Mute wood floor

A wood floor, mute technology, applied in the field of flooring, can solve the problems of noise pollution, damage to the board, difficult positioning, etc., to increase the buffer performance, prevent displacement, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

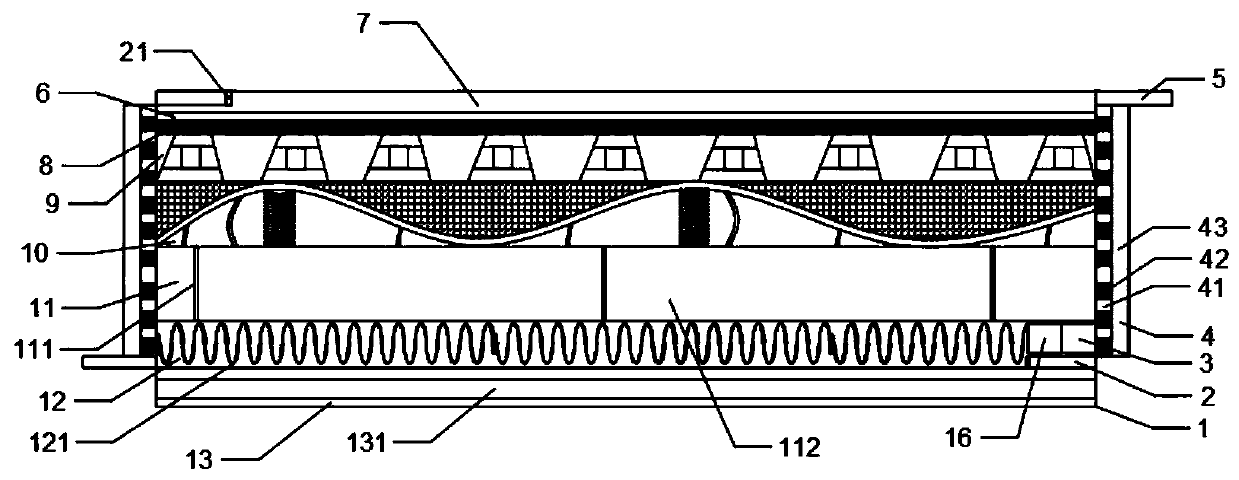

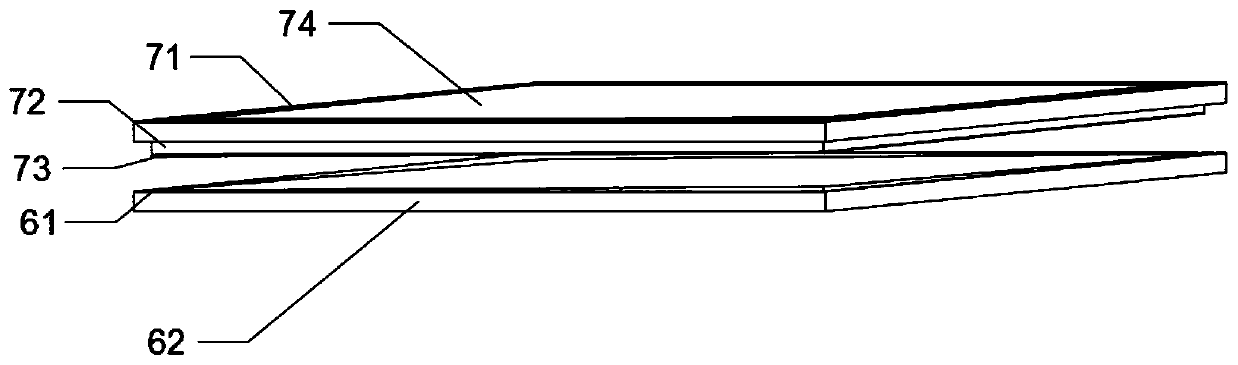

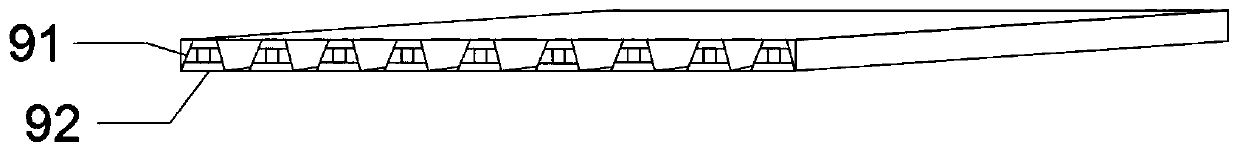

[0022] like Figure 1-Figure 5 As shown, the silent wooden floor provided by this embodiment includes a base 1 and a decorative layer 7 installed inside the base 1 from top to bottom, a thermal insulation layer 6, a waterproof and breathable layer 8, a first sound-absorbing chamber 9, and a second sound-absorbing chamber 10. Solid wood layer 11, dry layer 12 and positioning layer 13. A buffer layer 4 is installed at both ends of the substrate 1 respectively. The buffer layer 4 includes a buffer cavity 41 and a rubber block 43 installed on one side of the buffer cavity 41. The buffer cavity 41 The inside is provided with a plurality of evenly distributed buffer spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com