Soldering flux melting injection device and preparation method and preparation equipment of flux-cored welding rod

A technology of injection device and flux-cored electrode, which is applied in welding equipment, metal processing equipment, welding medium, etc., and can solve problems such as physical health damage of production personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The flux-cored electrode 8 includes a flux 802 and a brazing sheath 801 wrapped outside the flux 802. The brazing flux 802 is usually powder or particles including various metals. The manufacturing process of the brazing sheath 801 is usually first made of copper, silver, The alloy ingot melted by zinc according to a certain ratio, after the alloy ingot is rough-turned to remove the scale and annealed, the alloy ingot is extruded into a brazing sheet strip by a horizontal extruder, and then the brazing sheet strip is multiplied. The second rolling forms a brazing filler metal strip, which can be used as the brazing filler metal sheath 801 of the flux cored electrode 8 .

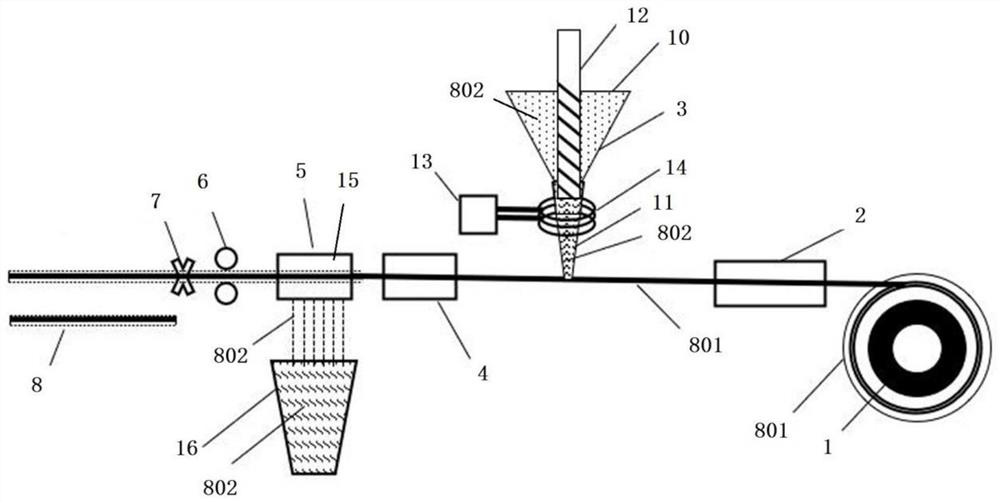

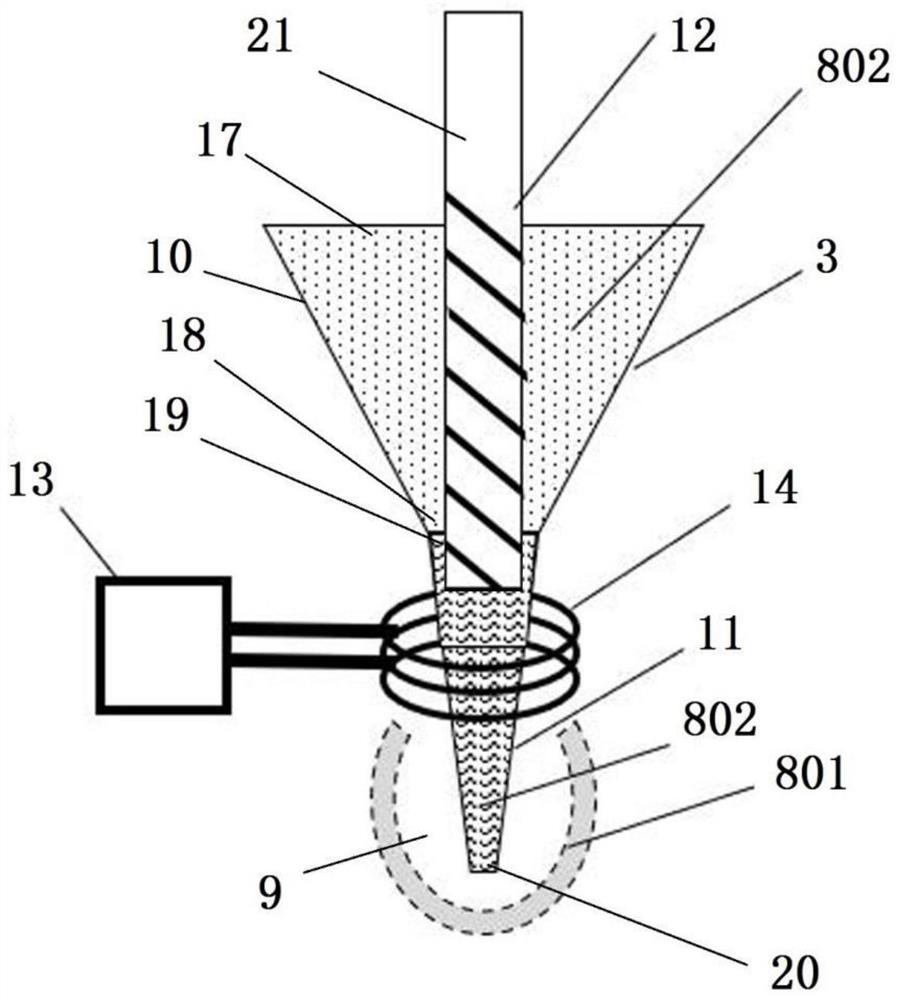

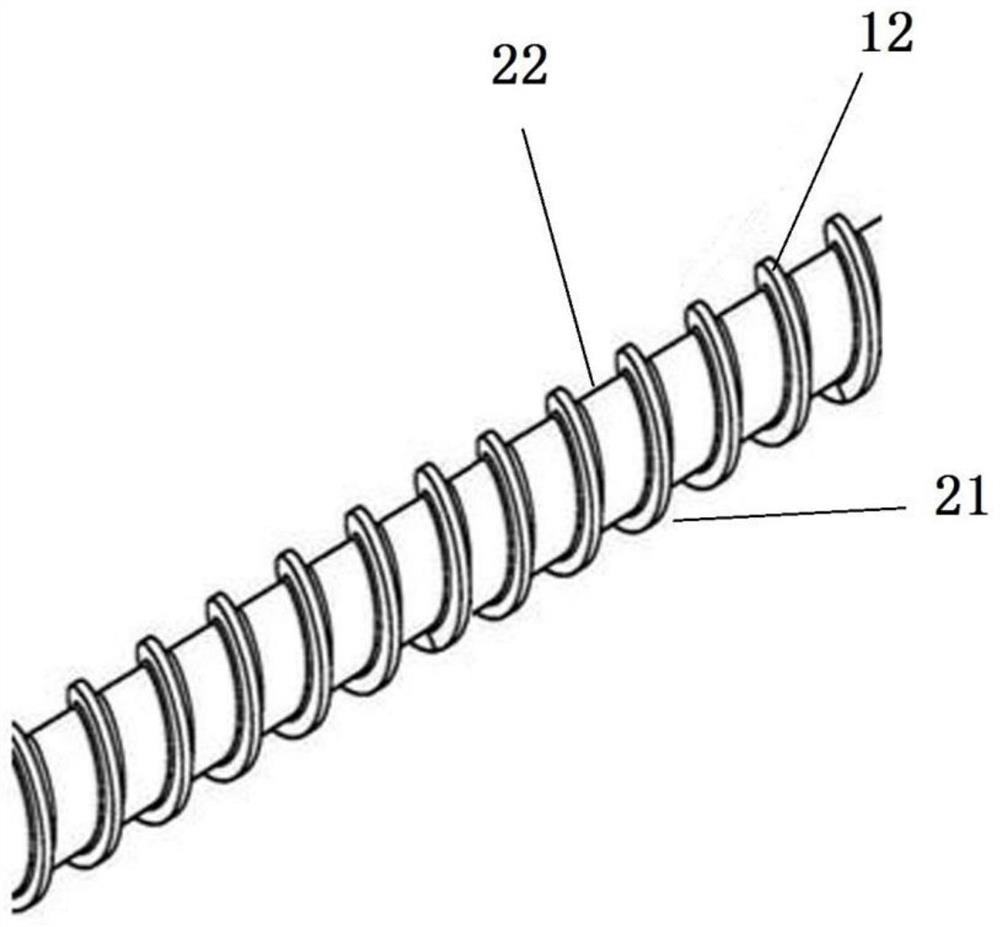

[0055] After preparing the solder sheath 801 of the flux-cored electrode 8 and the brazing flux 802, it can be used as Figure 1 to Figure 3 The shown flux-cored electrode preparation equipment prepares a flux-cored electrode 8, and the flux-cored electrode preparation equipment includes an unwinding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com