Patents

Literature

37results about How to "Material realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

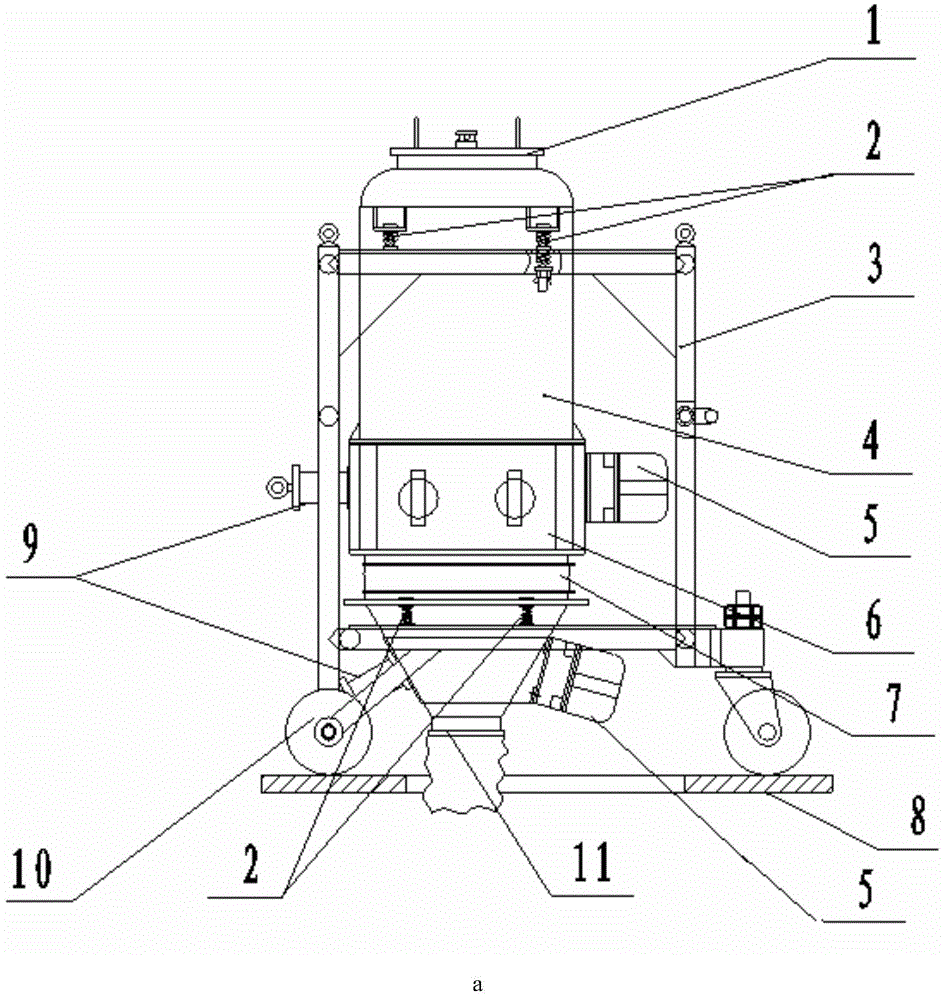

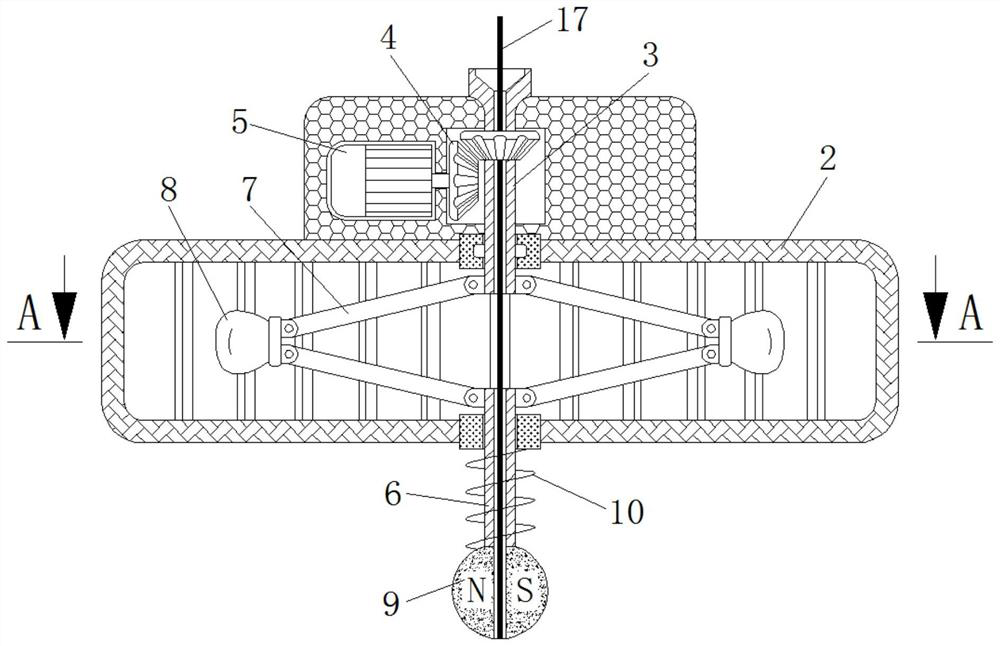

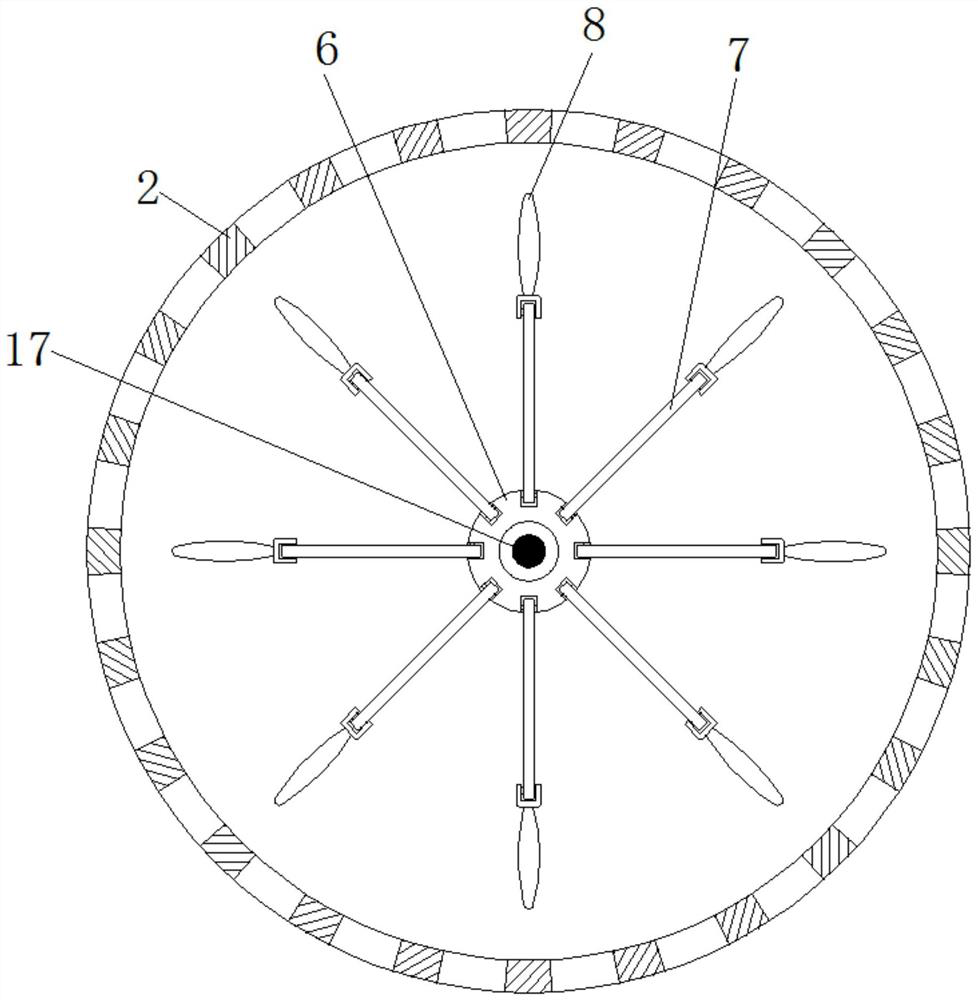

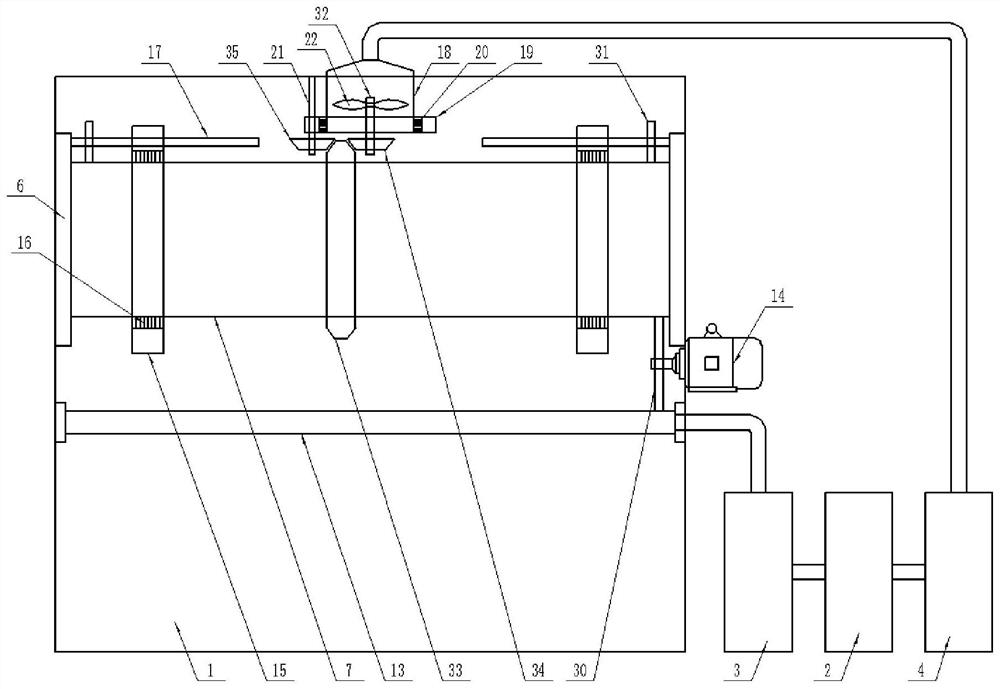

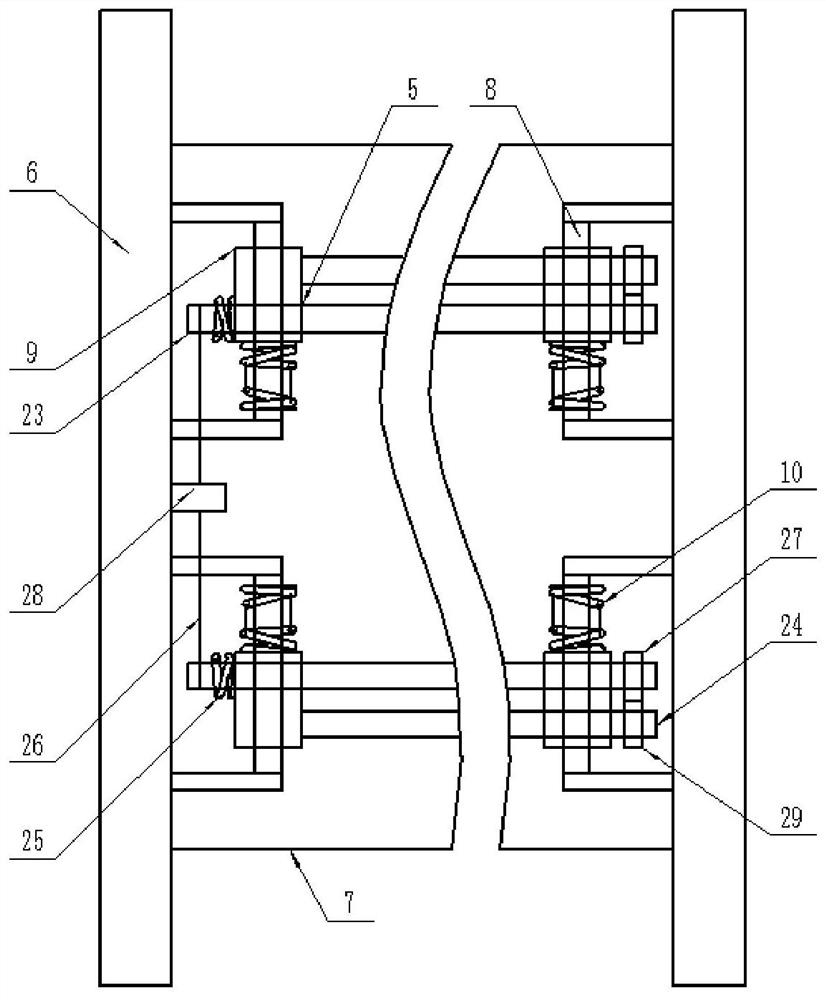

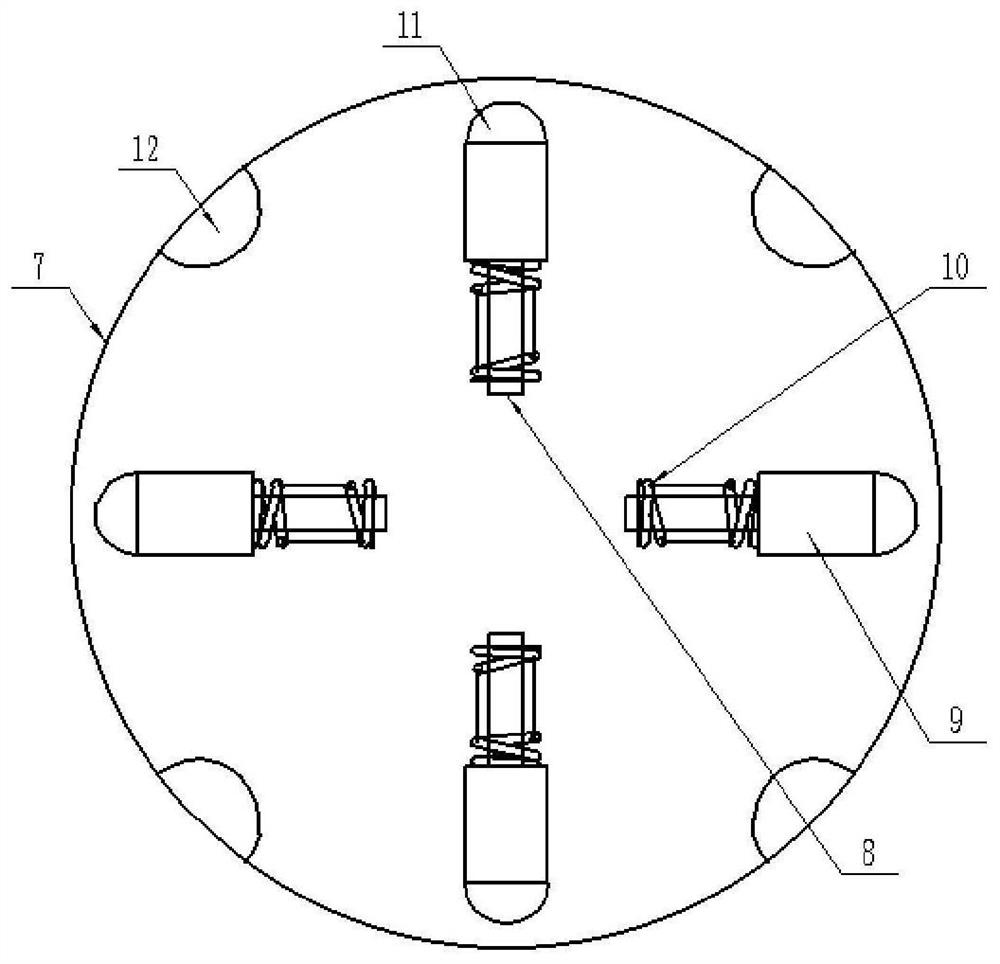

Building rubbish recycling device for rubbish recycling

InactiveCN107824596AEasy dischargeEasy to recycleSievingConstruction waste recoveryLitterConstruction waste

The invention relates to a recycling device, in particular to a building rubbish recycling device for rubbish recycling. The technical problem to be solved by the invention is to provide the buildingrubbish recycling device for rubbish recycling, which is capable of recycling different building rubbish thoroughly. In order to solve the technical problem, the building rubbish recycling device forrubbish recycling, provided by the invention, comprises an installing frame and the like, wherein a discharging mechanism is arranged on the installing frame and is connected to a charging tank; a magnetism absorbing mechanism is arranged at the upper part of the installing frame; and the lower part of the magnetism absorbing mechanism is located in the charging tank. The building rubbish recycling device for rubbish recycling has the beneficial effects that the arrangement of the discharging mechanism can facilitate the discharging of the charging tank; the arrangement of the magnetism absorbing mechanism can realize the recycling of waste metal in building rubbish; and the arrangement of an installing tank and a filter screen can facilitate the recycling of finely broken soil and stones.

Owner:饶胜智

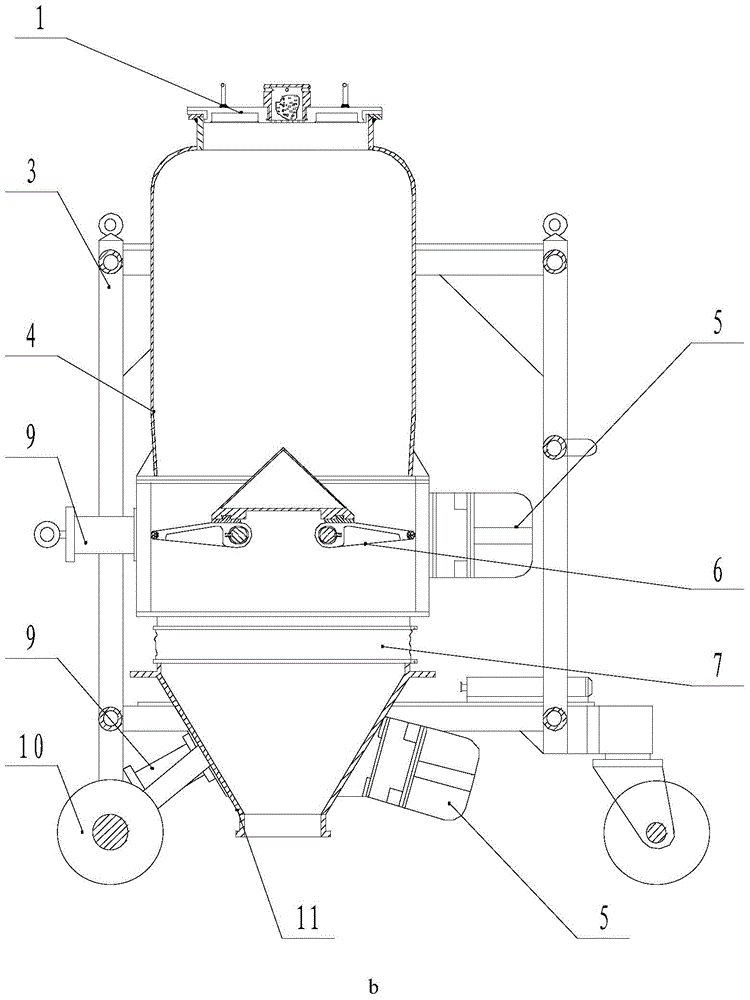

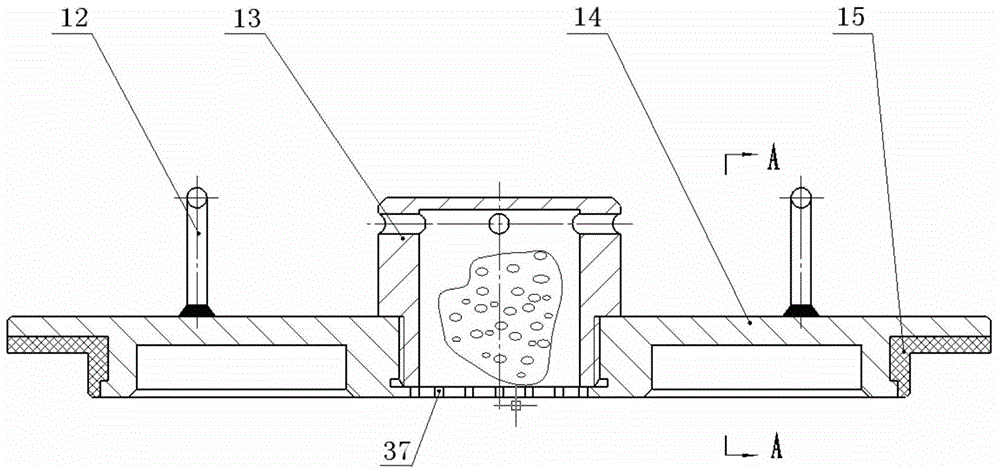

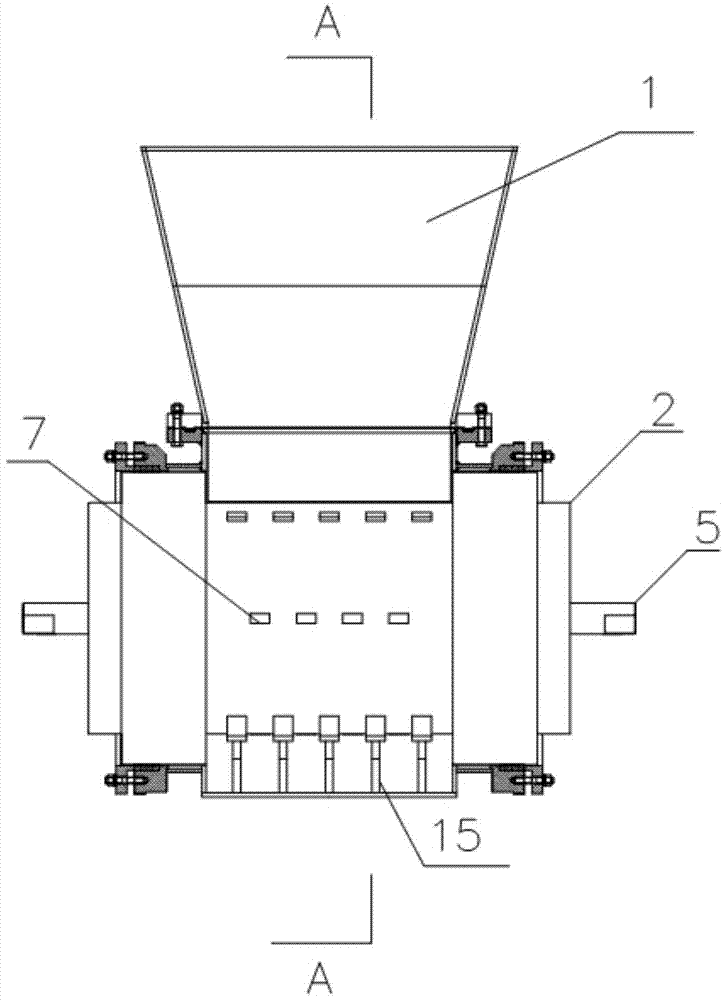

Powder storage device with quantitative discharging function

ActiveCN104309956APrevent blocking phenomenonUniform feedingLarge containersMechanical engineeringEngineering

The invention relates to a powder storage device with a quantitative discharging function. The powder storage device is characterized in that a material containing barrel is mounted on an upper cross beam of a frame through a flexible connector; a quantitative discharging device is fixedly arranged below the material containing barrel; a discharging hopper is fixedly arranged below the quantitative discharging device; a dustproof cover is arranged on the discharging hopper in a sleeving way; the number of explosion-proof electromagnetic vibrators is two, the two explosion-proof electromagnetic vibrators are respectively mounted on a supporting base of the quantitative discharging device and a connecting base of the discharging hopper; the number of air hammers is two, one of the air hammers is mounted on the supporting base of the quantitative discharging device, and the other air hammer is mounted on a connecting plate of the discharging hopper. The powder storage device has the benefits that the powder storage device can be used for automatic quantitative discharging, transportation and storage of a lot of power stored; through the design of the structure and the adjustment of the vibration frequency of the explosion-proof electromagnetic vibrators, the arching and agglomeration phenomenon of the powder in the blanking process can be greatly reduced, so that smooth blanking is ensured; the power quantitative discharging is realized through real-time monitoring of power weight in the discharging process.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

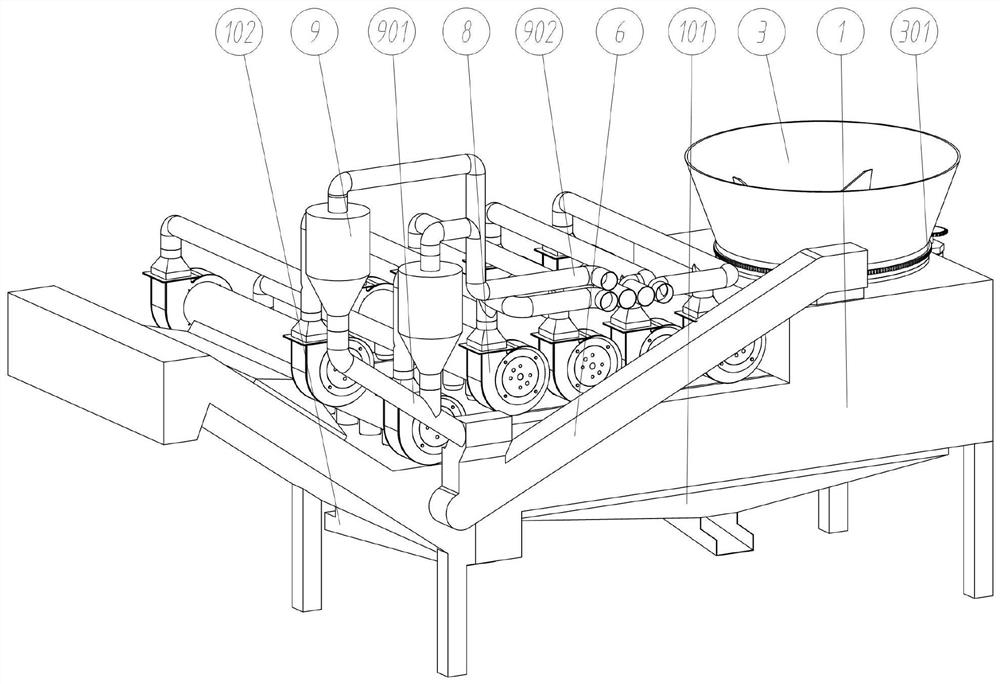

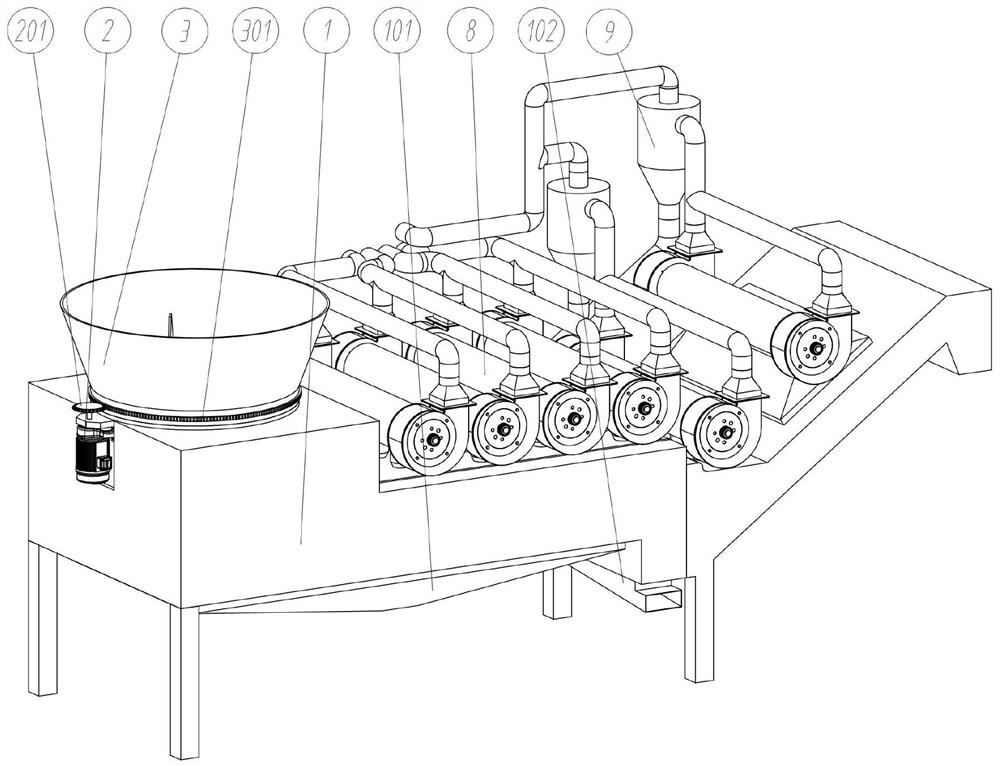

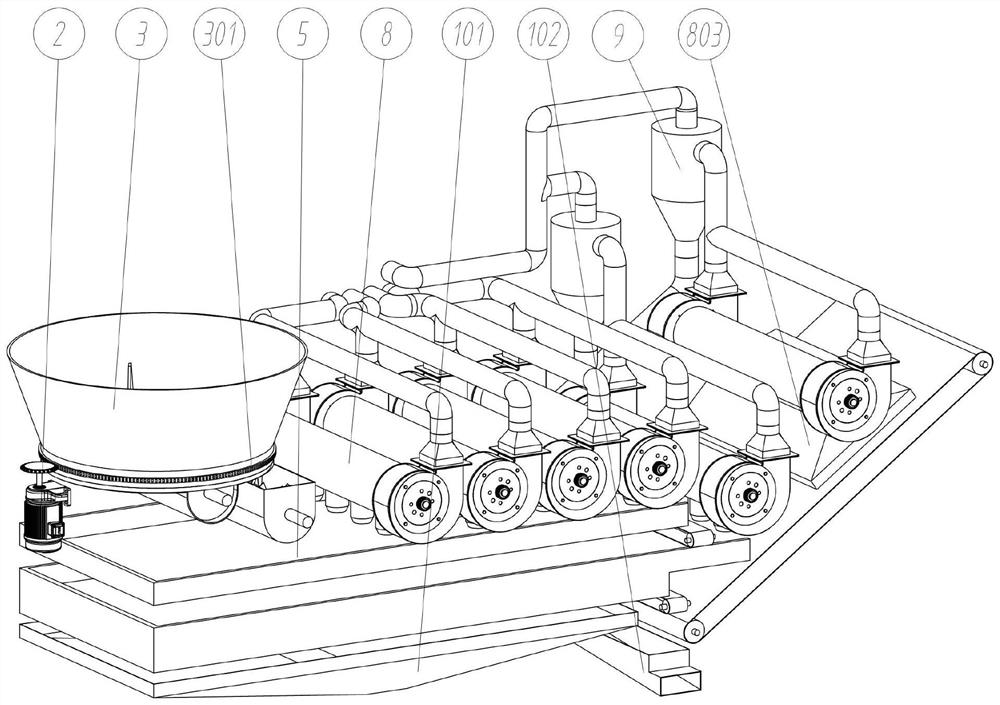

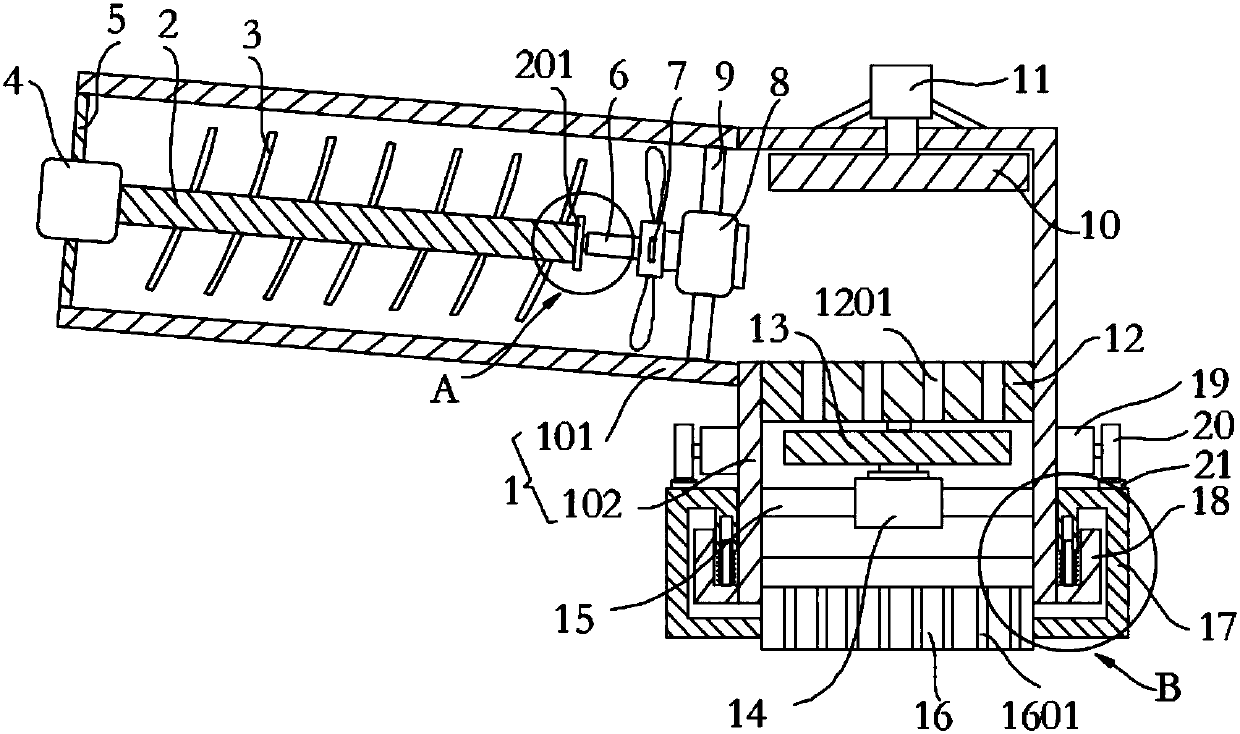

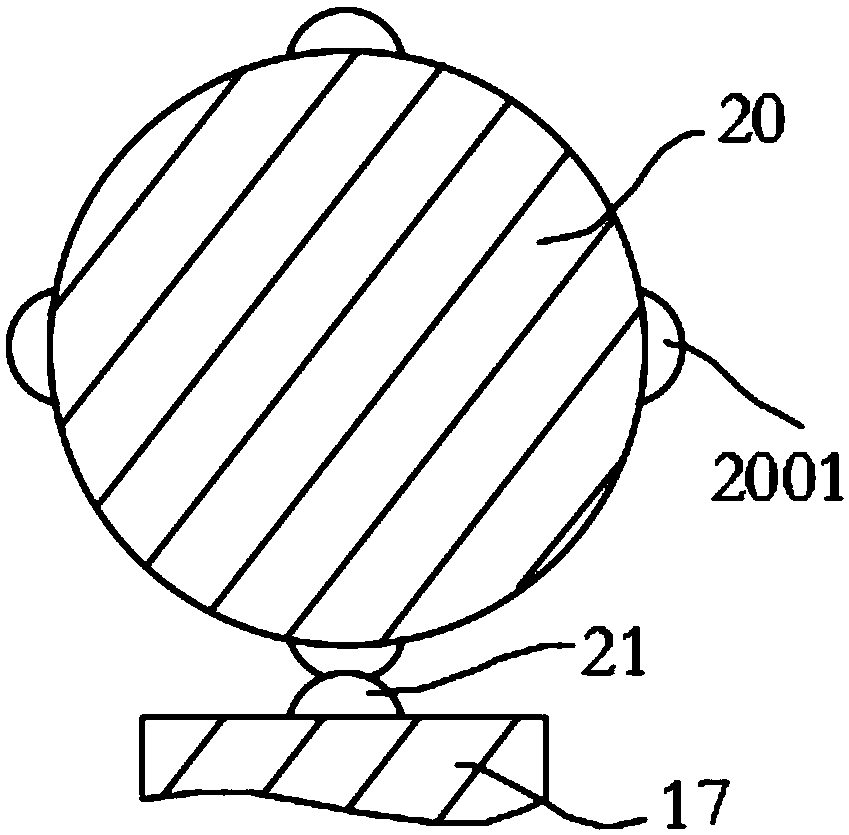

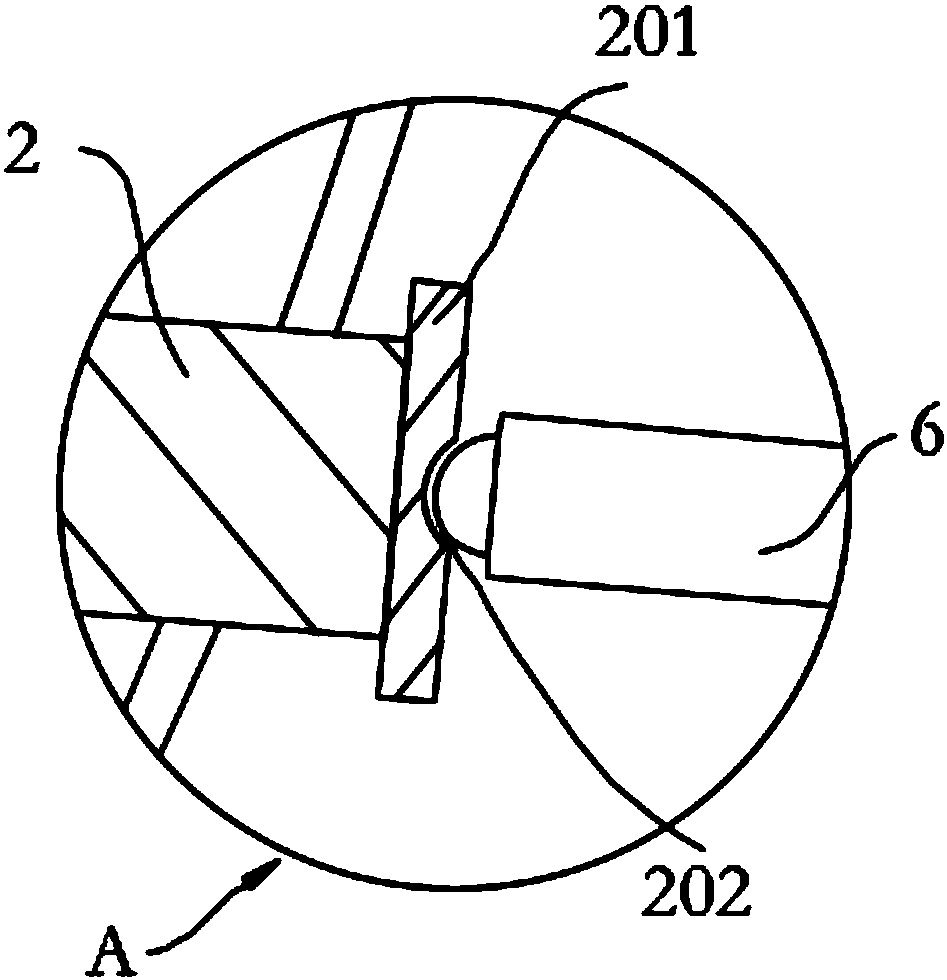

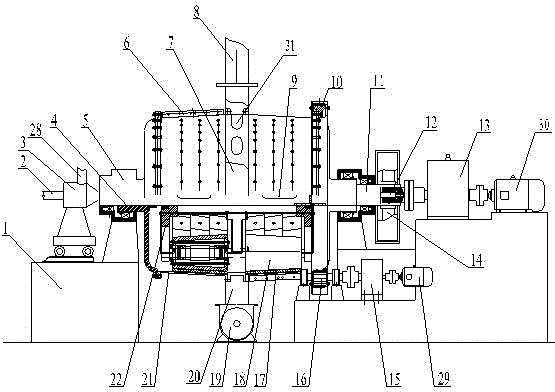

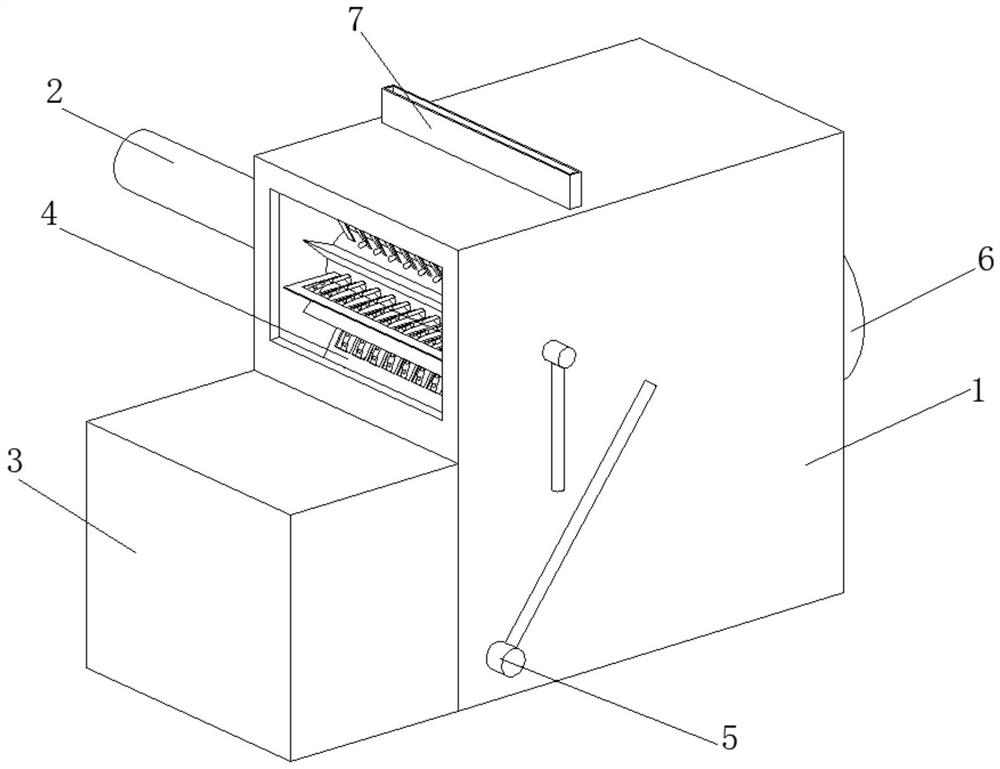

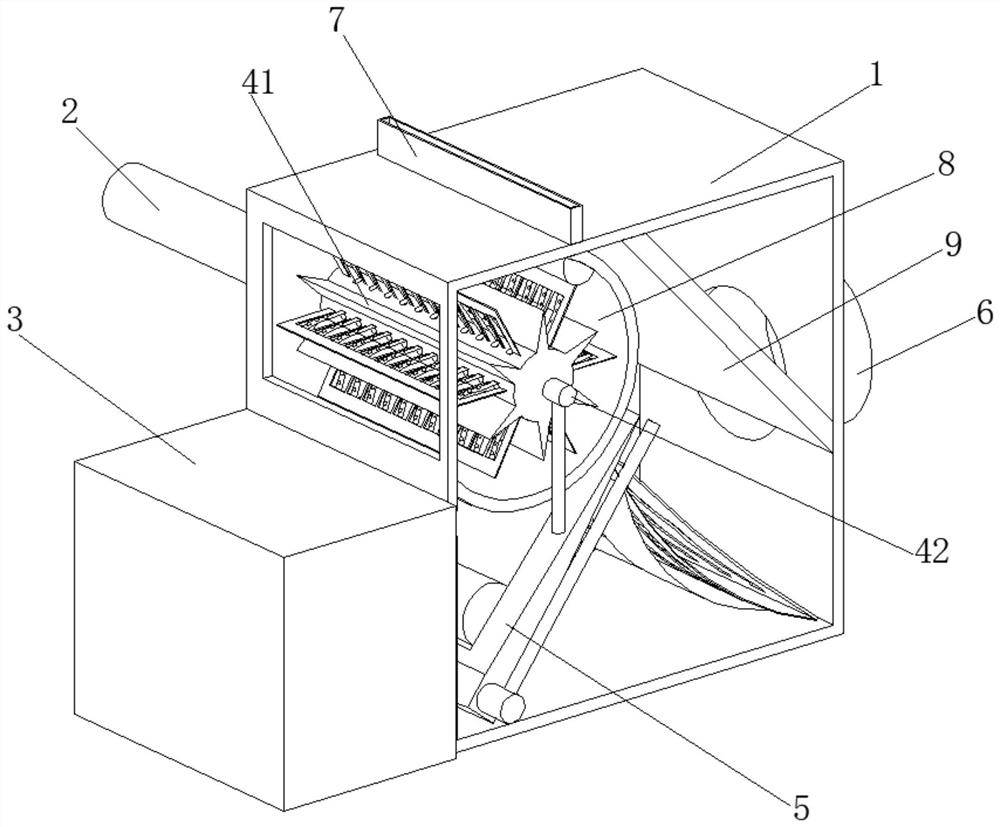

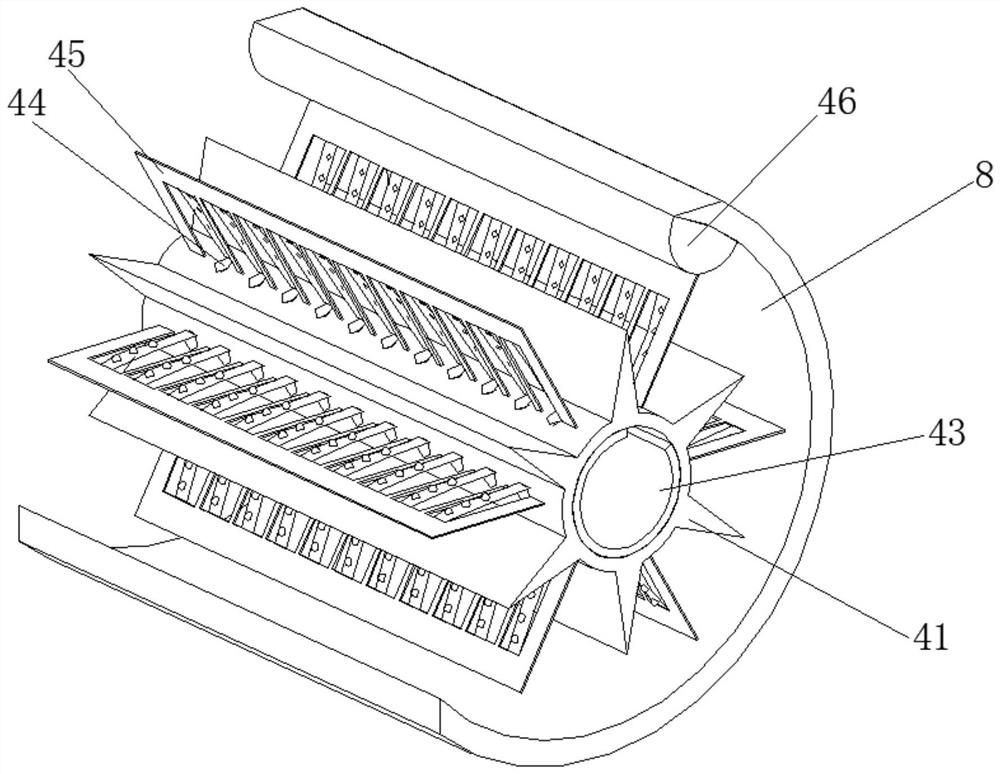

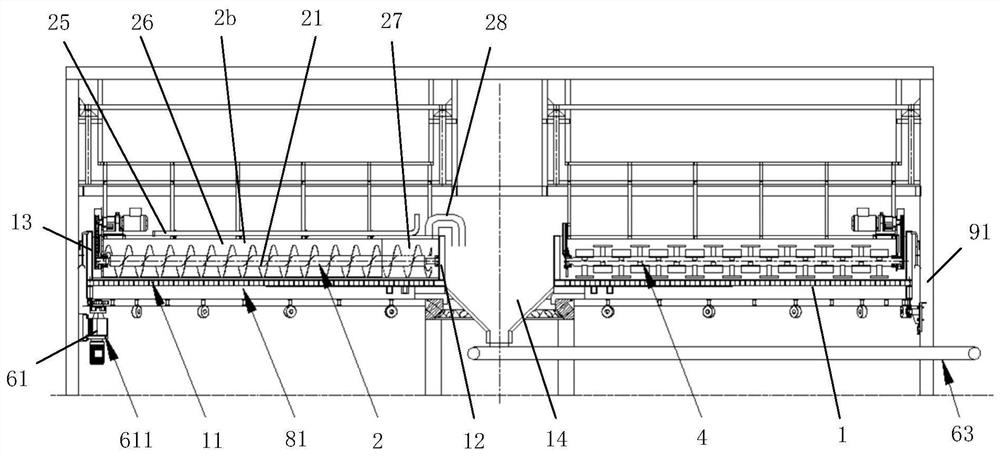

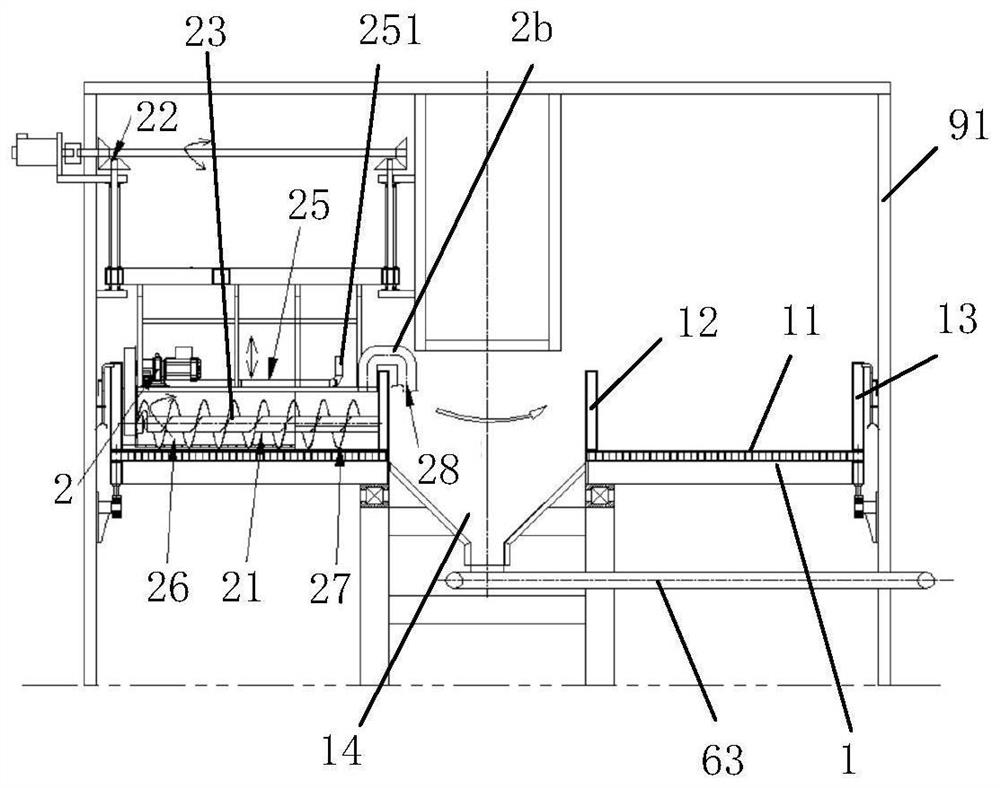

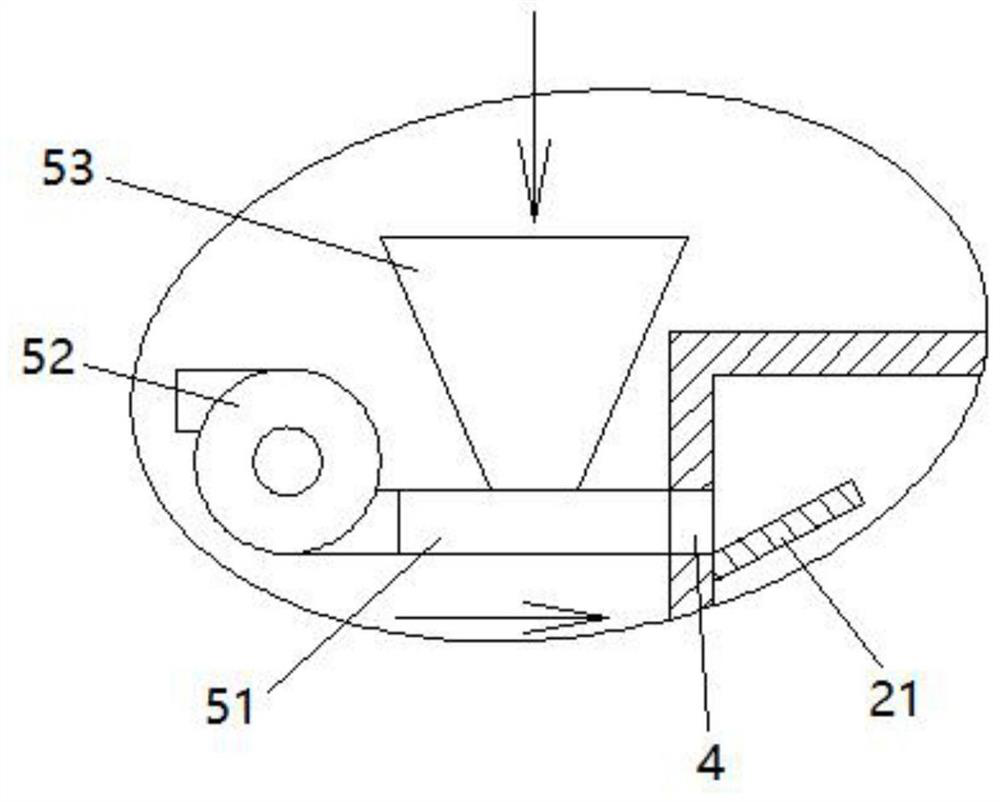

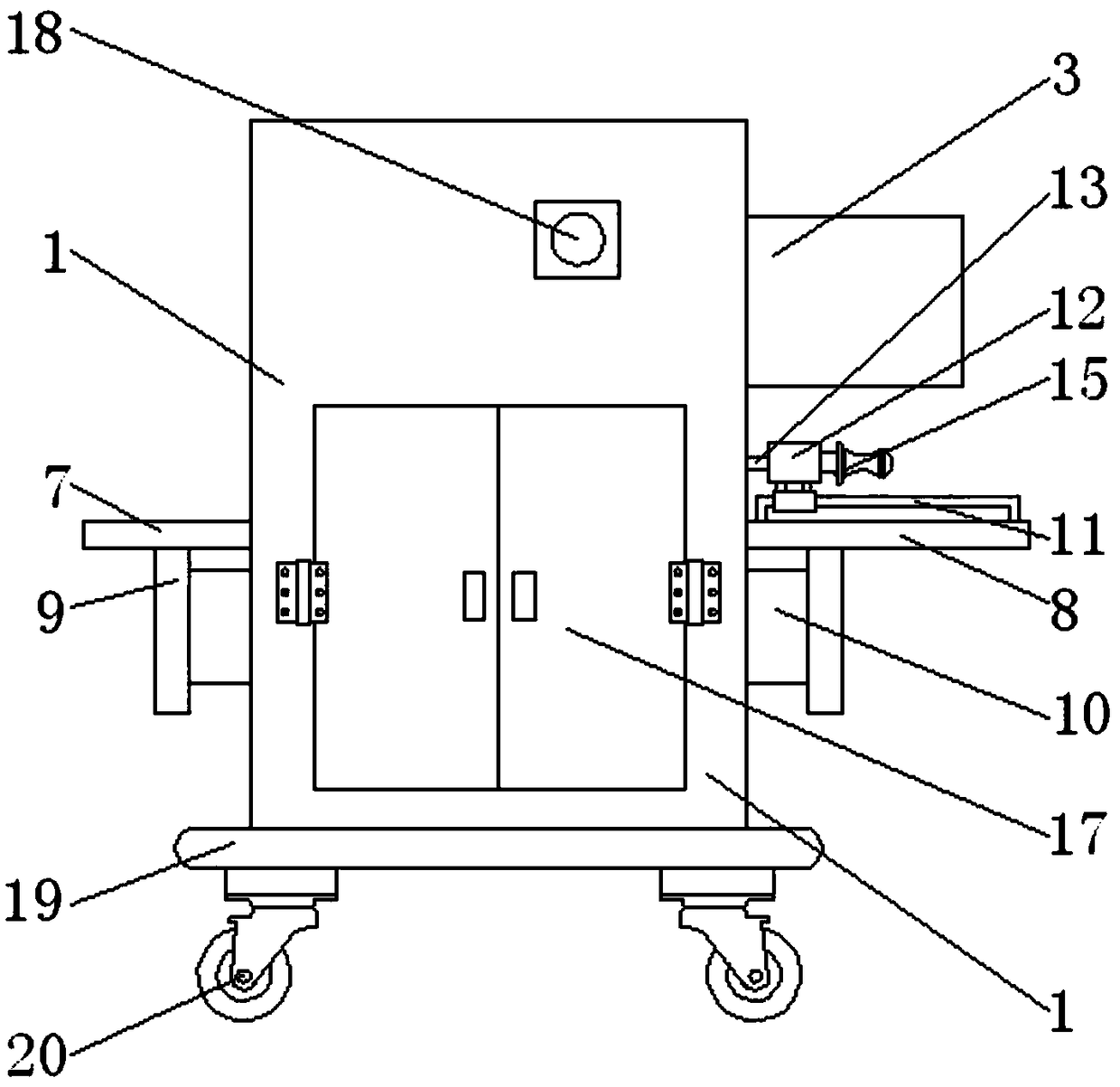

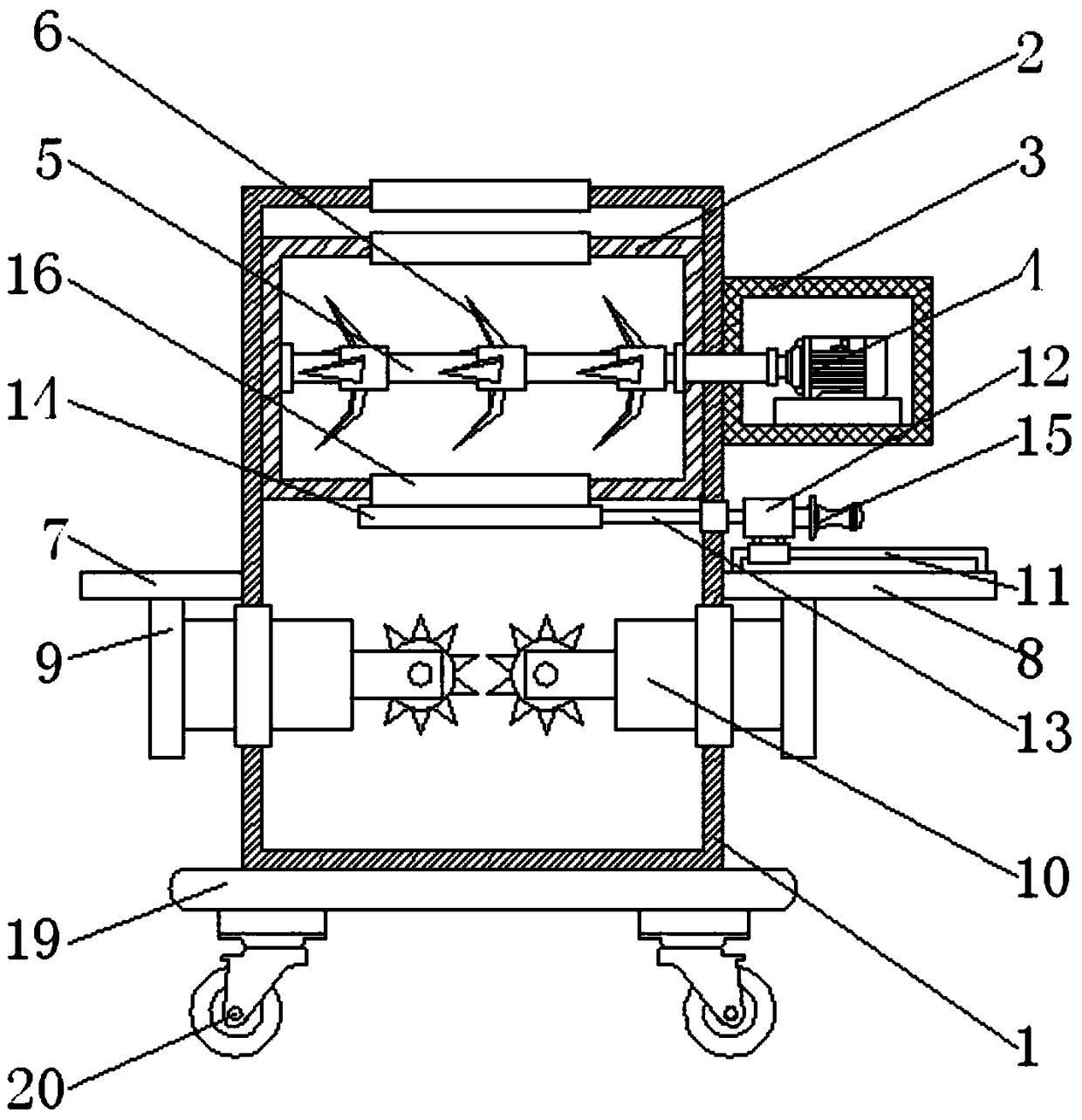

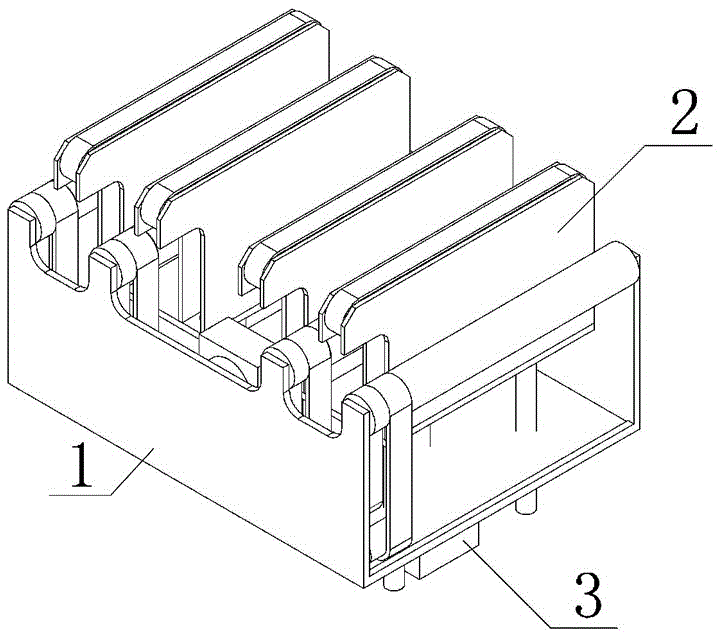

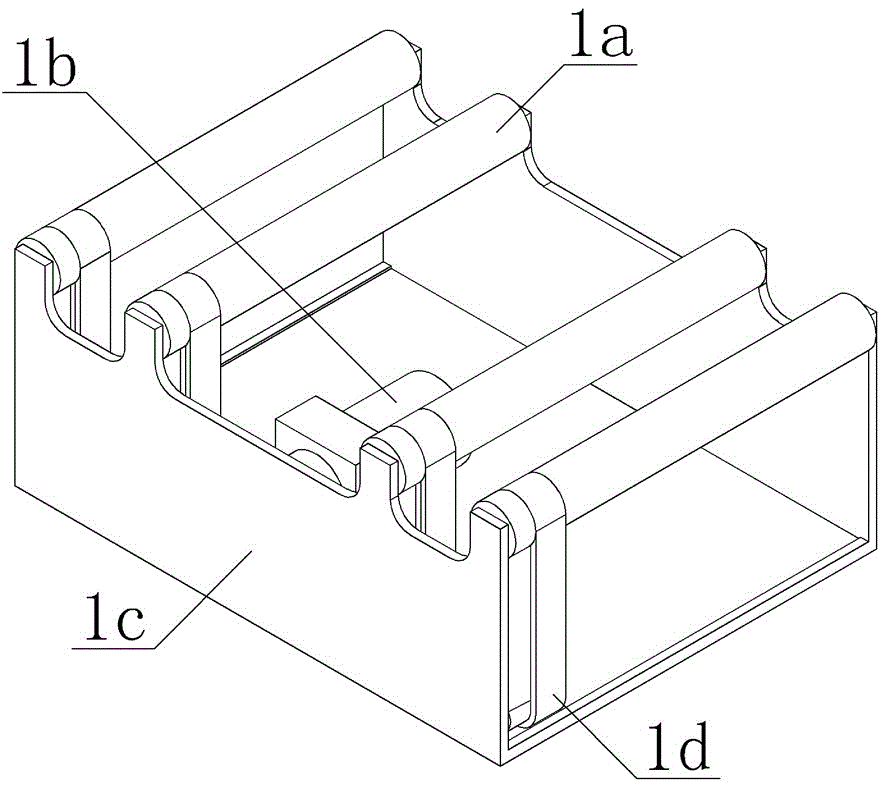

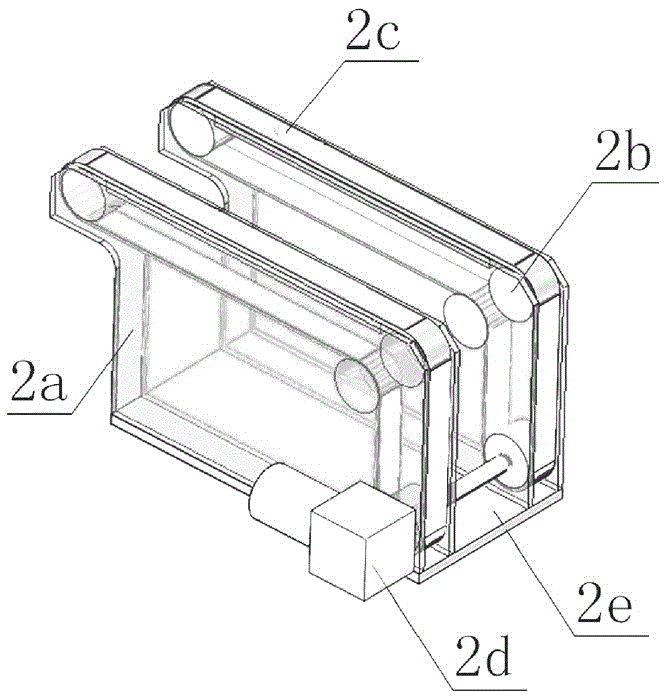

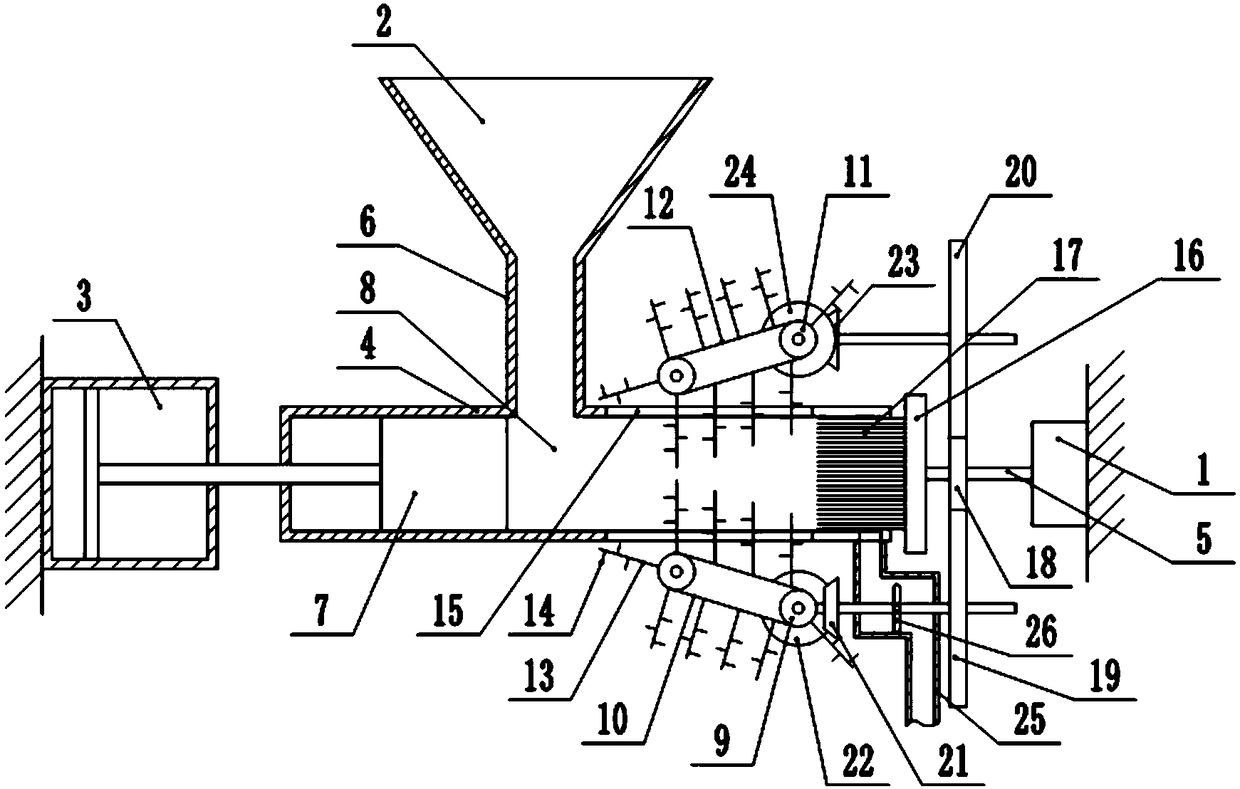

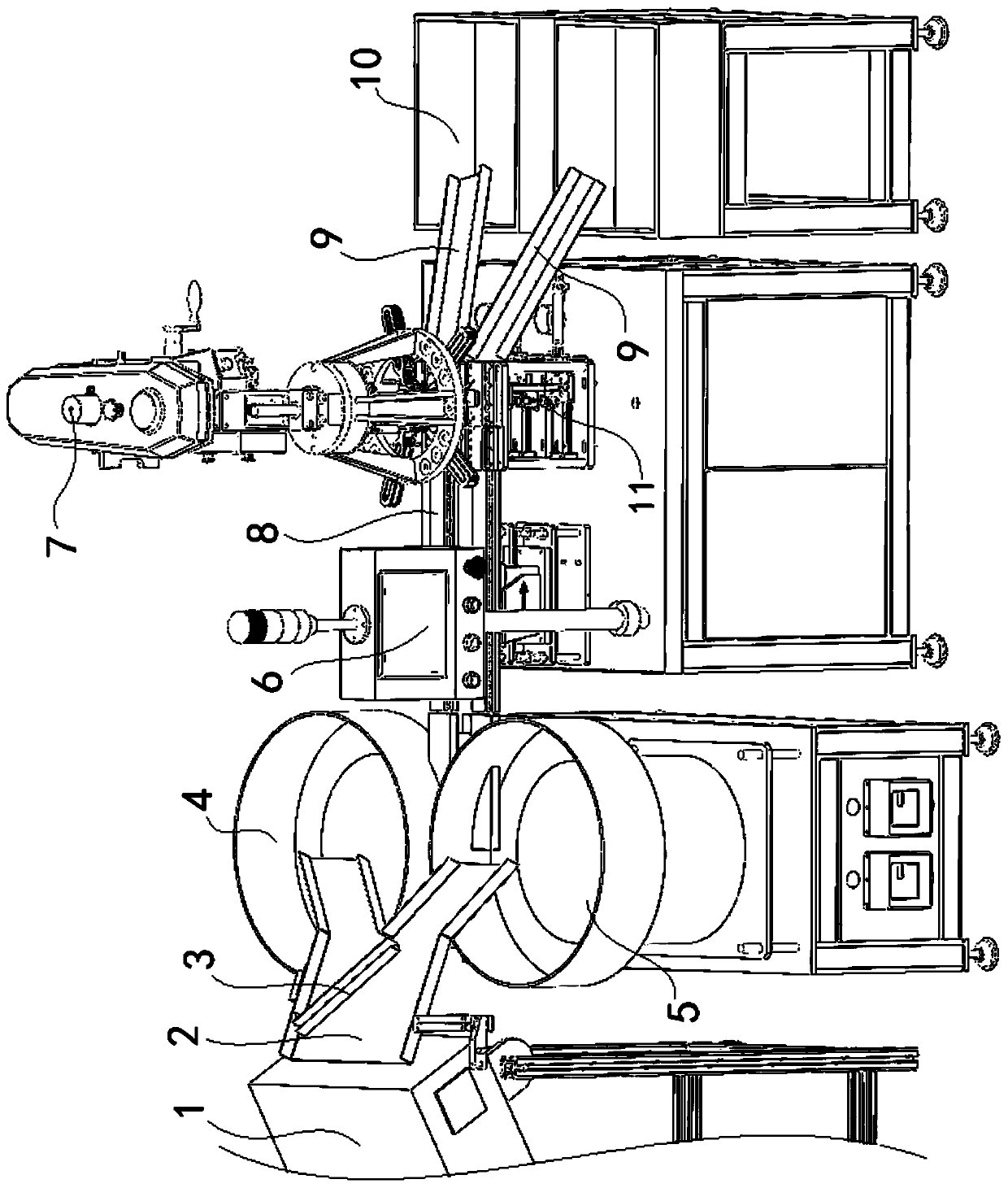

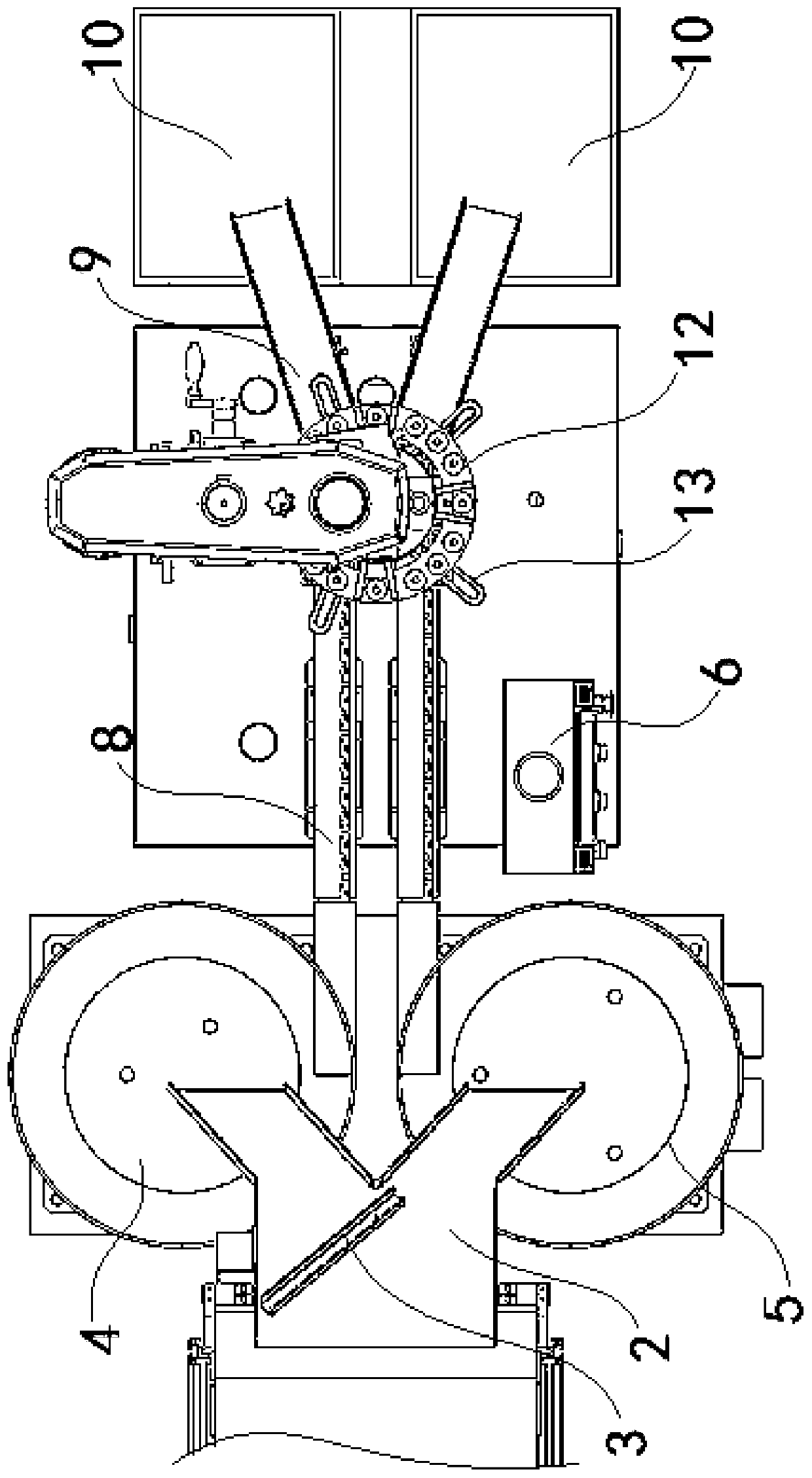

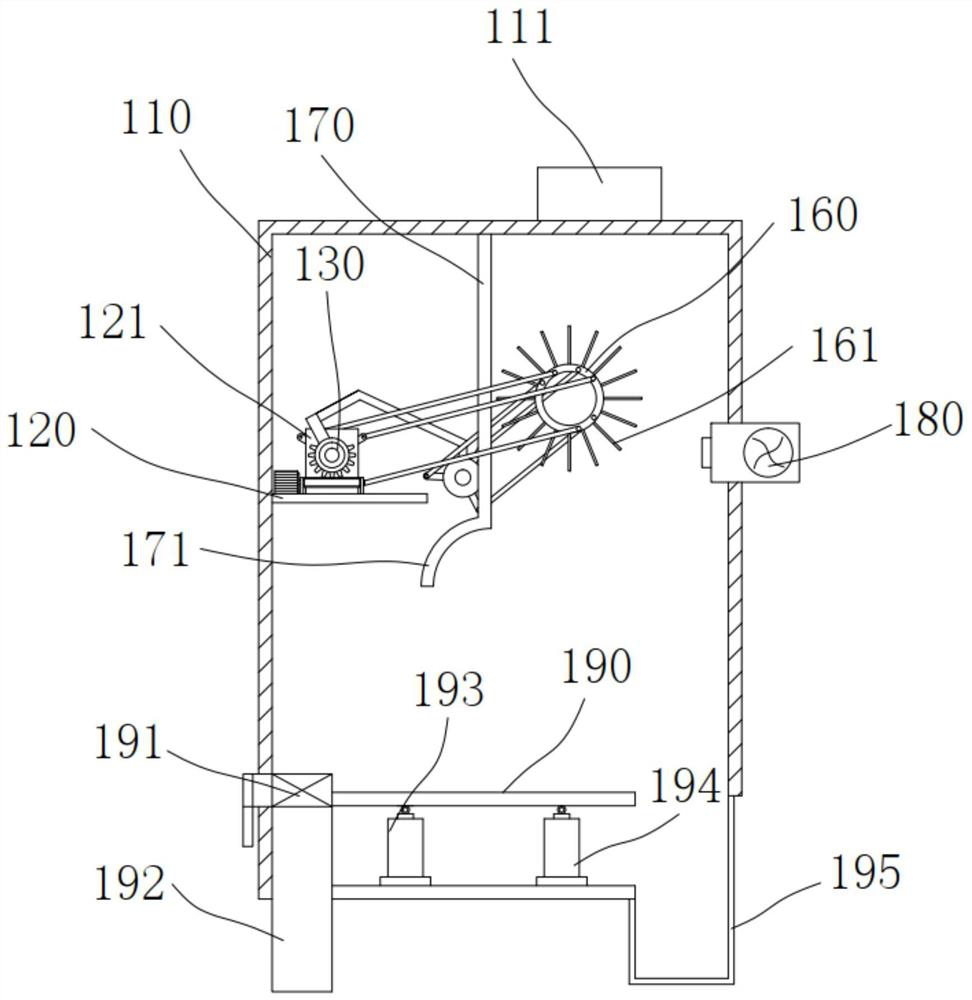

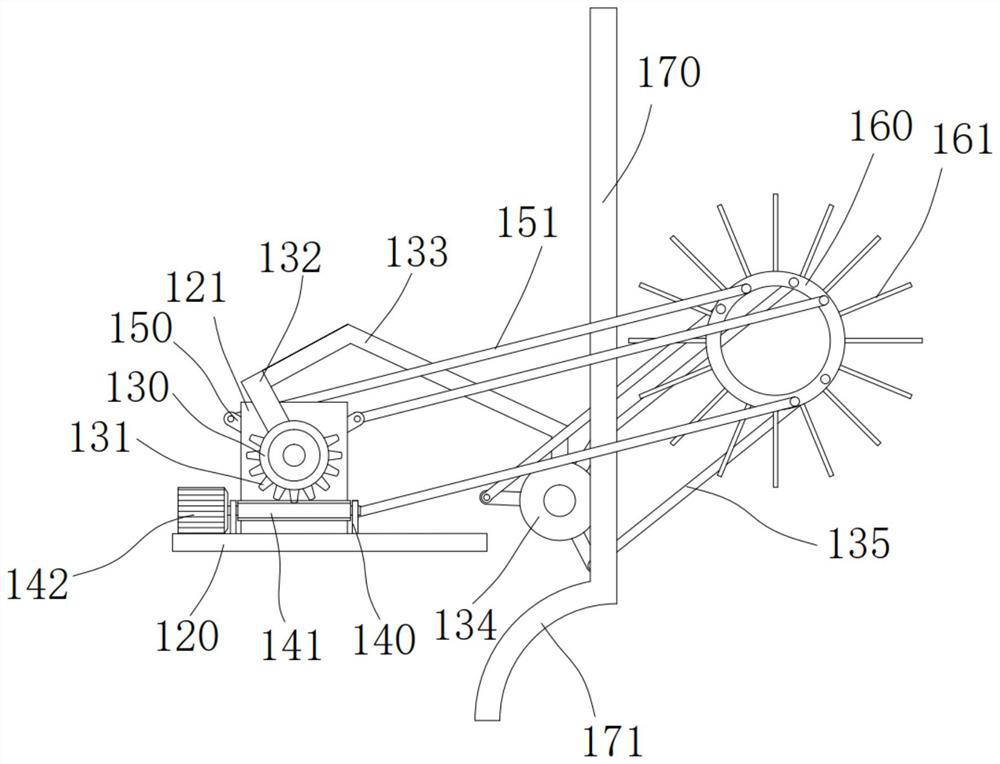

Intelligent-control peanut vine film-removing rubbing and cutting machine with automatic feeding function

ActiveCN113439554AAvoid stockpilingAchieve separationGas current separationFood processingAgricultural scienceFeed drive

The invention discloses an intelligent-control peanut vine film-removing and rubbing and cutting machine with an automatic feeding function, relates to the technical field of feed processing, and solves the problems that an existing film-removing rubbing and cutting machine is poor in screening effect, effective screening is difficult to carry out during rough kneading-cutting, meanwhile, fine materials are easily discharged along with dust, waste is caused, meanwhile, peanuts in peanut vines cannot be recovered and waste is caused. The intelligent-control peanut vine film-removing and rubbing and cutting machine comprises a rubbing and cutting machine body and a feeding system, wherein the feeding system is arranged on the right side of the rubbing and cutting machine body, the feeding system is composed of a feeding driving part and a disc type feeding part, the feeding driving part is fixedly connected to the right side of the rubbing and cutting machine body, and the disc type feeding part is rotationally connected to the top of the right side of the rubbing and cutting machine body. Material accumulation is effectively avoided, meanwhile, multi-stage screening is achieved, the film removing effect is good, the film content in finished products is reduced, the product quality is improved, meanwhile, peanuts can be recycled, the income is greatly increased, and good economic benefits are achieved.

Owner:日照市福勇智能装备有限公司

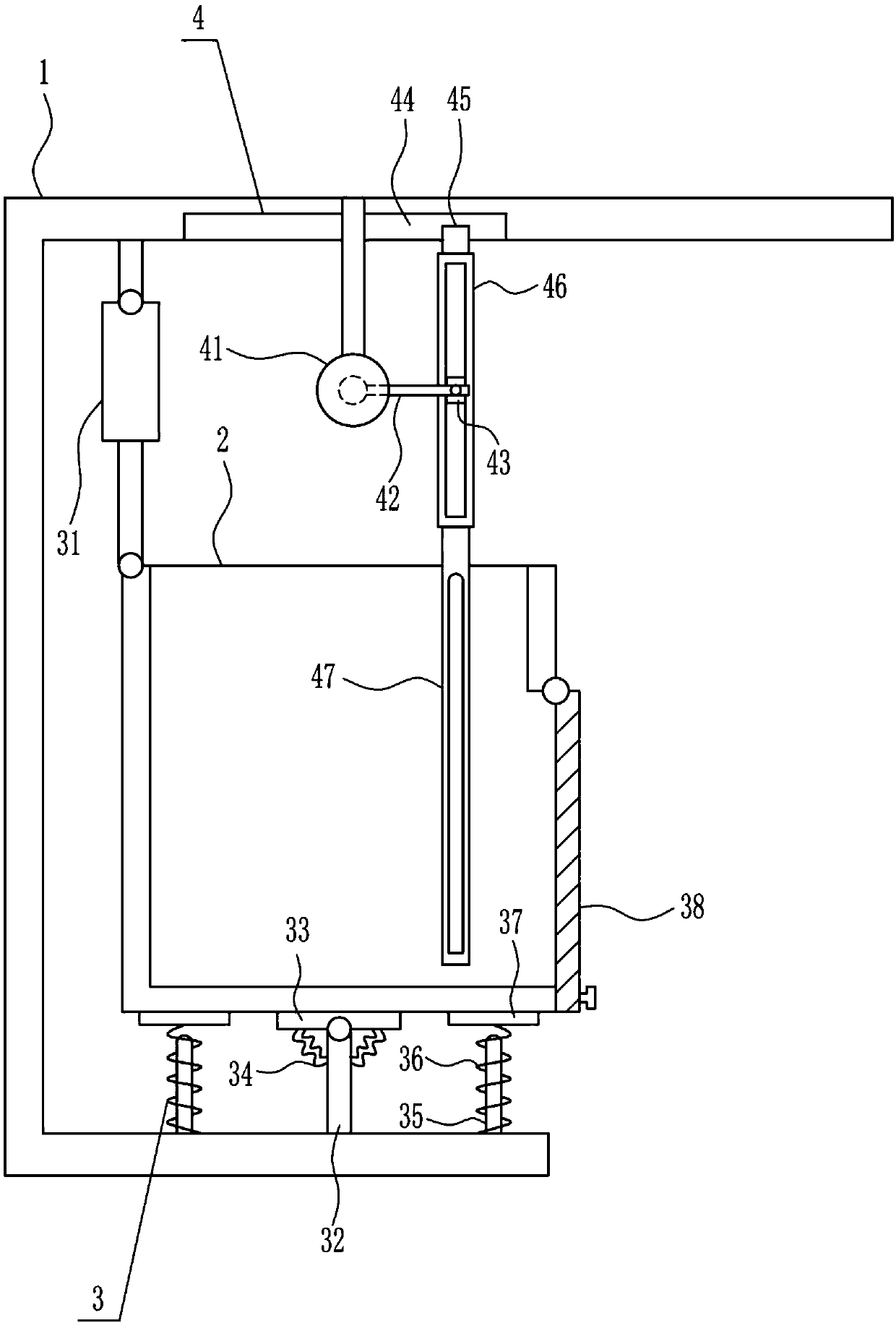

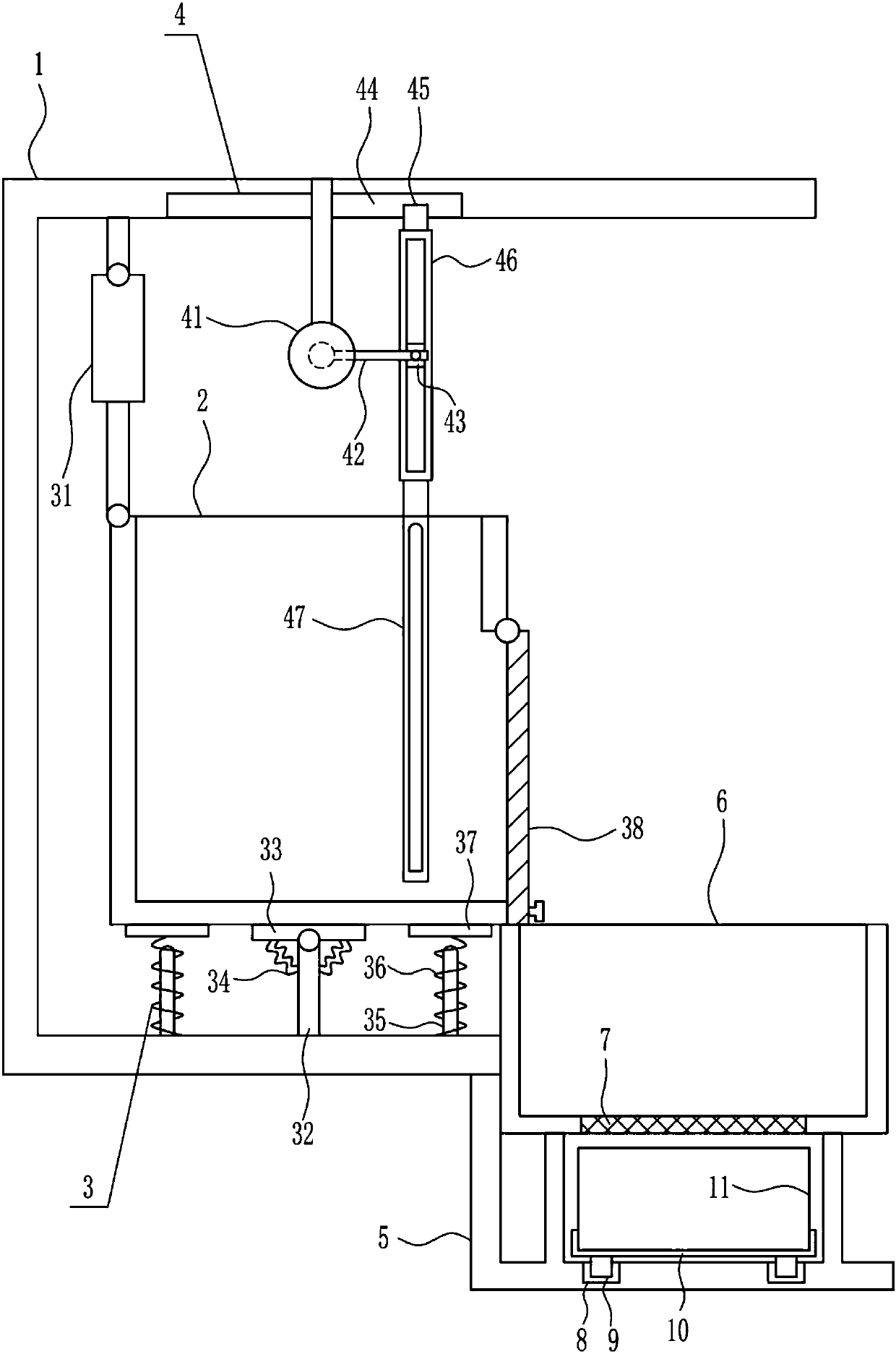

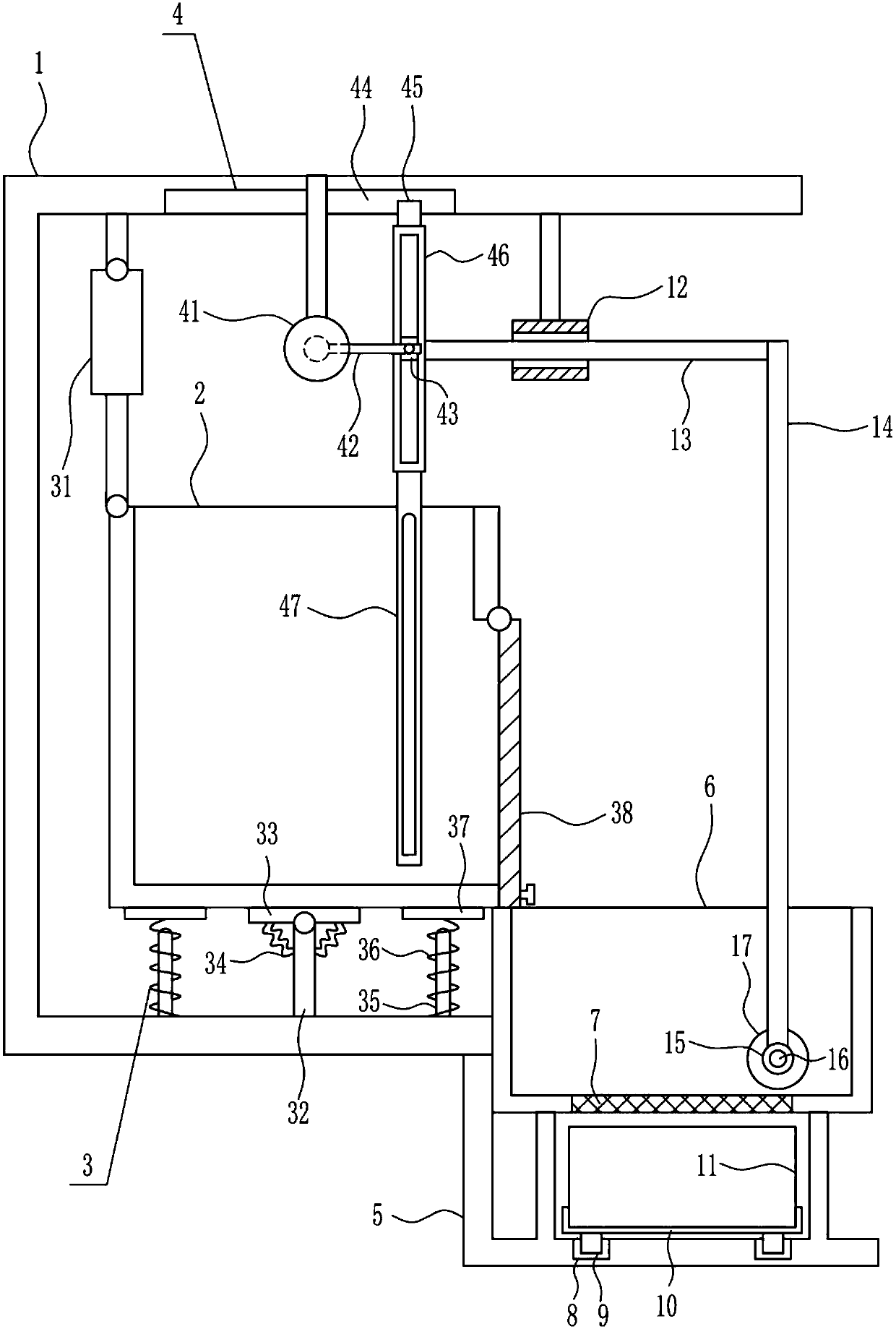

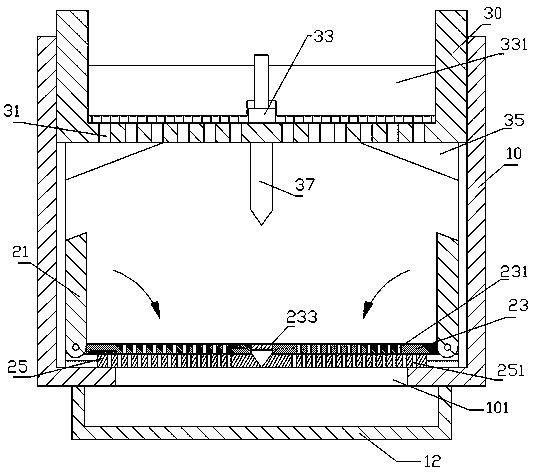

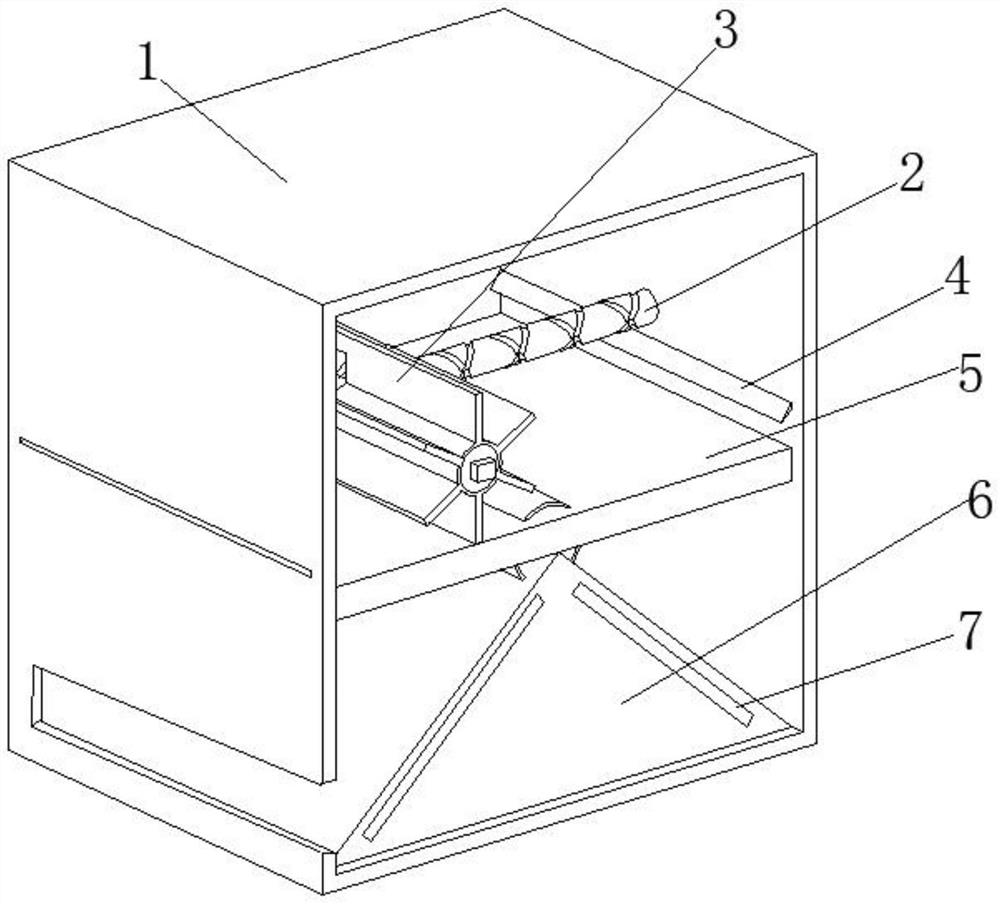

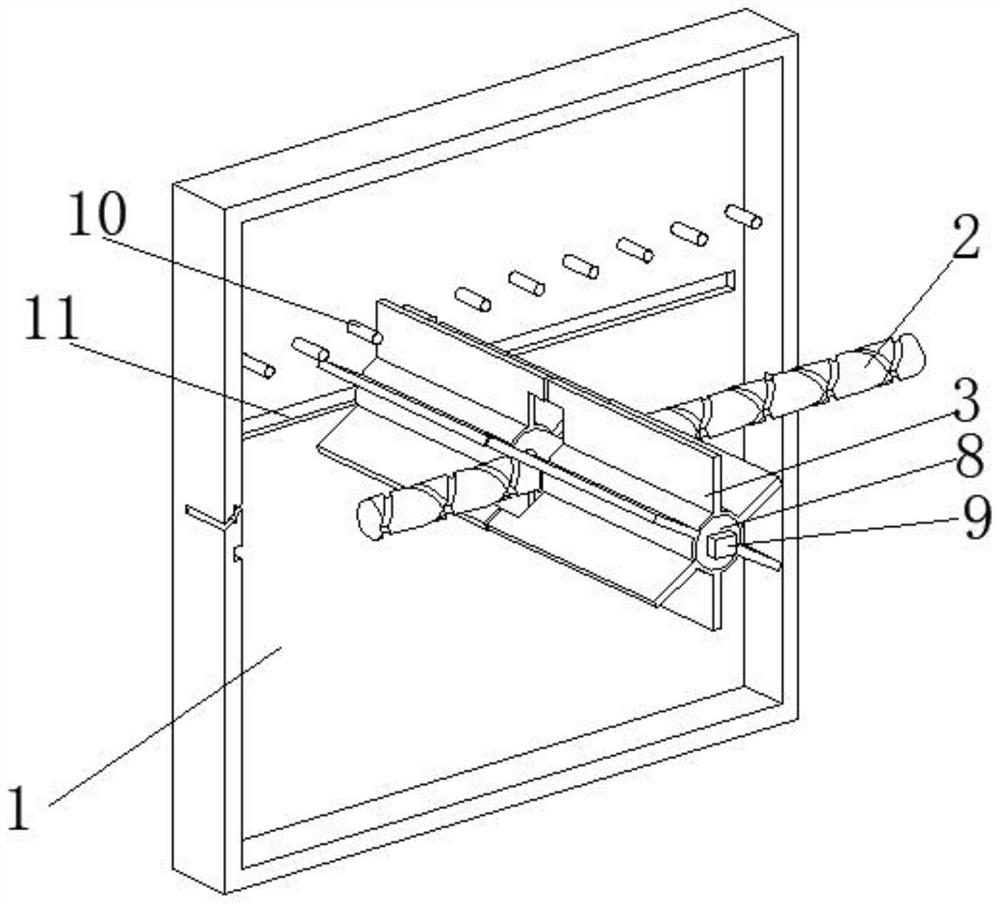

Automatic discharging device for building material forming equipment

InactiveCN107930787AGuaranteed stabilityMaterial realizationSievingScreeningMolding machineEngineering

The invention provides an automatic discharging device for building material forming equipment. The automatic discharging device comprises discharging hoppers. A first motor is connected to the position of an opening of the first discharging hopper through a fixing rod, the drive end of the first motor is fixedly connected with a feeding rotating shaft, and the feeding rotating shaft is fixedly provided with spiral feeding disks. A second motor is fixed to the position of a discharge port in the inner end of the first discharging hopper through a connection rod, the drive end of the second motor is fixedly provided with a shredding cutter disk, the lower end in the second discharging hopper is fixedly provided with an upper abrasive disk, the upper abrasive disk is vertically provided witha plurality of discharge holes in a penetration manner, and a material sieving disk is movably inserted into the position of an opening of the second discharging hopper. According to the automatic discharging device, the rotating spiral feeding disks are used for conveying materials to the inner end of the first discharging hopper, the second motor drives the shredding cutter disk to rotate at ahigh speed so that smashing treatment can be carried out on the materials, the materials are further ground through grinding cutters on the top face of a lower abrasive disk, sieving is carried out through the material sieving disk which vibrates at a high speed, and the sieved materials enter a forming machine so that the next working procedure can be carried out.

Owner:嵇旭辉

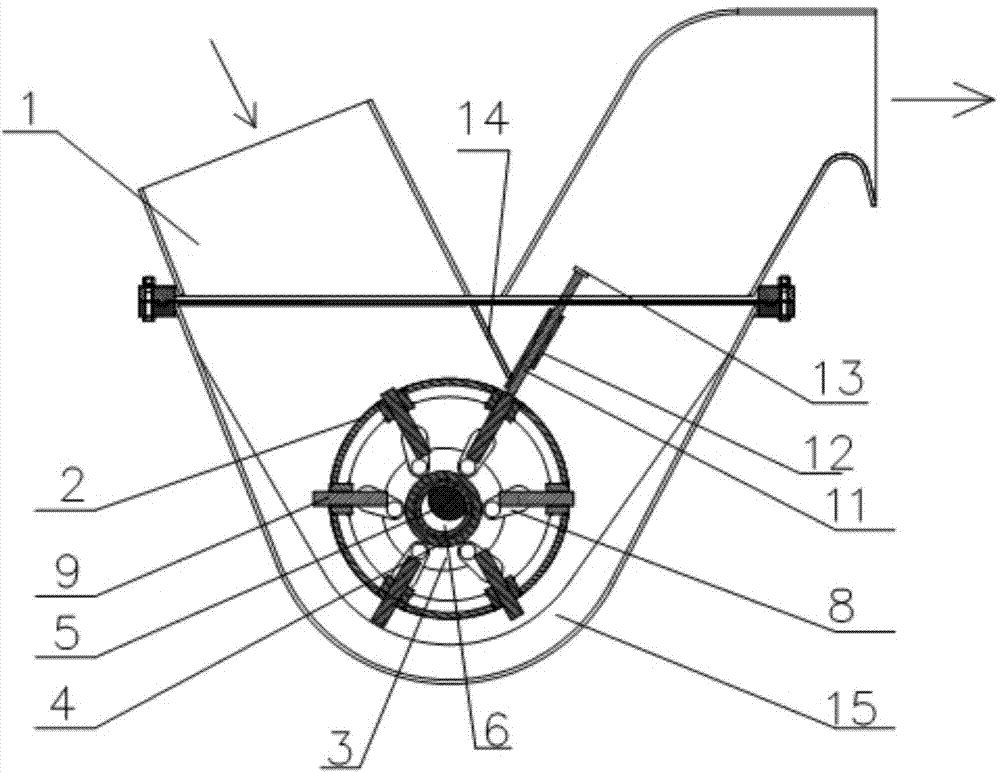

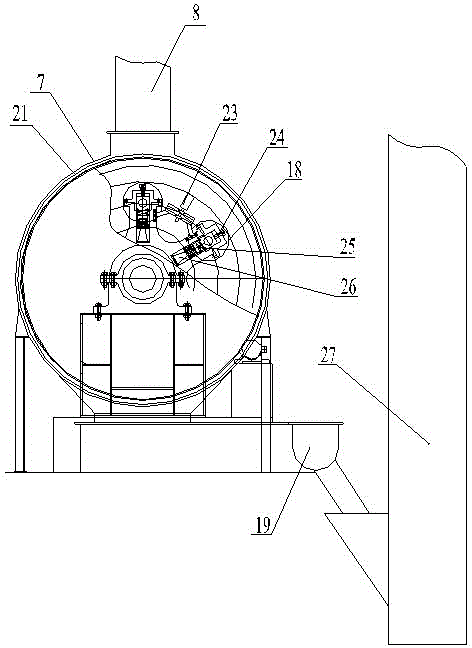

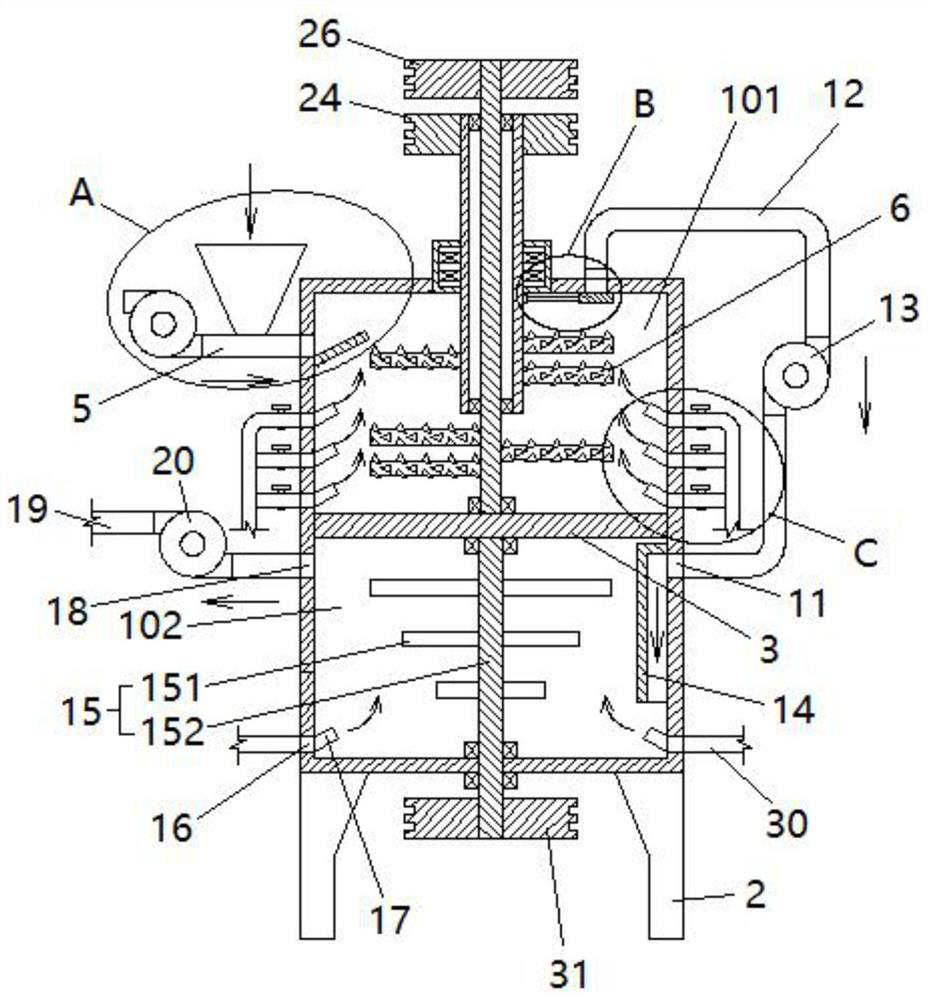

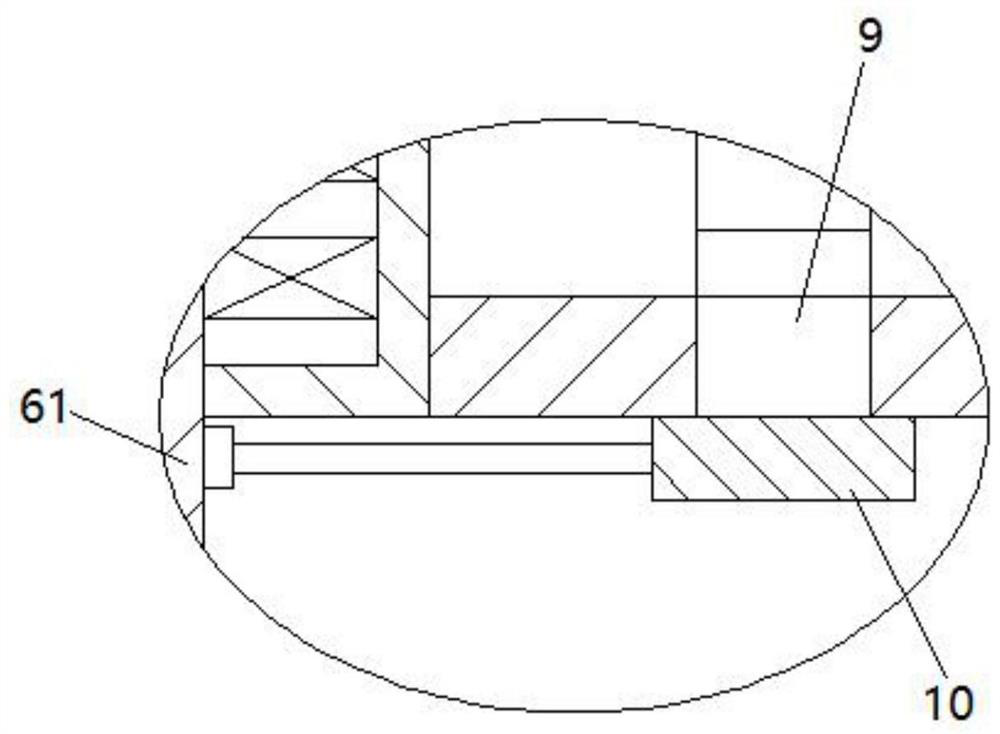

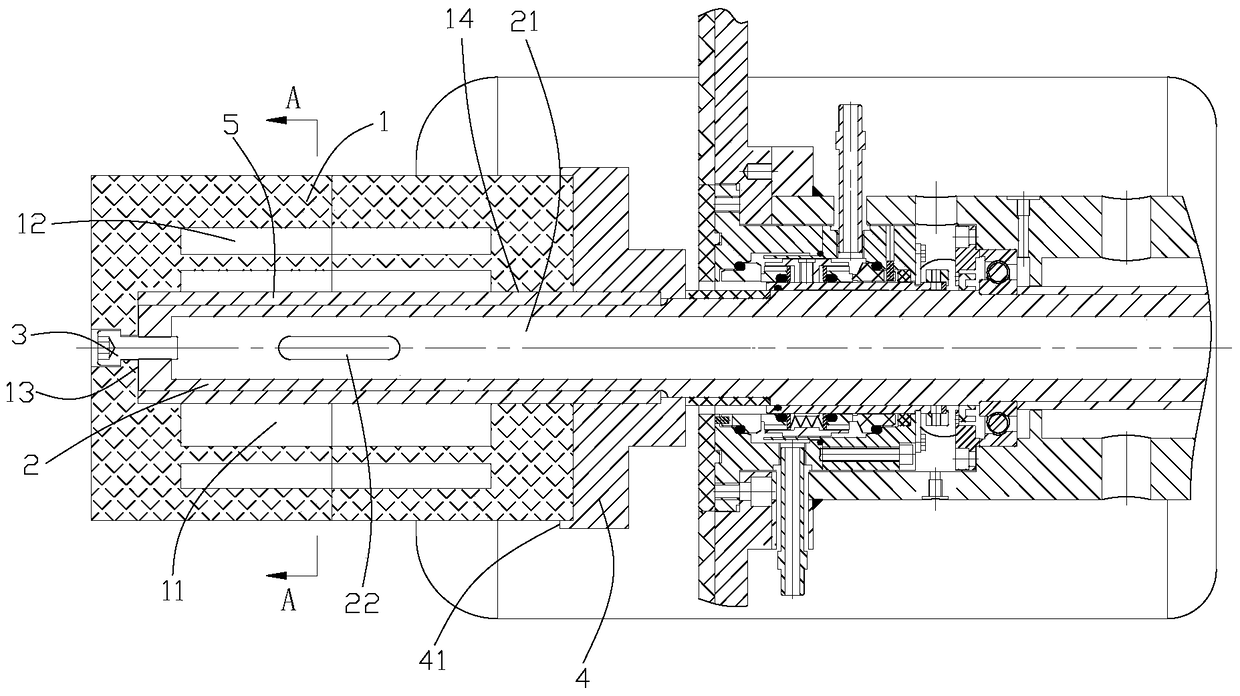

Cracking discharging process and equipment of junked tire

ActiveCN103695020AMaterial realizationPlay the role of sealingPigmenting treatmentLiquid hydrocarbon mixture productionChemical industryMechanical engineering

The invention relates to field of chemical industry, and particularly relates to cracking discharging process and equipment of a junked tire. The process mainly comprises the step as follows: discharging is finished under a sealing state after the overall junked tire is cracked. The equipment comprises a stock bin, wherein a discharge mechanism, a sealing device and a baffle plate are arranged inside the stock bin; the discharge mechanism sequentially comprises a drum, a turntable and an eccentric shaft from outside to inside; a rotating sleeve is arranged between the turntable and the eccentric shaft; the eccentric shaft is composed of a shaft I and a shaft II, which are integrated; the axis of the shaft I is arranged above the axis of the shaft II; the turntable is concentric with the shaft I; the turntable is sleeved at two ends of the shaft II and concentric with the shaft II; an open pore is formed on the drum; connecting rods are arranged on the turntable; an expansion link group movably embedded into the open pore is arranged between two connecting rods of the turntable; the bottom end of the baffle plate is connected with the sealing device; the sealing device and the baffle plate are arranged at the shortest part of the expansion link on an outer barrel. By adopting the interaction of the eccentric structure and the sealing structure, continuous cracking discharging of the overall tire under the sealing state is achieved, and a bran-new path is provided for cracking of the junked tire.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

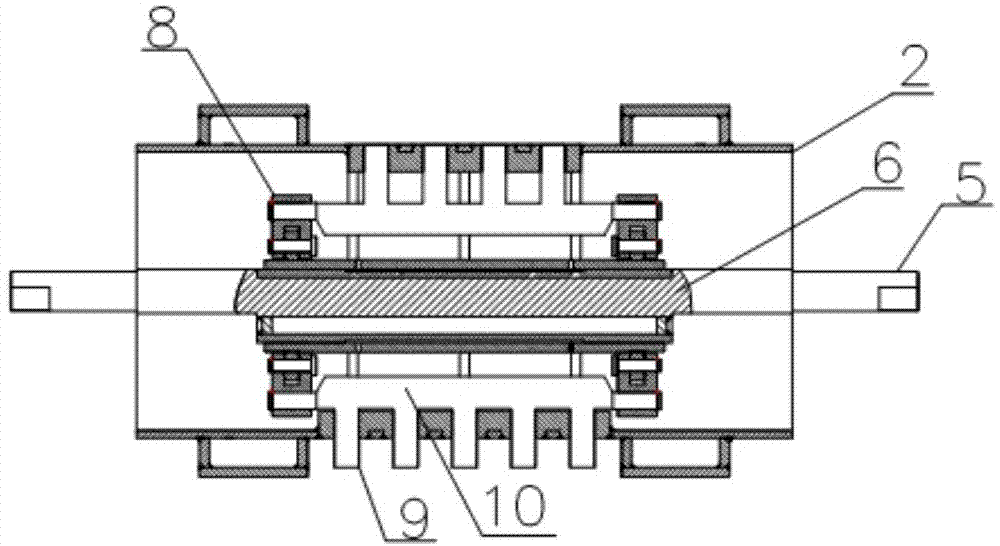

Planet flour mill

InactiveCN104984789AEasy dischargeMaterial realizationGrain treatmentsDischarge efficiencyEngineering

A planet flour mill comprises a spindle. The spindle is hollow. A planet support is arranged in the middle of the spindle. The two sides of the planet support are each provided with a set of crushing rollers which are circumferentially distributed in a vertical face. The crushing rollers are of a truncated-cone structure. A barrel is arranged outside the crushing rollers. The inner surface of the barrel is an arc-shaped face which is tightly attached to the truncated-cone faces of the crushing rollers and has the cross slope. An anti-abrasive liner plate is arranged on the inner surface of the barrel. Hollow barrel shafts are arranged at the two ends of the barrel. The barrel is movably connected with the spindle through the hollow barrel shafts. A discharging port is formed in the middle of the outer wall of the barrel in the circumferential direction. A dust cover is arranged outside the barrel. A discharging pipe is arranged at the bottom of the dust cover. A spraying port is formed in the middle of the spindle. A feeder is arranged at the feeding end of the spindle and provided with a feeding pipe and a feeding air pipe. A spindle power system and a hollow barrel shaft power system are further arranged. The spindle power system is connected with the spindle. The hollow barrel shaft power system is connected with the hollow barrel shafts. The planet flour mill is high in flour milling efficiency and discharging efficiency and materials are convenient to discharge.

Owner:陈韧坚

Water conservancy project silt treatment device and treatment method

PendingCN113800687AGuaranteed unobstructedAvoid accumulationSpecific water treatment objectivesTreatment involving filtrationHydraulic engineeringMechanical engineering

The invention relates to the technical field of water conservancy projects, and discloses a water conservancy project silt treatment device which comprises a box body, the left side of the box body communicates with a discharging pipe, the front portion of the box body communicates with a collecting box, a separating device is arranged on the inner wall of the box body, and a settling device is arranged on the inner wall of the box body; and the settling device is located below the separating device, the rear portion of the box body communicates with a pipeline, the top wall of the box body communicates with a feeding pipe, the inner wall of the box body is fixedly connected with a filter screen and a filter plate, and the filter plate is located at the rear portion of the filter screen. According to the invention, river water about to enter the pipeline can be directly filtered through the filter screen, mud and gravel existing in the river water can be filtered, then the river water can be directly discharged from the pipeline, silt cannot enter the pipeline, the mud can be prevented from adhering to the inner wall of the pipeline, meanwhile, the gravel is adsorbed to be accumulated, and smoothness of the pipeline can be guaranteed.

Owner:张文娇

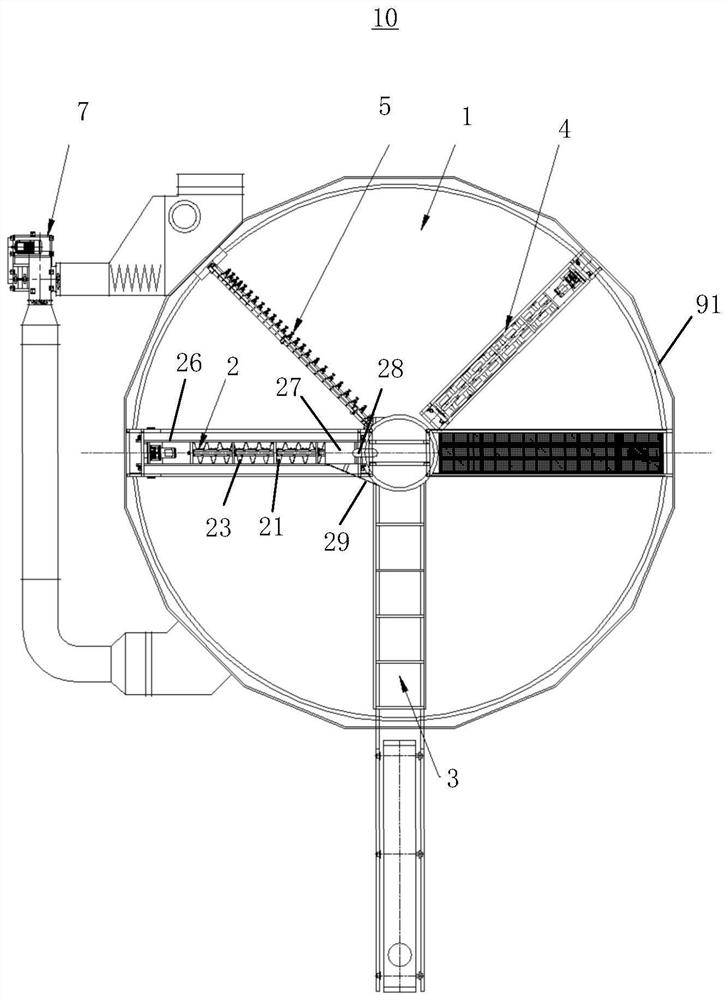

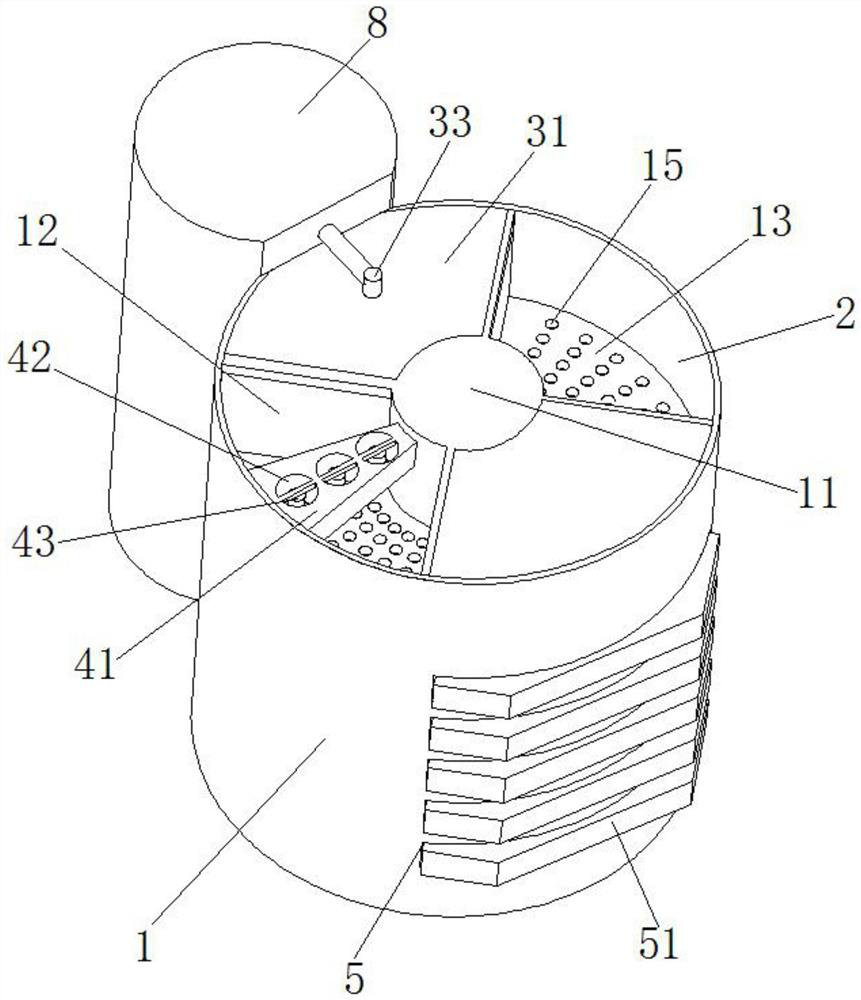

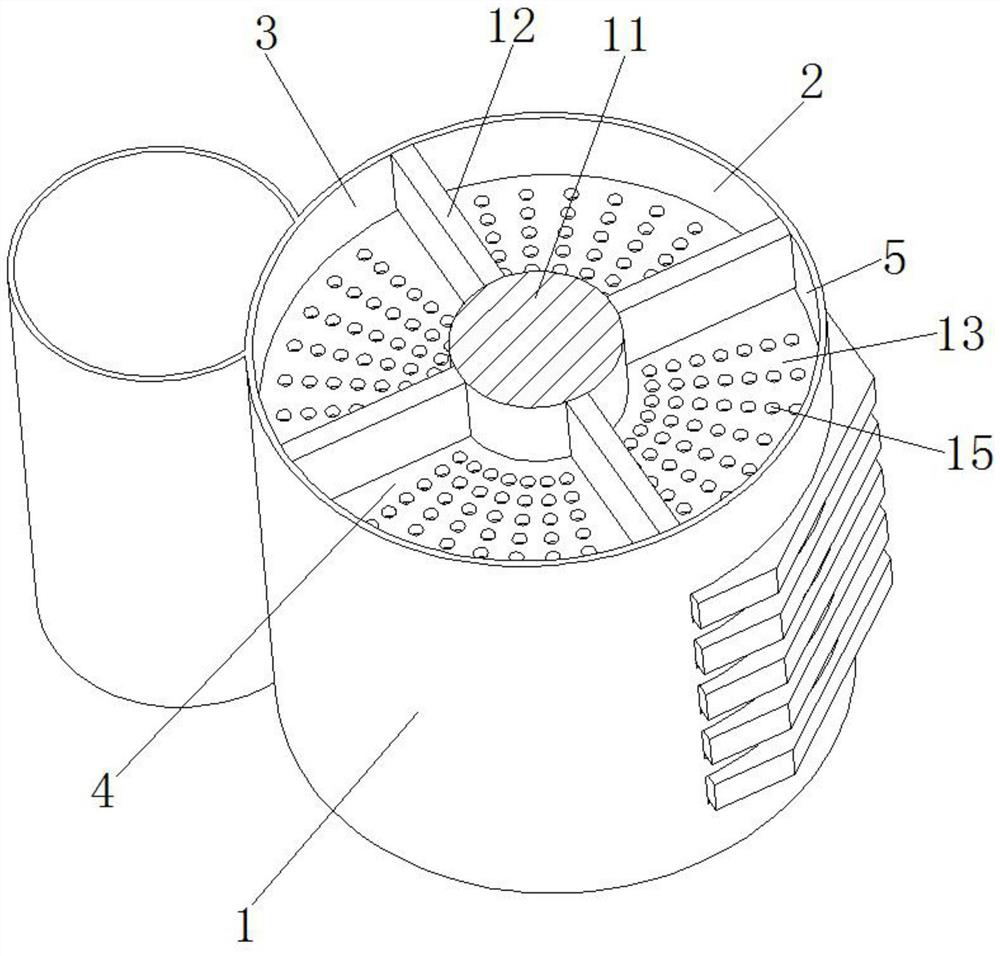

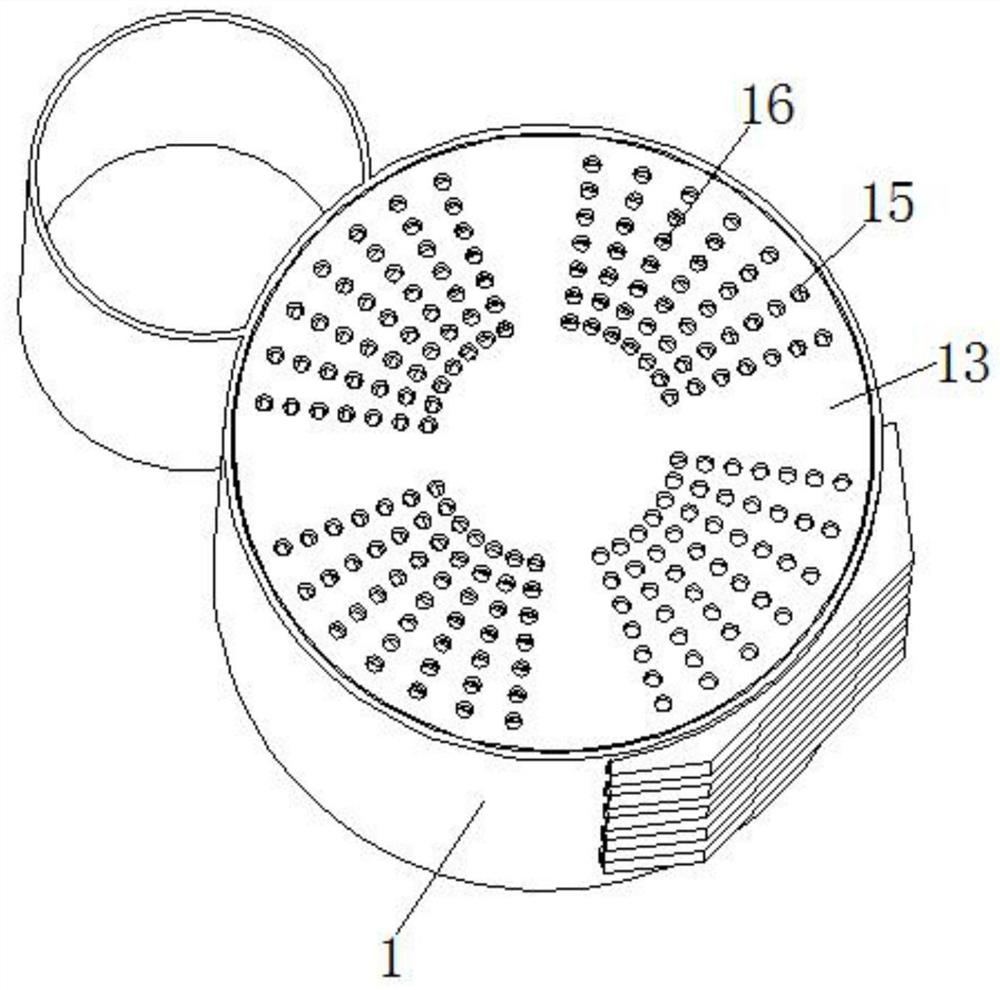

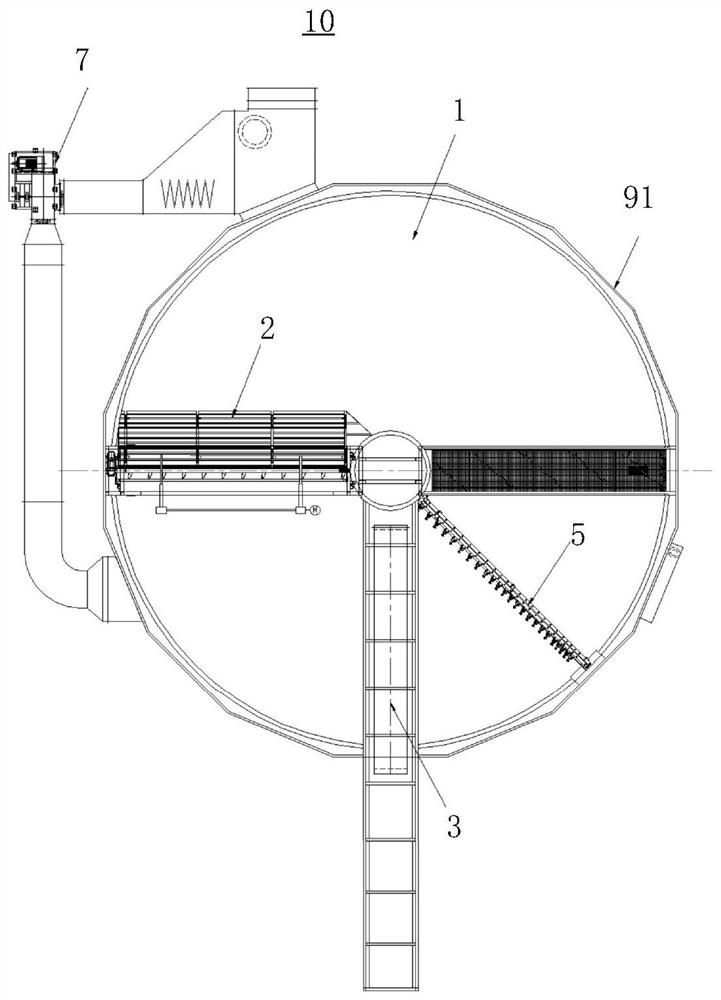

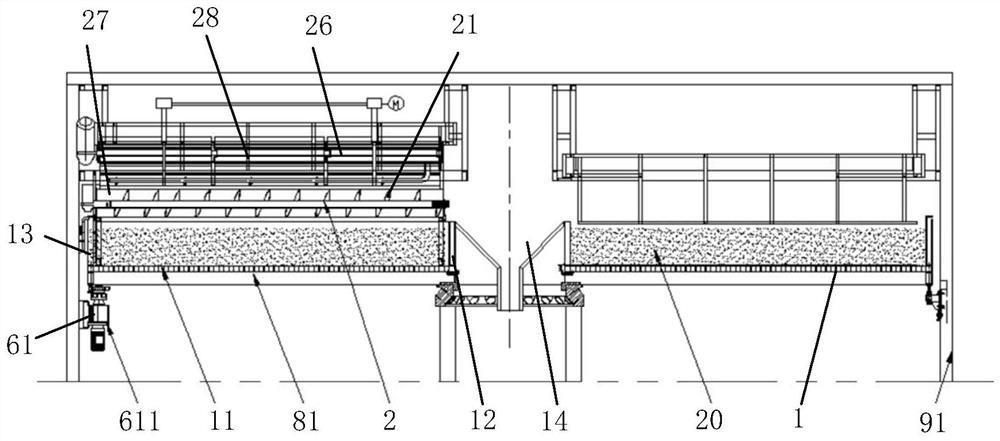

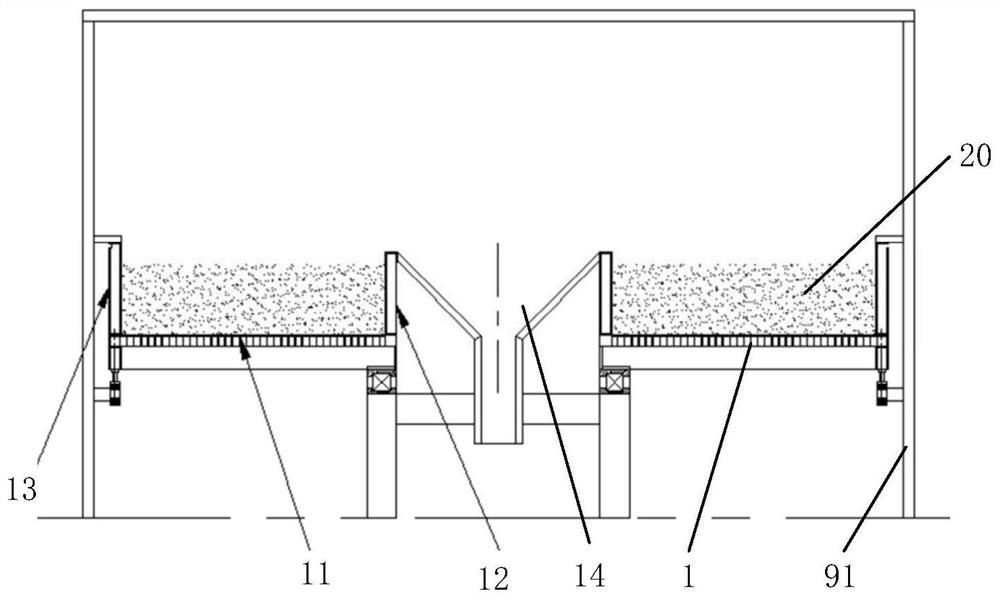

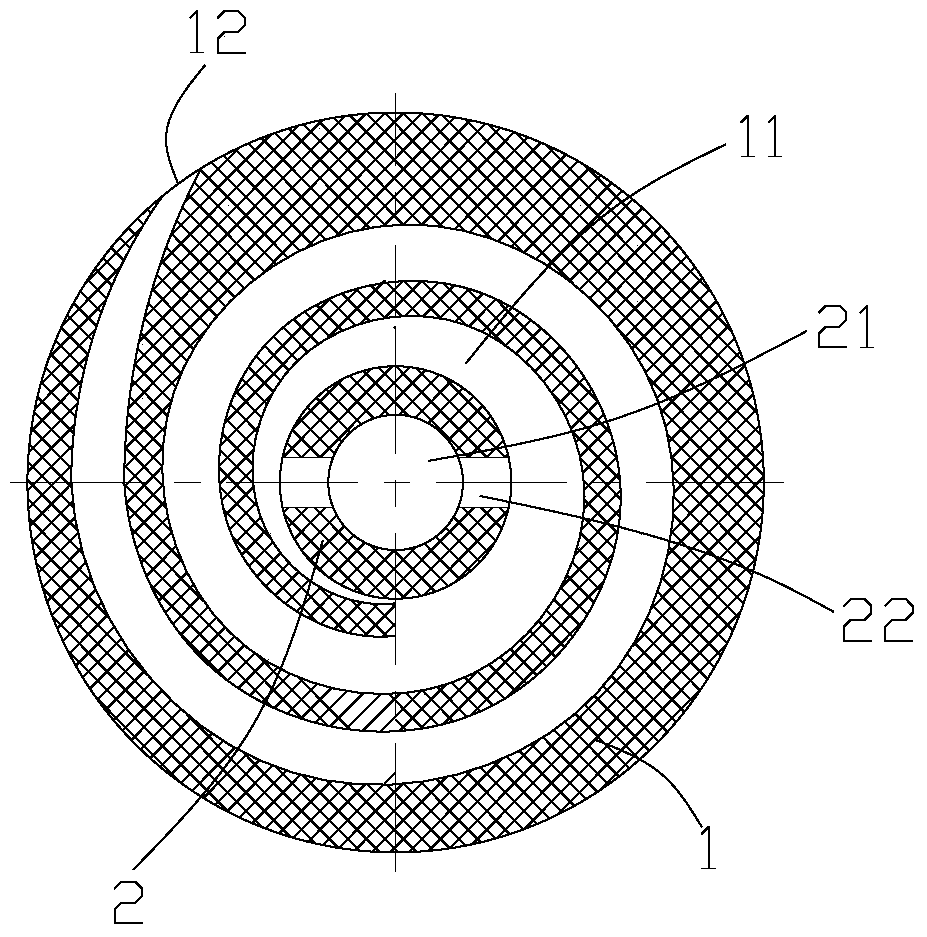

Raw starter maker

PendingCN113716315AMaterial realizationSolve the discharge problemBioreactor/fermenter combinationsBiological substance pretreatmentsCircular discMaterials science

The invention relates to the technical field of fermentation brewing equipment, in particular to a raw starter maker. The raw starter maker comprises a disc and a discharging mechanism; the disc comprises a disc body, an inner ring and an outer ring, the inner ring and the outer ring being respectively arranged on the inner ring and the outer ring of the disc body; and the discharging mechanism is arranged above the disc body and can rotate relative to the disc, and the discharging mechanism conveys materials towards the radial side of the disc and enables the materials conveyed to the radial side of the disc to rise to the position above the inner ring or the outer ring and fall off from the inner side of the inner ring or the outer side of the outer ring. On the basis, discharging of the annular-groove-shaped disc can be conveniently achieved, and the discharging problem of the annular-groove-shaped disc is effectively solved.

Owner:GUANGDONG TIANNIANG INTELLIGENT EQUIP CO LTD

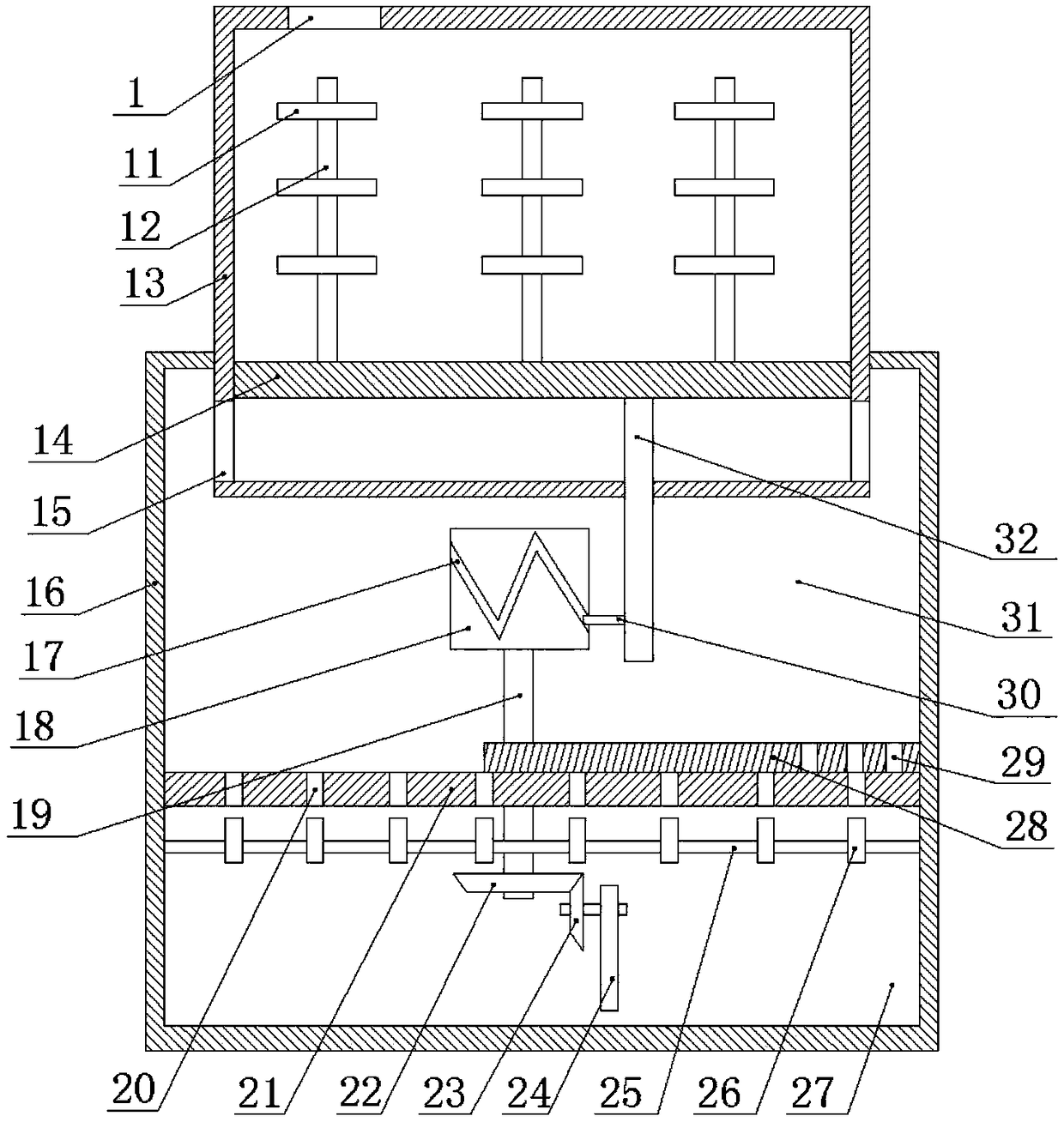

Mixing and crushing integrated machine for producing and manufacturing wettable powder

PendingCN112973893AUniform particle sizeUniform materialTransportation and packagingMixersPulverizerWettable powder

The invention discloses a mixing and crushing integrated machine for producing and manufacturing wettable powder. The mixing and crushing integrated machine comprises a box body, wherein the inner part of the box body is divided into an upper chamber and a lower chamber; a feeding hole is formed in the upper part of the upper chamber and is connected with a feeding mechanism; a crushing mechanism is mounted in the upper chamber; a plurality of first air inlets are formed in two side walls of the upper chamber and are connected with first air nozzles; a discharging hole is formed in the top wall of the upper chamber; a baffle plate which rotates along with a first crushing part to periodically block the discharging hole is arranged at the discharging hole; a feeding hole and a discharging hole are formed in the upper parts of two side walls of the lower chamber; a feeding pipeline is connected between the discharging hole and the feeding hole; a stirring mechanism is mounted in the lower chamber; and a plurality of second air inlets are formed in two sides of the bottom end of the lower chamber respectively and are connected with second air nozzles. The mixing and crushing integrated machine integrates mixing and crushing functions, so that the production cost is reduced and the production efficiency is improved; and crushed material particles are uniform and mixed materials are uniform.

Owner:蚌埠圣丹生物化工有限公司

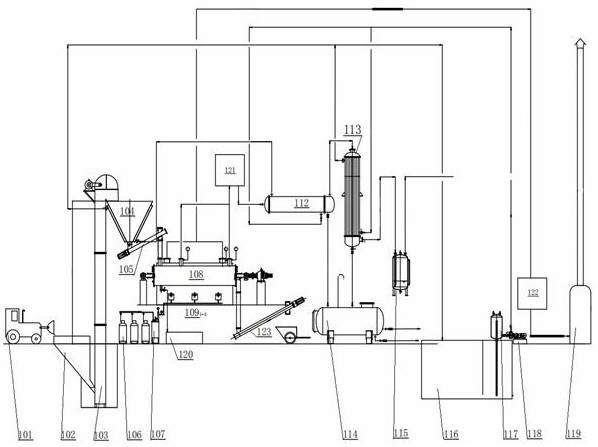

Continuous pyrolysis device

PendingCN112063398AFully pyrolyzedHigh densityIndirect heating destructive distillationSpecial form destructive distillationMolten saltEngineering

A mixture of sodium chloride and calcium chloride is added into a pyrolyzing furnace of the pyrolyzing device, the mixture becomes molten salt after being heated and melted, materials entering the pyrolyzing furnace are heated and decomposed, and due to the fact that the molten salt has the advantages of being large in density, high in heating speed, high in heat storage capacity and the like, thematerials can be pyrolyzed rapidly and fully; the rotary main shaft is arranged in the pyrolyzing furnace body, the main shaft structure can play a role in stirring and feeding by adopting a paddle and spiral combination mode, meanwhile, the top of the paddle is designed to be in a sharp tooth shape, materials bonded to the inner wall of the pyrolyzing furnace can be continuously swept off duringrotation, and heat transfer is prevented from being affected by serious coking. After the rotary main shaft pushes pyrolyzed materials to the discharging end of the pyrolyzing furnace, the discharging end of the pyrolyzing furnace is provided with an inclined small spiral conveyor, the lower end of the small spiral conveyor is inserted into molten salt, the materials accumulated at the discharging end can be smoothly pushed out of the pyrolyzing furnace and then fall into a discharging pipe, and therefore discharging in a sealed state is achieved.

Owner:河南省正源环境科技有限公司

Coating material processing equipment

PendingCN108499460AAchieve hybridAchieving stirringShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMaterials processing

The invention relates to the technical field of architectural decoration, and particularly relates to coating material processing equipment comprising a cylindrical mixing box, wherein a feeding holeis formed in the top of the mixing box, an annular discharge hole is formed in the side wall of the bottom of the mixing box, a thread is formed in the inner wall of the mixing box, a bottom plate istransversely arranged at the bottom in the mixing box, the edge of the bottom plate is in threaded connection with the inner wall of the mixing box, a driving mechanism for driving the bottom plate tomove up and down is connected below the bottom plate, a plurality of stirring shafts are vertically arranged on the bottom plate, and a plurality of stirring blades are arranged on the stirring shafts. The coating material processing equipment solves the problem of non-uniform mixing of coating in the prior art.

Owner:重庆阿罗科技有限公司

Domestic garbage disposal device with good pulverization effect

The invention discloses a domestic garbage disposal device with the good pulverization effect, and relates to the technical field of domestic garbage disposal. The domestic garbage disposal device comprises a first box body, a second box body is fixedly connected between the two sides of the inner wall of the first box body, the top of one side of the first box body is fixedly connected with a fixed box, the bottom of the inner wall of the fixed box is fixedly connected with a first motor through a connecting block, one end of an output shaft of the first motor is fixedly connected with a rotating rod through a coupling, the end, far away from the first motor, of the rotating rod sequentially penetrates the fixed box, the first box body and a second box body to extend to the inside of thesecond box body, and the end, extending to the inside of the second box body, of the rotating rod is rotatably connected to one side of the inner wall of the second box body through a bearing. The domestic garbage disposal device with the good pulverization effect can realize rapid and full pulverization of domestic garbage, the domestic garbage pulverizing effect is greatly enhanced, workers canconveniently treat the domestic garbage, time is saved, and the disposal efficiency is improved.

Owner:芜湖青悠静谧环保科技有限公司

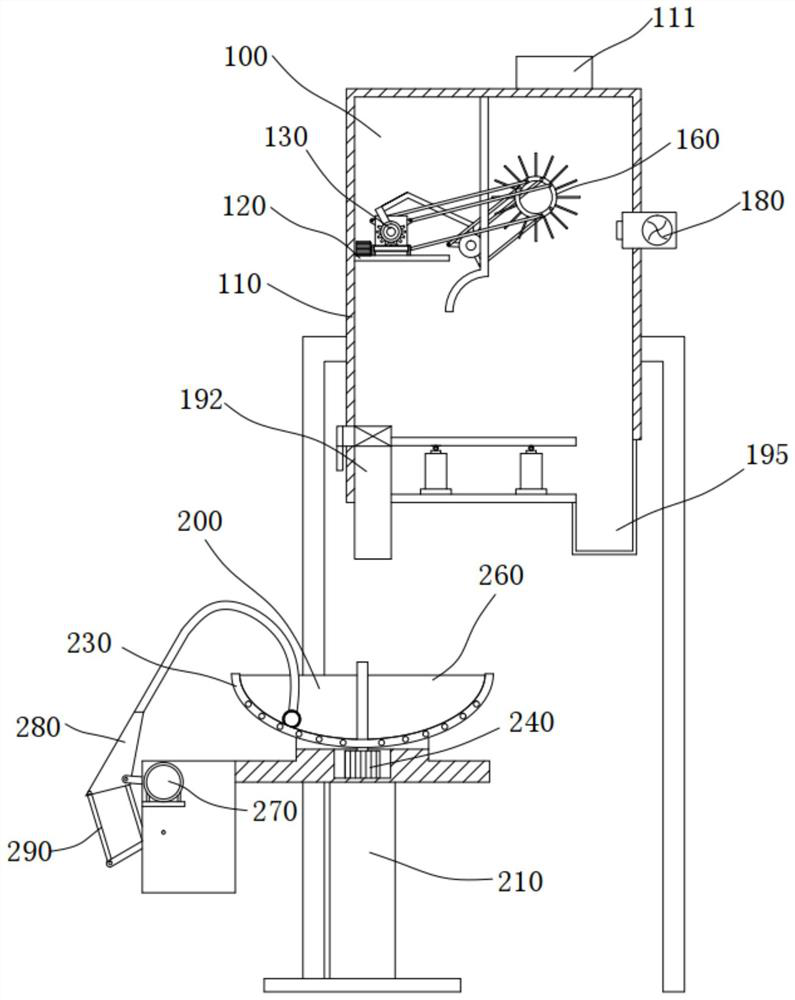

Preparation and processing system of vitamin capsules and preparation method thereof

InactiveCN113350183AImprove production efficiencyEasy to cleanDrying gas arrangementsCapsule deliverySurgeryVitamin

The invention relates to the field of capsules preparation, in particular to a preparation and processing system of vitamin capsules and a preparation method thereof. The preparation and processing system comprises a main body, the main body is of a tubular structure, and a feeding bin, a cleaning bin, a drying bin and a discharging bin are sequentially and annularly distributed in the circumferential direction of the main body, a first support of a cross-shaped structure is fixedly installed on the top of the inner wall of the main body, a first partition plate is arranged at the bottom of the first support and located among the feeding bin, the cleaning bin, the drying bin and the discharging bin, a first motor is fixedly installed at the bottom of the first support, a rotating disc is fixedly installed at the output end of the first motor, and the top of the rotating disc makes contact with the bottom of the first partition plate; a second partition plate of a cross-shaped structure is arranged on the inner wall of the main body and located below the rotating disc, the top of the second partition plate makes contact with the bottom of the rotating disc. According to the invention, the formed vitamin capsules can be automatically cleaned and dried, the preparation efficiency of the vitamin capsules is greatlyimproved, and the preparation and processing system of vitamin capsules and preparation method thereof are suitable for popularization.

Owner:武汉古太慕食品科技有限公司

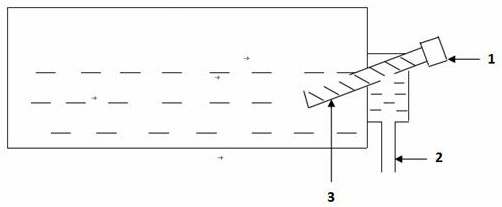

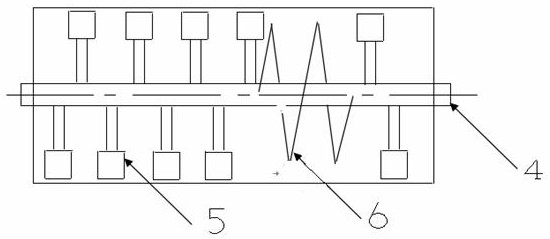

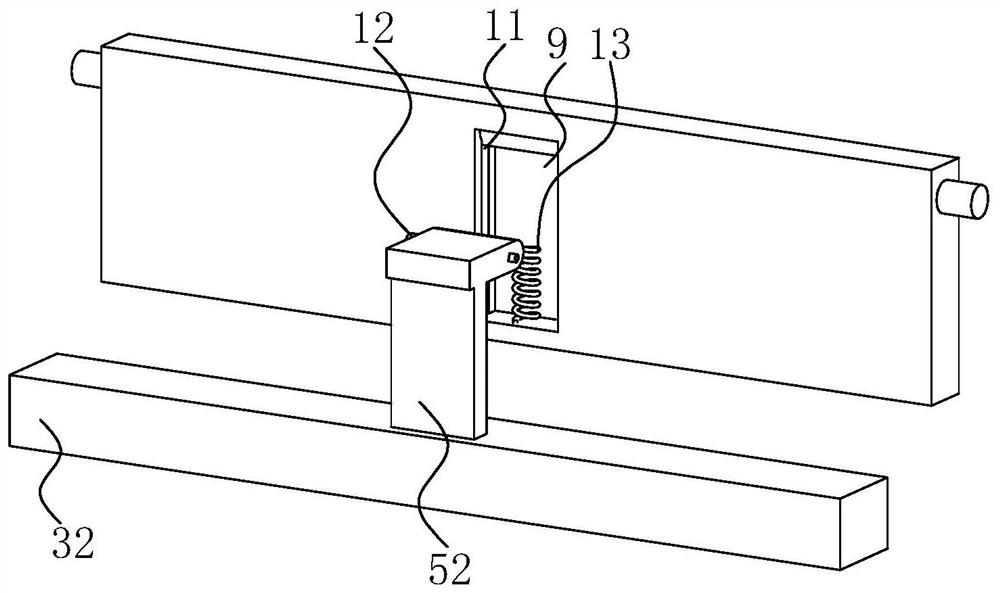

Cross-platform material shunting device

ActiveCN105540233AMaterial realizationLogistics realizationConveyor partsShunt DeviceLogistics management

The invention discloses a cross-platform material shunting device which comprises a material distributing mechanism, material receiving mechanisms, a rising and falling mechanism and a control device. The material receiving mechanisms are arranged in the material distributing mechanism, the top of each material receiving mechanism is higher than that of the material distributing mechanism, the rising and falling mechanism is arranged at the bottoms of the material receiving mechanisms to enable the material receiving mechanisms to rise and fall, and the control device controls rising and falling of the rising and falling mechanism. When materials arrive at the material receiving mechanisms, the rising and falling mechanism enables the material receiving mechanisms to fall, the materials fall on the material distributing mechanism, a material distributing driving device drives rollers of the material distributing mechanism to rotate forwards or rotate reversely to enable the materials to be moved away towards the different directions, and therefore material distributing is achieved; the cross-platform material shunting device can be arranged between two logistics platforms, has the effect of a connecting link between the preceding and the following and can distribute the materials of the last logistics platform and deliver the materials to the next logistics platform, and therefore cross-platform material shunting is achieved.

Owner:YUNNAN KELAIZHONGCHENG INTELLIGENT EQUIP CO LTD

Plastic processing device

InactiveCN108527727AAchieve fixationEasy to grind and crushPlastic recyclingMechanical material recoveryEngineeringStainless steel wire

The invention relates to the technical field of plastic processing, and particularly discloses a plastic processing device which comprises a rack. A motor, a feeding hopper, a smashing tank and an extensible cylinder are fixedly mounted on the rack, the output end of the motor is connected with a rotating shaft, a feeding pipe is communicated between the smashing tank and the feeding hopper, a pushing plate is slidably connected in the smashing tank, and the output end of the extensible cylinder is connected with the pushing plate. Conveying mechanisms are mounted on two sides of the smashingtank and arranged symmetrically according to the central line of the smashing tank, each conveying mechanism comprises a driving wheel, a driven wheel and a conveying belt, a plurality of steel needles for fixing plastic are hinged on each conveying belt, a spring is fixedly connected between each of two sides of each steel needle and the corresponding conveying belt, and a through groove for thesteel needles to pass is formed in the side wall of the smashing tank; one end, away from the motor, of the rotating shaft is fixedly connected with a turnplate, and one side, close to a right cavity,of the turnplate is fixedly connected with a plurality of stainless steel wires for rubbing the plastic. The plastic processing device can fix the plastic during foamed plastic smashing to avoid plastic flying up and down, thereby improving smashing efficiency.

Owner:宁波隆锐机械制造有限公司

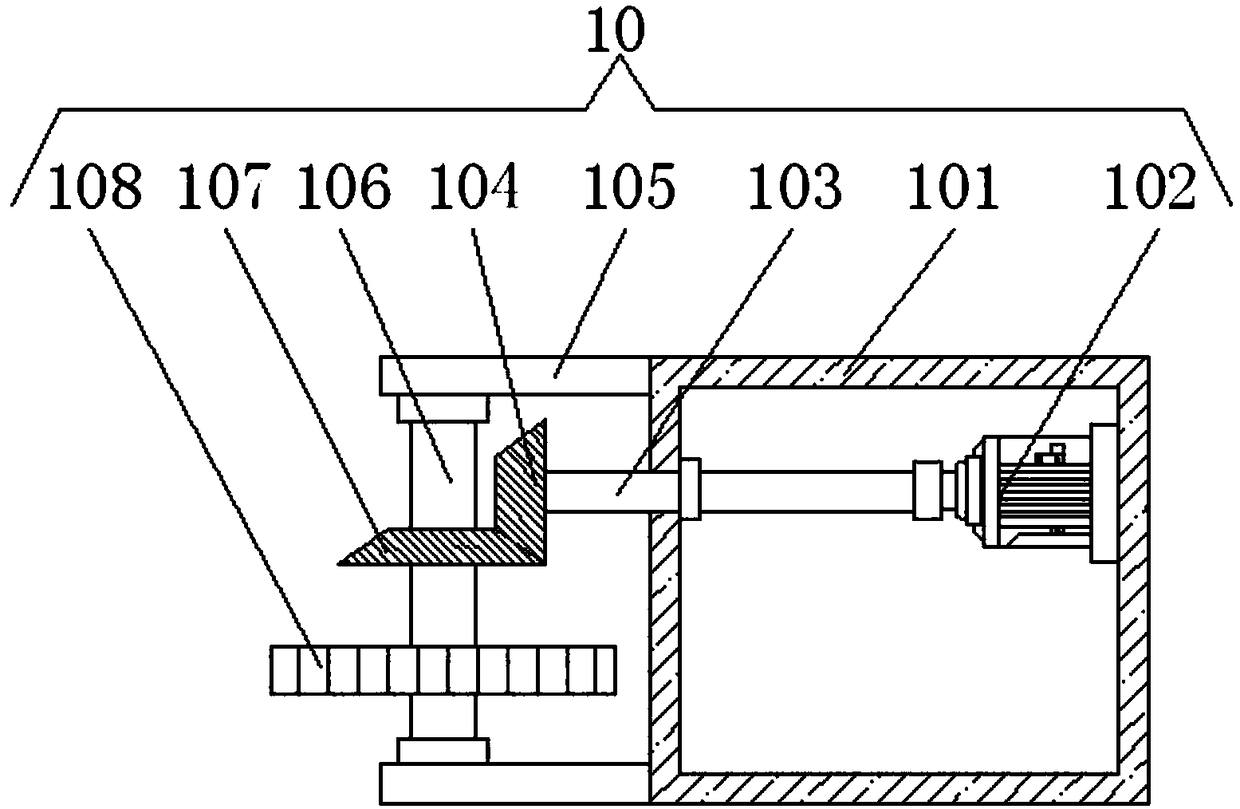

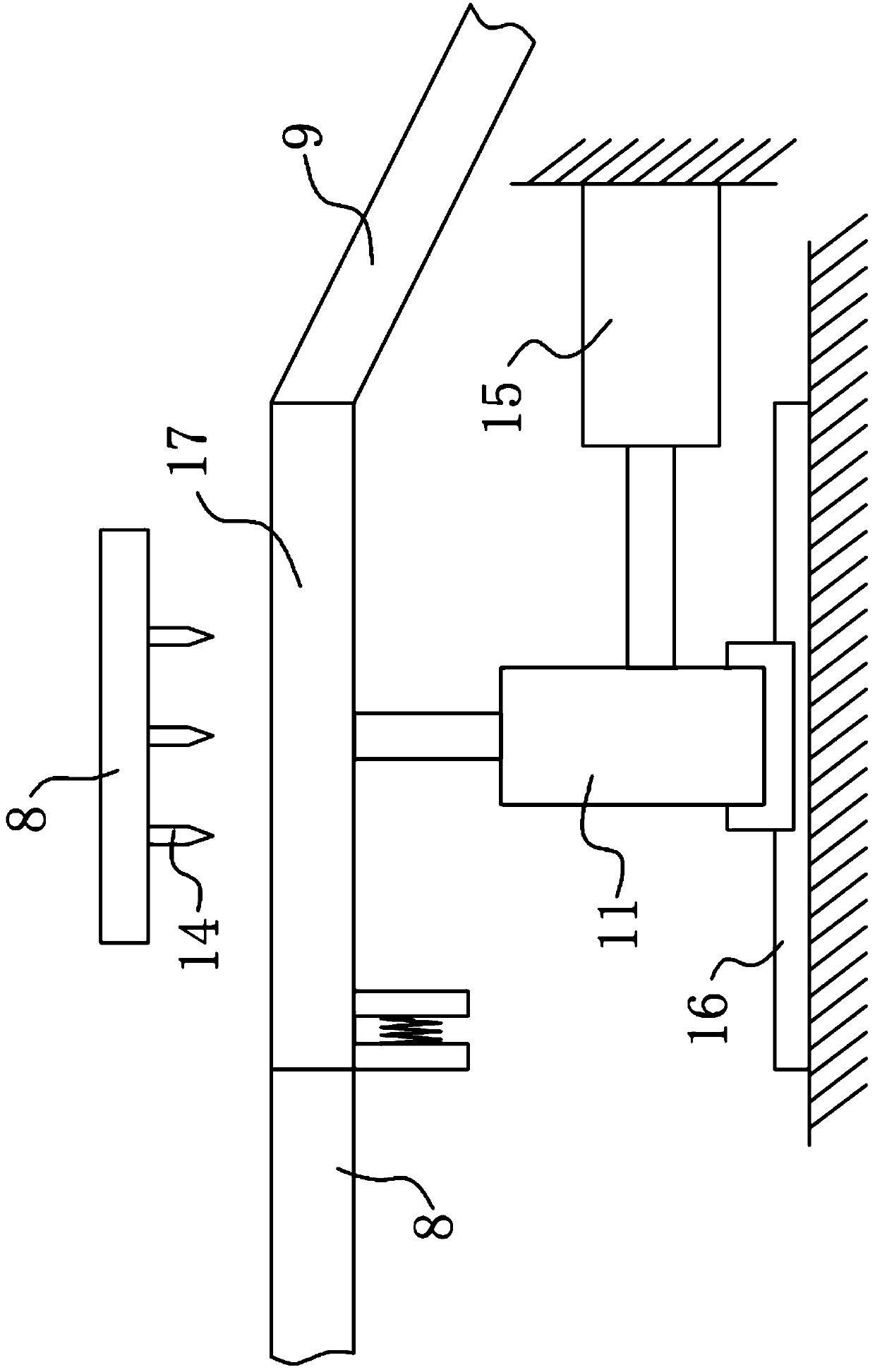

Automatic tapping assembly line

PendingCN110722228AEasy to tapStrong process controllabilityThread cutting machinesEngineeringAssembly line

The invention discloses an automatic tapping assembly line. The automatic tapping assembly line comprises a feeding mechanism, a tapping mechanism and a discharging mechanism, wherein the feeding mechanism comprises a Y-shaped slide way and a vibration disc; the height of the Y-shaped slide way is gradually reduced in the feeding direction; two branched slide ways are arranged at the bottom of theY-shaped slide way; a shifting rod for shifting workpieces is movably connected to the Y-shaped slide way; the rotating center of the shifting rod is positioned at the junction of the two slide ways;the vibration disc comprises a first vibration disc and a second vibration disc which are positioned below the two slide ways respectively; the outlet of the first vibration disc and the outlet of the second vibration disc are each connected with a horizontal and parallel linear feeding channel; the tapping mechanism is provided with a plurality of parallel screw taps extending downward; a lifting table is arranged under the screw taps; the two linear feeding channels are horizontally in butt joint with the lifting table; the lifting table receives the workpieces on the two linear feeding channels at the same time; the lifting table ascends, and the screw taps are used for tapping the workpieces; and the discharging mechanism is provided with a discharging channel in butt joint with the lifting table. By the adoption of the automatic tapping assembly line, the workpieces are distributed, a plurality of workpieces are tapped at the same time, the machining efficiency is high, and conveying is coherent.

Owner:CHERRY CHIEF PRECISION IND KUNSHAN

Decolorizing method of stevia sugar water extracting solution

InactiveCN112493326AStir-fry effect is goodImprove Stir-Fry QualityGas current separationPre-extraction tea treatmentEngineeringTea leaf

Owner:金寨县铁冲农业科技开发有限公司

Processing equipment for soybeans

ActiveCN106583250BIncrease the output speedMaterial realizationSievingGas current separationProcess equipmentEngineering

The invention relates to processing equipment for bean products, in particular to processing equipment for soybeans. The processing equipment for the soybeans comprises a processing barrel body, wherein the processing barrel body is provided with a discharging port; a collecting box is arranged on the lower part of the processing barrel body; the upper part of the processing barrel body is connected with a screening box in a sliding way; the collecting box comprises a bottom plate and pressing plate hinged on the two sides of the bottom plate; a first sieve hole is formed in the bottom plate; the center of the bottom plate is hinged with a sealing cover; two sliding plates are connected between the lower end face of the bottom plate and the bottom surface of the processing barrel body in a sliding way; the sliding plates are symmetrically arranged along the bottom plate and are provided with filtering holes; one side of each sliding plate is connected with the side wall of the processing barrel body through a pressure spring and the other side of each sliding plate is an inclined plane; a second sieve hole is formed in the screening box; the two sides of the lower end face of the screening box are connected with wedge blocks; the wedge blocks move downwards to press the pressing plates to rotate; the central position of the lower end of the screening box is connected with a driving rod; and the longitudinal section of the lower part of the driving rod is a conical shape matched with the sliding plates. The invention aims to provide processing equipment capable of screening without vibration.

Owner:重庆刘二嘎农业科技有限公司

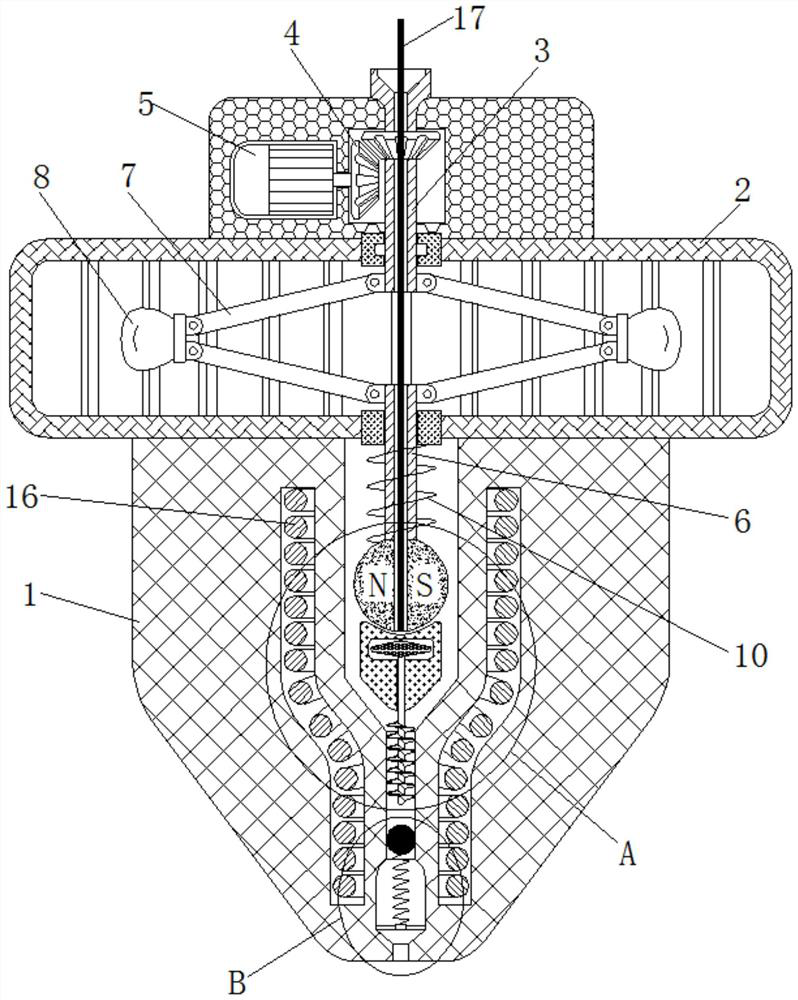

Discharging head for 3D printing of animation design model

InactiveCN112793153AMaterial realizationAvoid premature meltingManufacturing heating elements3D object support structuresAnimationHeat Avoidance

The invention provides a discharging head for 3D printing of an animation design model, and relates to the technical field of animation design. The discharging head for the 3D printing of the animation design model comprises a printing head, a heat dissipation frame is fixedly installed at the top end of the printing head, the center of the top of the heat dissipation frame is rotationally connected to an upper rotating drum, the periphery of the top of the upper rotating drum is in transmission connection with a motor through a bevel gear, the center of the bottom of the heat dissipation frame is rotationally connected to a lower rotating drum, a transmission rod is in transmission connection between the upper rotating drum and the lower rotating drum, and fan blades are rotationally connected to the periphery of the transmission rod. According to the discharging head for the 3D printing of the animation design model, advanced melting of a printing line at an inlet by heat can be avoided, continuous input of the printing line is guaranteed, the melting speed and the downward flowing speed of the printing line can be automatically adjusted, then the printing effect is improved, the continuity of next-time printing is guaranteed, and meanwhile, the pollution of casting to works is avoided.

Owner:徐州品赢网络科技有限公司

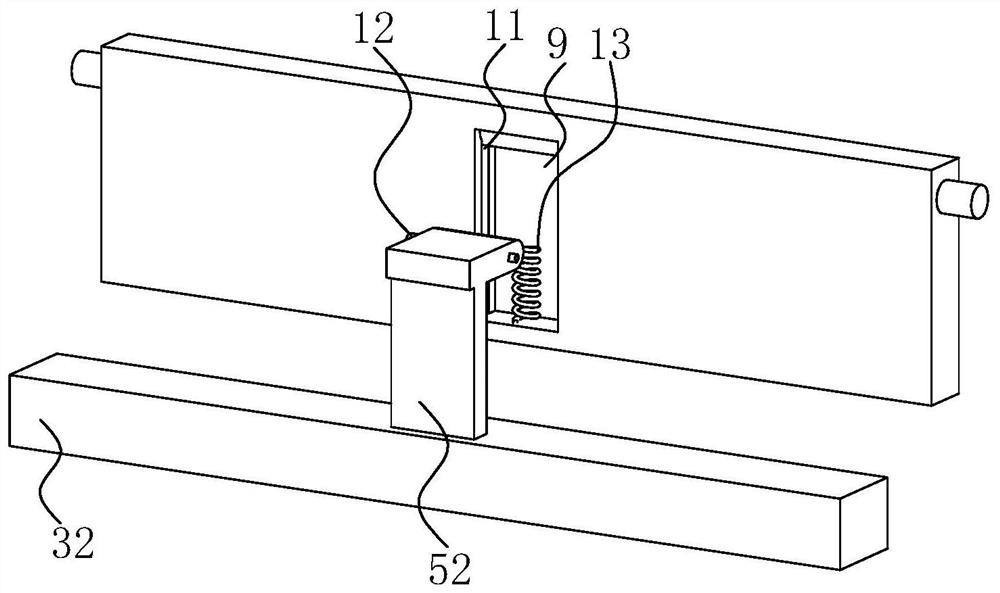

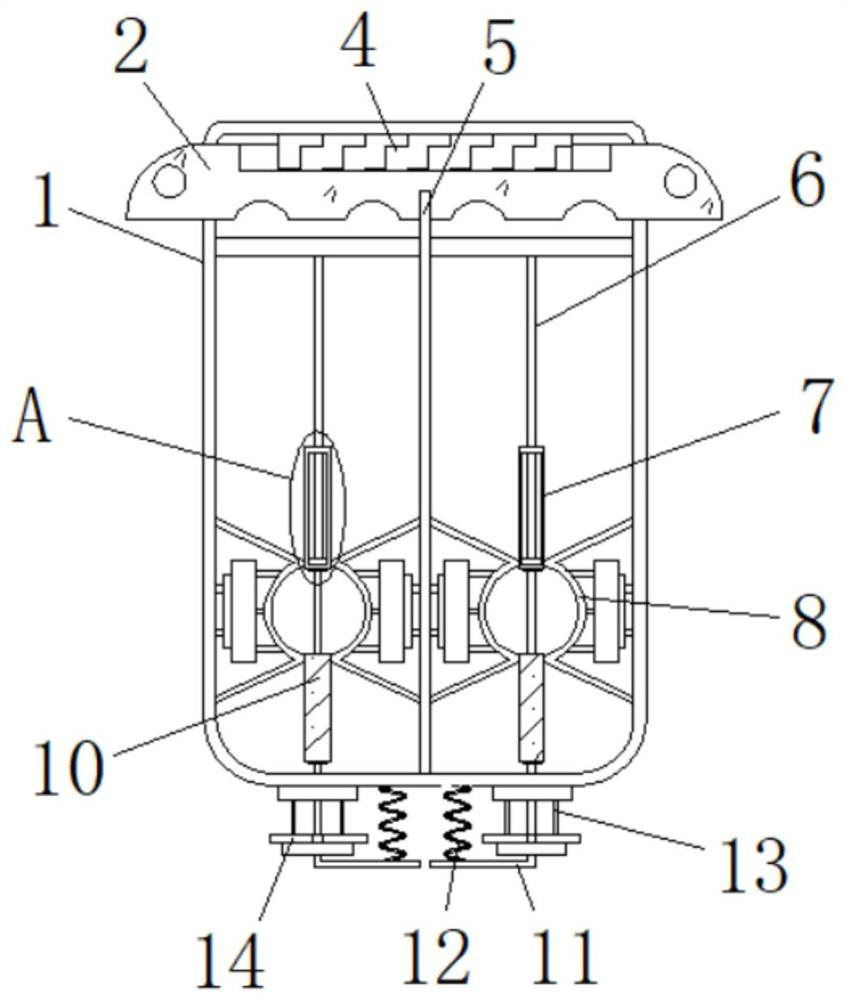

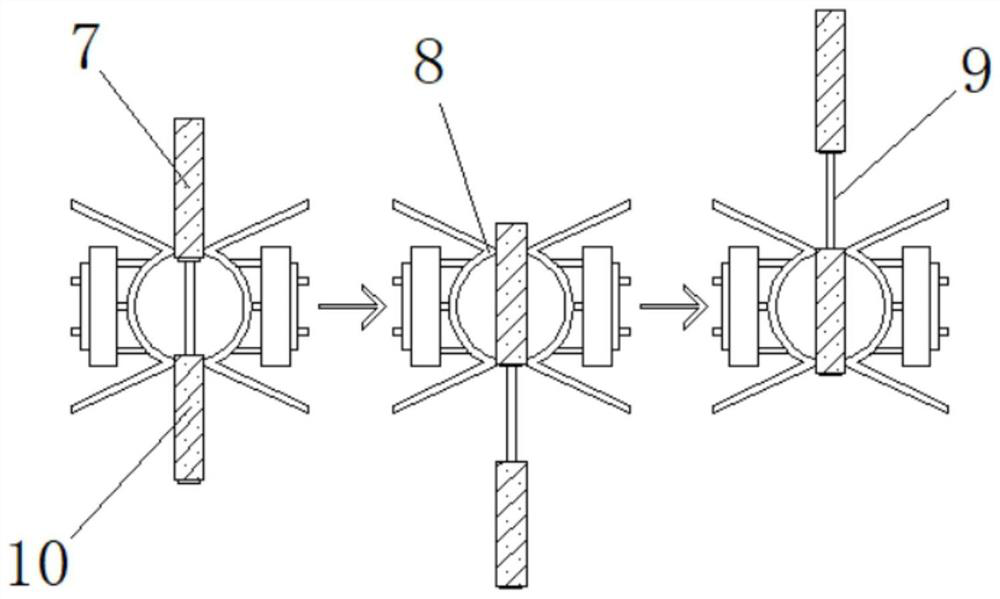

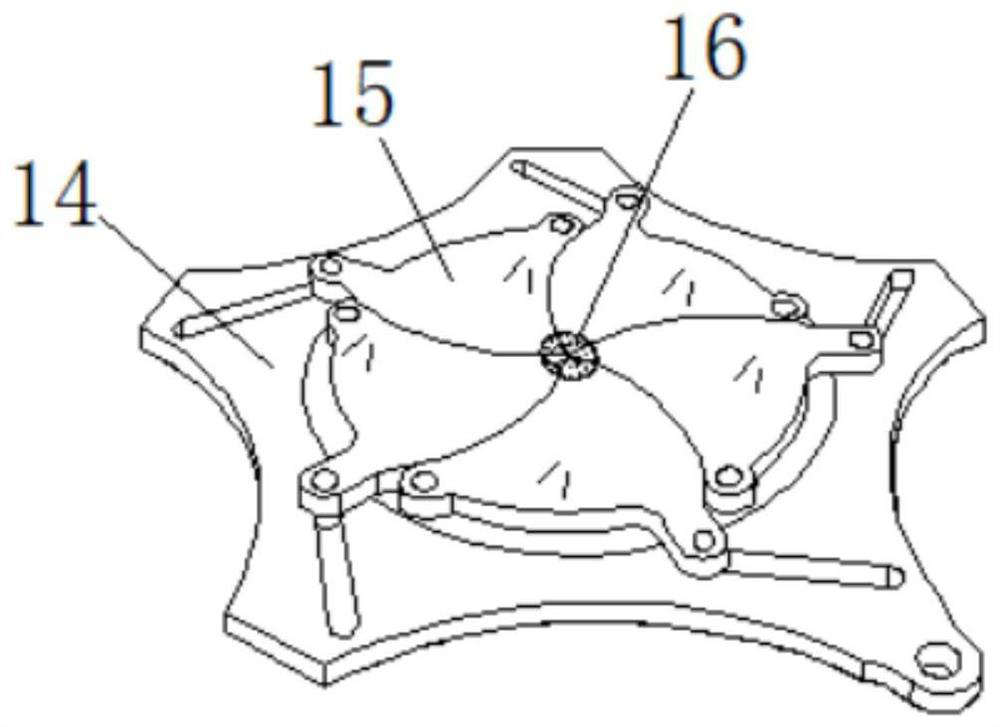

A planetary gear CNC lathe discharge device

ActiveCN112238226BRealize the output workImprove discharge efficiencyAutomatic workpiece supply/removalMetal working apparatusNumerical controlGear wheel

The application relates to a discharge device for a planetary gear CNC lathe, and relates to the technical field of mechanical processing equipment, wherein, a discharge device for a planetary gear CNC lathe includes a workbench, a first pushing unit located on the workbench, a second Pushing unit and regularizing unit, the moving direction of the second pushing unit is perpendicular to the moving direction of the first pushing unit, the regularizing unit is located at the end of the push-out stroke of the second pushing unit, and the first pushing unit The material unit is located between the starting end and the end of the pushing stroke of the second pushing unit, the regularizing unit is hingedly connected to the workbench, and the regularizing unit is connected with an opening and closing unit. A discharge device for a planetary gear CNC lathe in the present application has the effect of improving the discharge efficiency of a CNC lathe for a planetary gear.

Owner:上海万众实业股份有限公司

Stock bin discharging port gate for metal plate manufacturing

InactiveCN108861182AMaterial realizationSolve the inconvenience of operationLarge containersEngineeringStainless steel material

The invention discloses a stock bin discharging port gate for metal plate manufacturing. The stock bin discharging port gate comprises an inserting plate device and an inserting plate supporting device, wherein the inserting plate device comprises an inserting plate body and a handle, the inserting plate supporting device comprises a supporting frame, guide wheels and guide wheel shafts, and the supporting frame is composed of a supporting front transverse support, a supporting rear transverse support and a supporting side support. According to the stock bin discharging port gate for metal plate manufacturing, a traditional lifting gate is changed into a horizontal gate, so that the structure is simple, the operation is convenient, the weight is light, moreover, each metal plate part is made of stainless steel, and then the situation that the operation of the gate is inconvenient due to the rustiness caused by the moist environment in the using process is avoided; and discharging of astock bin can be conveniently and rapidly achieved through the stock bin discharging port gate.

Owner:太仓森楚源机械设备有限公司

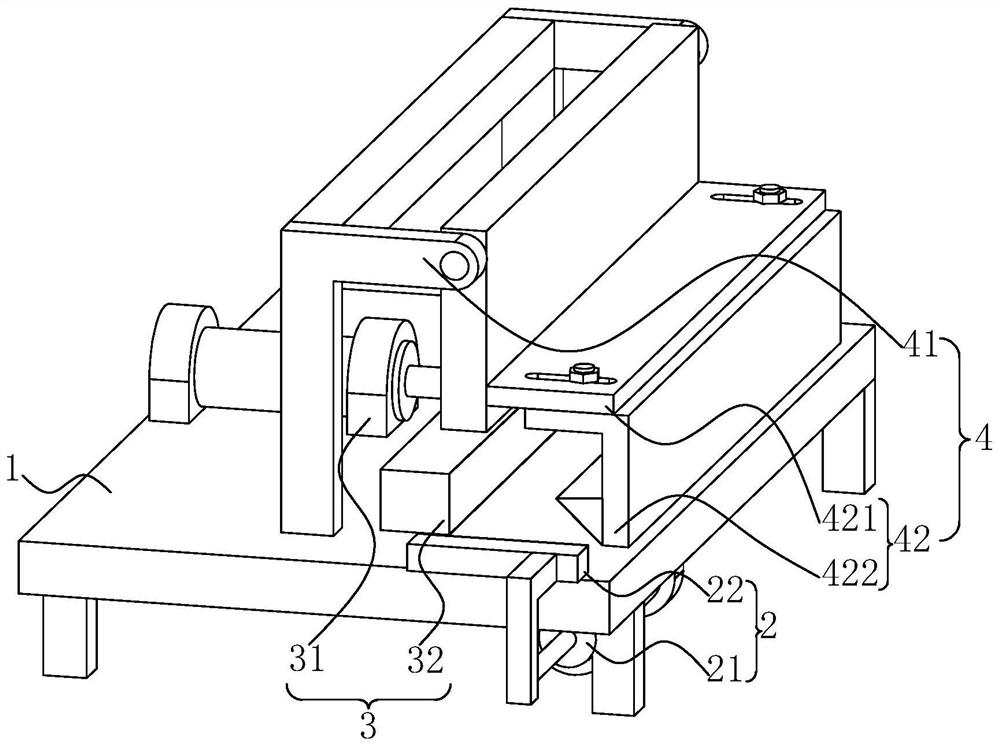

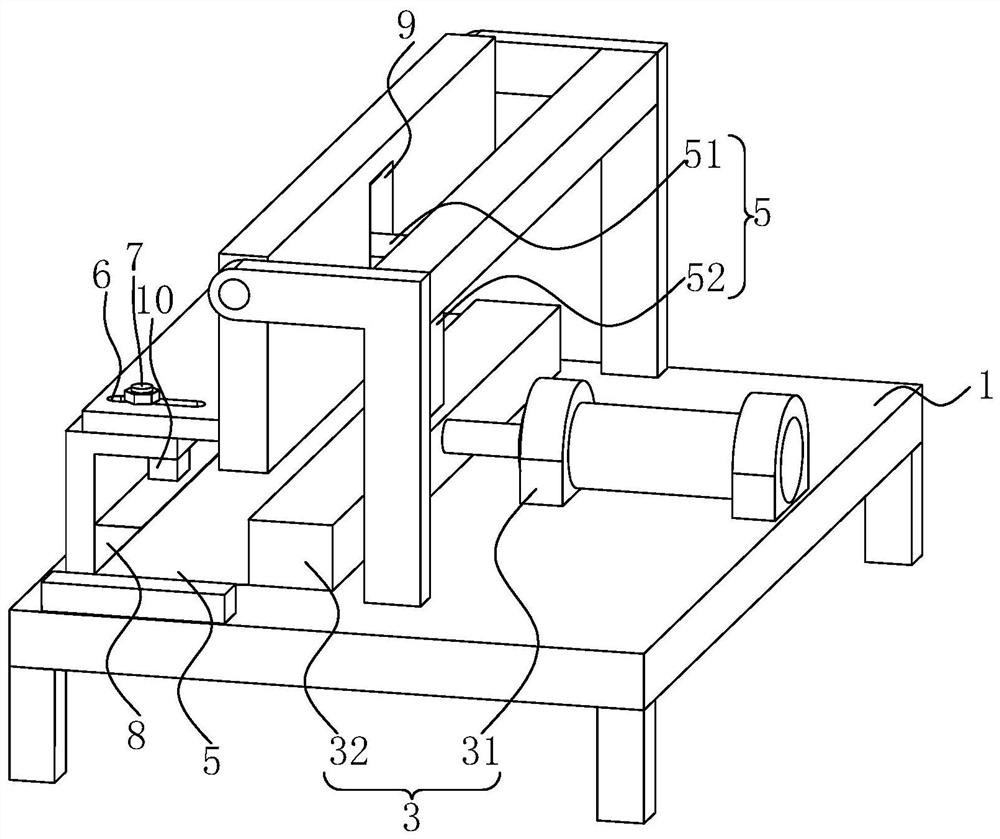

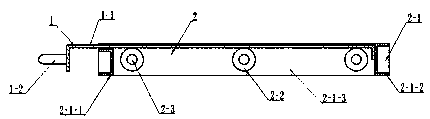

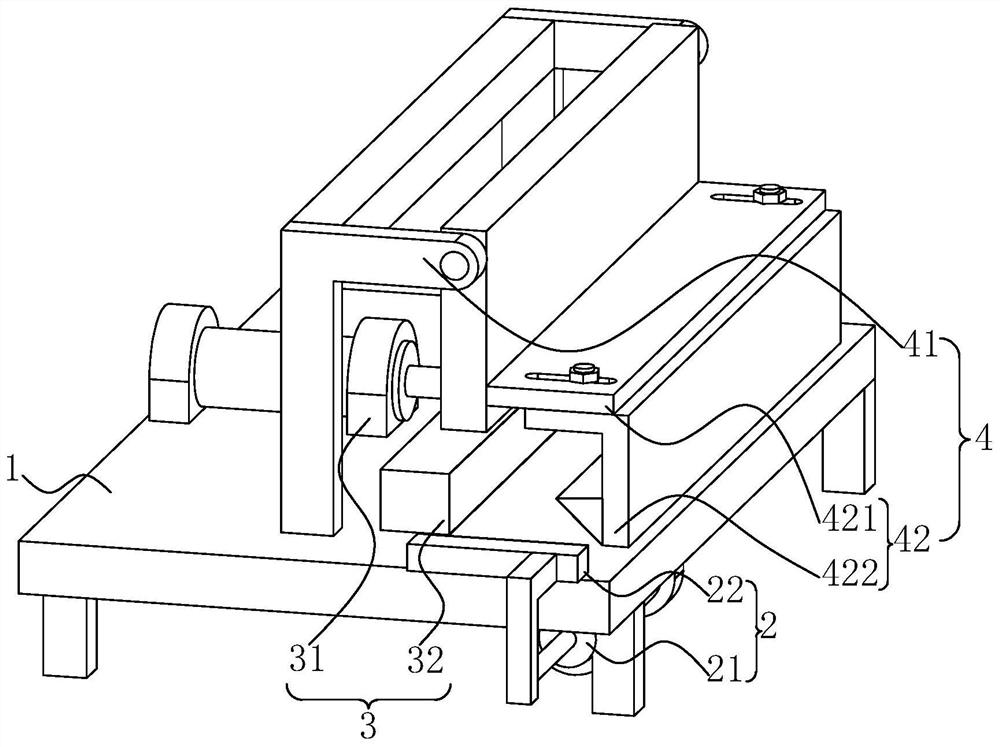

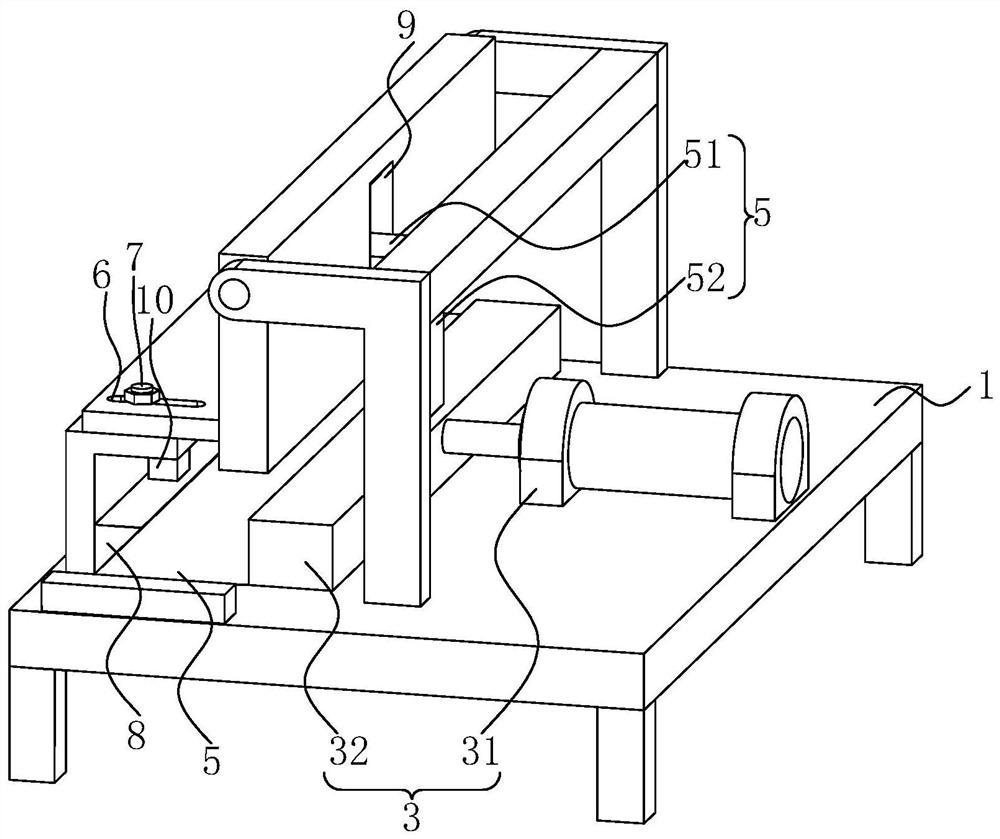

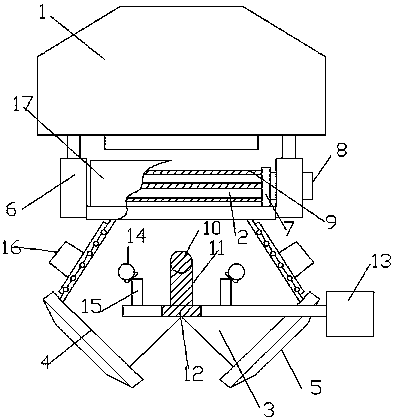

Planet gear numerical control lathe discharging device

ActiveCN112238226ARealize the output workImprove discharge efficiencyAutomatic workpiece supply/removalMetal working apparatusNumerical controlGear wheel

The invention relates to the technical field of machining equipment, in particular to a planet gear numerical control lathe discharging device. The planet gear numerical control lathe discharging device comprises a workbench, a first pushing unit, a second pushing unit and a tidying unit, and the first pushing unit, the second pushing unit and the tidying unit are located on the workbench. The moving direction of the second pushing unit is perpendicular to the moving direction of the first pushing unit, the tidying unit is located at the tail end of the pushing-out stroke of the second pushingunit, the first pushing unit is located between the starting end and the tail end of the pushing-out stroke of the second pushing unit, and the tidying unit is connected with the workbench in a hinged manner and is connected with an opening and closing unit. The planet gear numerical control lathe discharging device has the effect of improving the discharging efficiency of a numerical control lathe to a planet gear.

Owner:上海万众实业股份有限公司

A quantitative discharge type grain packaging bag that can be weighed by itself when discharging

ActiveCN111470168BWill not be affected by moistureAvoid breakingBagsSacksEngineeringMechanical engineering

A quantitative discharge type grain packaging bag that can be weighed by itself when discharging, including a bag body, a pressure sensor, a vertical rod and a discharge port. The inner top of the bag body is fixed with a top plate, and the front and rear ends of the top plate are Both are connected with a convex plate, and the middle position of the lower surface of the top plate is fixed with a partition that equally divides the inner space of the bag body. The inside of the connecting plate is interspersed with a connecting rod whose top end is welded with the first block, and the second The bottom end of the blocking block is fixedly connected with an adjustment rod located below the bag body, the outer side of the adjustment rod is provided with a discharge port communicating with the lower surface of the bag body, and the lower surface of the horizontal plate is connected with a baffle. The quantitative discharge type grain packaging bag, which can be weighed by itself when discharging, can carry out quantitative discharge after the grain is packed, so as to ensure that the amount of packaging remains the same, and at the same time, it can also be carried out during the discharge process. Weighing, and at the same time, it can protect the grain from moisture and deterioration when storing grain.

Owner:温州华南印业有限公司

Hot air drying device for fat powder

PendingCN113566505AEnergy savingImprove efficiencySievingDispersed particle filtrationElectric machineryHot blast

The invention discloses a hot air drying device for fat powder, and relates to the field of fat powder production. The hot air drying device comprises a drying box body, a fan, a heater and a filter, and the drying box body is internally provided with a grinding and screening mechanism and a cylindrical air guide pipe. The grinding and screening mechanism comprises a mounting bracket, a first cylindrical filtering frame, a radial shaft, a radial sliding block, a spring, a grinding part, a driven convex block and a driving convex block, a driving motor is arranged on the outer end wall of the drying box body, a first annular cleaning frame sleeves the outer end of the first cylindrical filtering frame, and first bristles are arranged on the inner end wall of the first annular cleaning frame. A second cylindrical filtering frame is arranged at the top end in the drying box body, a second annular cleaning frame sleeves the second cylindrical filtering frame, second bristles are arranged on the inner end wall of the second annular cleaning frame, and air guide fan blades are arranged in the second cylindrical filtering frame. The hot air drying device for the fat powder realizes hot air drying of the fat powder, and reduces the harm caused by excessive water content in the fat powder.

Owner:南京郁氏生物科技有限公司

Automatic sensing material separation and delivery device

InactiveCN107640610AStrong sensoryUniform and stable deliveryLoading/unloadingEngineeringMaterial Separation

The invention provides an automatic sensing material separation and delivery device. The automatic sensing material separation and delivery device comprises a discharging bin, an overturning cylinderand a material separation bin which are sequentially arranged from top to bottom, wherein two mutually symmetrical discharging ports are formed in the bottom of the material separation bin, each discharging port is provided with a sensing valve, the discharging bin is connected and fixed with the material separation bin through an air cylinder. Two ends of the overturning cylinder are fixed to a supporting shaft at the upper end of the material separation bin, and one end of the overturning cylinder is connected and fixed to a motor. A plurality of scraping plates are arranged on the surface of the overturning cylinder. A rotary shaft is arranged in the material separation bin, and a material separation plate is fixed to the rotary shaft. One end of the material separation plate is connected and fixed to one end block of an electric-hydraulic pusher through a convex block. A sensor paired with each sensing valve is arranged on the material separation bin, and a sensing block is arranged on the electric-hydraulic pusher. The automatic sensing material separation and delivery device has the advantages of being strong in sensing and uniform and stable in conveying and improving the working efficiency.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

Raw starter maker

PendingCN113716316AMaterial realizationSolve the discharge problemBioreactor/fermenter combinationsBiological substance pretreatmentsCircular discEngineering

The invention relates to the technical field of fermentation brewing equipment, in particular to a raw starter maker. The raw starter maker comprises a disc and a discharging mechanism; the disc comprises a disc body, an inner ring and an outer ring, the inner ring and the outer ring being respectively arranged on the inner ring and the outer ring of the disc body; and the discharging mechanism is arranged above the disc body and can rotate relative to the disc, and the discharging mechanism is used for lifting the materials on the disc to the position above the inner ring and / or the outer ring and conveying the lifted materials out of the disc. On the basis, discharging of the annular-groove-shaped disc can be conveniently achieved, and the discharging problem of the annular-groove-shaped disc is effectively solved.

Owner:GUANGDONG TIANNIANG INTELLIGENT EQUIP CO LTD

Intelligent Nano Dynamic Centrifugal Rotary Separation Device

The invention relates to the field of grinding equipment, in particular to an intelligent nanometer dynamic centrifugal rotary separation device, which includes a separation cylinder arranged in the grinding barrel of a sand mill, a cavity is formed inside the cylinder, and the two axial ends of the cylinder are Closed, the hollow shaft that drives the cylinder to rotate is axially inserted into the cavity, the cavity communicates with the inner cavity of the hollow shaft, and a vortex is opened inwardly from the outer wall of the cylinder, and the vortex communicates with the cavity. The separation device of the present invention completely abandons the structure of the existing screen separator, which allows the material to enter the inner cavity of the hollow shaft from the vortex to complete the discharge; since the separation device is driven by the hollow shaft to rotate, the strong centrifugal force generated during rotation Throw the grinding media, namely the grinding beads and the coarser material, to prevent the grinding beads from entering the inner cavity of the hollow shaft from the vortex; while the finer material can overcome the centrifugal force and enter the hollow shaft from the vortex under the pressure of the grinding cylinder. cavity, and then flow to the inner cavity of the hollow shaft to realize shaft discharge.

Owner:PUHLER GUANGDONG SMART NANO TECH CO LTD

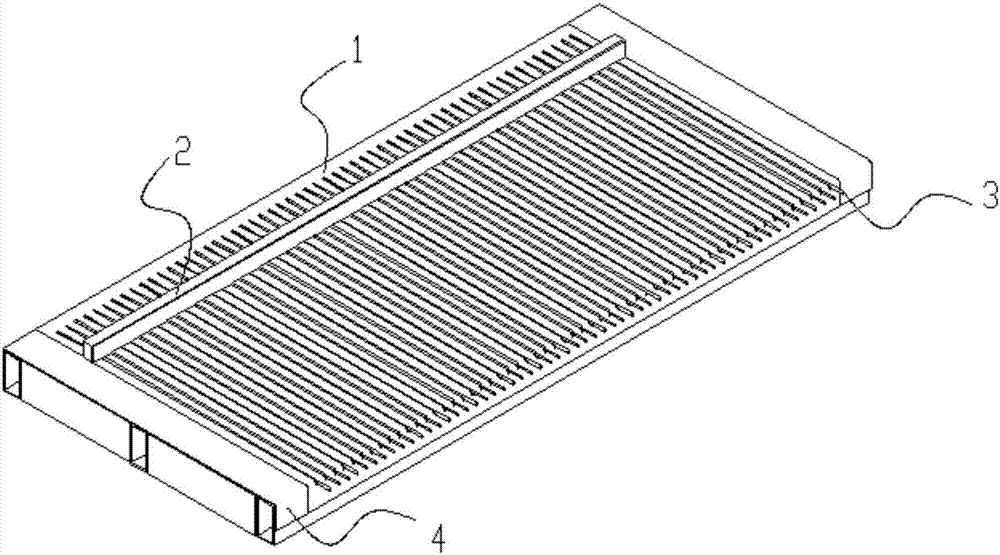

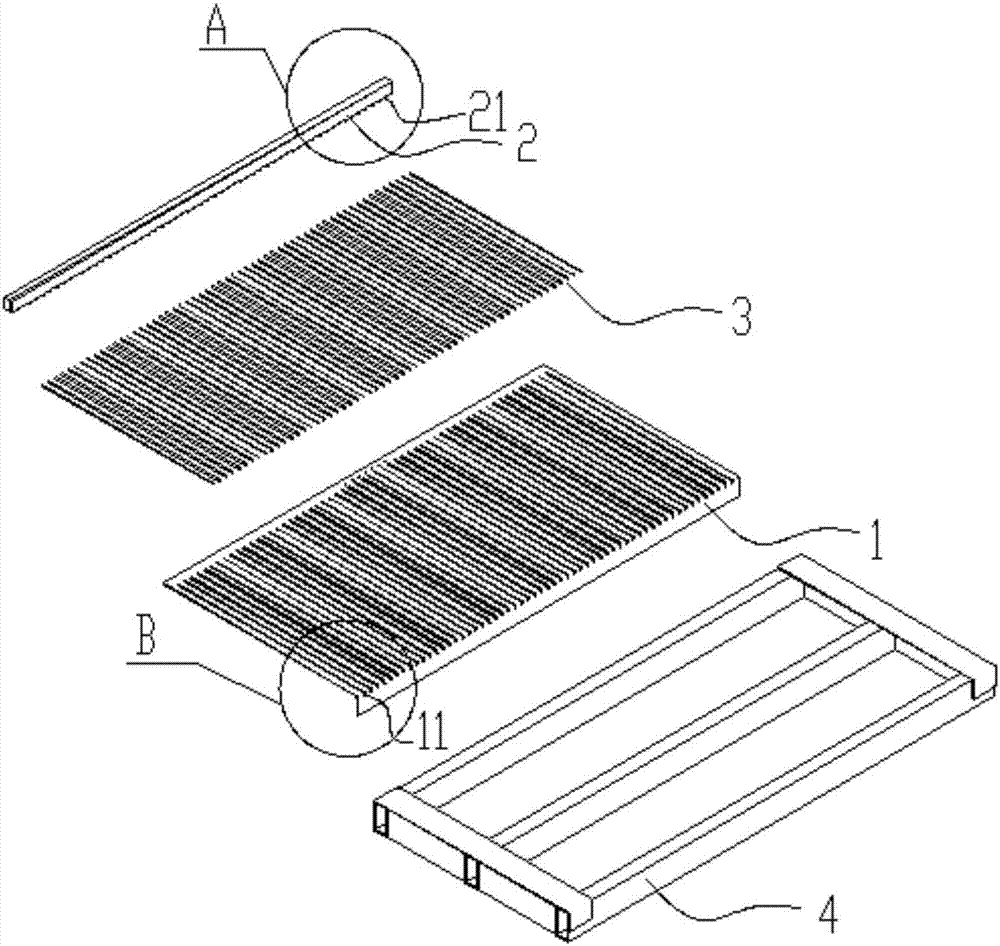

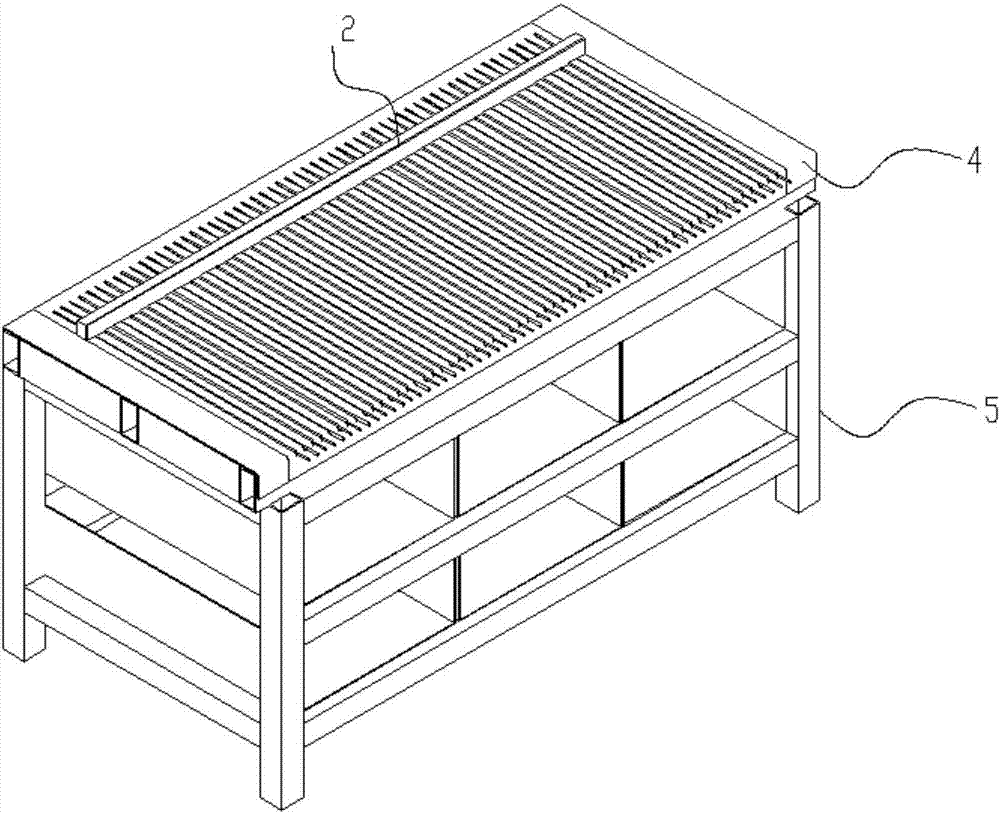

Wiring platform

The invention discloses a wiring platform, which can be a manual wiring platform or an automatic wiring platform. The manual wiring platform includes a material swing platform and a width adjustment bar. The groove can only accommodate one material rod, and also includes a bracket platform and a material rack supporting the swing platform. In addition to the manual wiring platform, the automatic routing platform is also provided with a pushing mechanism and a power device connected with the pushing mechanism. The manual wiring platform of the present invention can realize that the operator pushes the material rods on the material swing platform with bare hands or with the help of tools, and the material rods will automatically fall into the wire groove one by one; the automatic wiring platform is based on the manual wiring platform. Automation, the power device drives the pushing mechanism to automatically complete the material placement process on the material placement platform, which can be operated by one person and multiple machines; the above two wiring platforms not only reduce the dependence of placement on manual skills, save manpower, but also have high placement efficiency , The scrap rate is almost zero.

Owner:QINLONG METAL IND KUNSHAN

Impurity filtering device for water treatment agent production

InactiveCN114699823APrevent unfilterable phenomenaMaterial realizationSustainable biological treatmentMoving filtering element filtersImpellerEngineering

The invention relates to the technical field of water treatment, and discloses an impurity filtering device for water treatment agent production, the impurity filtering device comprises a box body, the inner wall of the box body is rotatably connected with a screw rod, the surface of the screw rod is movably connected with a transmission rod, the two ends of the transmission rod are fixedly connected with sliding blocks, the surface of the transmission rod is rotatably connected with an impeller, and the impeller is fixedly connected with the screw rod. A plurality of clamping rods are fixedly connected to the inner walls of the front side and the rear side of the box body, and sliding grooves are formed in the inner walls of the front side and the rear side of the box body. Raw materials are added into the box body, the raw materials can be filtered through a filter plate, so that impurities in the raw materials are blocked; the spiral rod can drive the transmission rod to move left and right in a reciprocating mode through the crossed spiral grooves in the surface and the clamping blocks on the inner wall of the transmission rod, the transmission rod can drive the impeller to move together, the impeller can be stirred by the clamping rods to rotate, and at the moment, caked raw materials on the filter plate can be broken by the impeller to be conveniently filtered.

Owner:蚌埠志达装饰工程有限公司

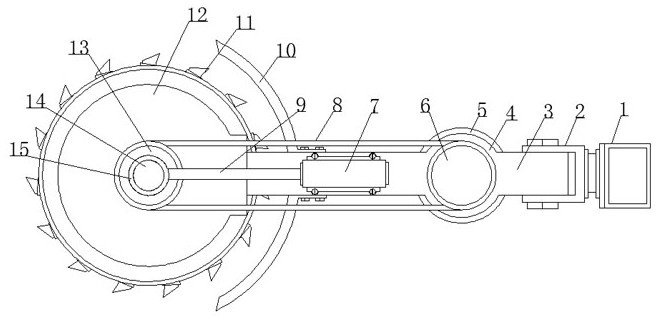

Water mist sand blasting derusting device for ships

PendingCN112809560AHigh strengthRust removal achievedAbrasive feedersAbrasive blasting machinesGear wheelMarine engineering

In order to solve the problem that the sand blasting force is not easy to control in the prior art, the invention discloses a water mist sand blasting derusting device for ships, which comprises a mounting rack, a connecting frame is fixedly mounted at the right end of the mounting rack, a handle is fixedly mounted on the right end surface of the connecting frame, a connecting rack is fixedly connected to the right side in the mounting rack, a motor is fixedly mounted on the rear surface of the connecting rack, a first gear is mounted at the front end of the motor, a water mist sand blasting machine is fixedly mounted on the left side of the surface of the mounting rack, a spray pipe is mounted on the left side of the water mist sand blasting machine, a lantern ring is fixedly connected to the left end of the spray pipe, a rotating shaft is sleeved with the lantern ring, the front end of the surface of the rotating shaft is fixedly sleeved with a second gear, a chain is connected between the first gear and the second gear, and the surface of the rotating shaft is fixedly sleeved with a rotating disc. The rotating disc can be driven by the motor to rotate, the water mist sand blasting force can be enhanced through centrifugal force, and therefore derusting through water mist sand blasting is effectively achieved.

Owner:ZHOUSHAN LIGANG SHIPBUILDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com