Rivet-free belt buckle and belt

A belt buckle, rivet-free technology, applied in the direction of belt buckles, fasteners, clothing, etc., can solve the problems of easy wear on the belt surface, unfavorable appearance and influence of the neat appearance of the belt pin buckle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

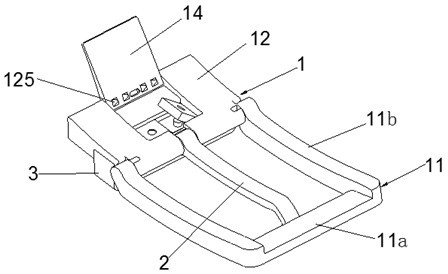

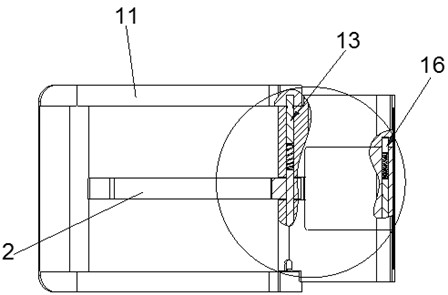

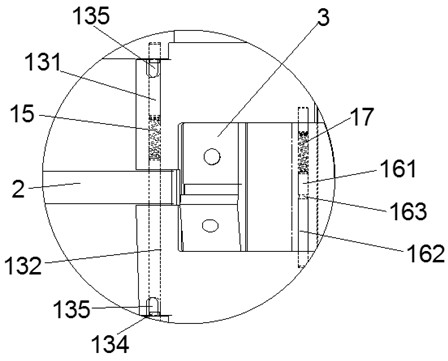

[0029] Such as Figure 1-6 As shown, the present embodiment provides a rivetless belt buckle and a belt, including a buckle head main body 1 and a buckle pin 2, the buckle head main body 1 includes a buckle ring 11 and a pin buckle seat 12, the buckle ring 11 and the pin buckle The buckle seat 12 is connected by the first pin shaft 13, the front end of the needle buckle seat 12 is provided with a gap 121, and the front end of the needle buckle seat 12 is provided with a first through hole passing through the gap 121, and the buckle ring 11 It includes a front frame 11a and two side frames 11b, and a first blind hole is provided on the inner side of the rear end of the two side frames 11b, and the first pin shaft 13 is passed through the first blind hole and the first through hole. , the rear end of the pin 11 is arranged at the notch 121 to be rotatably connected to the first pin shaft 13, and the front end of the pin 2 abuts against the upper surface of the front frame 11a. ...

Embodiment 2

[0040] Such as Figure 7-8 As shown, the present embodiment provides a belt, including a belt body and the above-mentioned belt buckle, the belt body includes a belt free end and a belt fixed end, and the belt fixed end is inserted into the slot 124, through the protrusion 125 Clamp the fixed end of the belt, and the free end of the belt is provided with a plurality of belt holes 21 for the pin 2 to pass through. The section of the belt hole 21 is a trapezoidal structure. When the belt is in normal use, the inclined surface of the trapezoidal structure The inclination angle of the belt is consistent with the inclination angle of the pin buckle 21, and this structural design reduces the arching phenomenon of the belt when worn.

[0041] Among them, such as figure 1 As shown, the lower surface of the front frame 11a of the buckle 11 is the channel through which the free end of the belt passes, and it is designed as a groove structure, which limits the vertical sliding of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com