the charging barrel at intervals of 120 degrees with the axis of the main shaft as the center, the feeding trough is arranged on a base plate, and the drinking device is arranged on the left side of a lowerconnecting link. According to the invention, on-demand feeding is realized through the cooperation of the ratchet wheel structure and a set of spiral blade at the lower part of the main shaft, thus reducing the loss and waste of feed; spray-like water drops can increase the moisture content of the feed and reduce the occurrence probability of respiratory diseases in pigs. The slow-type feeding device is simple and reasonable in structure design, convenient in operation and strong in applicability.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

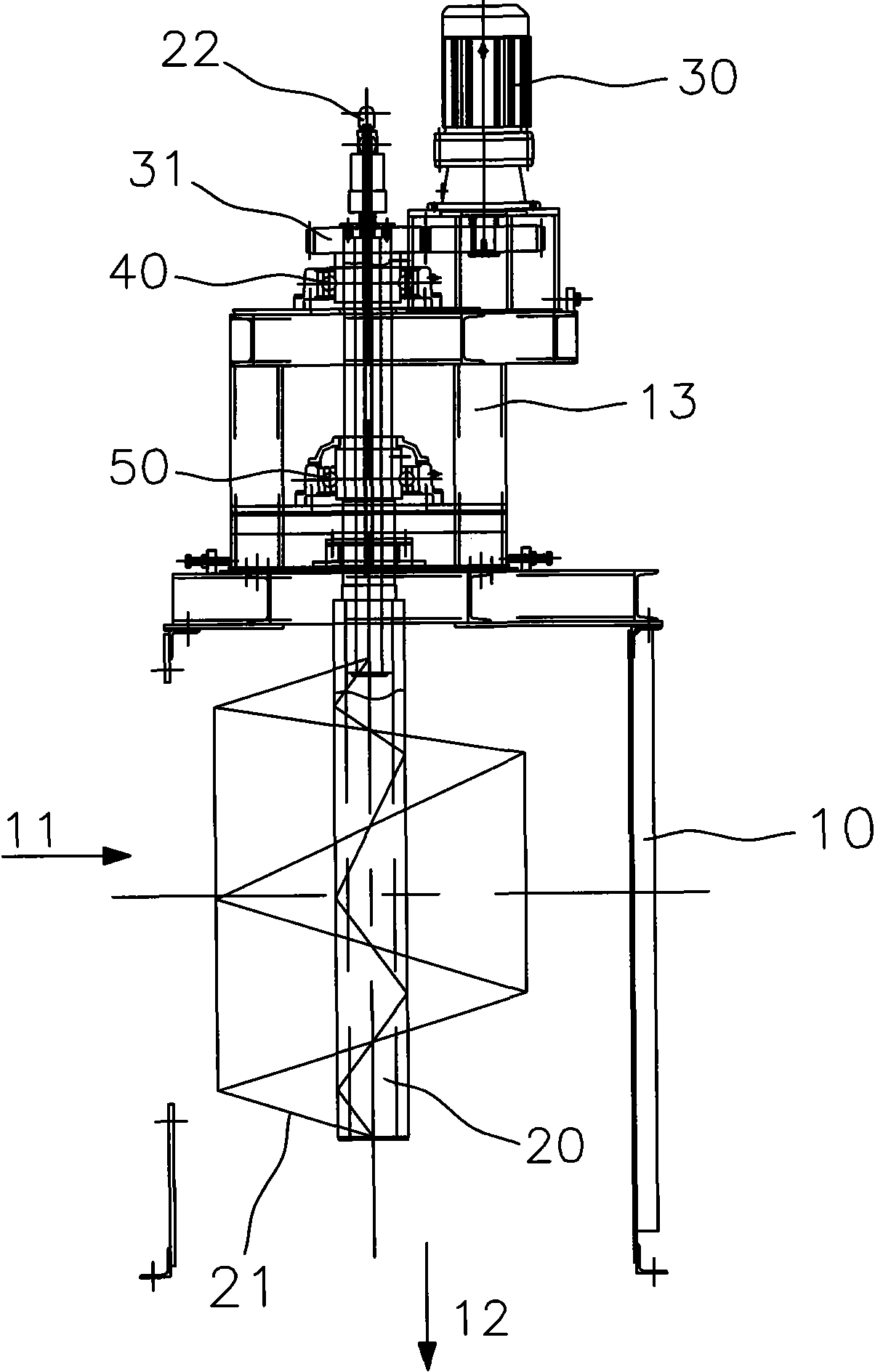

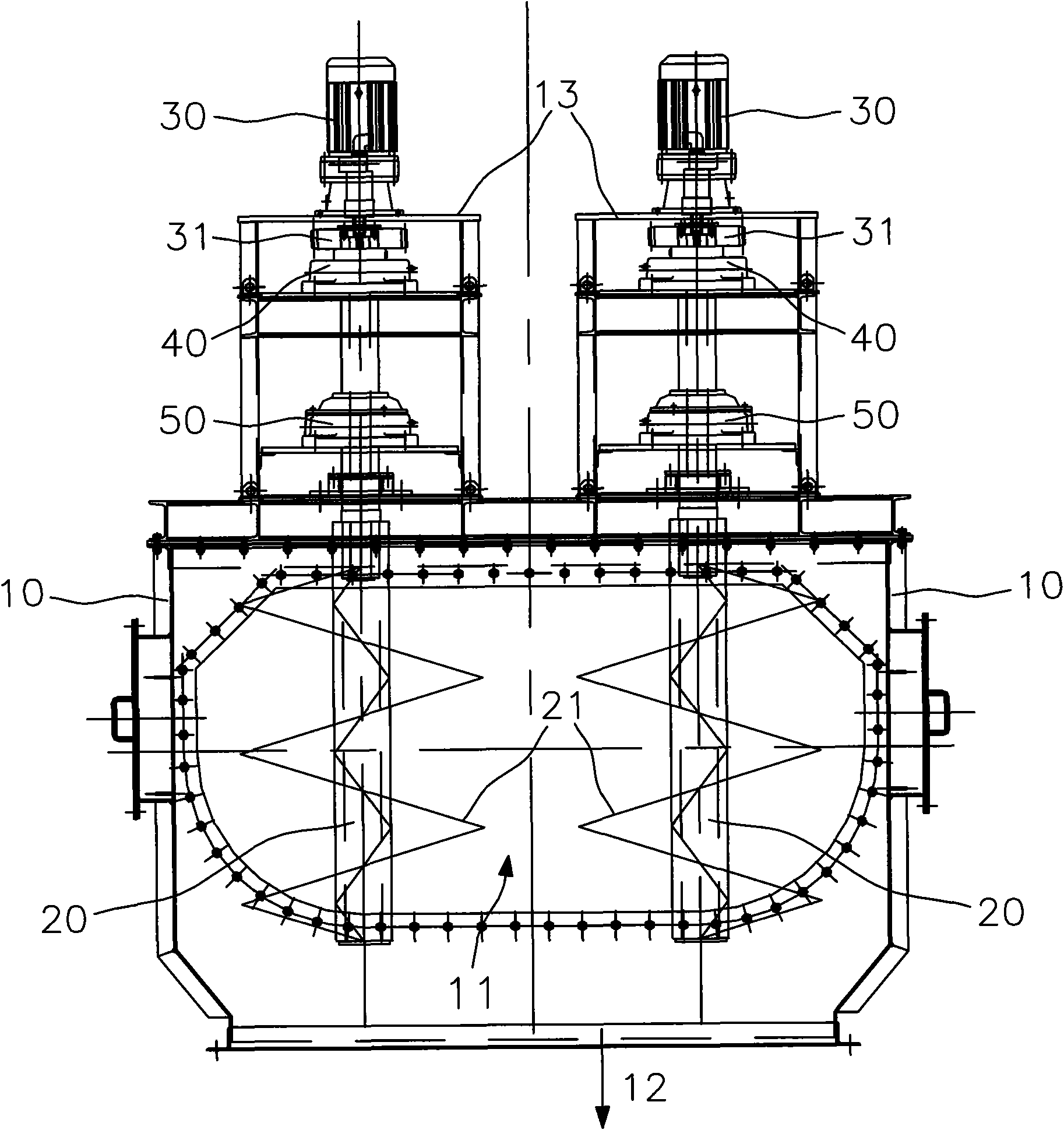

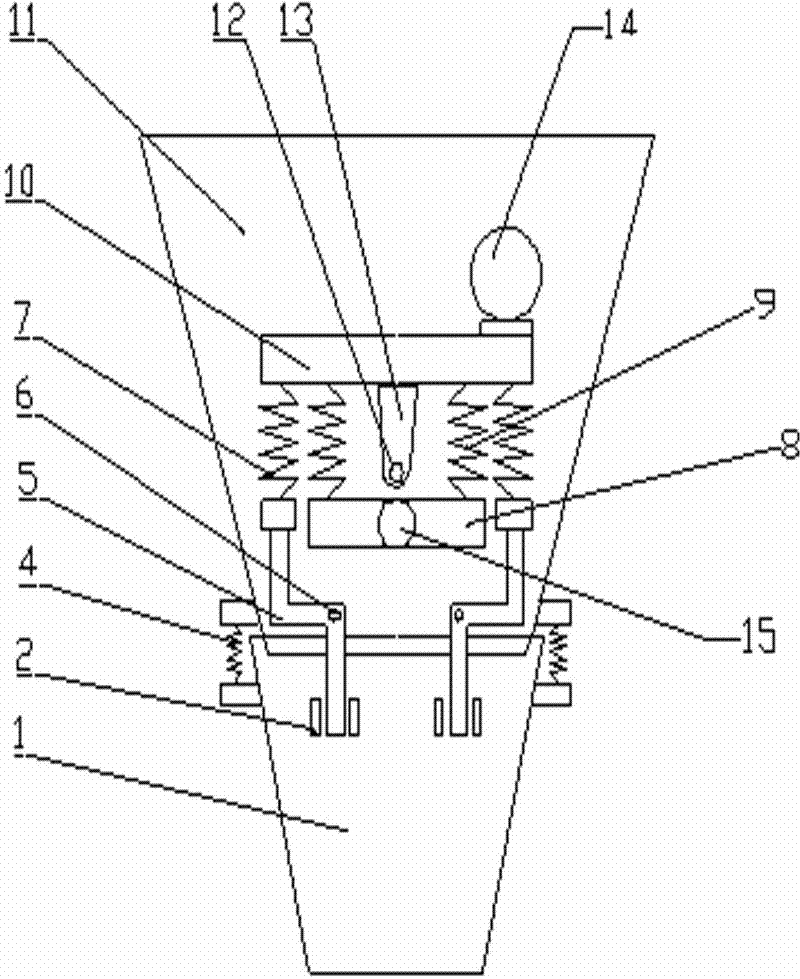

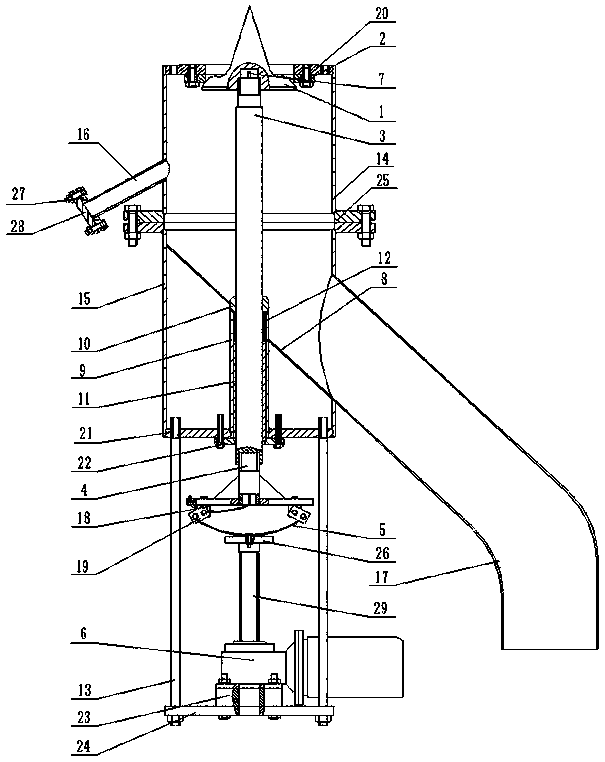

Method and device for dredging discharged materials of storage bin

ActiveCN102180321BAvoid damaging shocksReduce archingLarge containersMechanical engineeringEnergy storage

The invention discloses a method and device for dredging discharged materials of a storage bin. A movable hopper is connected with the lower part of the storage bin through a flexible lifting frame and is provided with a vibration pick-up block, the storage bin is provided with a vibrating frame, a vibrator is eccentrically arranged on the vibrating frame, meanwhile, a transmission swing bar is articulated on the storage bin, one end of the transmission swing bar is connected with the vibrating frame through a swing-bar vibration transmitting spring, the other end of the transmission swing bar is arranged beside the vibration pick-up block, the energy generated due to the vibration of the vibrator is transmitted to the transmission swing bar through the swing-bar vibration transmitting spring, the transmission swing bar moves to strike the vibration pick-up block to drive the movable hopper to undergo composite impact movement of tangential rotation and transverse translation, so thatthe caking arch of materials can be prevented or eliminated in the movable hopper. In the invention, the mode integrating composite impact as well as energy storage and energy release of the vibration transmitting spring is adopted to solve the problem of discharge material blockage in the storage bin, so that the effects of preventing blockage and dredging are better.

Owner:SHANXI SANHESHENG IND TECH +1

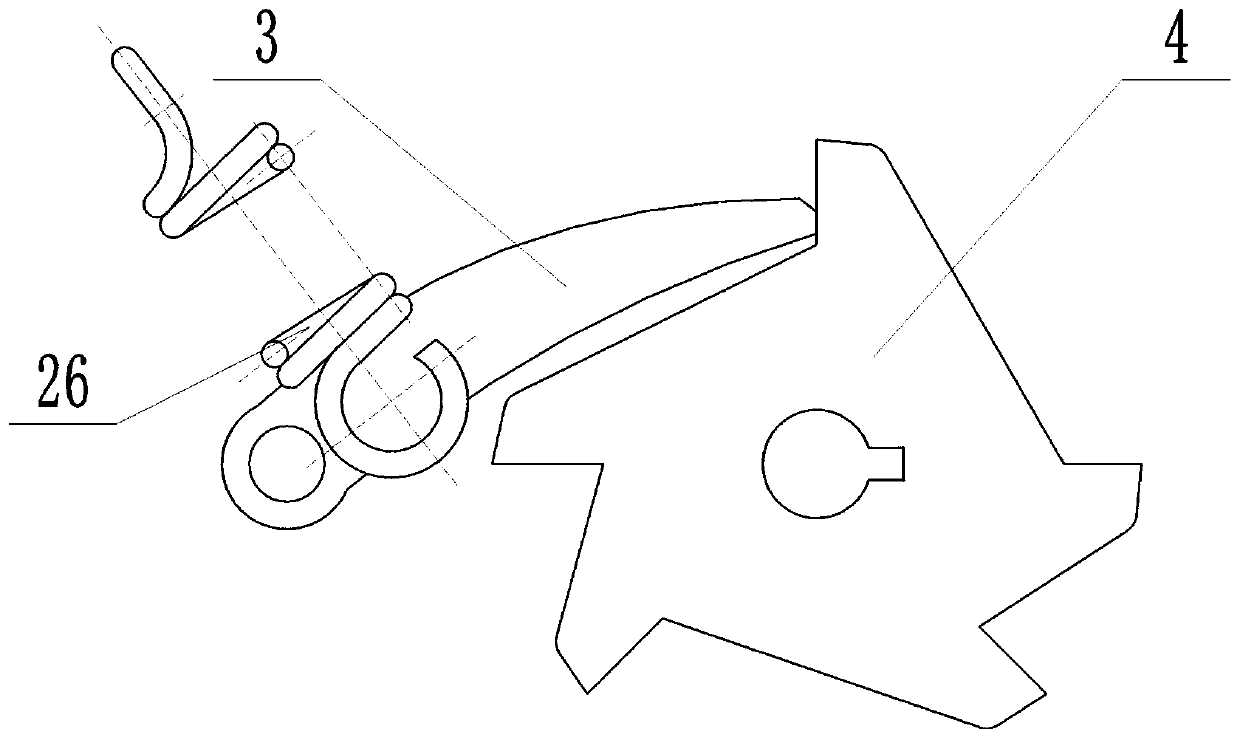

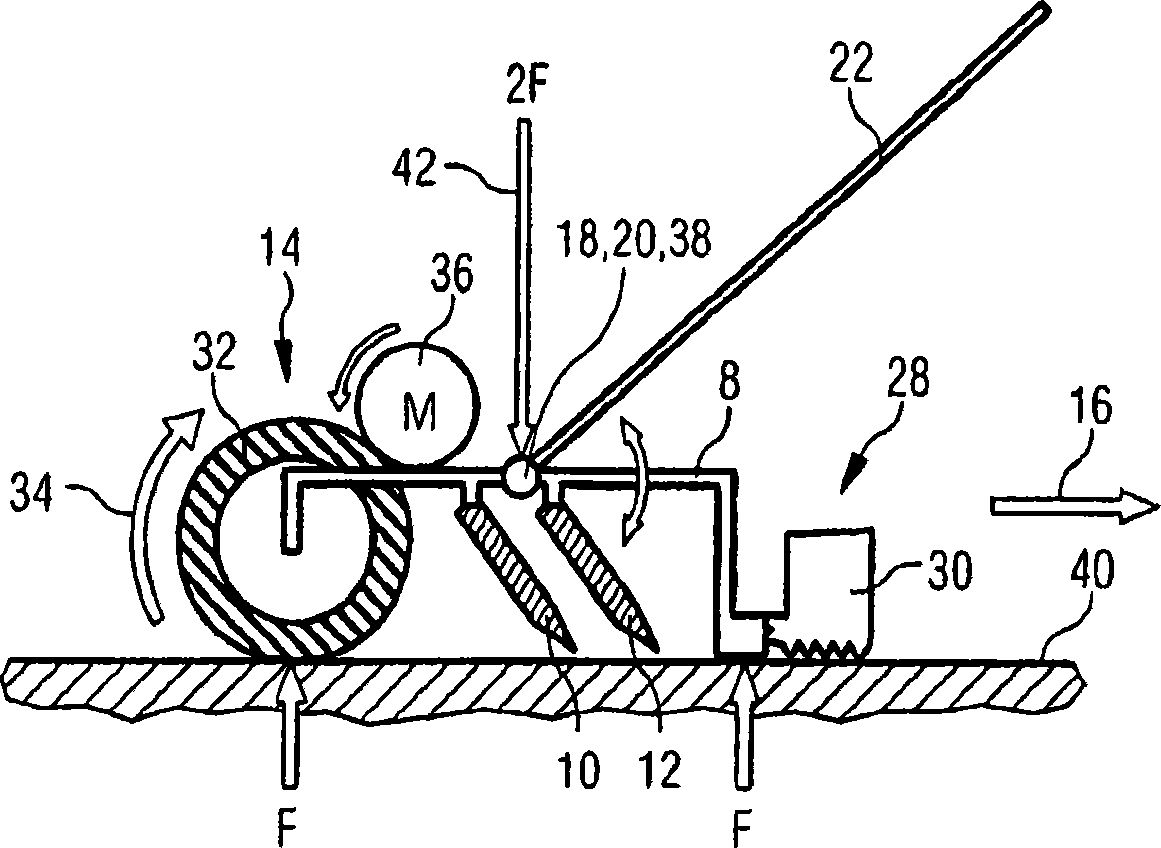

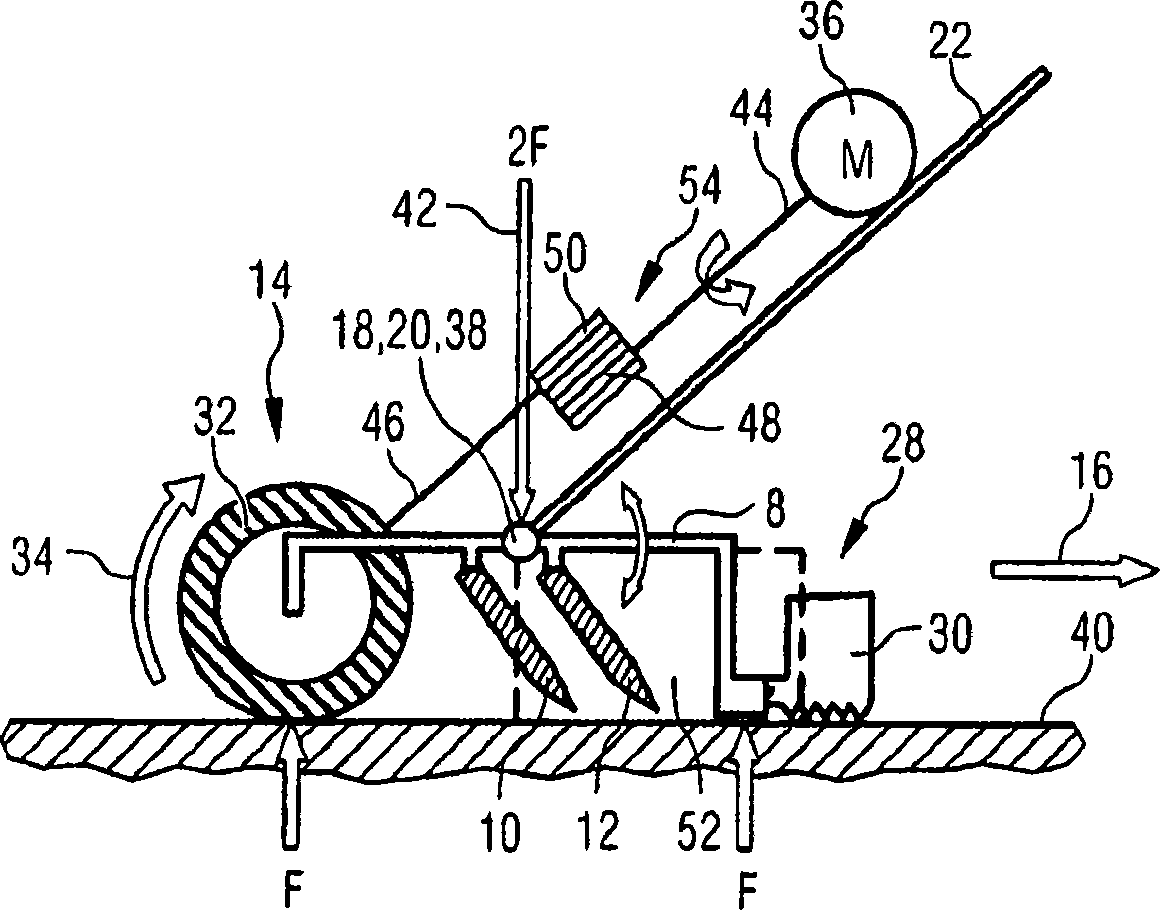

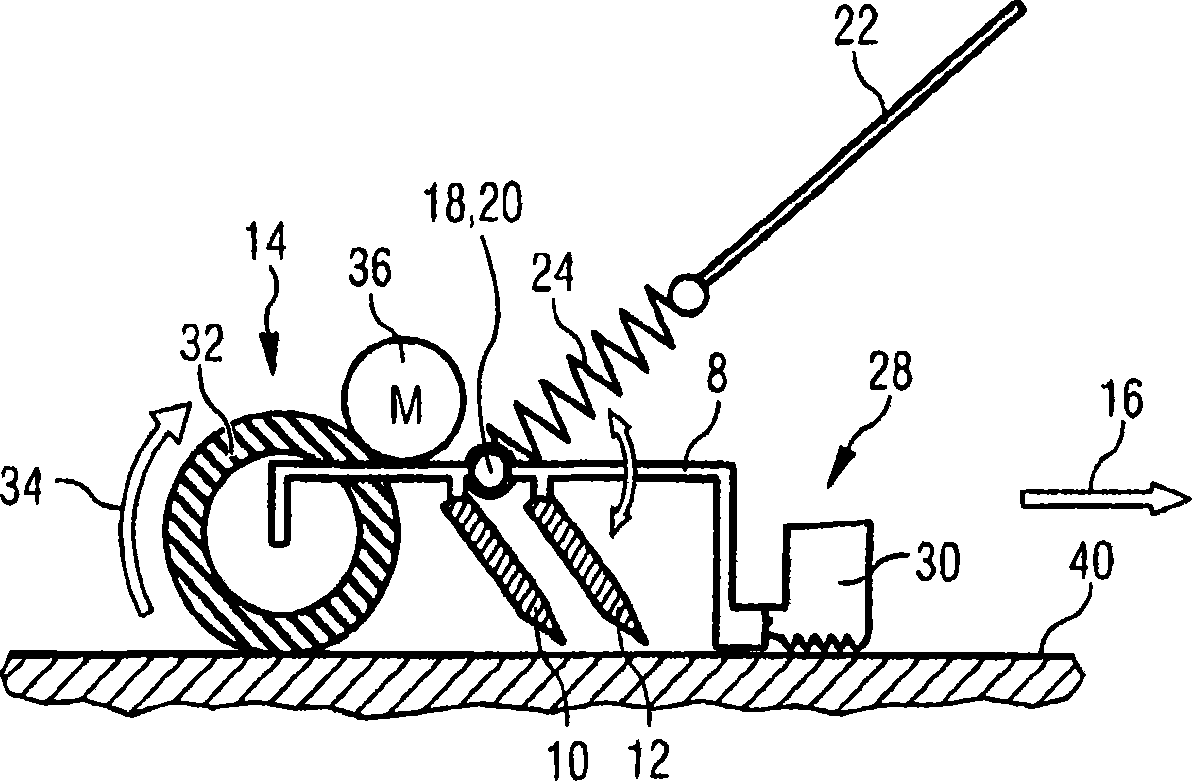

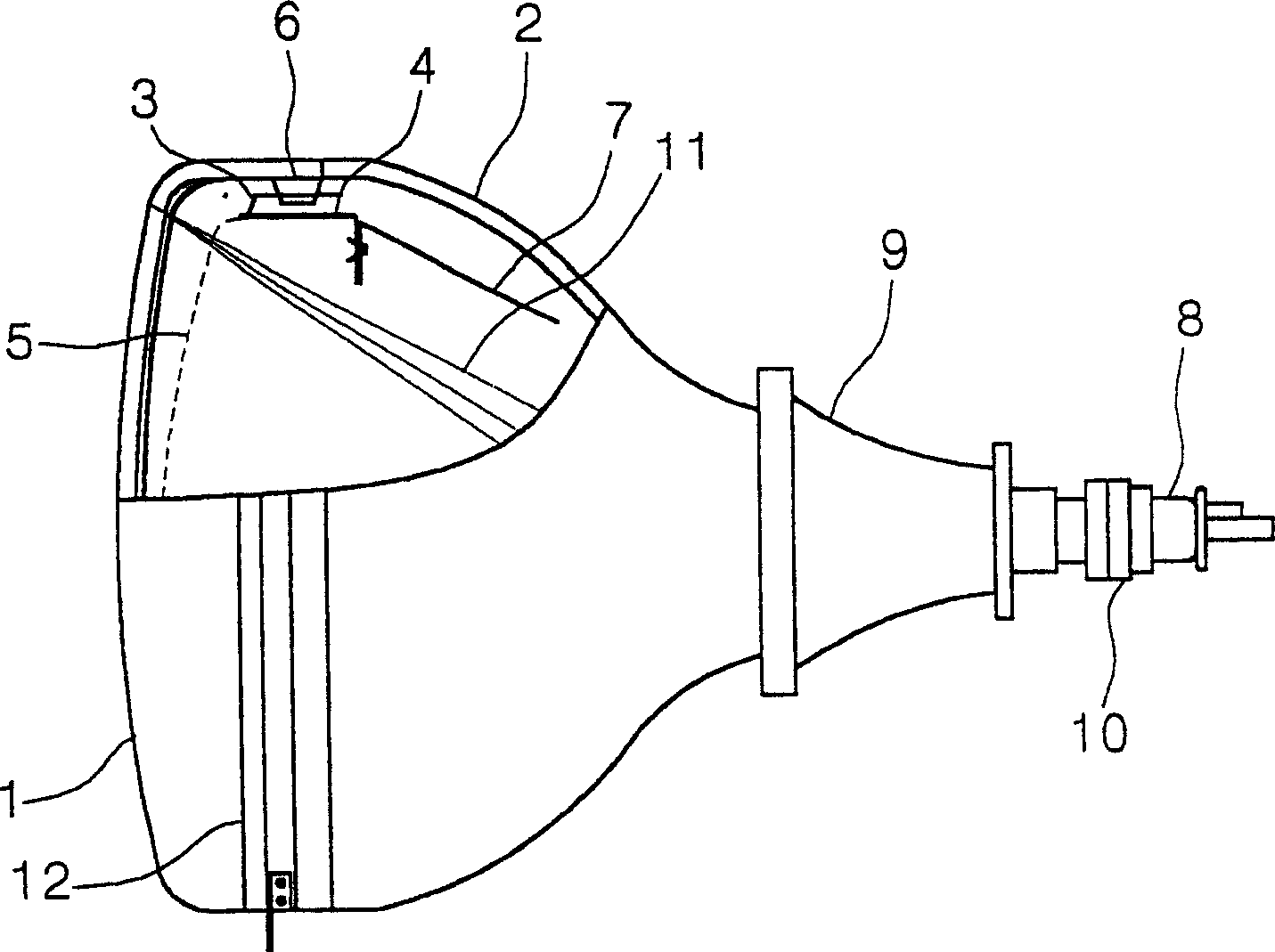

Shaving head with skin stretching member

InactiveCN1890065BConstant driving forceEasy to controlMetal working apparatusEngineeringKnife blades

The invention is directed to a shaving head (8) comprising at least one cutting blade (10, 12) and actively driveable skin stretching means (14) arranged behind said cutting blade (10, 12) relative to a cutting direction (16) of said cutting blade (10, 12). The actively driveable skin stretching means (14) are provided to reduce the possibility that ni cks and cuts or irritations of the skip to be shaved are created during the shaving operation. In accordance with the invention the shaving head (8) comprises means (18) for providing a pivot axis (20) between the shaving head (8) and a handie (22) attached or attachable to said shaving head (8), said pivot axis (20) being arranged at least essentially parallel to said cutting blade (10, 12). By providing the pivot axis (20) the force ratiobetween a force applied to the actively driveable skin stretching means (14) and forces applied to other parts ofthe shaving head (8) may be kept constant for different angles of the handle. This improves the functioning of the actively driveable skin stretching means (14).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Mute wood floor

InactiveCN110878624AReduce tensionReduce archingCovering/liningsFlooring insulationsSolid woodStructural engineering

The invention discloses a mute wood floor, and belongs to the technical field of floors. The mute wood floor comprises a base body, and a decoration layer, a heat preservation layer, a waterproof breathable layer, a first silencing cavity, a second silencing cavity, a solid wood layer, a drying layer and a positioning layer which are sequentially arranged in the base body from top to bottom, wherein buffer layers are installed at the two ends of the base body respectively, each buffer layer comprises a buffer cavity and a rubber block installed on one side of the buffer cavity, a plurality ofuniformly distributed buffer springs are arranged in the buffer cavities, the decoration layer comprises a decorative plate and a positioning convex block installed at the bottom of the decorative plate, and a magnet is fixedly mounted on the positioning convex block. According to the mute wood floor, by arranging the buffer layers and arranging the rubber blocks and the buffer springs in the buffer layers, when the two floors are spliced and installed, the rubber blocks and the buffer springs can buffer tension between the two floors when expansion and contraction of the floor in summer occurs, the arching of the floor after expansion and contraction is reduced, the buffering performance of the floor can be improved, and the service life of the floor is prolonged.

Owner:安徽欧陆佳家居用品有限公司

Application method of mixer

The invention provides an application method of a mixer. The application method of the mixer includes the steps of A, fixedly placing an upper slide plate of a feed trough above a feed trough pipeline; B, fixedly connecting a motor output shaft to a motor output shaft connection on a feed bin, and setting the speed of 15-30 rpm with a frequency converter; C, placing a feed track above a feed inlet; and D, inserting an air tube in an air hole to inject air into the feed bin, and allowing pneumatic and mechanical power to assist in feed feeding. The application method is effective and is convenient to use, utilization rate of feeding equipment is increased, and feeding is smooth.

Owner:QINGDAO TIANRUI ECOLOGICAL TECH

How to install floor slabs

Owner:CHINA FIRST METALLURGICAL GROUP

A high temperature and corrosion resistant airtight slag discharge valve with temperature measurement

The invention provides a high-temperature-resistant corrosion-resistant airtight residue discharge valve with a temperature measurement function and belongs to the technical field of residue dischargevalves. A residue inlet is formed in the top surface of an outer barrel. A residue discharge port is formed in the barrel wall of the outer barrel. A flow guide plate inclined downwards and communicating with the residue discharge port is arranged in the outer barrel. A valve seat is made of ceramics and is arranged below the residue inlet. A valve element is made of ceramics and comprises a valve element bottom, a valve element spherical surface, a valve element inverted arch surface and a valve element arch breaking cone. A valve rod penetrates through the flow guide plate and the bottom surface of the outer barrel. The top end of the valve rod is inserted in a blind hole in the bottom of the valve element. The bottom end of the valve rod is connected with a connecting frame. A plate spring is of a platy structure bending downwards. The ends of the plate spring are mounted on the connecting frame. The bottom of the plate spring is fixed to a lifter. A temperature measurement elementis arranged at the top end of the valve rod. A lead wire penetrates out from the bottom end of the connecting frame along the valve rod to be connected with an external temperature display device. The high-temperature-resistant corrosion-resistant airtight residue discharge valve has the functions of arch caking prevention and arch breaking and also has the advantages of being resistant to high temperature and corrosion, capable of measuring the temperature and good in sealing performance.

Owner:TAIYUAN UNIV OF TECH

Mixer of feeding unit

The invention provides a mixer of a feeding unit. The mixer comprises a feed bin and a charge inlet. The feed bin is provided with a bent segment which is provided with a plurality of air holes. The charge hole is arranged above the bent segment. A rotary shaft is further disposed below the bent segment. A rotary leaf plate is disposed on the rotary shaft. The rotary shaft is connected with the feed bin through a shaft. The rotary leaf plate is fixedly connected with the rotary shaft. A motor output shaft joint is disposed at one end of the rotary shaft. A chute is arranged below the rotary leaf plate, and a feed trough pipeline is connected below the chute. The chute is fixedly connected with the feed bin and inclines at 65 DEG. The feed bin is integrated with the air holes during manufacturing. The mixer is simple in structure and convenient to use, utilization rate of the feeding unit can be increased, and feeding is smoothed.

Owner:QINGDAO TIANRUI ECOLOGICAL TECH

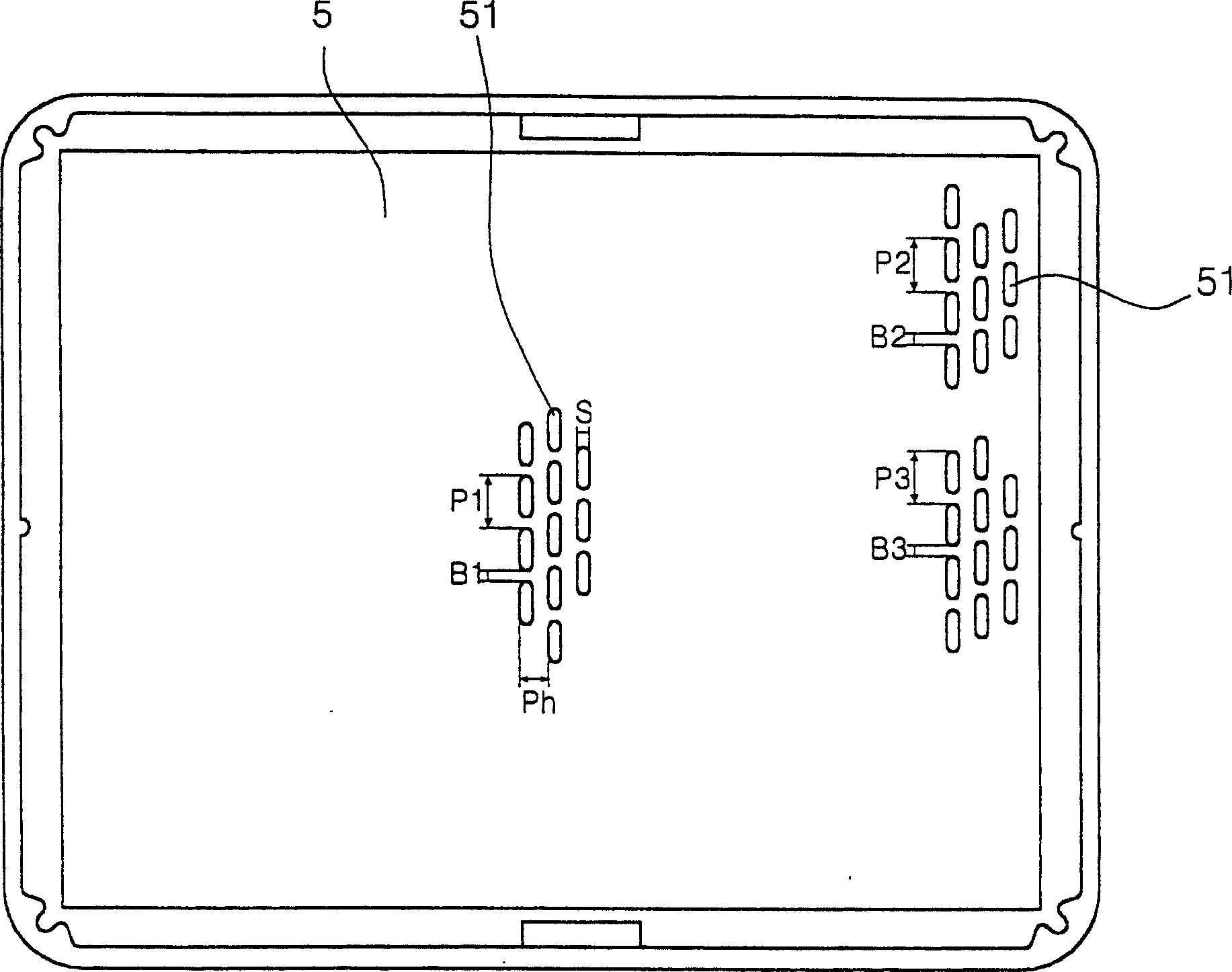

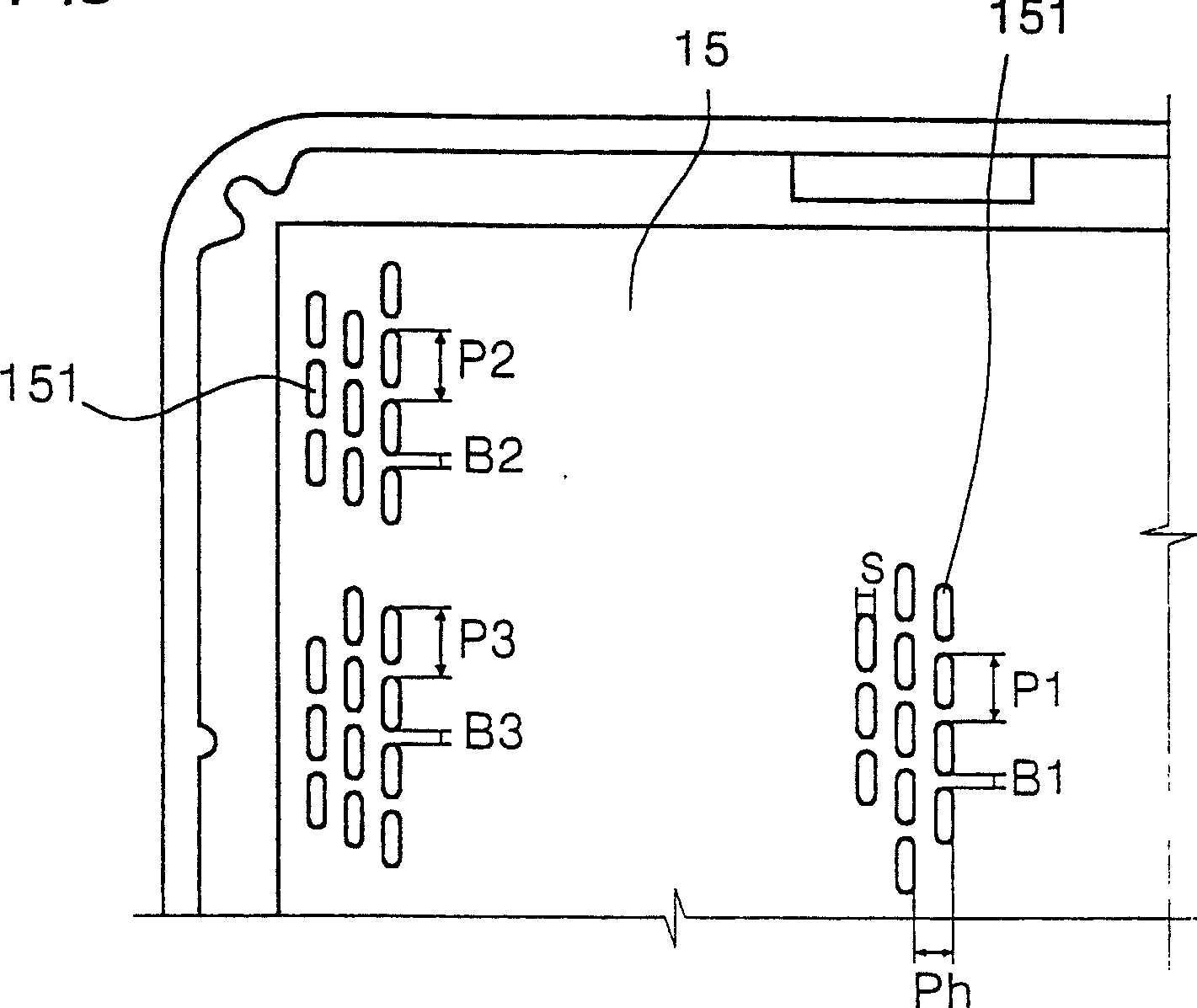

Color cathode ray tube

InactiveCN1741233AAppropriate brightnessImprove brightness uniformityCathode-ray/electron-beam tube vessels/containersLong axisEngineering

The present invention provides A color cathode ray tube comprising: a panel having a flat outer surface and an inner surface that has a predetermined curvature; and a shadow mask, wherein B2 / P2<=B3 / P3 where B1 is a length of a bridge as a distance between holes in a vertical direction at a center portion of the shadow mask; B2 is a length of a bridge as a distance between holes in a vertical direction at four corner portions of the shadow mask; B3 is a length of a bridge as a distance between holes at edge portions of the shadow mask in a direction of a long axis thereof; P1 is a vertical pitch of the holes at the center portion of the shadow mask; P2 is a vertical pitch of the holes at the four corner portions of the shadow mask; and P3 is a vertical pitch of the holes at the edge portions of the shadow mask in a direction of a long axis thereof.

Owner:LG PHILIPS DISPLAY KOREA CO LTD

A four-link silo arch breaking system, arch breaking method and application

ActiveCN111301877BGuaranteed reliabilityPrevent backflowLarge containersDrive by wireClassical mechanics

The invention belongs to the technical field of material conveying equipment, and discloses a four-link type silo arch breaking system, an arch breaking method and its application. One arc-shaped plate swings around its hinge point with the silo; at the same time, the adjustable pull rod at the lower end of the first arc-shaped plate drives the second arc-shaped plate to swing around its hinge point with the silo; the material begins to fall, and the arching phenomenon is eliminated ;During the falling process of the material in the second stage, the material will completely fill the existing cavity. When the material acts on the anti-overflow plates on both sides, the anti-overflow plates respectively surround the hinge points of the first arc-shaped plate and the second arc-shaped plate. Swing to free up part of the space; the drive rod of the linear drive device is retracted to drive the swing arm and the first arc-shaped plate to swing around the hinge point between it and the silo, and start to reset. The breaker of the invention can quickly complete the arch breaking of granular materials, powdery materials and wet sticky materials with high moisture content.

Owner:陕西省农业机械研究所有限公司

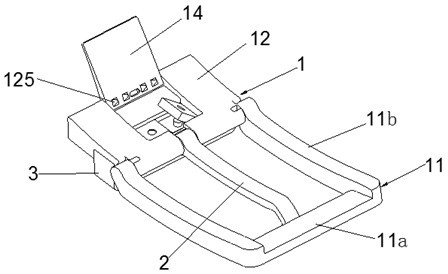

A single-sided floating fixture for plowing furrows on slabs

InactiveCN102773735BFasten the connectionHigh precisionPositioning apparatusMetal-working holdersSpring forceEngineering

The invention discloses a one-sided floating fixture for ploughing a groove on a flat plate. The one-sided floating fixture comprises a base, and a fixed clamp plate, a movable clamp plate, a movable baffle plate and a spring force adjustable mechanism arranged on the upper part of the base, wherein the fixed clamp plate is fixed on the left side of the base; the movable clamp plate and the movable baffle plate are arranged on the right side of the base through dovetail slot guide rails; the movable baffle plate is arranged on the right side of the movable clamp plate; the spring force adjustable mechanism is arranged in the middle of the movable baffle plate through screw threads; and a flat plate to be ploughed is arranged between the fixed clamp plate and the movable clamp plate. According to a one-sided floating clamping method, ploughing-extrusion force exists in a processing process, and a spring is compressed so as to be balanced with the ploughing-extrusion force, so that the movable clamp plate is moved outwards, a one-sided floating fixture mechanism is formed through the spring self-adaptively, clamping force is adjusted, the arch phenomenon generated by ploughing the flat plate is reduced, the processing accuracy is improved, the clamping is simple simultaneously, and the locating is convenient.

Owner:SOUTH CHINA UNIV OF TECH

Rivet-free belt buckle and belt

The invention relates to the technical field of fasteners used in cooperation with belts and the like, in particular to a rivet-free belt buckle and a belt. The belt buckle comprises a buckle pin, a buckle ring and a pin buckle base arranged at the rear end of the buckle ring, the buckle ring and the pin buckle base are connected through a first pin shaft, and the rear end of the buckle ring is rotationally connected with the first pin shaft; the front end of the buckle pin abuts against the upper surface of a front frame of the buckle ring, the lower surface of the front frame is provided with a groove used for a belt body to penetrate through, the rear half portion of the groove is designed to be a fillet, the section structure of a belt hole in a belt using the belt buckle is of a trapezoid structure, and the inclination angle of a trapezoid structure is consistent with the inclination angle of the buckle pin; no rivet or screw structure can be seen from the appearance when the belt is buckled, the simplification of the appearance is facilitated, the arching phenomenon during wearing is reduced when the belt is used, the abrasion of the surface of the belt is reduced, the service life of the belt is prolonged, and the flatness of the belt in the using process is ensured.

Owner:WUXI LUOLIER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com