Building rubbish recycling device for rubbish recycling

A construction waste and recycling device technology, which is applied in recycling technology, construction waste recycling, filter screening, etc., can solve problems such as insufficient classification, inability to use construction waste, and insufficient recycling of construction waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

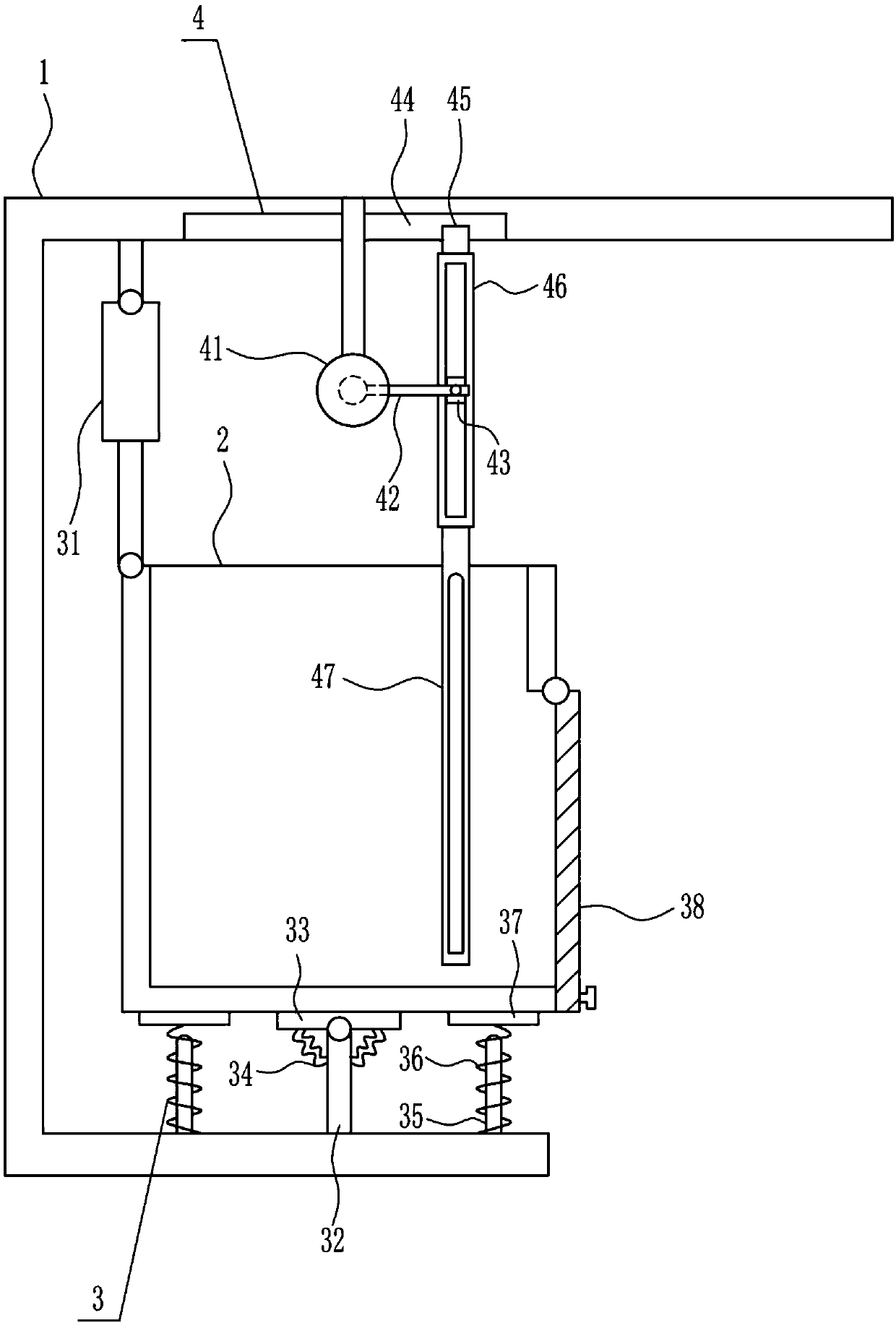

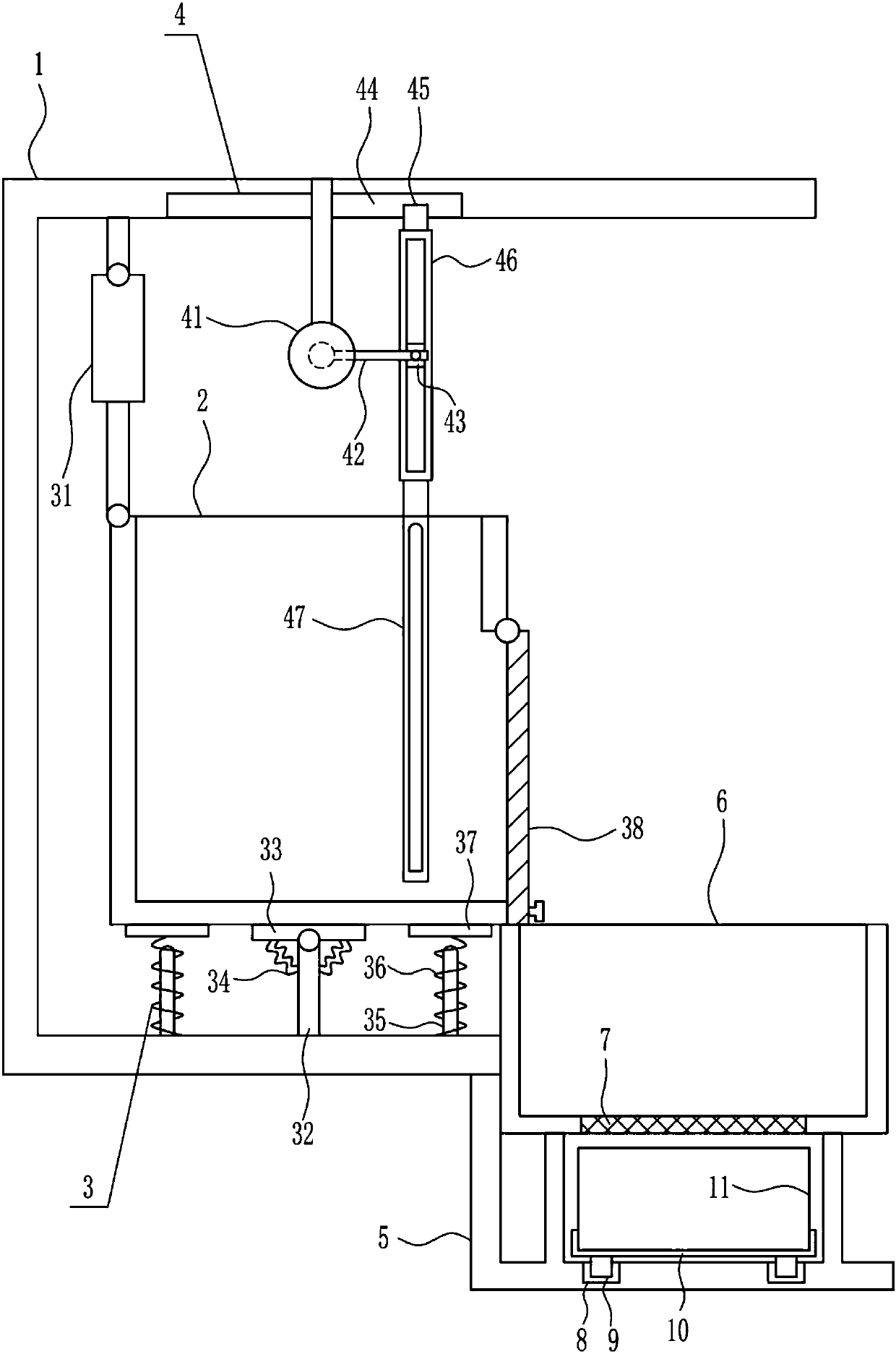

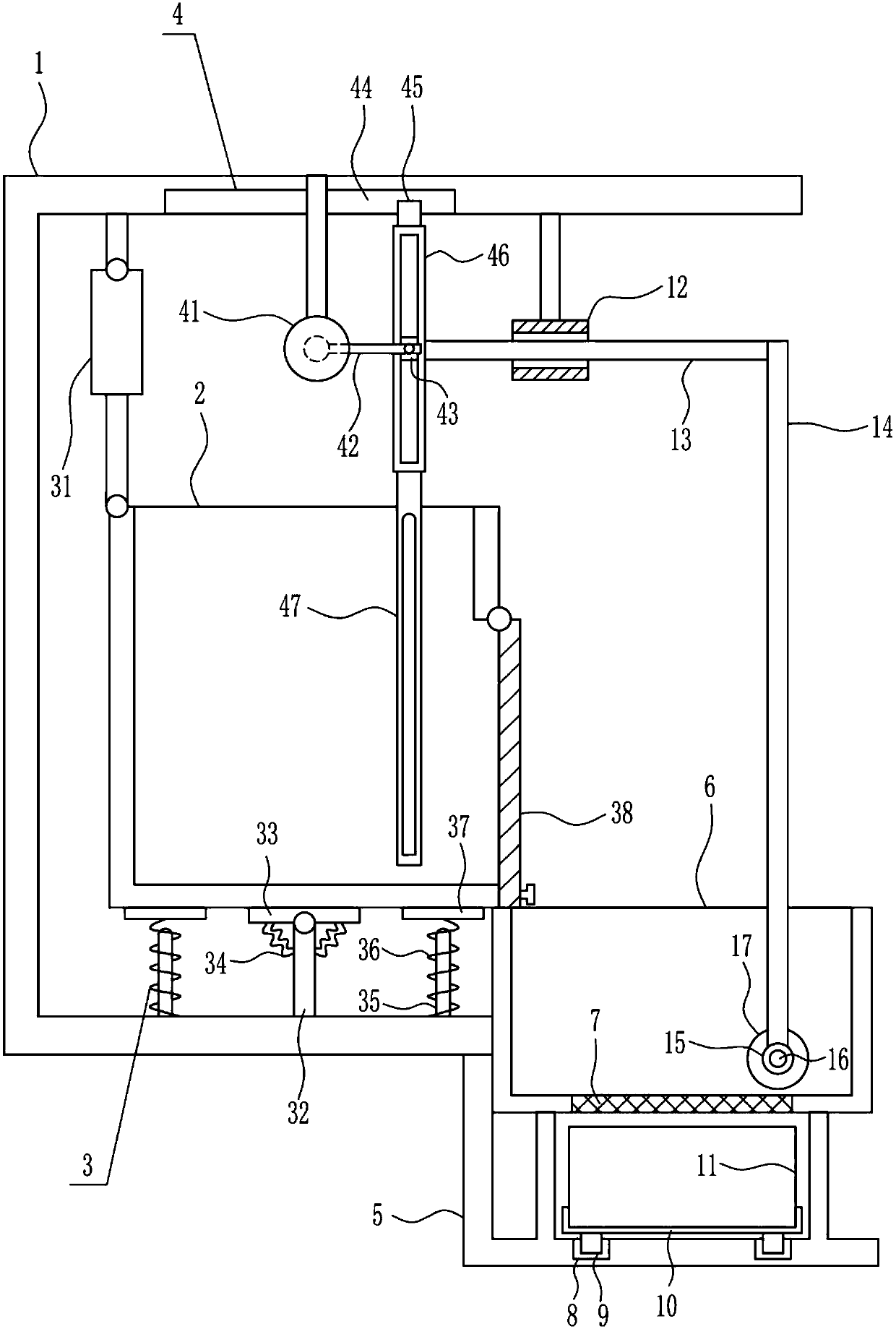

[0032] A construction waste recycling device for waste recycling, such as Figure 1-5 As shown, it includes a mounting frame 1, a charging box 2, a discharging mechanism 3, and a magnetic attraction mechanism 4. The mounting frame 1 is provided with a discharging mechanism 3, and the discharging mechanism 3 is connected with a charging box 2, and a mounting frame 1. The upper part is provided with a magnetic absorption mechanism 4, and the lower part of the magnetic absorption mechanism 4 is located in the charging box 2.

Embodiment 2

[0034] A construction waste recycling device for waste recycling, such as Figure 1-5 As shown, it includes a mounting frame 1, a charging box 2, a discharging mechanism 3, and a magnetic attraction mechanism 4. The mounting frame 1 is provided with a discharging mechanism 3, and the discharging mechanism 3 is connected with a charging box 2, and a mounting frame 1. The upper part is provided with a magnetic absorption mechanism 4, and the lower part of the magnetic absorption mechanism 4 is located in the charging box 2.

[0035] The discharging mechanism 3 includes an air cylinder 31, a support rod 32, a rotating plate 33, a first spring 34, a rubber column 35, a second spring 36, a support plate 37, and a baffle 38. The upper left side of the mounting frame 1 is rotatably connected with an air cylinder 31. The bottom end of the telescopic rod of the cylinder 31 is rotatably connected with the top left of the loading box 2, a support rod 32 is connected at the bottom of the mou...

Embodiment 3

[0037] A construction waste recycling device for waste recycling, such as Figure 1-5 As shown, it includes a mounting frame 1, a charging box 2, a discharging mechanism 3, and a magnetic attraction mechanism 4. The mounting frame 1 is provided with a discharging mechanism 3, and the discharging mechanism 3 is connected with a charging box 2, and a mounting frame 1. The upper part is provided with a magnetic absorption mechanism 4, and the lower part of the magnetic absorption mechanism 4 is located in the charging box 2.

[0038] The discharging mechanism 3 includes an air cylinder 31, a support rod 32, a rotating plate 33, a first spring 34, a rubber column 35, a second spring 36, a support plate 37, and a baffle 38. The upper left side of the mounting frame 1 is rotatably connected with an air cylinder 31. The bottom end of the telescopic rod of the cylinder 31 is rotatably connected with the top left of the loading box 2, a support rod 32 is connected at the bottom of the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com