Burdening device capable of increasing efficiency

An efficient and silo technology, applied in the field of batching devices to improve efficiency, can solve the problems of affecting product quality, easy to form ingredients, and inaccurate discharge, so as to reduce the labor intensity of workers, reduce the phenomenon of arching, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Various preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

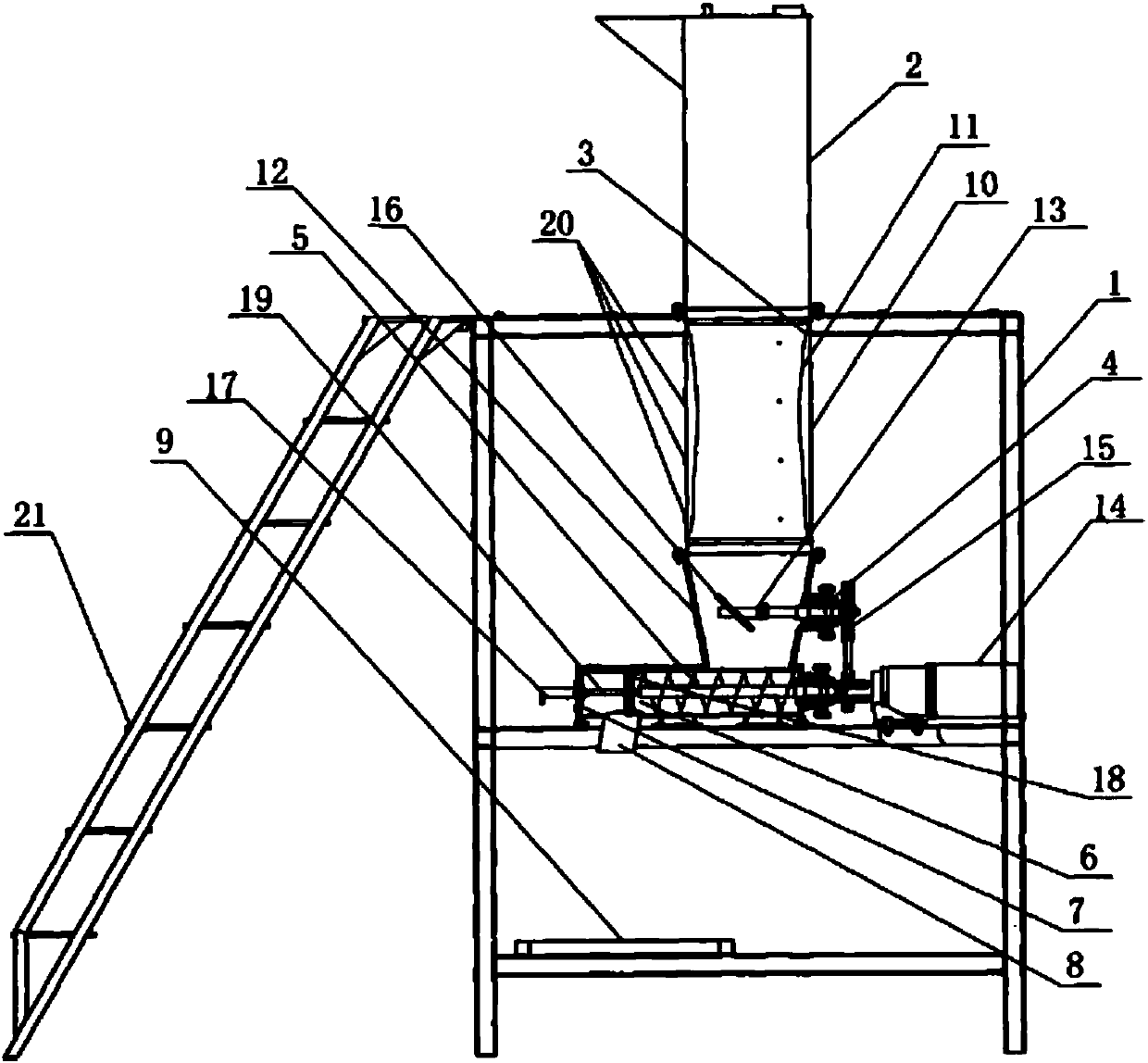

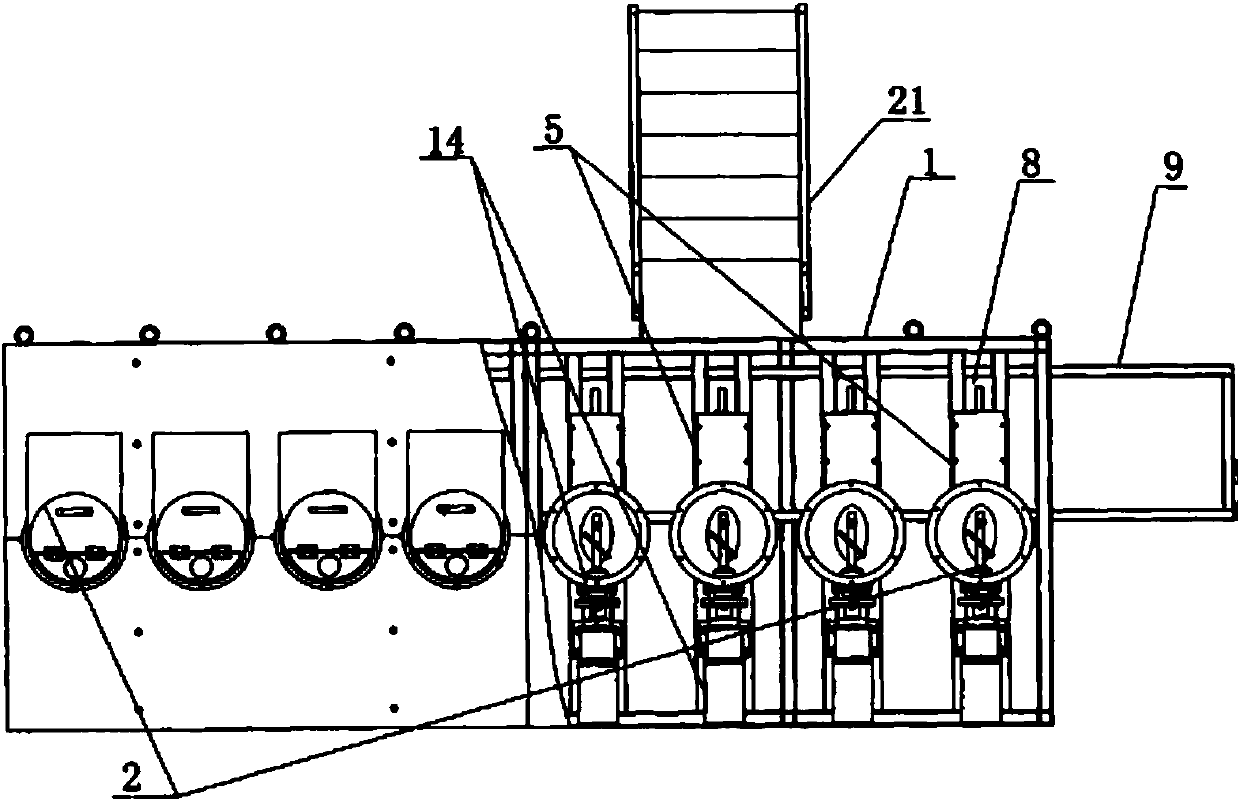

[0015] The invention provides a batching device with improved efficiency, scientifically and rationally improves the feed bin, and sets matching feeding carts on the track under the feed bin, and can configure multi-vehicle batching at one time according to needs, thereby improving production efficiency , The bag-type pneumatic arch breaking structure is used in conjunction with the crushing and mixing structure, which solves the problem of material arching and reduces the degree of material arching. Such as figure 1 As shown, the batching device for improving efficiency includes a frame 1 and a control system for controlling the operation of the batching device for improving efficiency. The frame 1 is provided with at least two rows of bins, and each row of bins includes at least four bins 2 , the middle part of the silo is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com