Patents

Literature

54 results about "Demolition waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Demolition waste is waste debris from destruction of buildings, roads, bridges, or other structures. Debris varies in composition, but the major components, by weight, in the US include concrete, wood products, asphalt shingles, brick and clay tile, steel, and drywall. There is the potential to recycle many elements of demolition waste.

Retrieving aggregates and powdery mineral material from demolition waste

ActiveUS20160046532A1Negatively propertyEasy retrievalSolid waste managementDemolition wasteGranularity

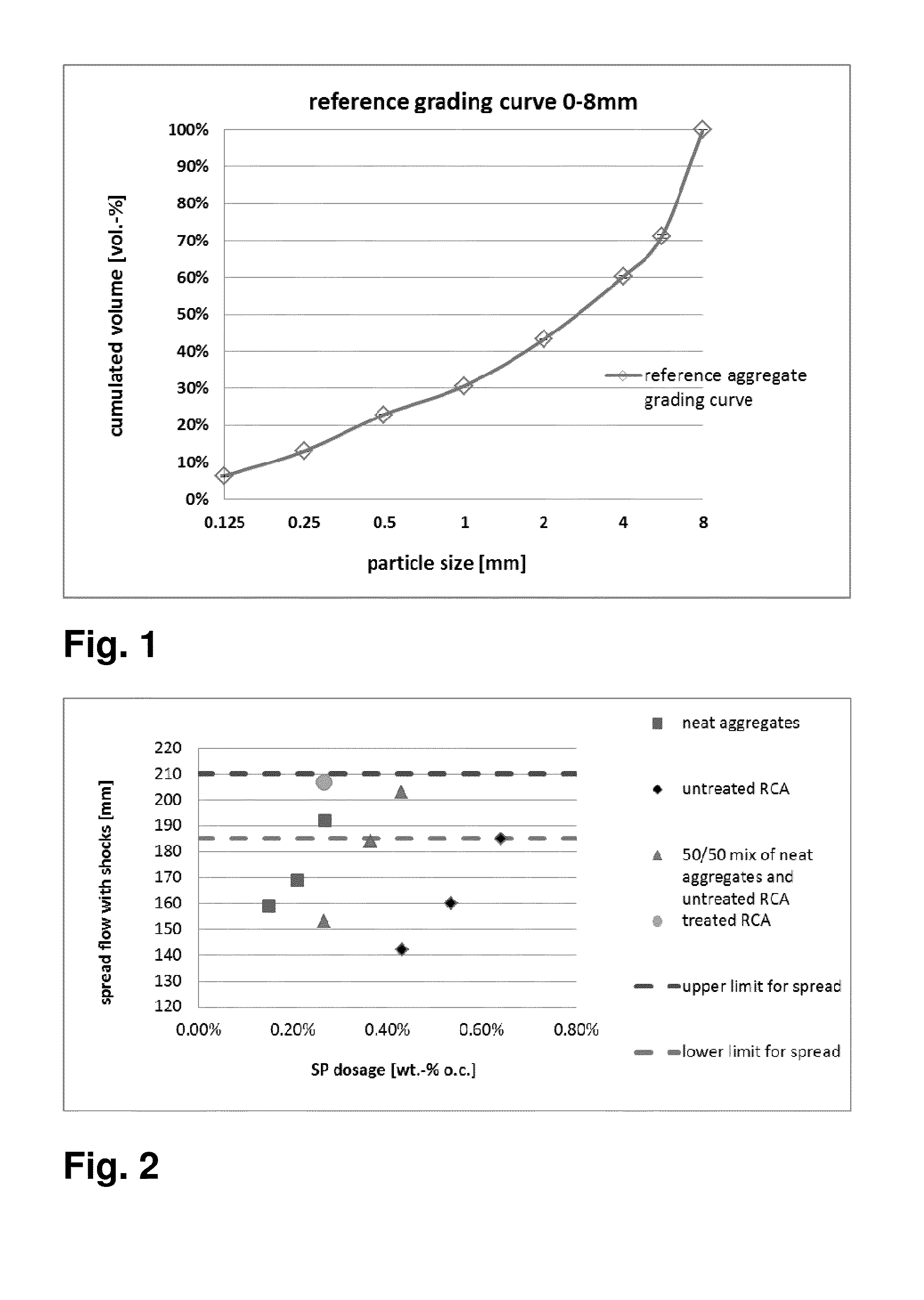

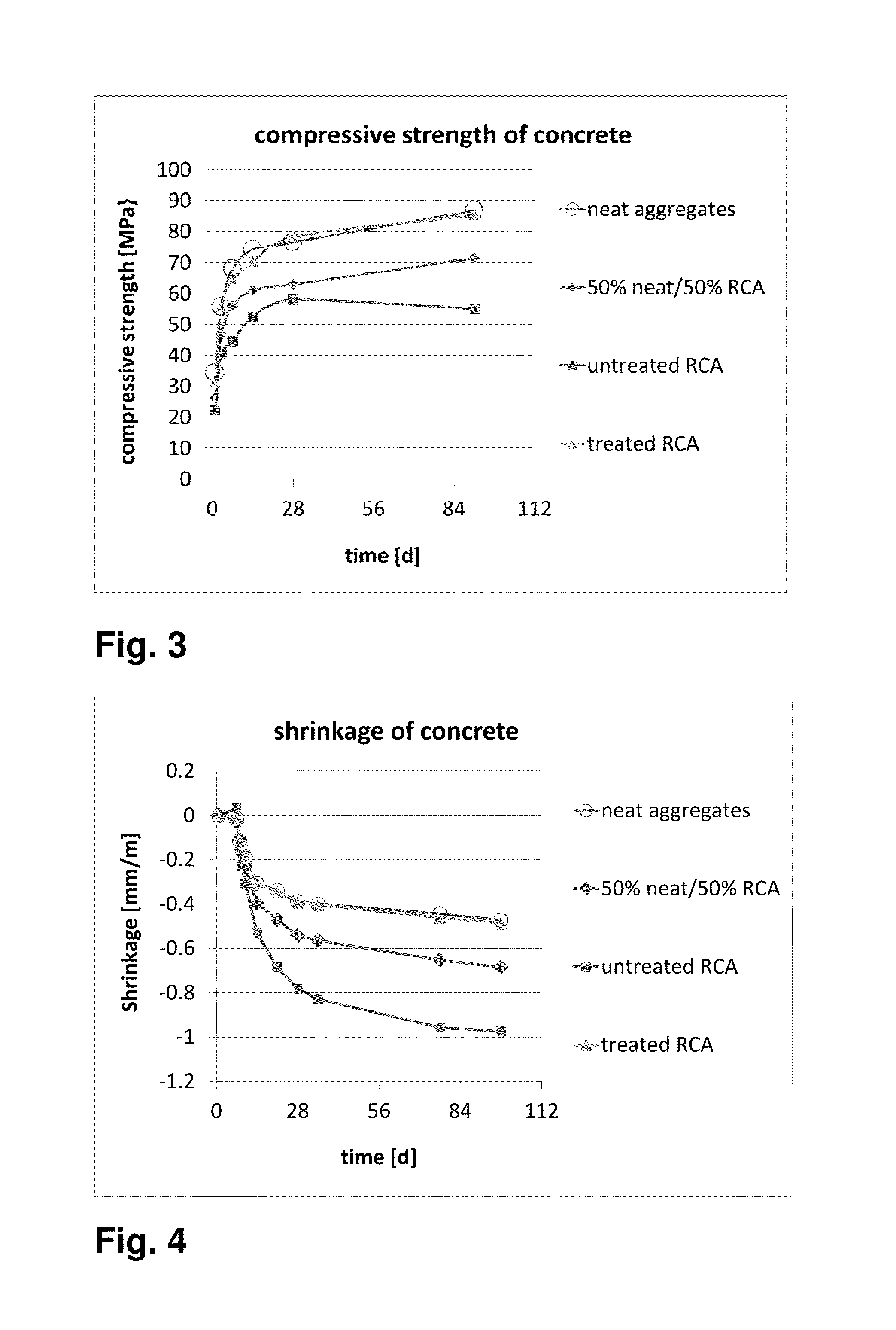

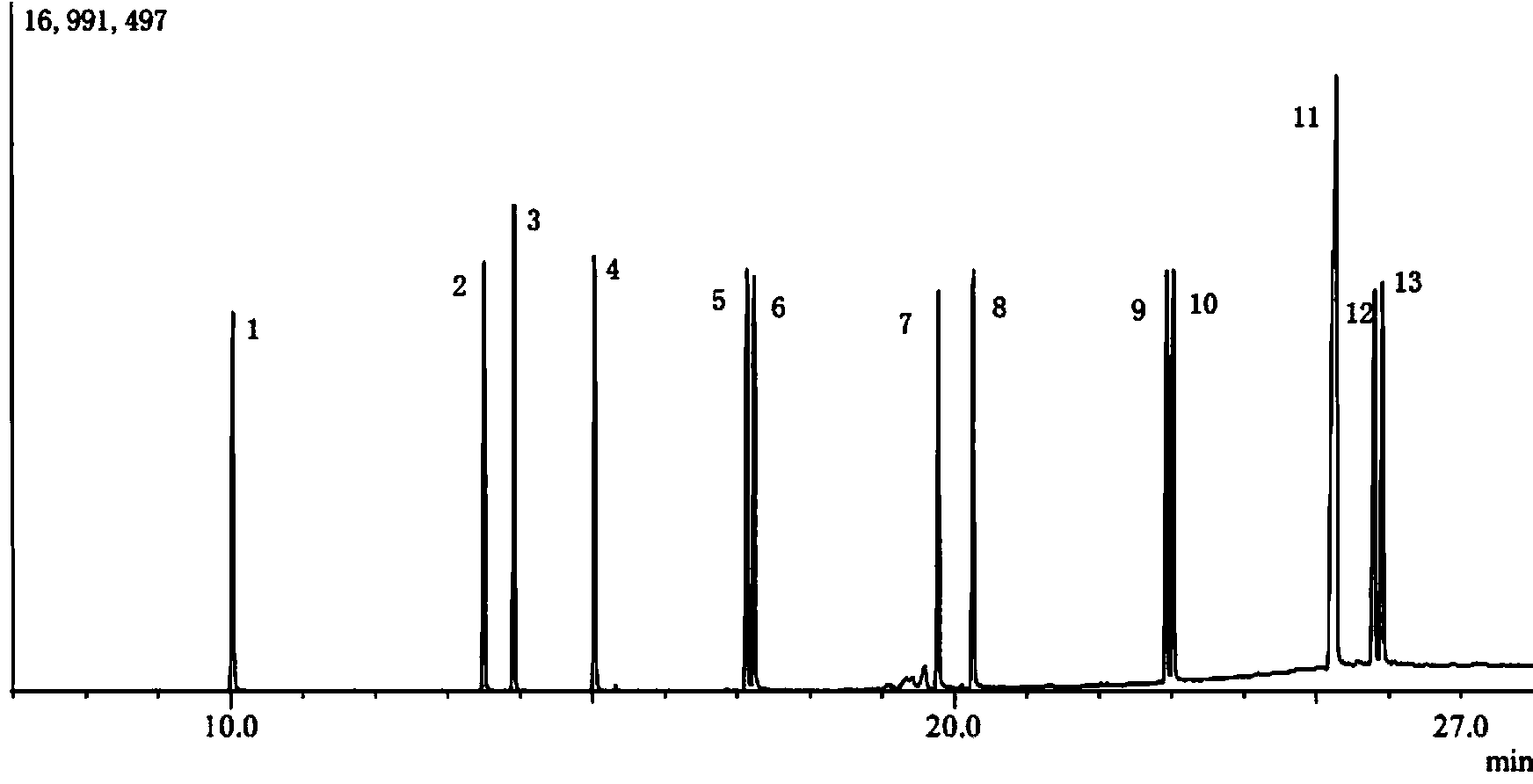

A method for retrieving aggregates and / or powdery mineral material from a source material comprising hardened mineral binder and aggregates, in particular a waste or demolition material, comprises the steps of: a) treating the source material in a disintegration process and (b) separation of the treated source material at a predefined cut-off grain size in order to retrieve treated aggregates with a grain size of at least the predefined cut-off grain size and / or in order to retrieve powdery mineral material with a grain size below the predefined cut-off grain size.

Owner:SIKA TECH AG

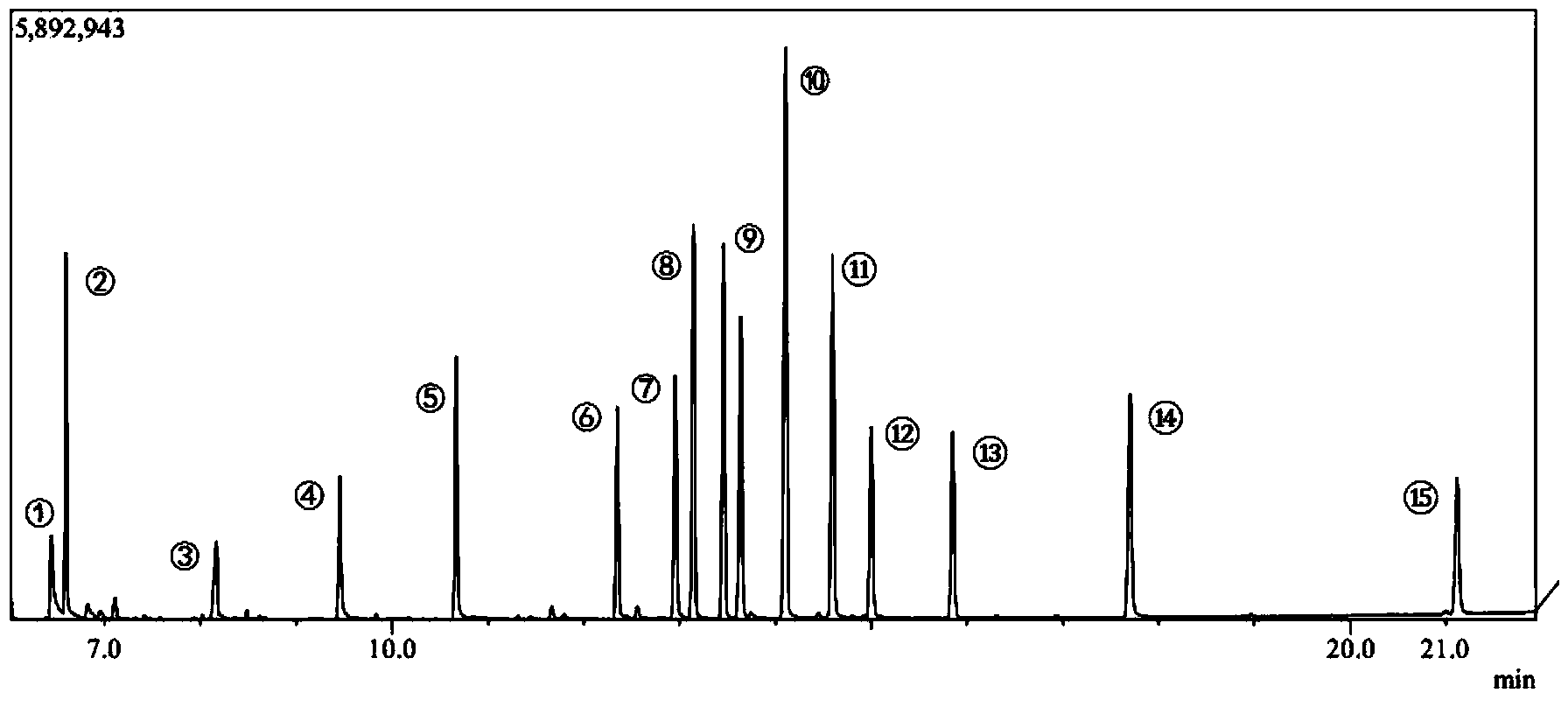

Method for determining organic matter in demolition wastes

InactiveCN104165956ASimple particle size requirementsReduce lossesComponent separationGas phaseVapor phase chromatography

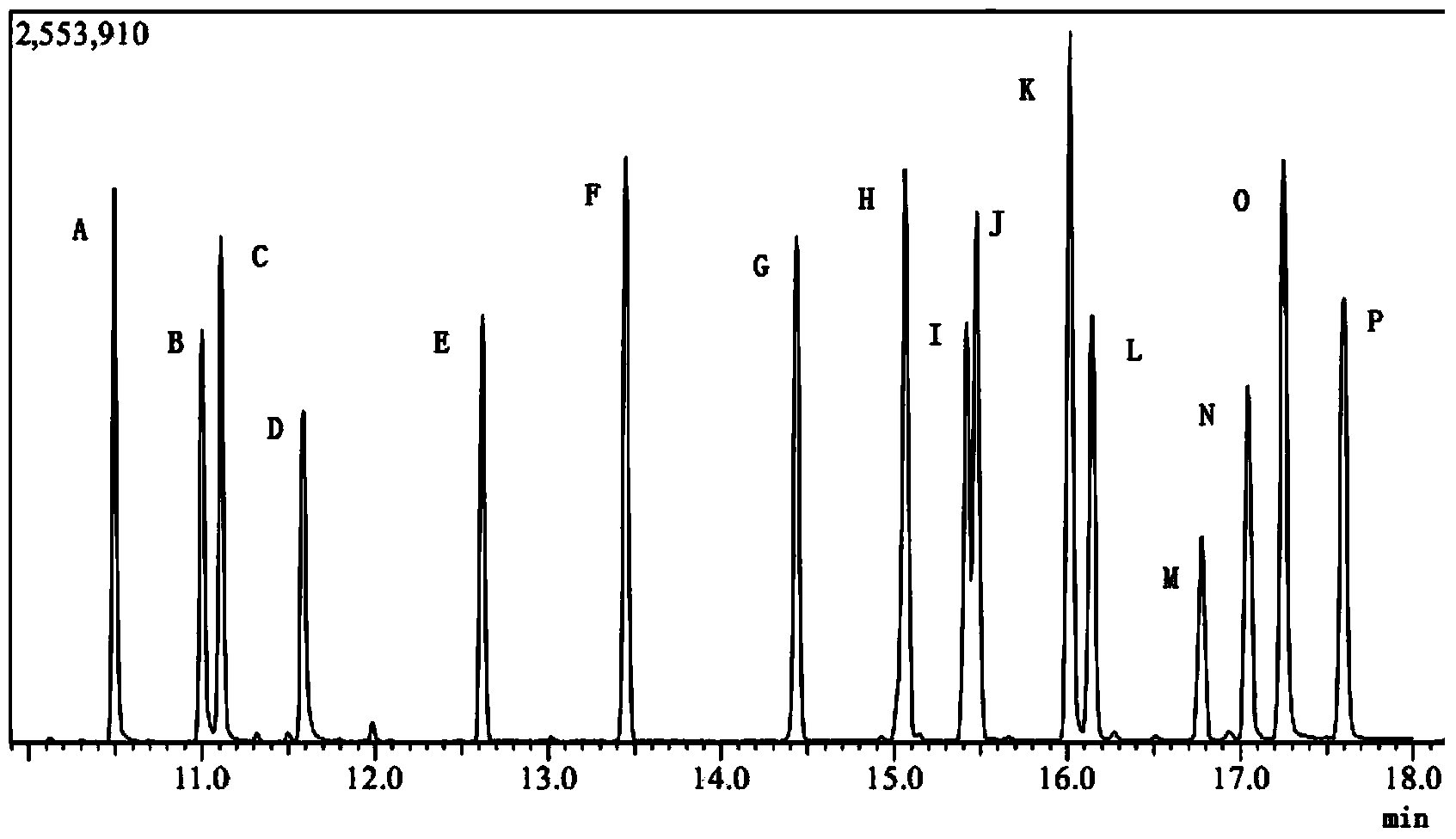

The invention relates to a method for determining organic matter in demolition wastes. The method comprises the following steps: adding an acetone solution into the demolition wastes, and carrying out synchronous pretreatment extraction through ultrasonic-centrifugal coupling to obtain extraction liquid containing organic matter; purifying the extraction liquid by a silicone solid-phase extraction column; and finally, determining the content of organic matter in the demolition wastes by a gas chromatograph-mass spectrometer (GC-MS). The organic matter in the demolition wastes include polluted construction wastes with various grain sizes in industrial enterprises and organic chlorine pesticides, organic phosphorus pesticides and polycyclic aromatic hydrocarbon in soil. The method is high in determining speed, accurate in analysis result, low in pretreatment cost and easy to combine with the GC-MS and is suitably used for synchronously extracting polycyclic aromatic hydrocarbon and pesticides from the demolition wastes of the industrial enterprises and purifying and determining organic pollutants such as pesticides and polycyclic aromatic hydrocarbon.

Owner:TONGJI UNIV

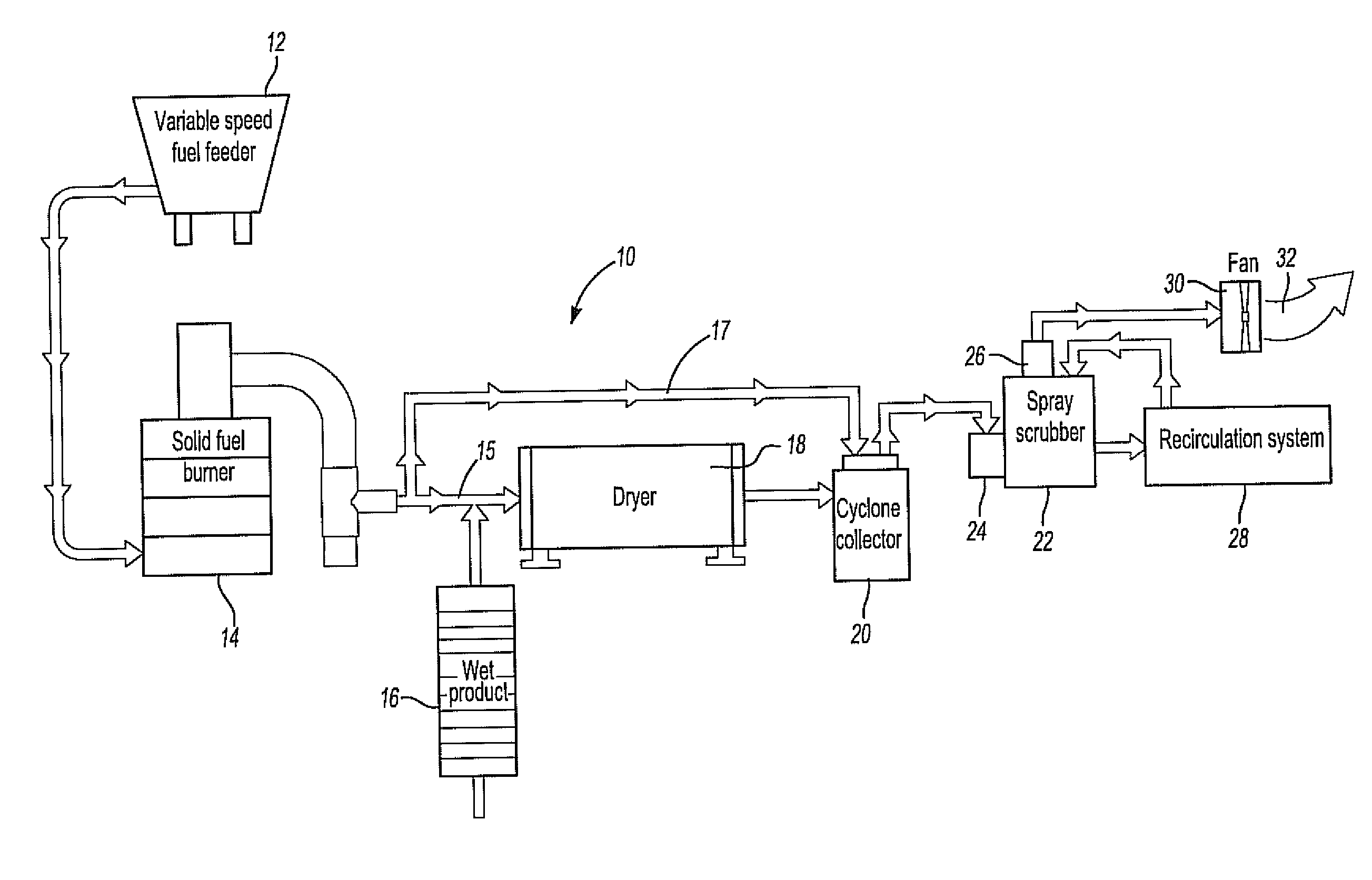

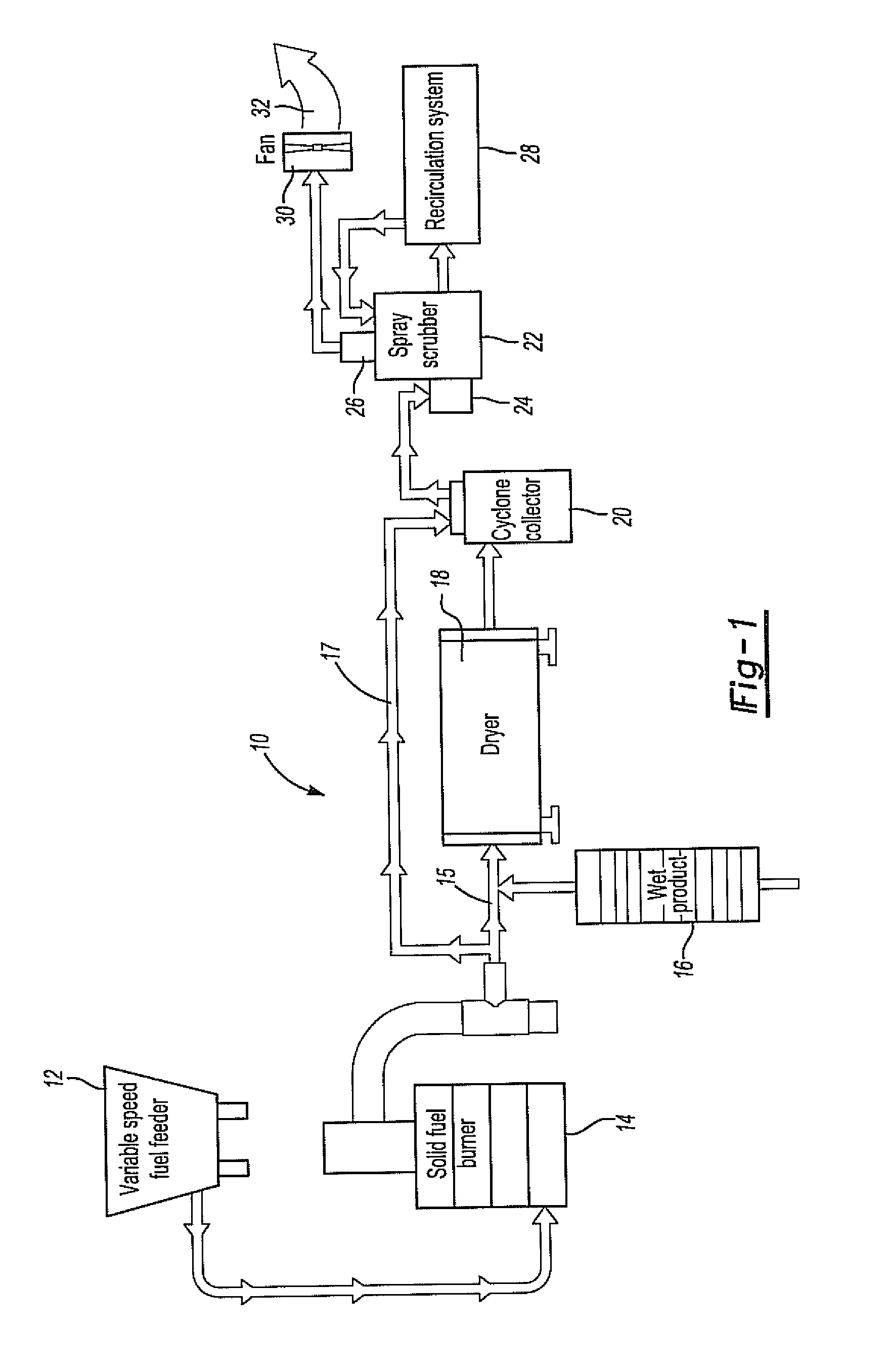

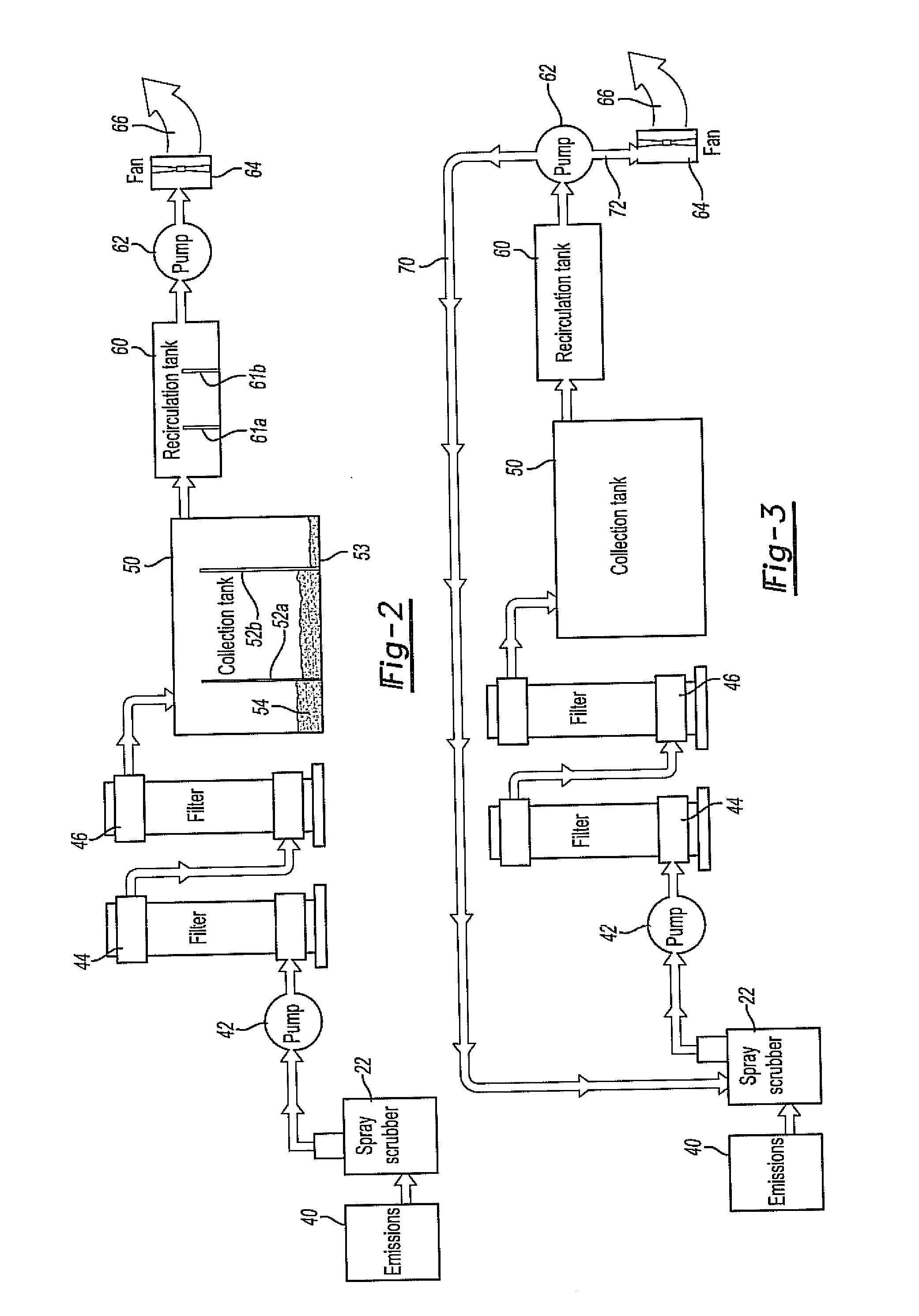

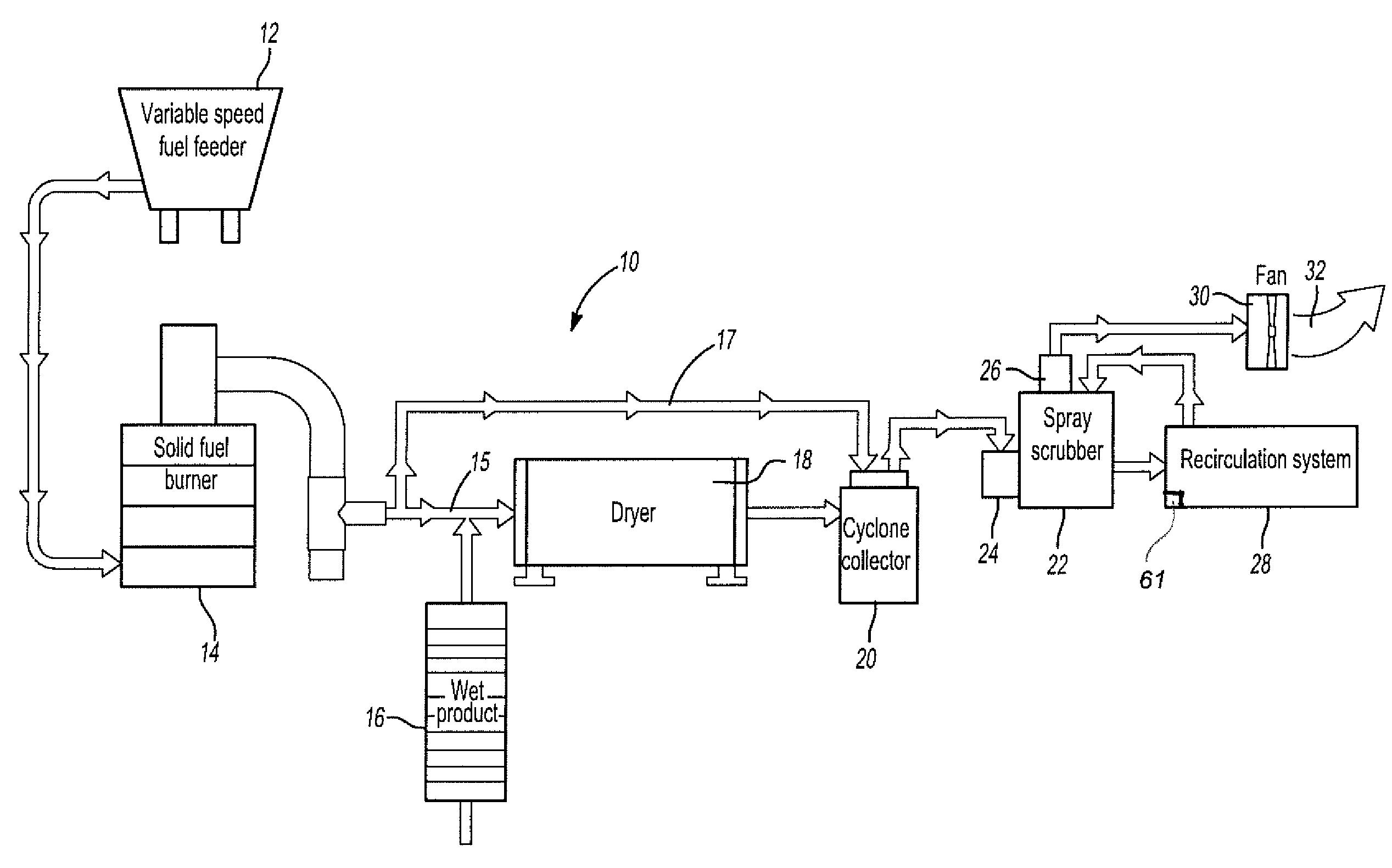

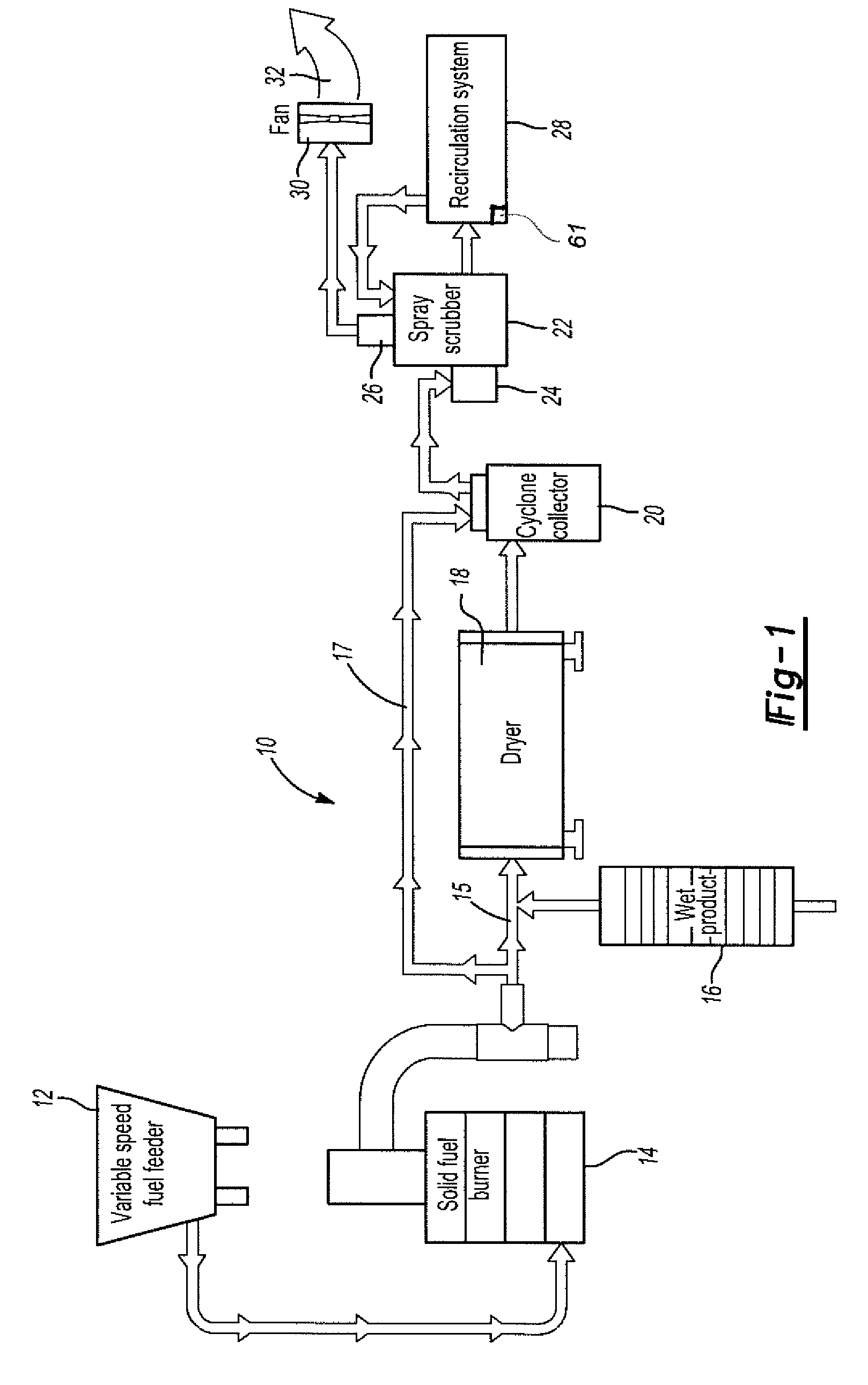

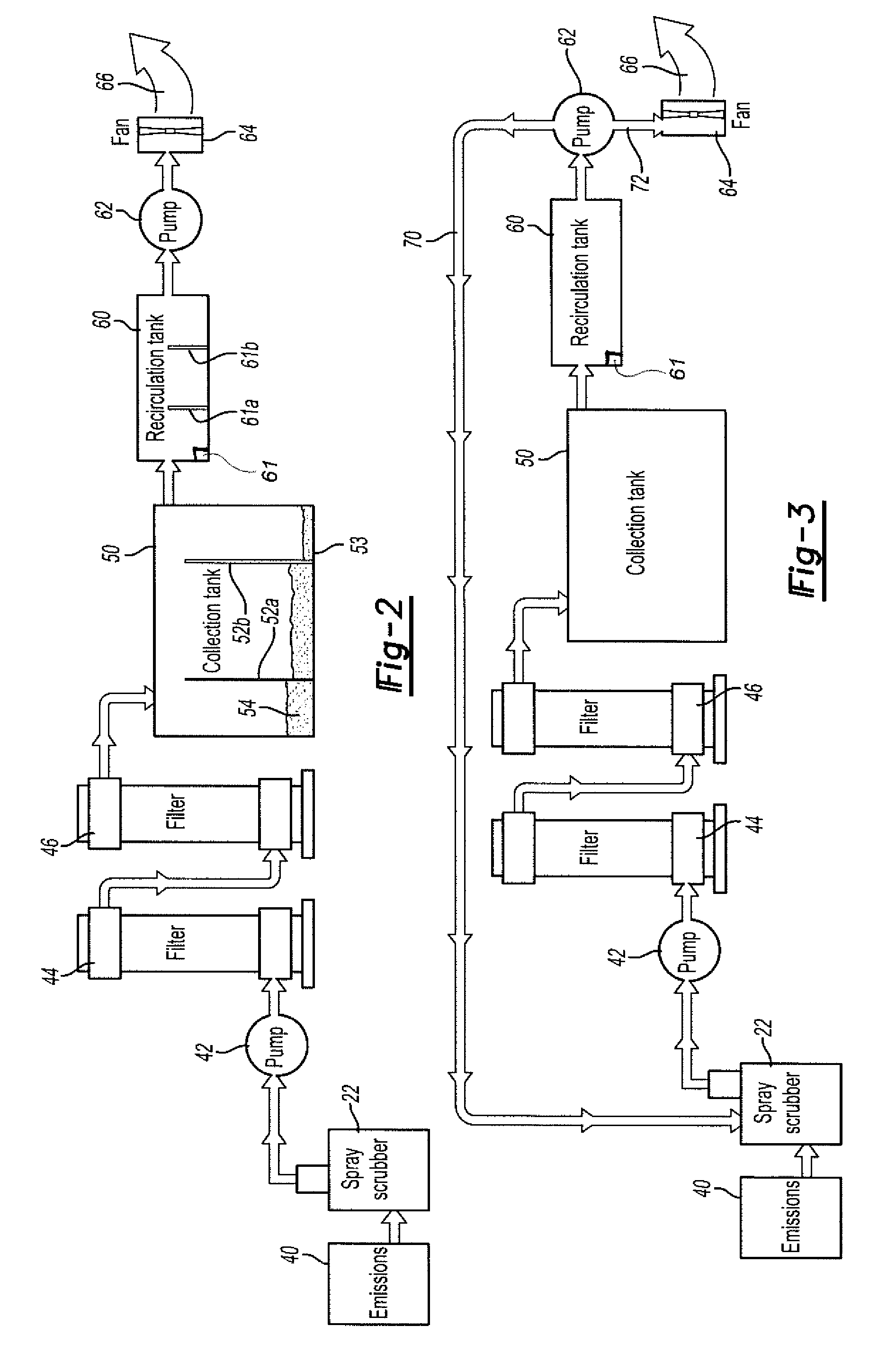

Biomass dryer/burner system

ActiveUS20100202949A1Moisten emissionMeet emissionsCombination devicesGas treatmentAir filtrationAtmospheric air

The present invention provides a biomass dryer / burner having an air cleaning apparatus adapted to accept emissions from the biomass dryer / burner and to convert said emissions to clean air to meet government emission standards. The biomass dryer / burner unit includes a dryer adapted to dry biomass, such as demolition waste or cut trees. The biomass dryer / burner unit optionally including a burner adapted to burn biomass. The biomass dryer / burner further producing emissions requiring cleaning before exhausting to the atmosphere. The air cleaning apparatus including a spray scrubber fluidly connected to the biomass dryer / burner adapted to moisten emissions, a recirculation tank in fluid communication with a collection tank, and the recirculation tank further having a sensor adapted to measure contaminant levels contained within the recirculation air filtration system. The sensor contained within the recirculation tank measures levels of carbon monoxide. If the air contained within the recirculation air filtration system measures above a predetermined contaminant level, then the air contained within the recirculation air filtration system is directed back into the spray scrubber. If the air contained within the recirculation air filtration system is below a predetermined level, then the air is exhausted into the atmosphere.

Owner:VALENTE PETER

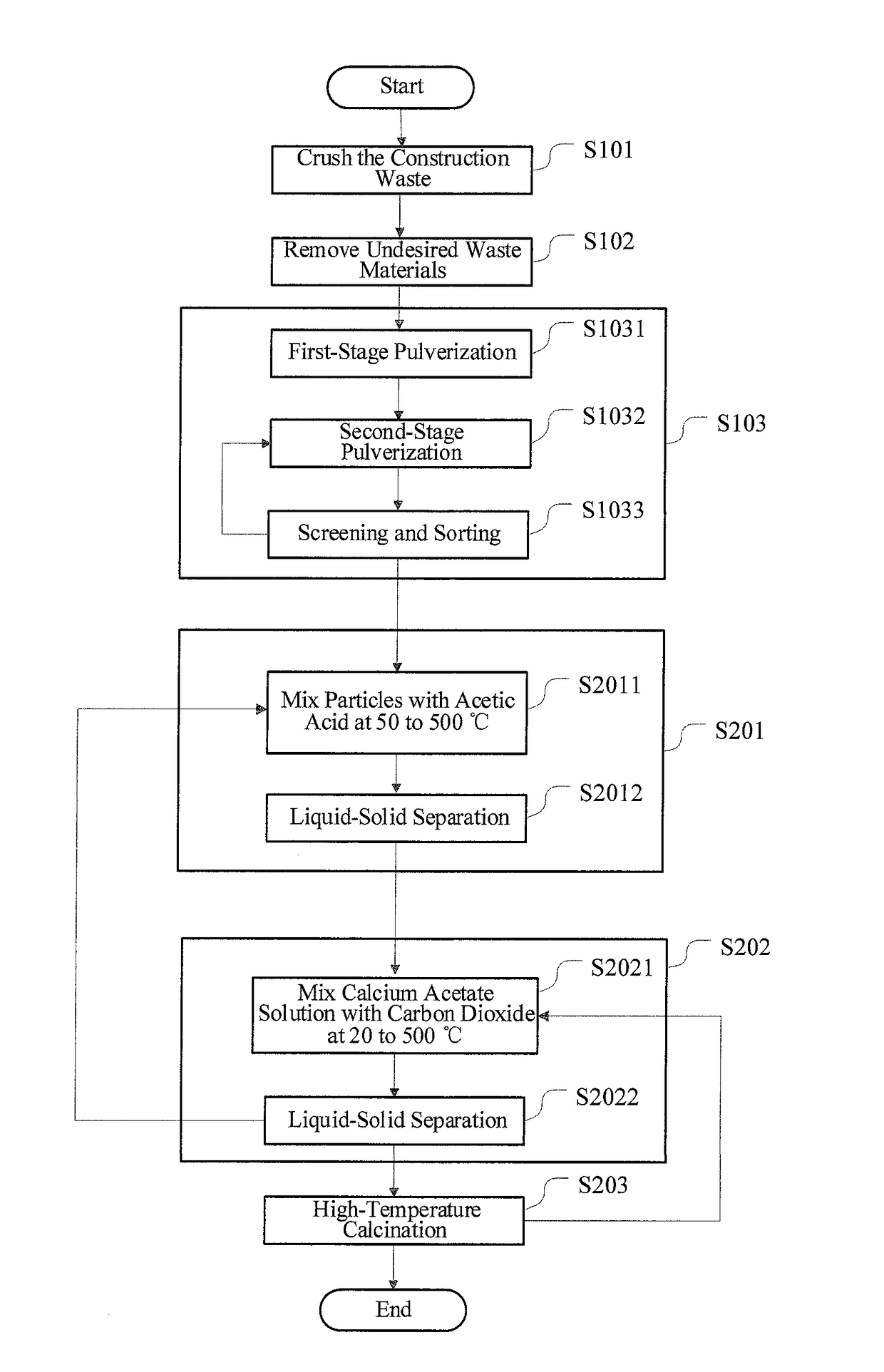

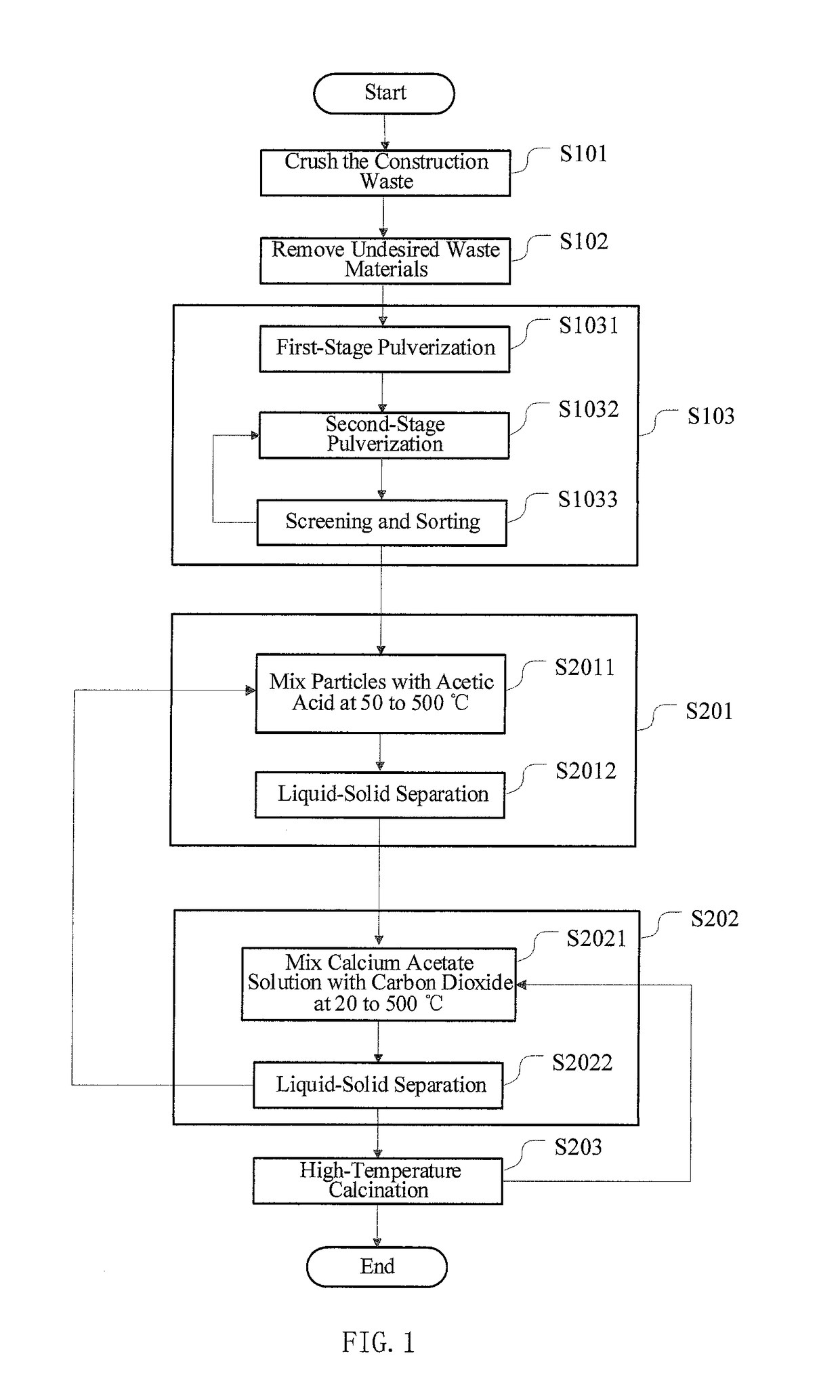

Method of utilizing construction and demolition waste

ActiveUS20180056344A1Reduce exploitationReducing greenhouse gas emissionCalcium/strontium/barium carbonatesSilicaDemolition wastePrill

A method of utilizing construction and demolition waste is disclosed. The method comprises pretreating the construction and demolition waste into particles with a predetermined range of size; and obtaining calcium carbonate from the particles. The method of the present invention enables to recycle a wide range of construction and demolition waste, furthermore it can convert these waste materials into the high purity calcium carbonate which can be widely used in many applications.

Owner:YUANCHU TECH (BEIJING) CO LTD

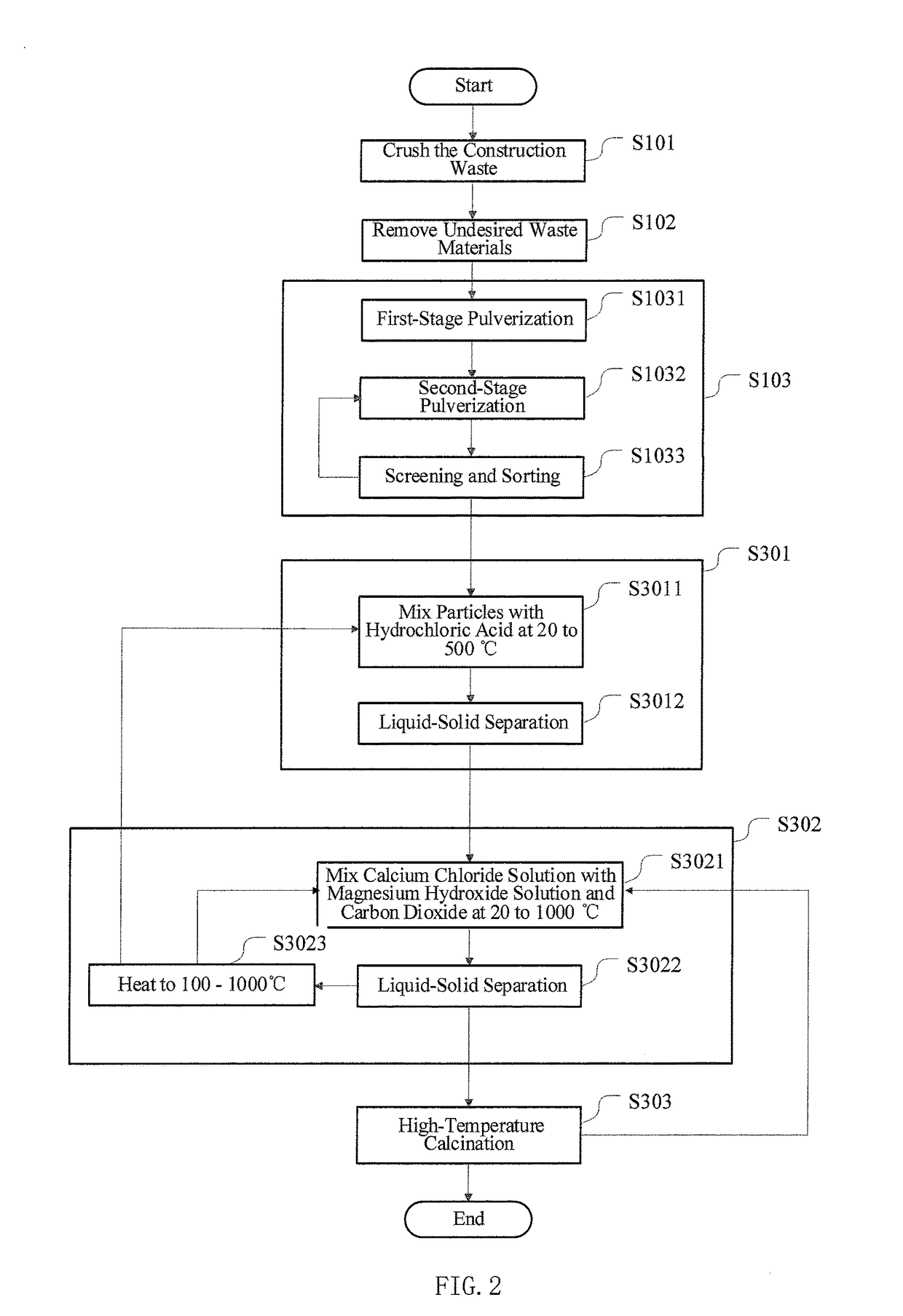

Technological method and system for treating construction waste

ActiveCN109967494AImprove processing efficiencySolve processing problemsConstruction waste recoverySolid waste disposalDemolition wasteEngineering

The invention provides a technological method and system for treating construction waste. The technological method comprises the steps that demolition waste is crushed into mixed materials; concrete block materials are treated by a first screening device, and first oversize materials, with the particle size larger than the screening limit of a first screening device, in the concrete block materials enter a first winnowing device for subsequent treatment; decoration waste is conveyed to a second screening device, waste, with the particle size larger than the second screening limit of the secondscreening device, in the decoration waste is obstacles, and second undersize materials with the particle size smaller than the second screening limit enter a third screening device; third oversize materials, with the particle size larger than the third screening limit of the third screening device, in the second undersize materials enter a second winnowing device, and third undersize materials with the particle size smaller than the third screening limit enters a fourth screening device; and oversize materials, with the particle size larger than the fourth screening limit, in the third undersize materials enter the first winnowing device, and undersize materials with the particle size larger than the fourth screening limit are discharged to an intermediate storage bin. The treatment efficiency of the construction waste can be improved.

Owner:宜兴华都琥珀环保机械制造有限公司

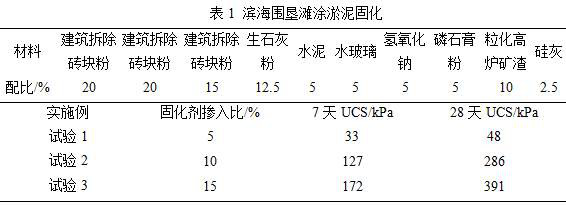

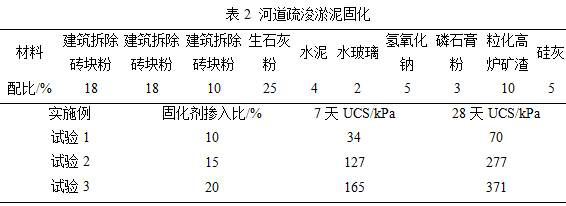

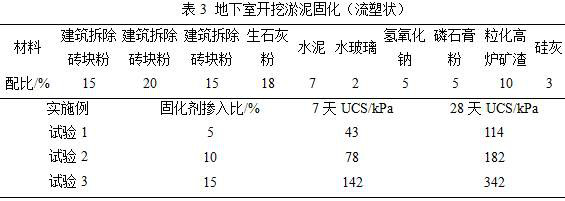

Sludge soft soil curing agent and sludge soft soil curing method

The invention belongs to the technical field of civil engineering, and particularly relates to a sludge soft soil curing agent and a sludge soft soil curing method. Broken bricks, concrete fragments and mortar fragments generated in the house demolition process are used as raw materials, part of exciting materials are added in a matched mode, the activity of building demolition waste is excited, the building demolition waste has a certain hydration characteristic, and the sludge soft soil curing agent is prepared according to the principle. The exciting materials include quicklime powder, cement, water glass, sodium hydroxide, ardealite powder and the like. The comprehensive production cost of the curing agent is obviously reduced compared with that of curing agents in the prior art. The prepared curing agent is uniformly mixed with sludge soft soil, so that the reinforced sludge has good mechanical strength and meets the requirement of engineering construction on bearing capacity, thereby achieving the purpose of resource utilization of building demolition garbage and soft soil sludge and achieving the effect of treating waste with waste.

Owner:温州市渣土利用开发股份有限公司

Retrieving aggregates and powdery mineral material from demolition waste

ActiveUS10029951B2Reduce negative impactImprove the hydraulicity of the ashesSolid waste managementDemolition wasteSource material

A method for retrieving aggregates and / or powdery mineral material from a source material comprising hardened mineral binder and aggregates, in particular a waste or demolition material, comprises the steps of: a) treating the source material in a disintegration process and (b) separation of the treated source material at a predefined cut-off grain size in order to retrieve treated aggregates with a grain size of at least the predefined cut-off grain size and / or in order to retrieve powdery mineral material with a grain size below the predefined cut-off grain size.

Owner:SIKA TECH AG

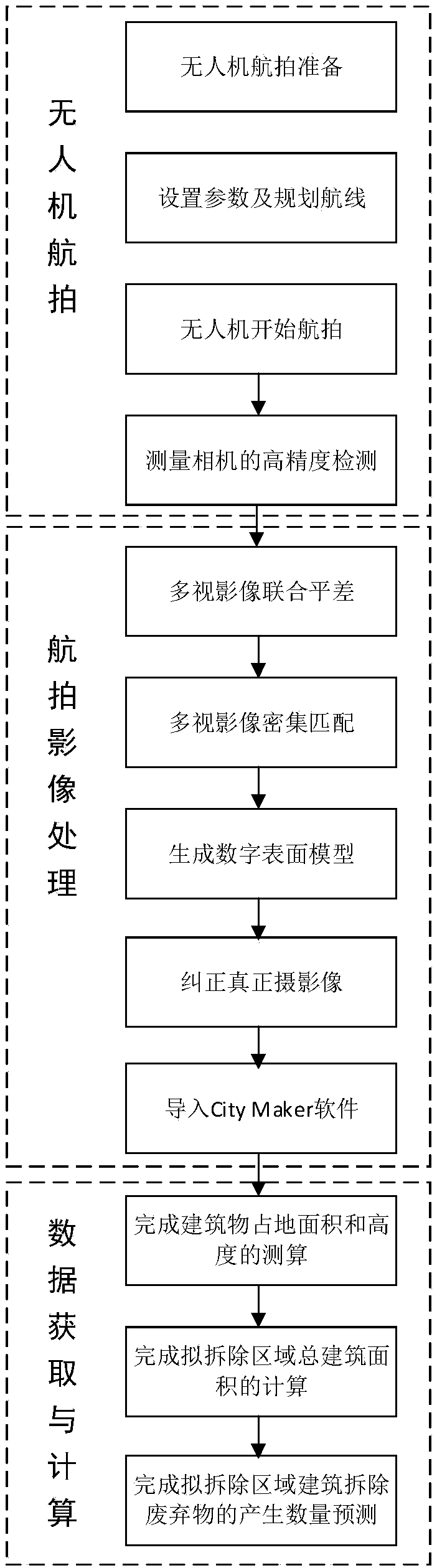

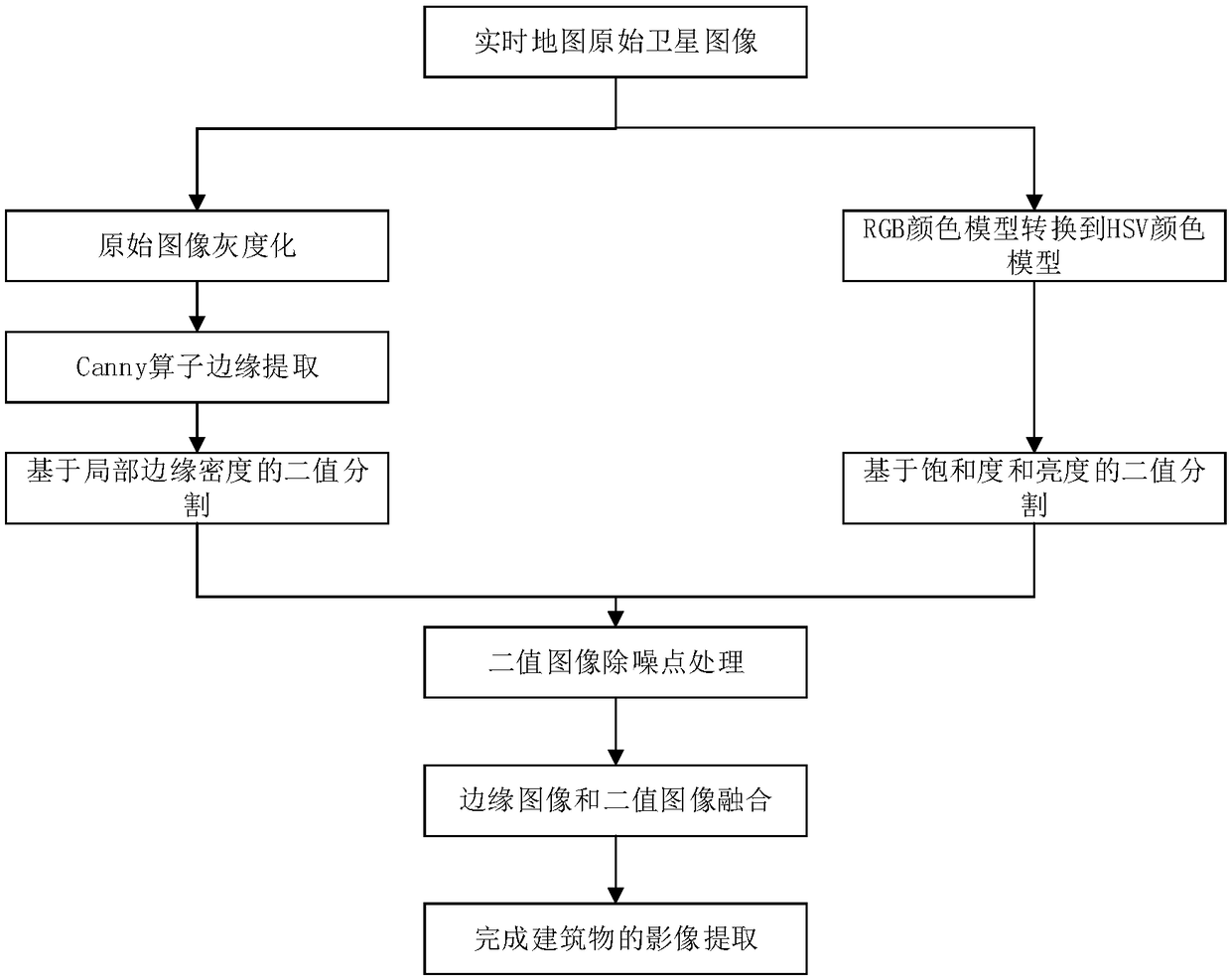

Method, system and medium for predicting waste production amount based on tilt photography

PendingCN109063638AFast and Automated 3D ModelingFast and automated footprintForecastingCharacter and pattern recognitionImaging processingDemolition waste

The invention discloses a method for predicting the generation amount of building demolition waste based on inclined photography, which comprises the following steps: setting flight parameters and route of an unmanned aerial vehicle; Acquisition of building images of the area to be demolished; Multi-view image processing is carried out on the building image data of the area to be demolished; Generate visualized digital surface model; Generate building documents for the area to be demolished; The building height and the occupied area of the area to be demolished are calculated, and then the amount of building demolition waste generated in the area to be demolished is obtained. A system for predict that amount of building demolition waste generate based on tilt photography comprises an aerial photograph control module, a data processing module, and a building demolition waste generating amount calculation module. And a computer readable storage medium. It improves the speed of data acquisition and realizes the rapid and automatic building three-dimensional modeling, so as to quickly obtain the floor area and height of the building, and effectively reduce the resources invested by thefield survey to obtain the index.

Owner:SHENZHEN UNIV

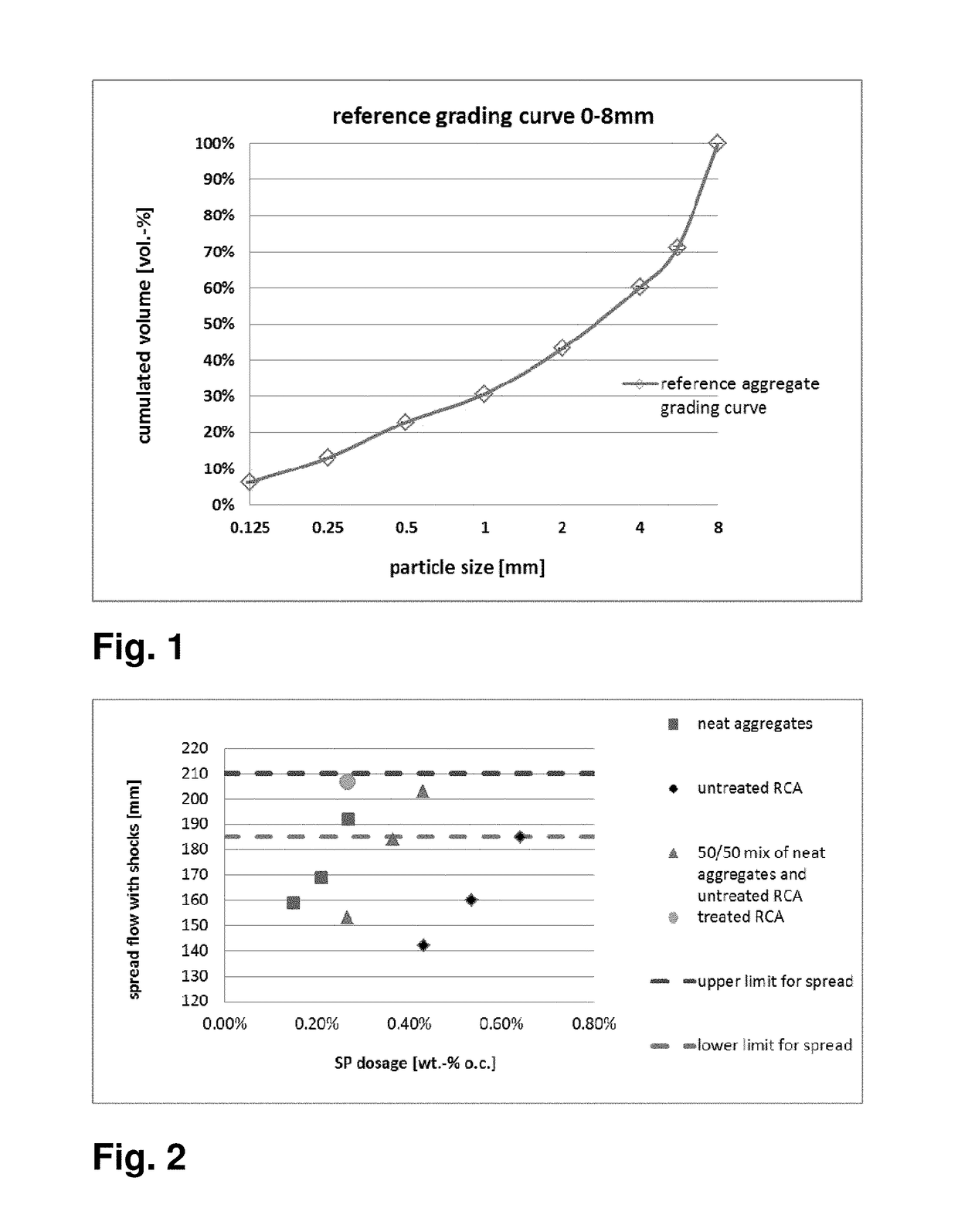

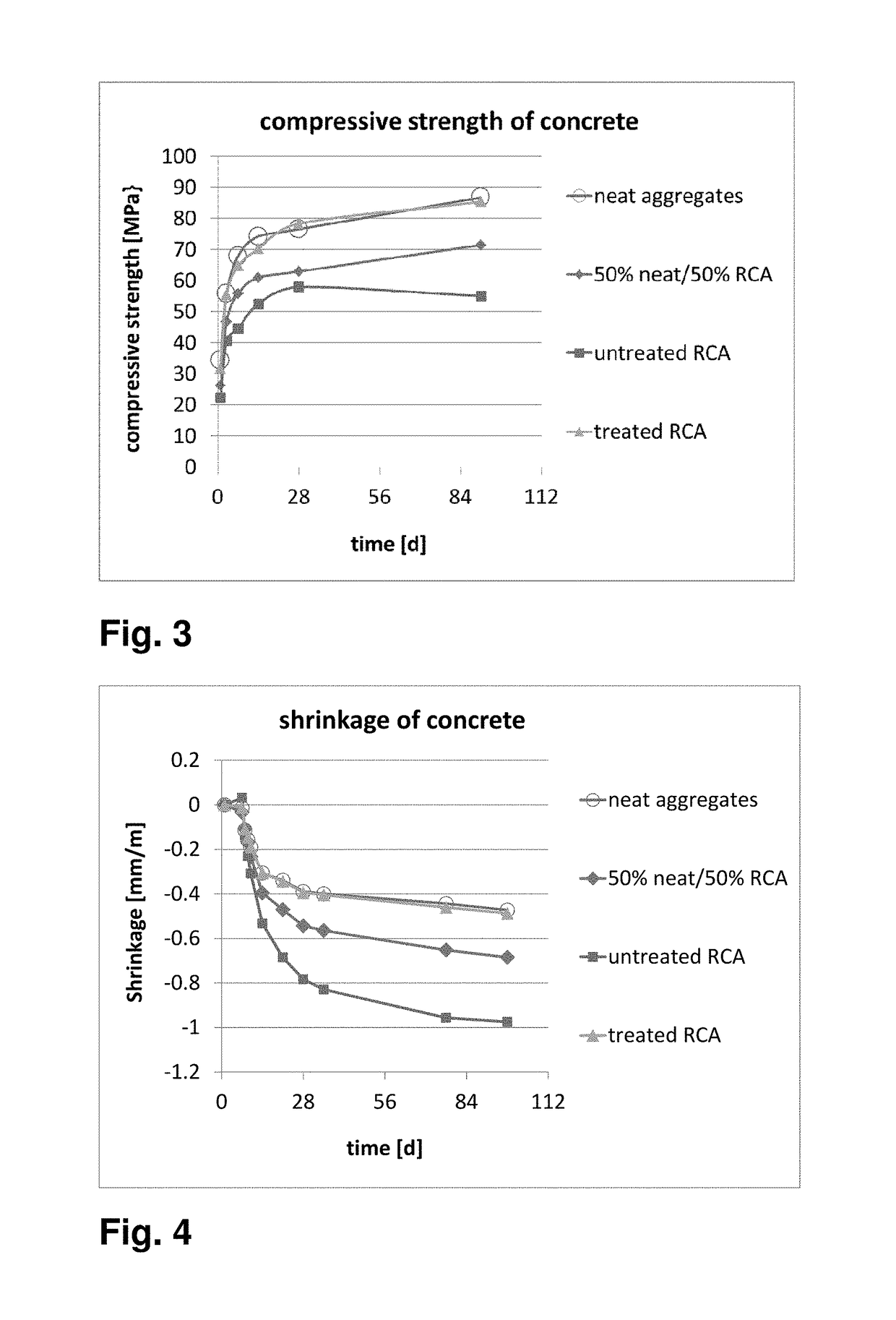

Concrete, a Dry Mixture for the Preparation of this Concrete, and a Method for the Preparation of this Concrete

The invention relates to fresh concrete which contains in 1 m3 135 to 250 kg of water, 135 to 400 kg of cement or 135 to 455 kg of a mixture of cement and substituents of cement in a ratio of cement to substituents of cement from 30:70 to 70:30, 28 to 52 kg of microsilica and 1000 to 2000 kg of aggregate with upper fraction of up to 16 mm, or up to 8 mm, whereby 70 to 100% of this aggregate is formed by brick or ceramic or mixed recyclate made from inert construction and demolition waste with a fraction of 0 to 16 mm, or 0 to 8 mm and / or concrete recyclate with a fraction of 0 to 16 mm, or 1 to 16 mm, or 0 to 8 mm, or 1 to 8 mm. A possible remaining part of the aggregate—up to a maximum of 30% by weight, is formed by natural aggregate with upper fraction of up to 16 mm or up to 8 mm. Another 0 to 30% by weight of the aggregate may be made up of at least one known improving component which enhances thermal and / or acoustic and / or fire resistance properties of concrete and which is commonly used in standard concretes.The invention also relates to a dry mixture for the preparation of this concrete, as well as a concrete product or a prefabricated element made from this concrete.In addition, the invention relates to a method for the preparation of this fresh concrete.

Owner:ERC TECH AS

Method, system, apparatus and medium for predicting production of building demolition waste

ActiveCN109034073AQuick forecastAccurate predictionForecastingCharacter and pattern recognitionDemolition wasteComputer science

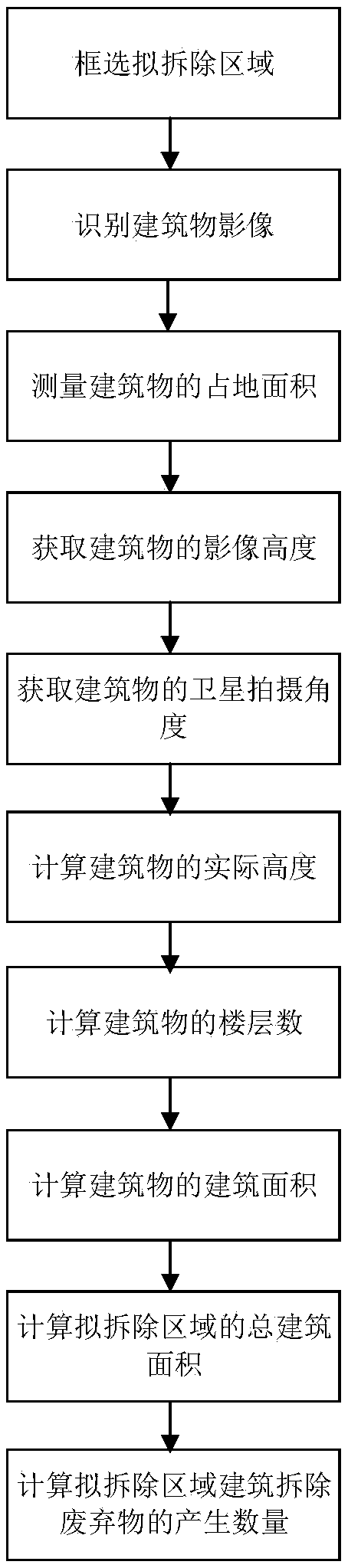

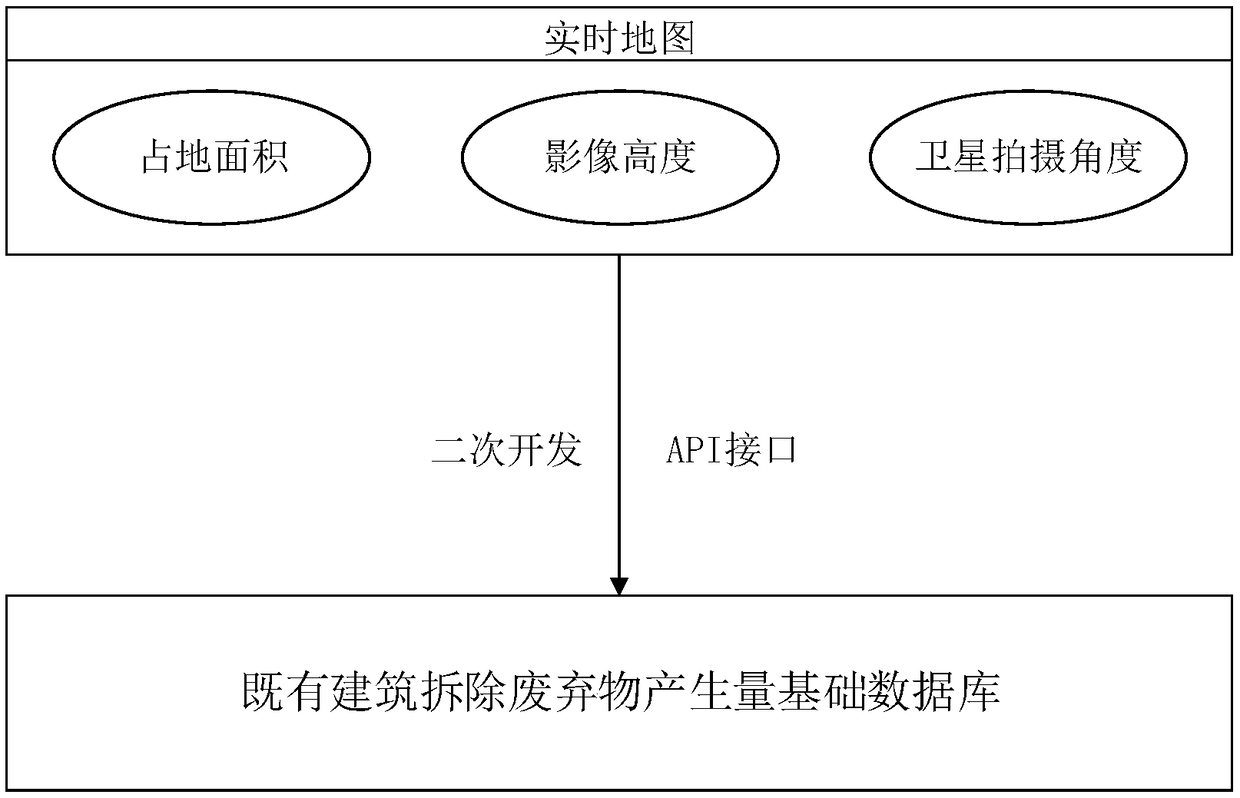

The invention discloses a method for predicting the amount of waste generated from demolition of an existing building, which comprises the following steps: obtaining the distribution of an area to bedemolished in a real-time map; acquiring an image of a building of the area to be demolished in a satellite map; obtaining an area occupied by the building, an image height and a satellite photographing angle; obtaining a total building area of the area to be demolished; the quantity of building waste generated in the area to be demolished being obtained by calculation. The invention relates to asystem for predicting the generation amount of existing building demolition waste, which comprises a region obtaining module to be demolished, a region information obtaining module and a calculation module of the generation amount of building waste. And an apparatus and a readable storage medium for predicting the amount of existing building demolition waste generated. This method provides guidance for the government to plan the quantity, location and scale of building waste comprehensive utilization enterprises and landfills, at the same time, it can reduce the resources invested in field survey, thus reduce the financial expenditure.

Owner:SHENZHEN UNIV

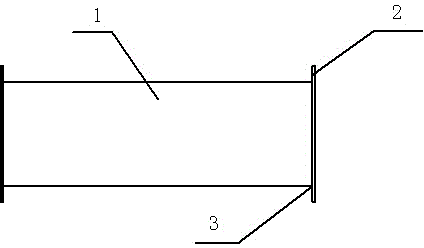

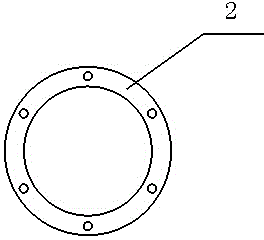

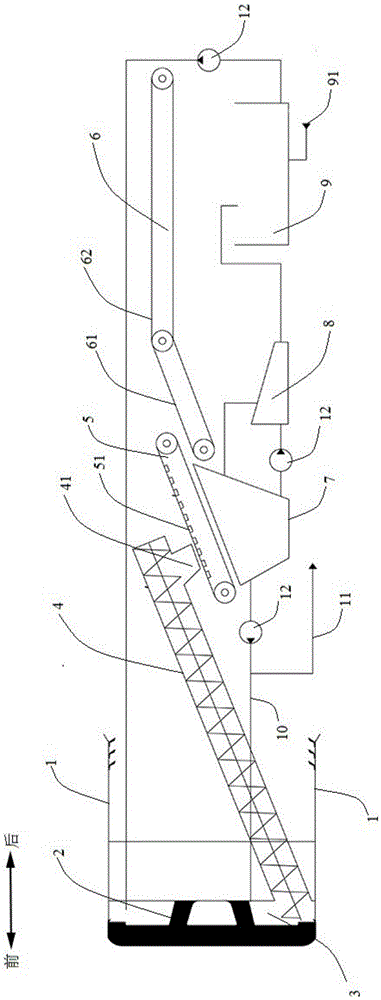

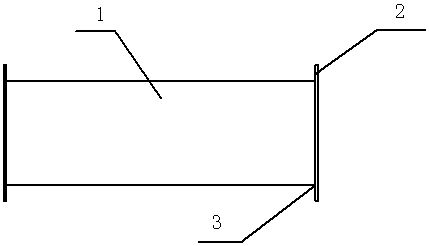

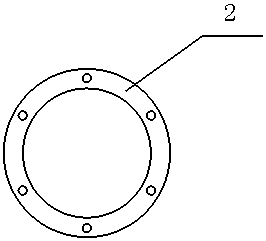

Method for conveying demolition waste materials obtained through overhaul of dry quenching boiler

ActiveCN106276030AImprove demolition efficiencyQuality assuranceChutesDemolition wastePulp and paper industry

The invention discloses a method for conveying demolition waste materials obtained through overhaul of a dry quenching boiler. The method is characterized by comprising the following steps of 1, making a discharging chute; 2, erecting an integral scaffold operating platform; and 3, connecting and mounting the chute. When the chute is mounted, a small-size device below an air cap is demolished, so that the chute passes through the air cap; a through discharging channel can be formed from the demolition point on the upper portion to the ground on the lower portion; and after entering the discharging chute, the waste materials are directly dumped to a waste material piling-up platform or the ground, and thus the effect that the waste materials are conveyed to the waste material piling-up platform or the ground from the demolition point in a one-step manner is achieved. The method for conveying the demolition waste materials obtained through overhaul of the dry quenching boiler has the beneficial effects that demolition efficiency of dry quenching overhaul is greatly improved; and on the premise that quality and safety are guaranteed, the demolition period can be shortened to a great extent.

Owner:MCC5 GROUP CORP SHANGHAI

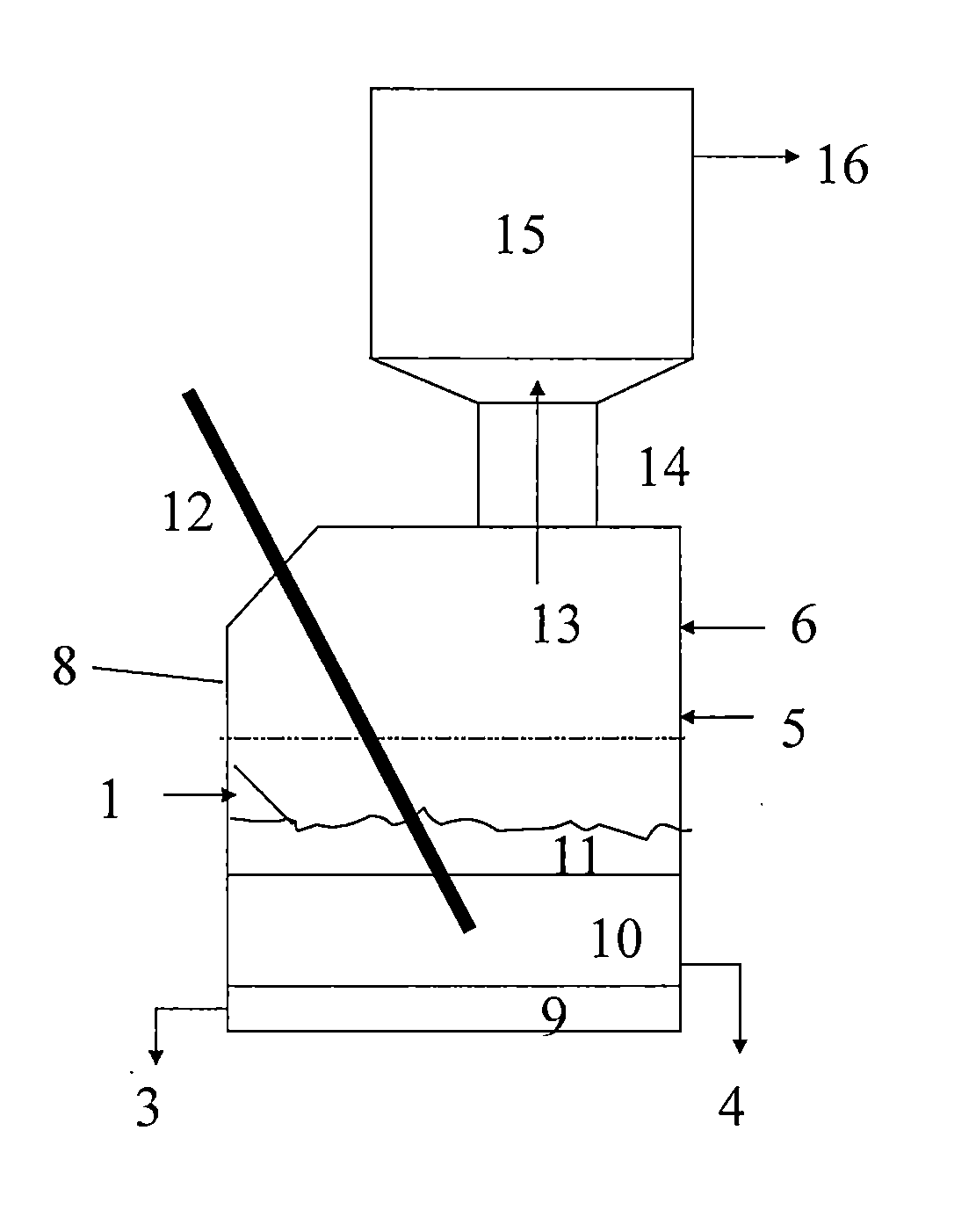

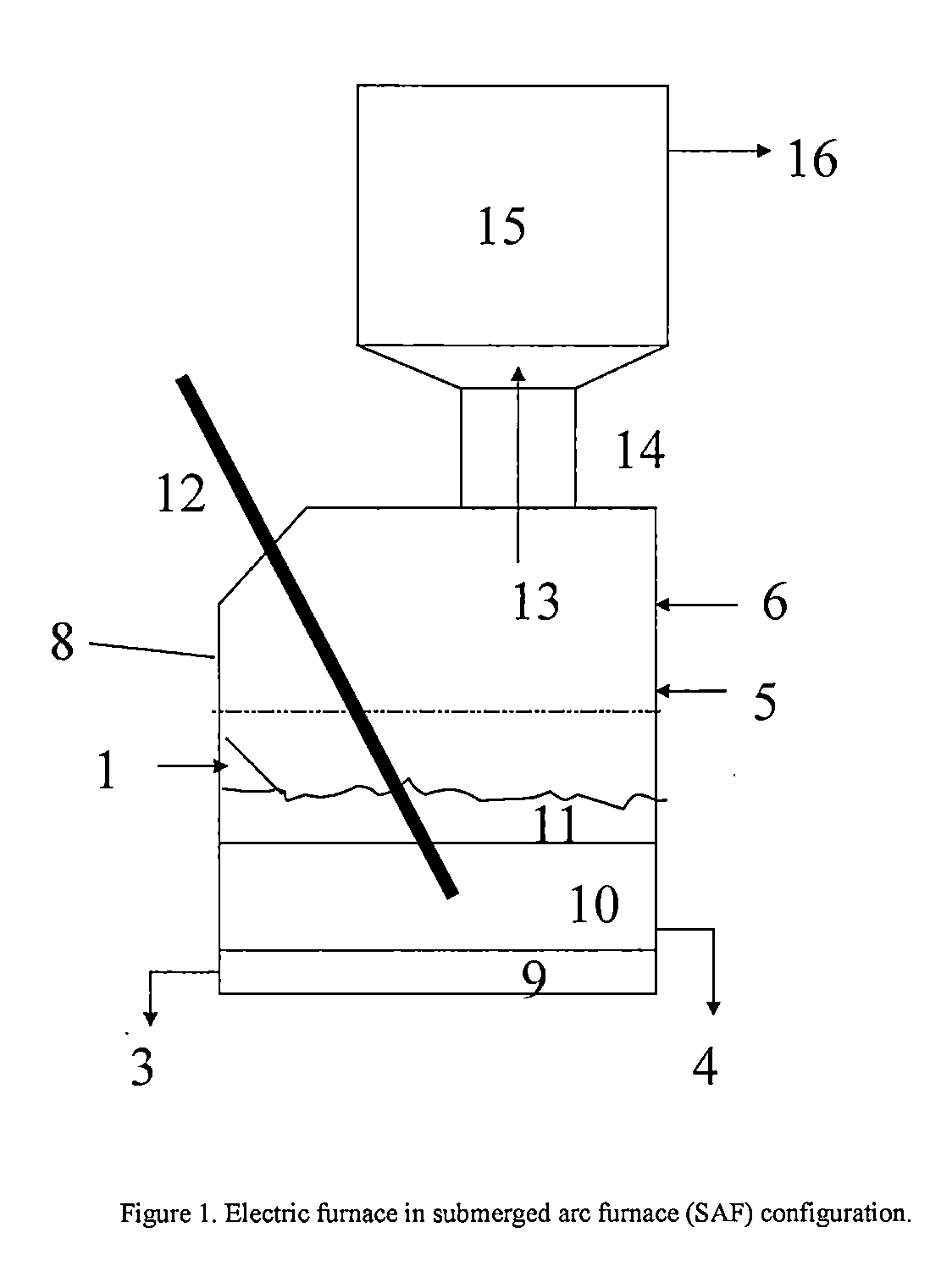

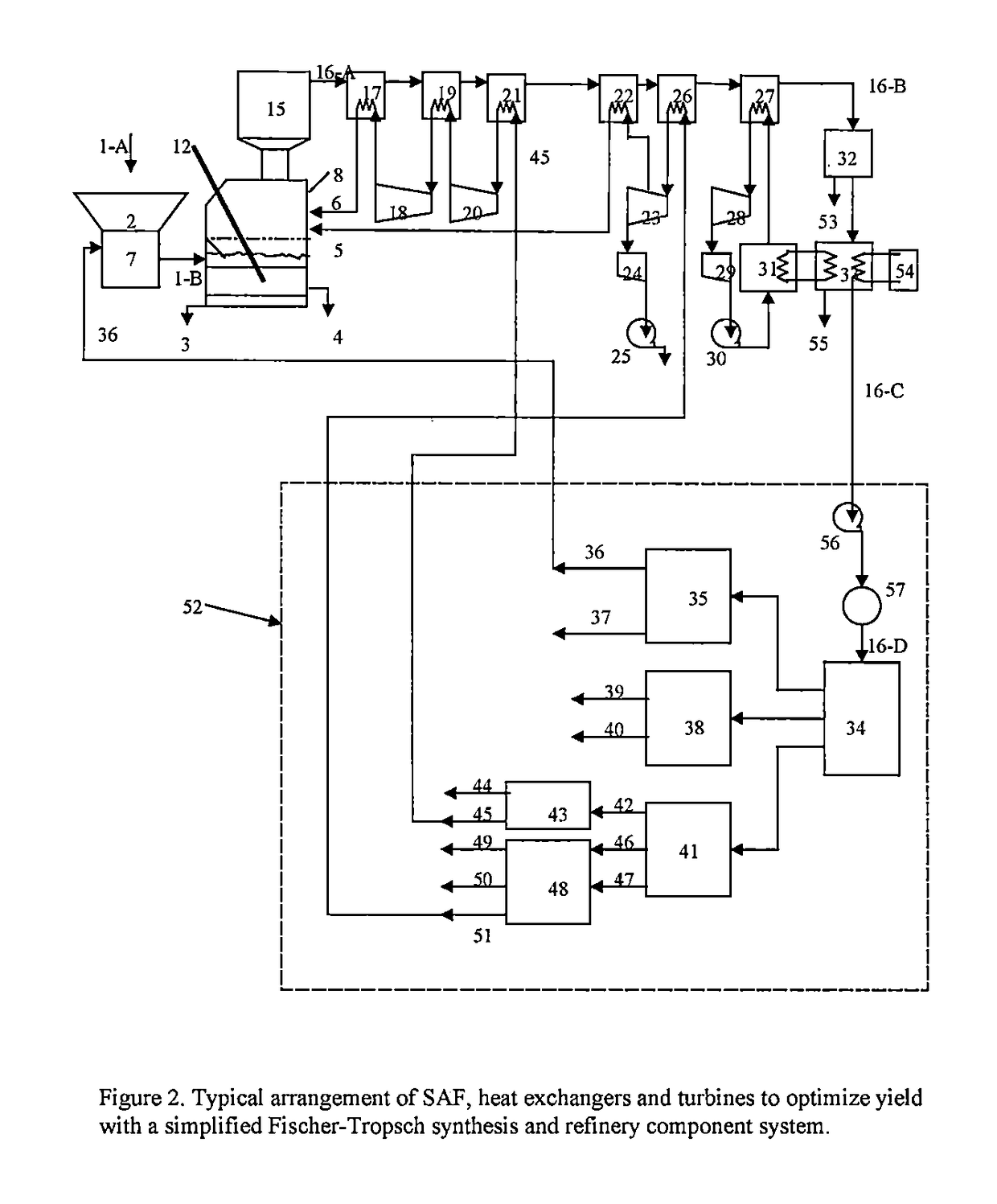

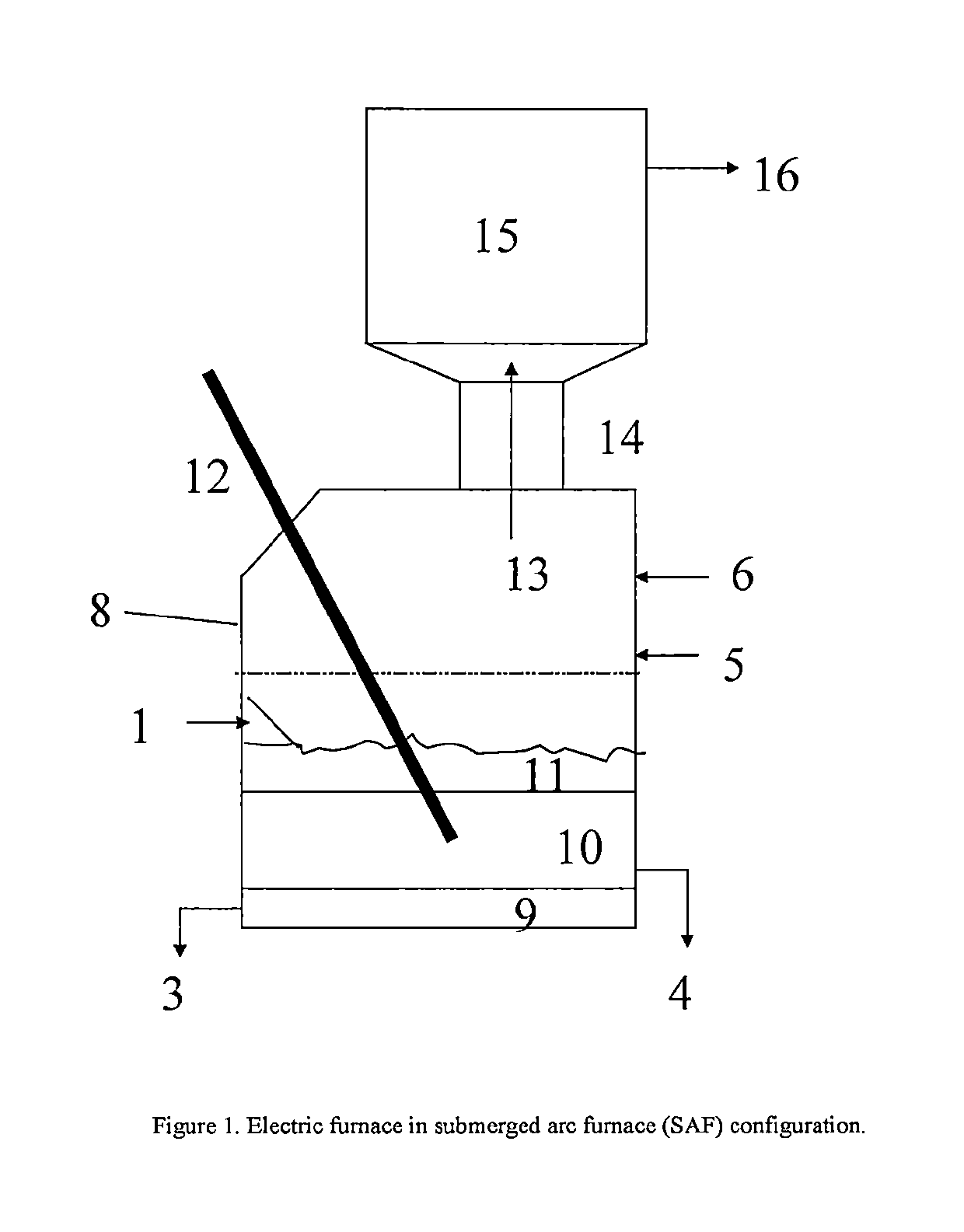

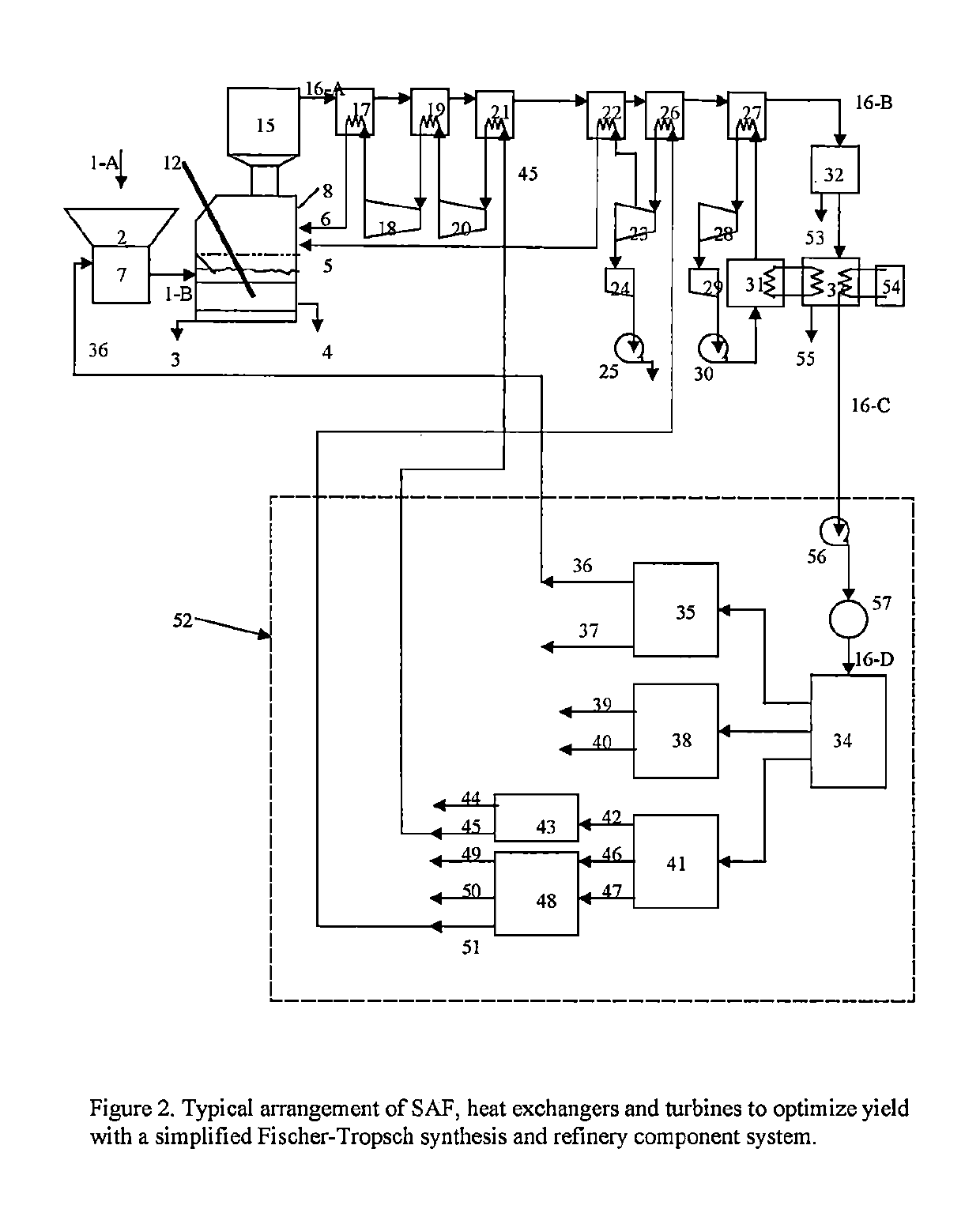

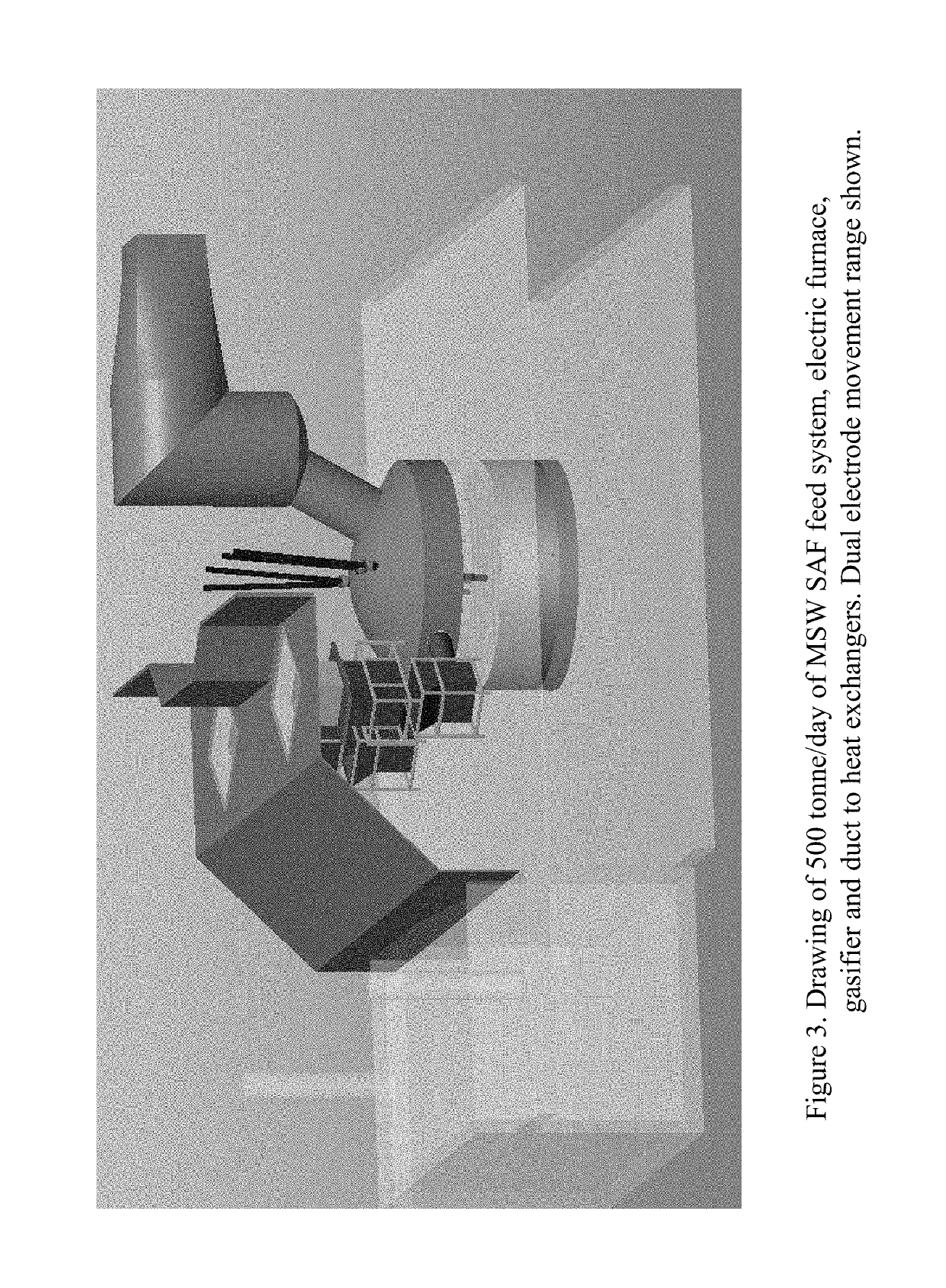

Coupling an electric furnace with a liquid fuel synthesis process to improve performance when processing heterogeneous wastes

An improved method for processing heterogeneous municipal solid waste, biomass and even construction and demolition waste into liquid hydrocarbon fuels and chemicals is obtained by coupling the synthesis process with an electric furnace. The furnace separates the metals and inorganics from the organic materials. The high temperatures gasify the organics into a relatively clean syngas after particulate and acid gas removal. The yield is increased above that expected from the feedstock by the addition of waste effluents from the synthesis process, such as CO2, H2O and possibly tail gas constituents. The recycled effluents are heated by the syngas being quenched in heat exchangers. Excess high pressure effluents are also heated by the syngas for power generation via gas or steam turbine generators. The optimum concentration of added effluents and heat exchanger configurations are determined by novel methods for maximum yield, energy efficiency and minimum carbon footprint.

Owner:EDDY THOMAS L +1

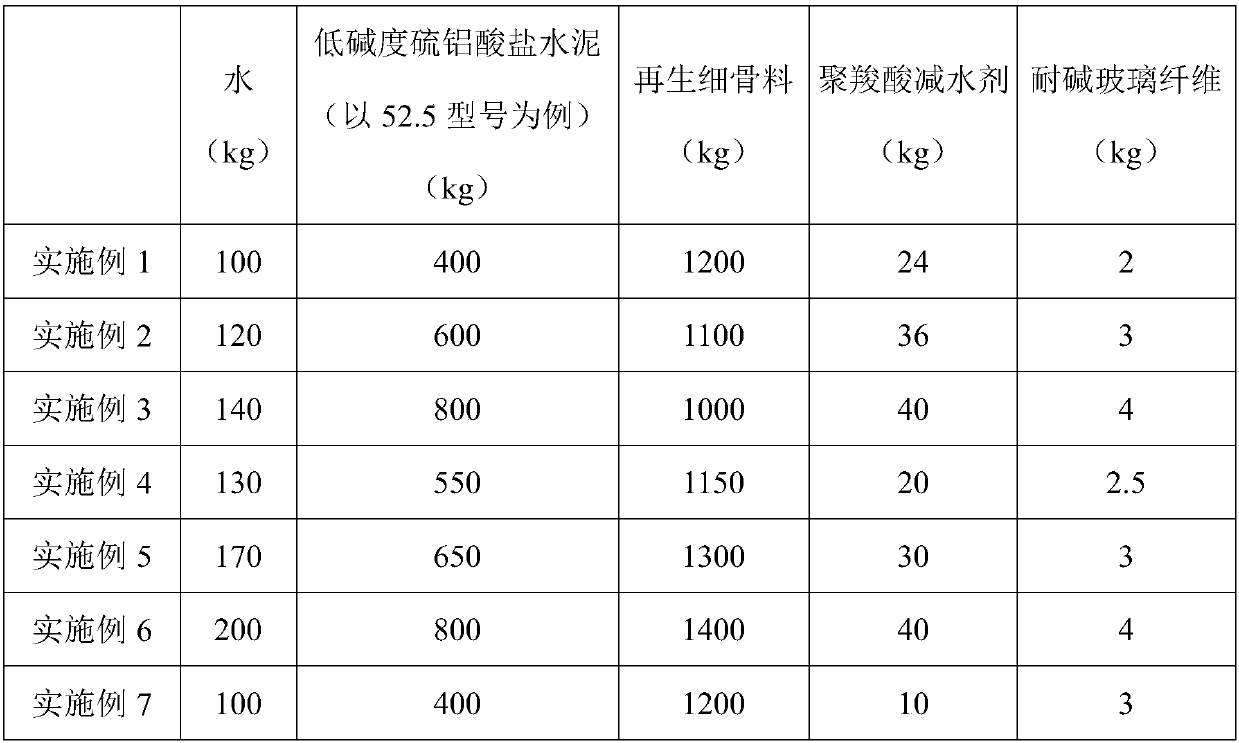

GRC (glass-fiber reinforced composite) decorative curtain wall board prepared from low-quality recycled fine aggregate and preparation method of GRC decorative curtain wall board

ActiveCN109678435AIncrease profitGood environmental benefitsSolid waste managementWallsGlass fiberAlkalinity

The invention relates to a GRC (glass-fiber reinforced composite) decorative curtain wall board prepared from low-quality recycled fine aggregate and a preparation method of the GRC decorative curtainwall board. The GRC decorative curtain wall board is prepared from components in parts by mass as follows: 400-800 parts of low-alkalinity sulphate aluminium cement, 1000-1400 parts of the recycled fine aggregate, 10-40 parts of a polycarboxylate superplasticizer and 2-4 parts of alkali-resistant glass fibers. According to the GRC decorative curtain wall board prepared from the low-quality recycled fine aggregate and the preparation method of the GRC decorative curtain wall board, the GRC decorative curtain wall board is prepared from the low-quality recycled fine aggregate, the application range of the low-quality recycled fine aggregate is expanded, the utilization rate of demolition waste of buildings is increased, and the GRC decorative curtain wall board has good environment benefit,economic benefit and social benefit.

Owner:深圳市绿志新型建材研究院有限公司

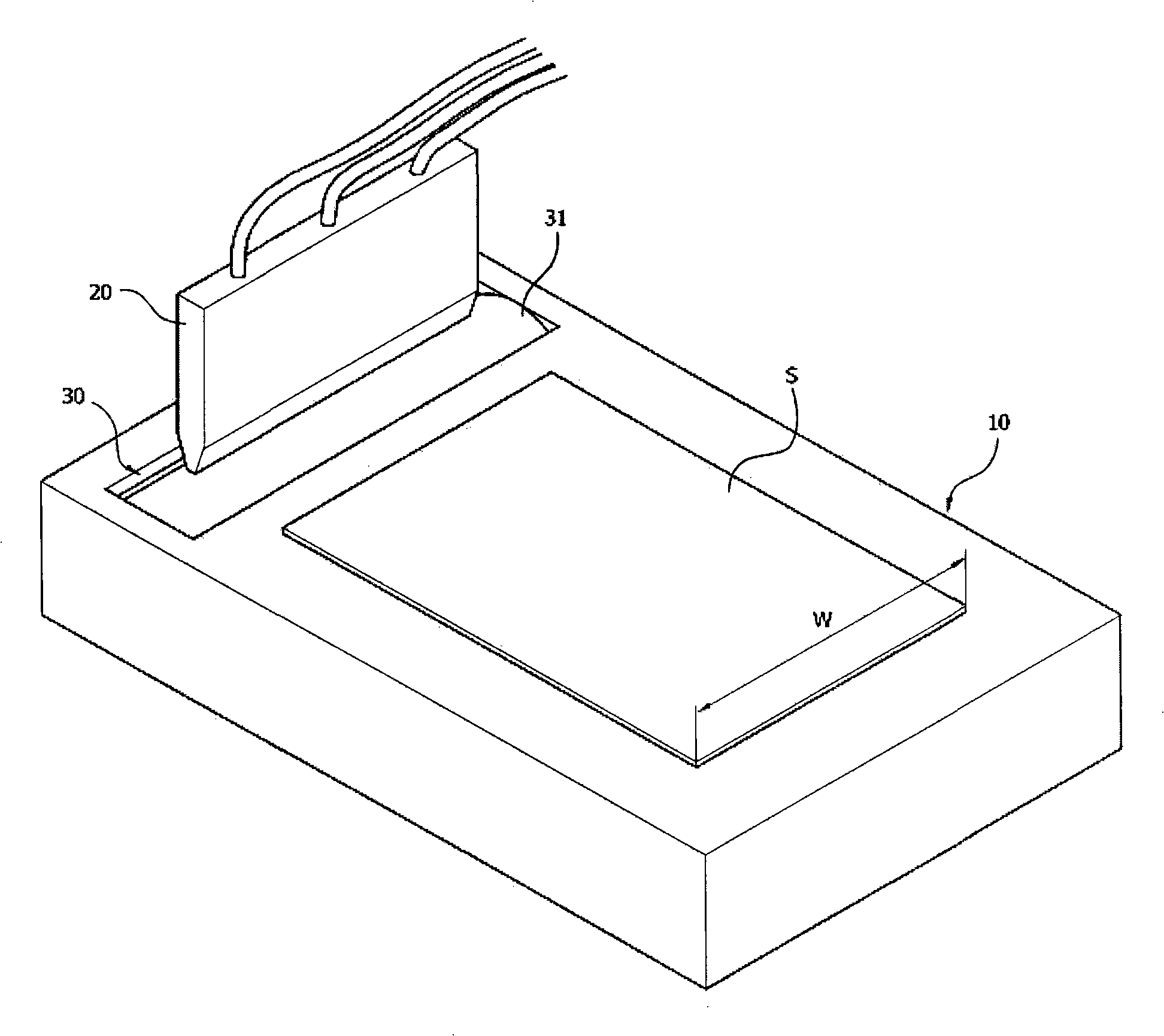

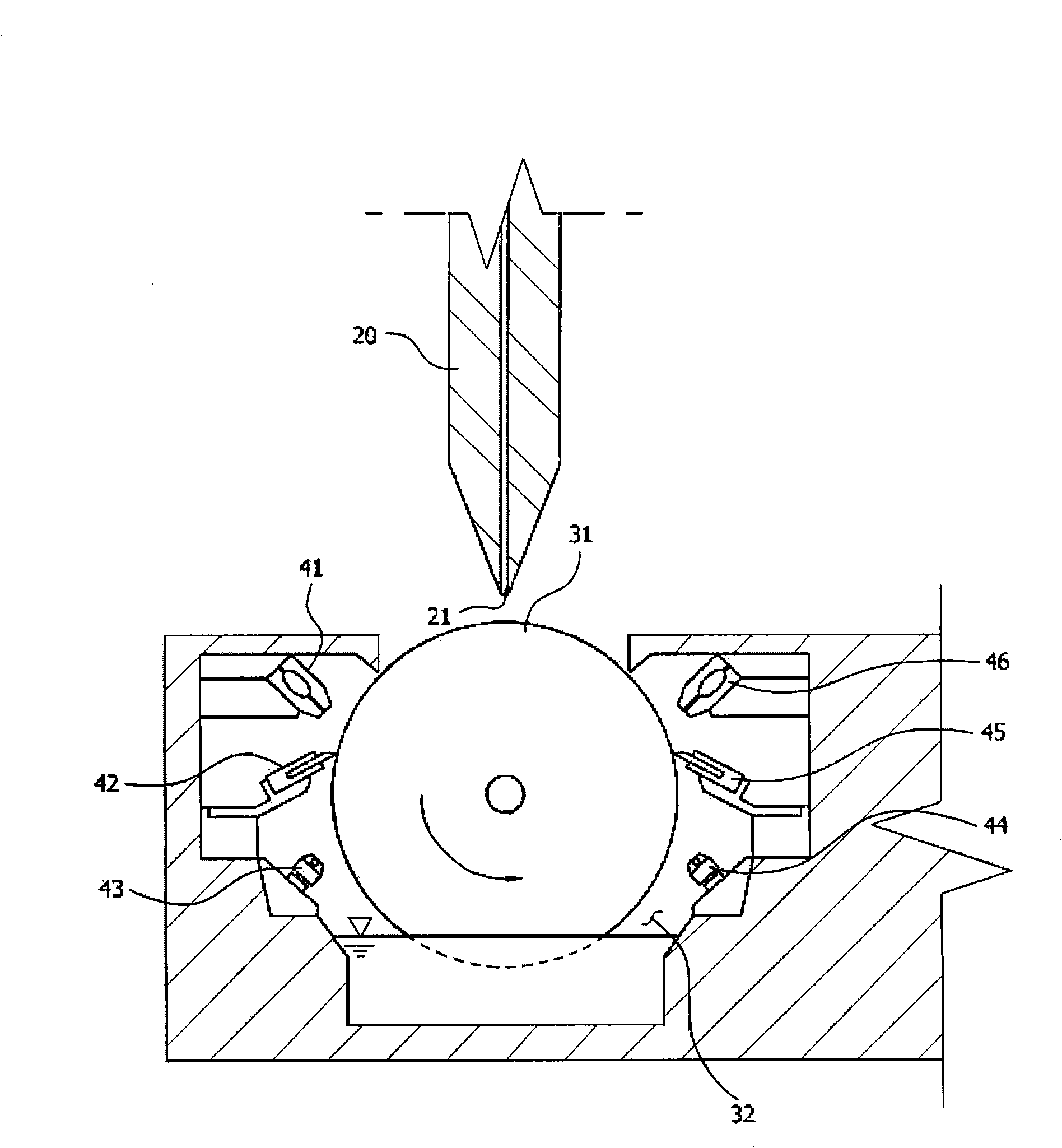

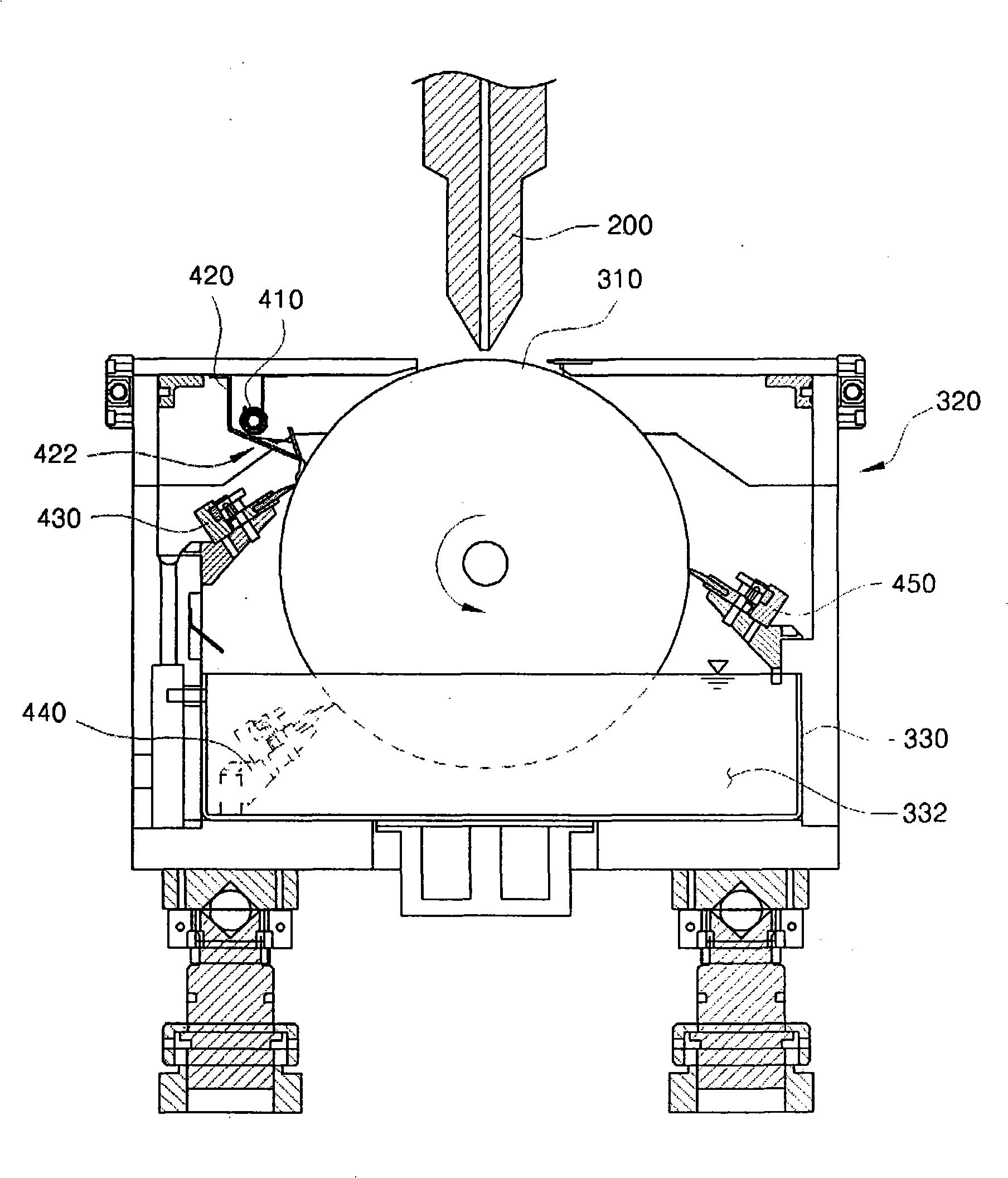

Preparation exhaust device for slit coating machine

ActiveCN101303530AReduce wasteUniform coatingLiquid surface applicatorsSemiconductor/solid-state device manufacturingForeign matterDemolition waste

The invention relates to a pre-discharger for a silt coating machine, comprising: a roller that receives photosensitive liquid pre-discharged from a silt nozzle; an accepting part that rotatablely supports the roller and expose part of the accepted roller to the outside; a cleaning part arranged closely along an outer surface of the roller, which comprises a solution supply pipe that supplies solution to dilute the photosensitive liquid; an inclined plate that enables the solution supplied by the solution supply pipe to flow to a surface of the roller; a plurality of scrapers in contact with an outer surface of the roller to remove impurity. According to the invention, the solution supplied by the solution supply pipe is provided to the roller side via the inclined plate so as to obviously reduce solution waste compared with former manner of jetting or pure dripping, and implement uniform coating of the solution on the surface of the roller; therefore, the invention can further enhance cleaning effect of photosensitive liquid on the surface of the roller.

Owner:K C TECH

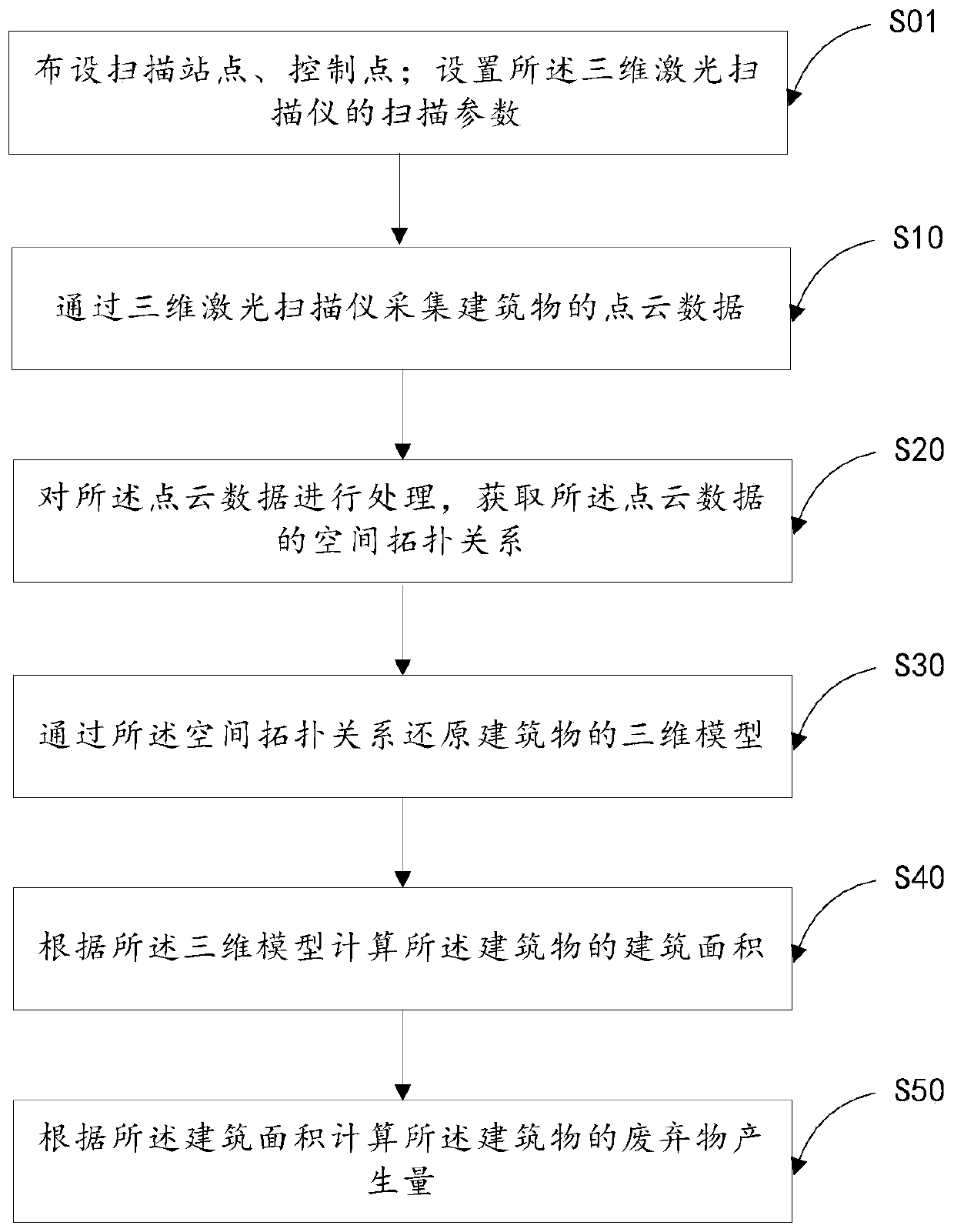

Method and device for predicting yield of building demolition waste

InactiveCN110348621AEasy to remove intelligentlyForecastingCharacter and pattern recognitionPoint cloudDemolition waste

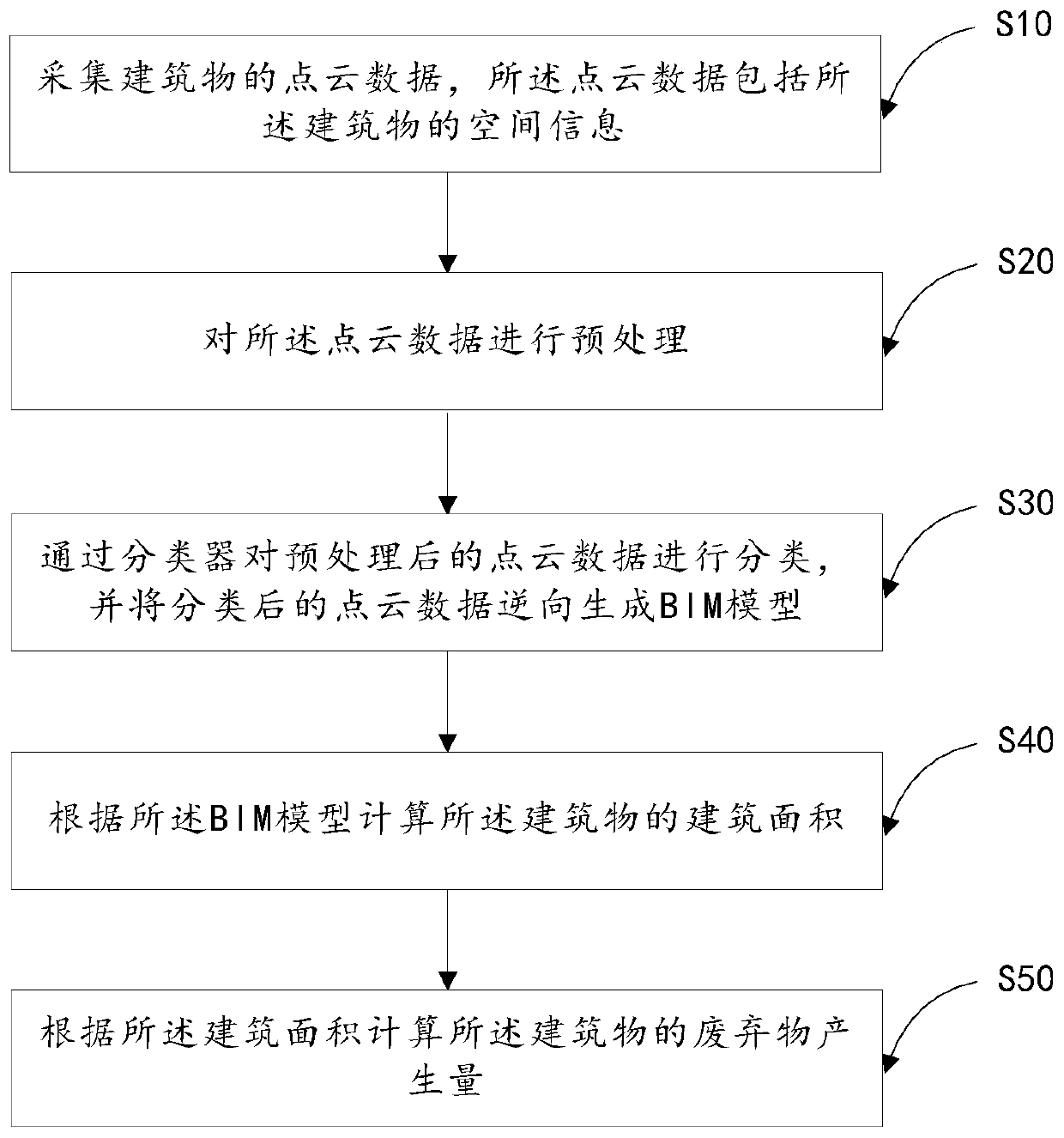

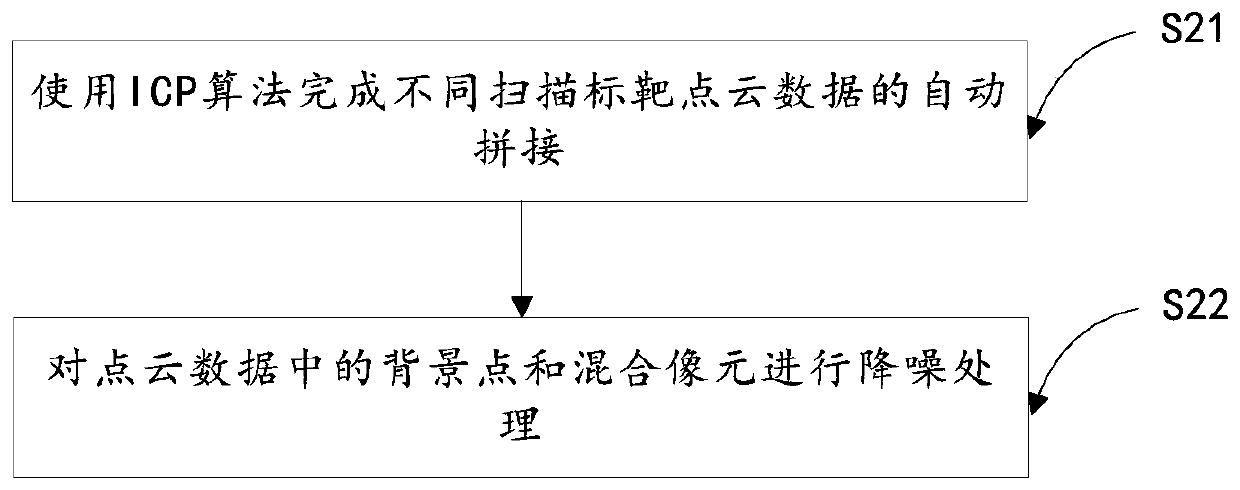

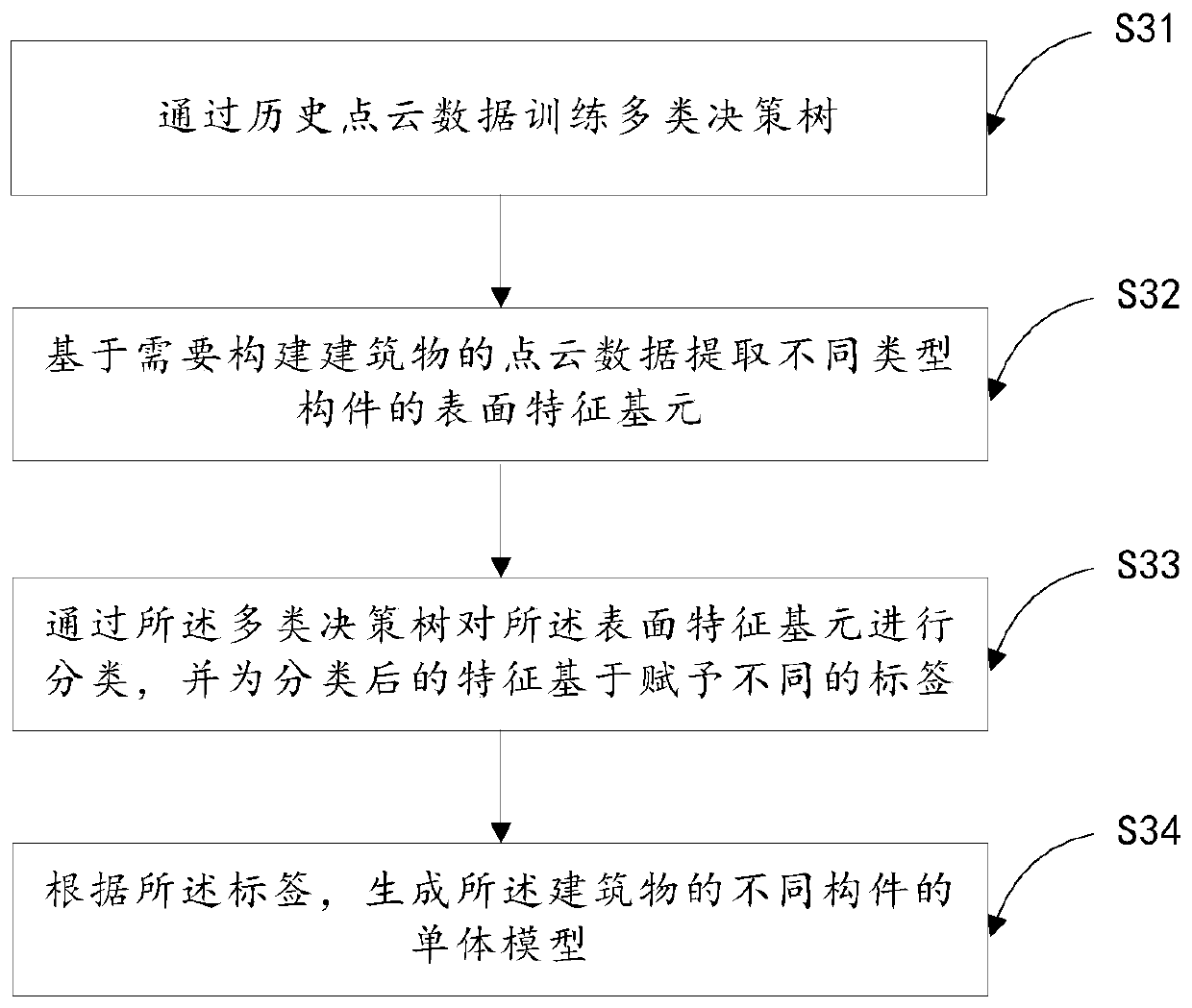

The invention relates to the technical field of intelligent buildings, and discloses a method and device for predicting yield of building demolition waste. The method comprises the steps: collecting point cloud data of a building, wherein the point cloud data comprises the spatial information of the building; preprocessing the point cloud data; classifying the preprocessed point cloud data througha classifier, and reversely generating a BIM model from the classified point cloud data; calculating the building area of the building according to the BIM model; calculating the waste output of thebuilding according to the building area; and through a reverse modeling technology, predicting the existing building demolition waste generation amount, thus facilitating intelligent demolition.

Owner:SHENZHEN UNIV +1

A novel masonry material utilizing recycled construction & demolition waste

ActiveUS20210163354A1Simplification of processSimple seismic reinforcementSolid waste managementCeramic shaping apparatusWaste processingDemolition waste

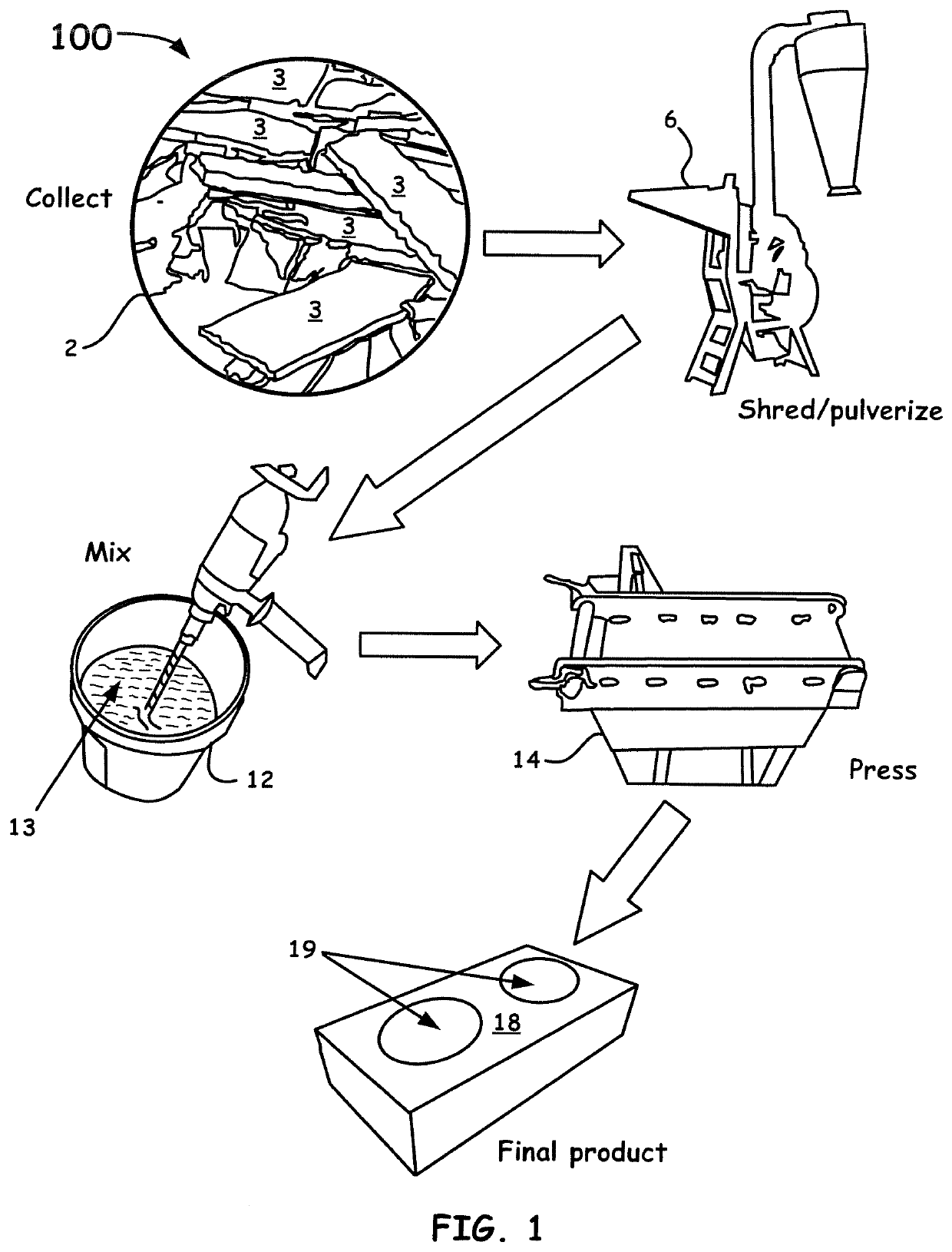

The embodiments herein are directed to dry wall waste mixtures, formed under pressure into example embodiments referred to herein as dry wall waste blocks (DWBs) and / or gypsum wallboard waste blocks (GWWBs) and tile structures. DWBs / GWWBs mixtures in particular, often incorporate a higher percentage in the composite mixtures from about 60% up to 85% of dry wall waste than other mixtures and beneficially often incorporates substantially all of the wallboard facing paper as part of the composite mixture. That is, waste processing is simplified by comingling core and paper layers in the final product. DWBs / GWWBs mixtures utilize demolition and construction waste, replacing a high percentage of Portland cement with waste-derived binder.

Owner:WASHINGTON STATE UNIVERSITY

Coupling an electric furnace with a liquid fuel synthesis process to improve performance when processing heterogeneous wastes

An improved method for processing heterogeneous municipal solid waste, biomass and even construction and demolition waste into liquid hydrocarbon fuels and chemicals is obtained by coupling the synthesis process with an electric furnace. The furnace separates the metals and inorganics from the organic materials. The high temperatures gasify the organics into a relatively clean syngas after particulate and acid gas removal. The yield is increased above that expected from the feedstock by the addition of waste effluents from the synthesis process, such as CO2, H2O and possibly tail gas constituents. The recycled effluents are heated by the syngas being quenched in heat exchangers. Excess high pressure effluents are also heated by the syngas for power generation via gas or steam turbine generators. The optimum concentration of added effluents and heat exchanger configurations are determined by novel methods for maximum yield, energy efficiency and minimum carbon footprint.

Owner:EDDY THOMAS L +1

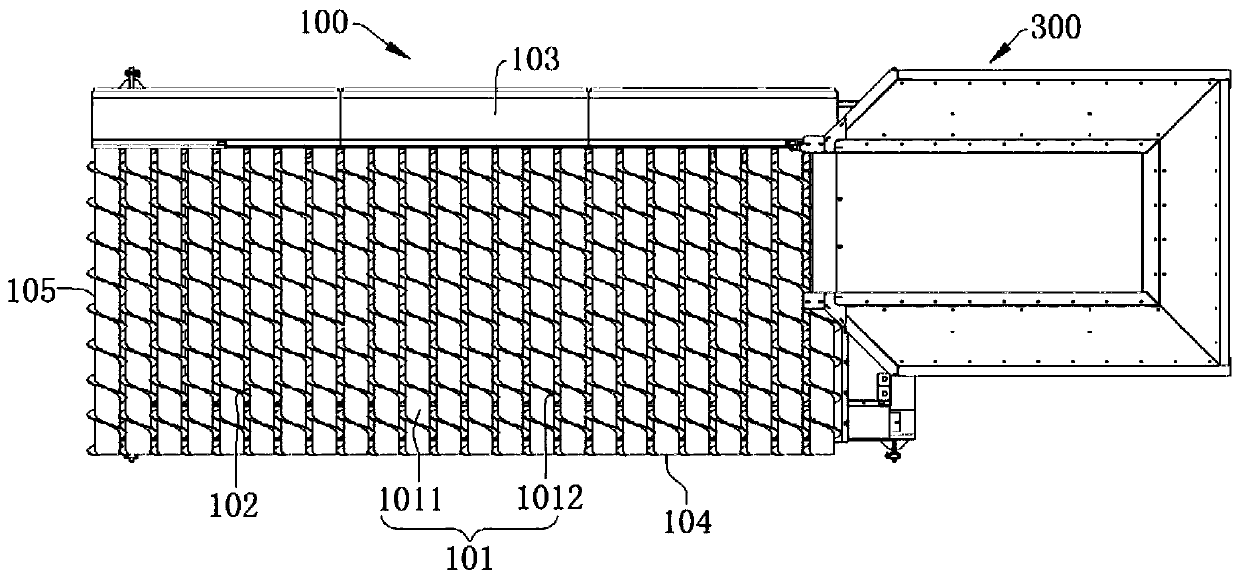

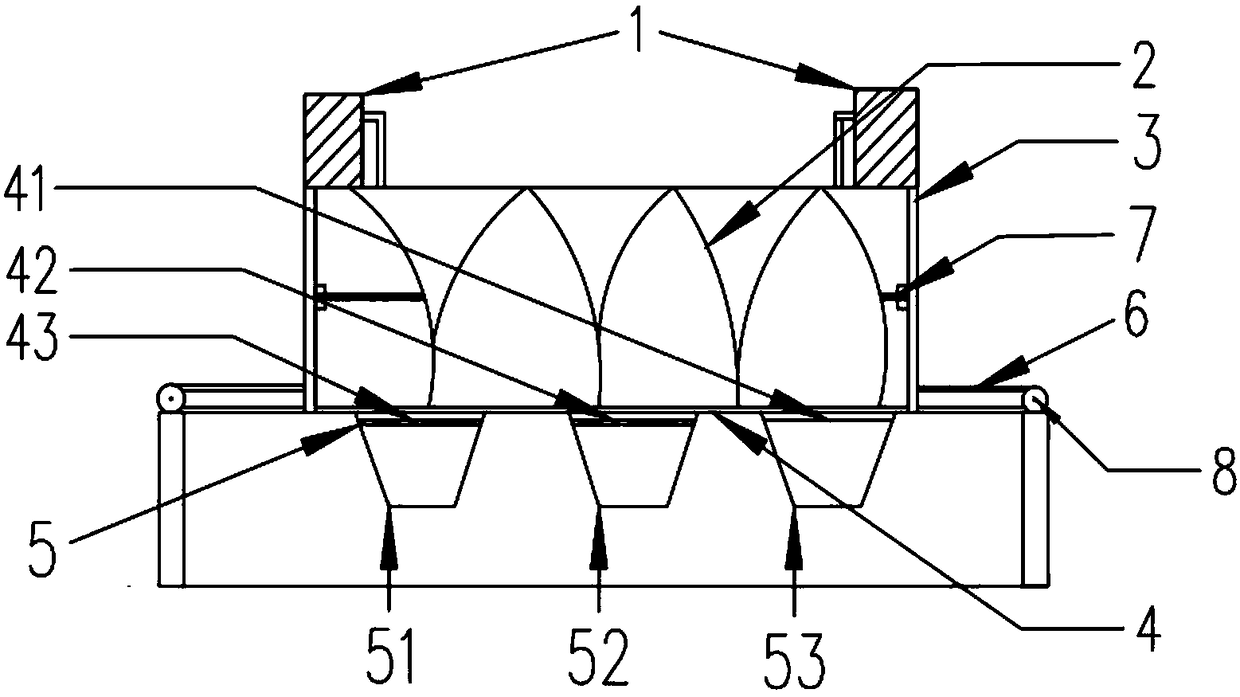

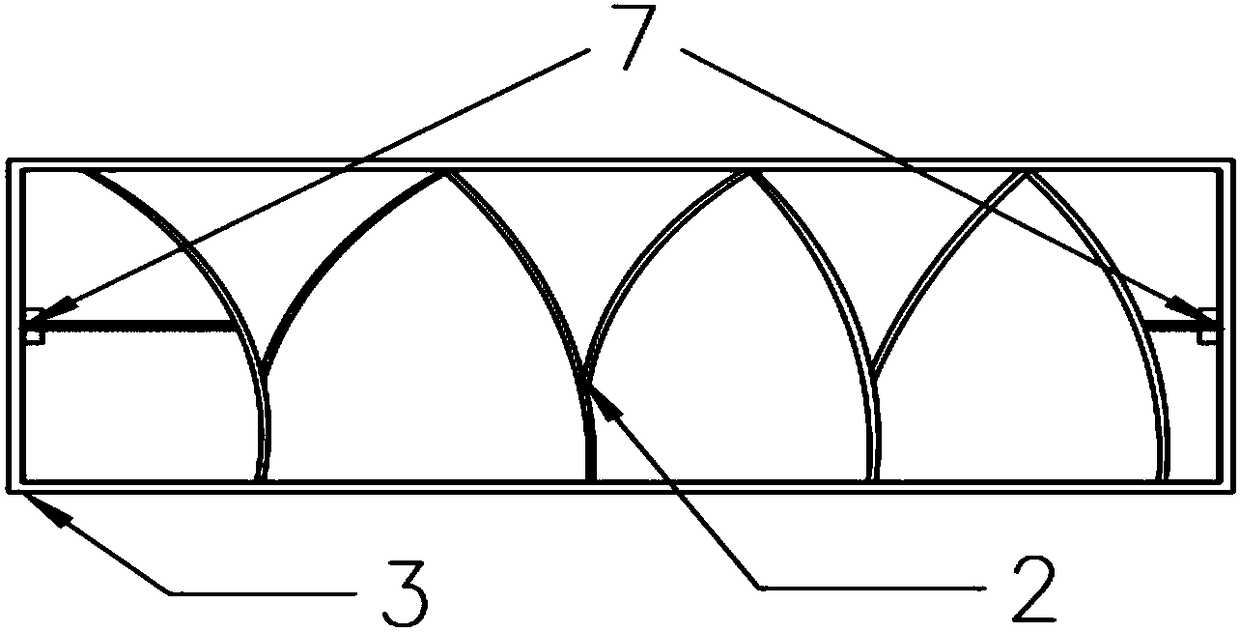

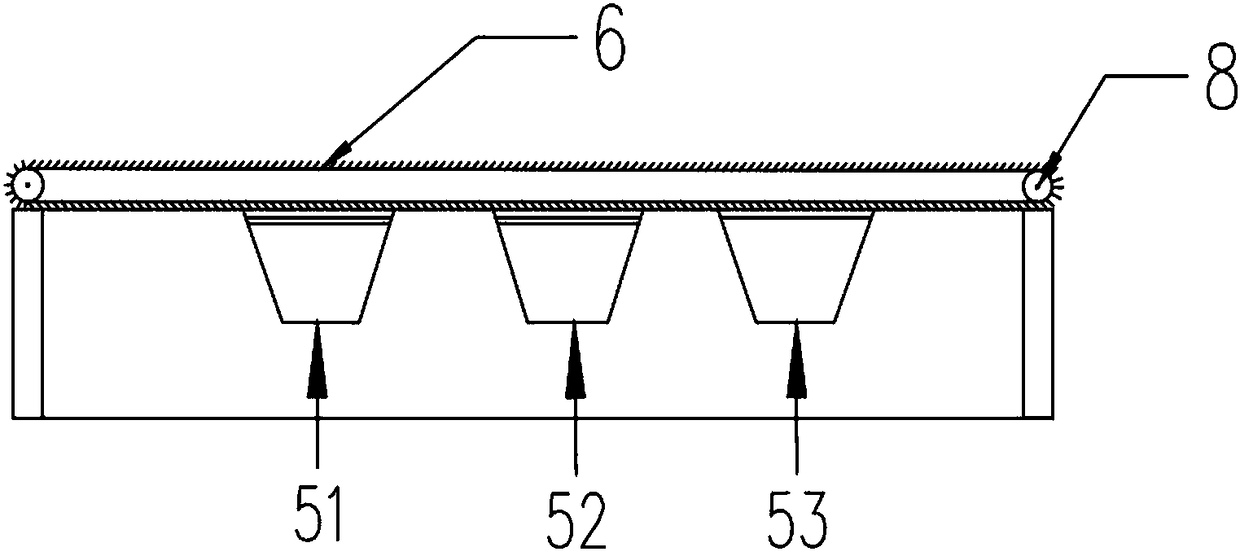

Multistage screening system capable of treating construction and decoration waste

The invention provides a multistage screening system capable of treating construction and decoration waste. The multistage screening system capable of treating the construction and decoration waste comprises a motor, a screening box, an auger delivery device, screen clearing belts, screens and screen barrels. The multistage screening system is characterized in that the auger delivery device is horizontally placed in the screening box; the position of a center shaft of the screening box is connected with a driving shaft; the driving shaft is sleeved with a belt pulley; the belt pulley is connected with the motor; the screens comprise the narrow-meshed screen, the medium-meshed screen and the wide-meshed screen and are arranged in the screen barrels in the advancing direction of materials sequentially; a fine material outlet, a medium-sized outlet and a rough material outlet are formed in the bottoms, corresponding to the narrow-meshed screen, the medium-meshed screen and the wide-meshedscreen, of the screen barrels sequentially; the shaft end of a rotating shaft is sleeved with a screen clearing belt pulley; the screen clearing belt pulley is connected with a belt pulley belt; andthe screen clearing belt is located above the screens and advances from left to right. The auger delivery device of the multistage screening system grinds and delivers the materials through unceasingrotation, so that stage treatment on the materials is realized; and the multistage screening system is simple to assemble, so that the assembling intensity of technical personnel is not increased.

Owner:南通瑞强机械制造有限公司

Biomass dryer/burner system

The present invention provides a biomass dryer / burner having an air cleaning apparatus adapted to accept emissions from the biomass dryer / burner and to convert said emissions to clean air to meet government emission standards. The biomass dryer / burner unit includes a dryer adapted to dry biomass, such as demolition waste or cut trees. The biomass dryer / burner unit optionally including a burner adapted to burn biomass. The biomass dryer / burner further producing emissions requiring cleaning before exhausting to the atmosphere. The air cleaning apparatus including a spray scrubber fluidly connected to the biomass dryer / burner adapted to moisten emissions, a recirculation tank in fluid communication with a collection tank, and the recirculation tank further having a sensor adapted to measure contaminant levels contained within the recirculation air filtration system. The sensor contained within the recirculation tank measures levels of carbon monoxide. If the air contained within the recirculation air filtration system measures above a predetermined contaminant level, then the air contained within the recirculation air filtration system is directed back into the spray scrubber. If the air contained within the recirculation air filtration system is below a predetermined level, then the air is exhausted into the atmosphere.

Owner:VALENTE PETER

Biofuel

A biofuel that includes a blend of municipal solid waste, selected recyclables, and / or construction and demolition waste including about 40% to 60% wood, about 10% to 20% paper, about 10% to 20% cardboard, about 5% to 10% non-chlorinated plastics, about 5% to 10% rags, about 5% to 10% rugs, and an emission reducing agent, the emission reducing agent being one or more of urea, calcium hydroxide, hydroquinone, anthraquinone, ammonium hydroxide, ammonia, and an ammonium compound.

Owner:WAGNER LOUIS

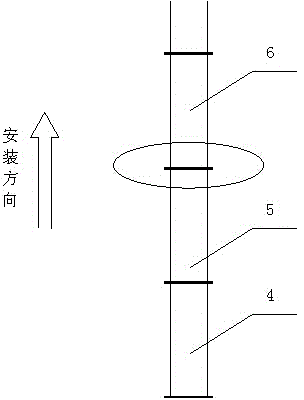

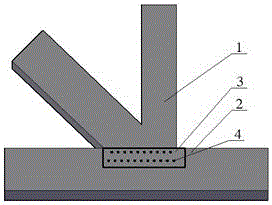

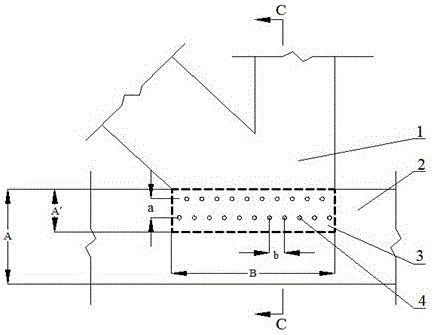

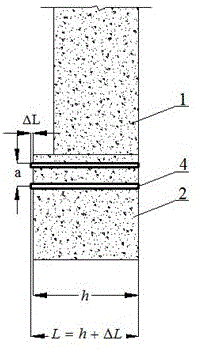

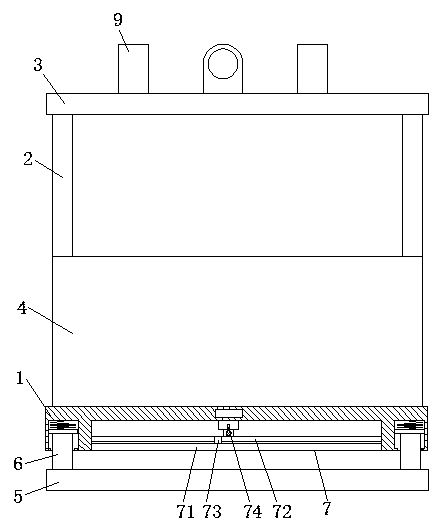

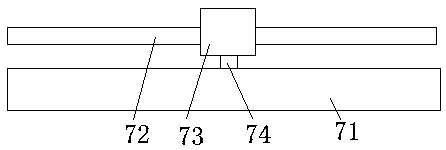

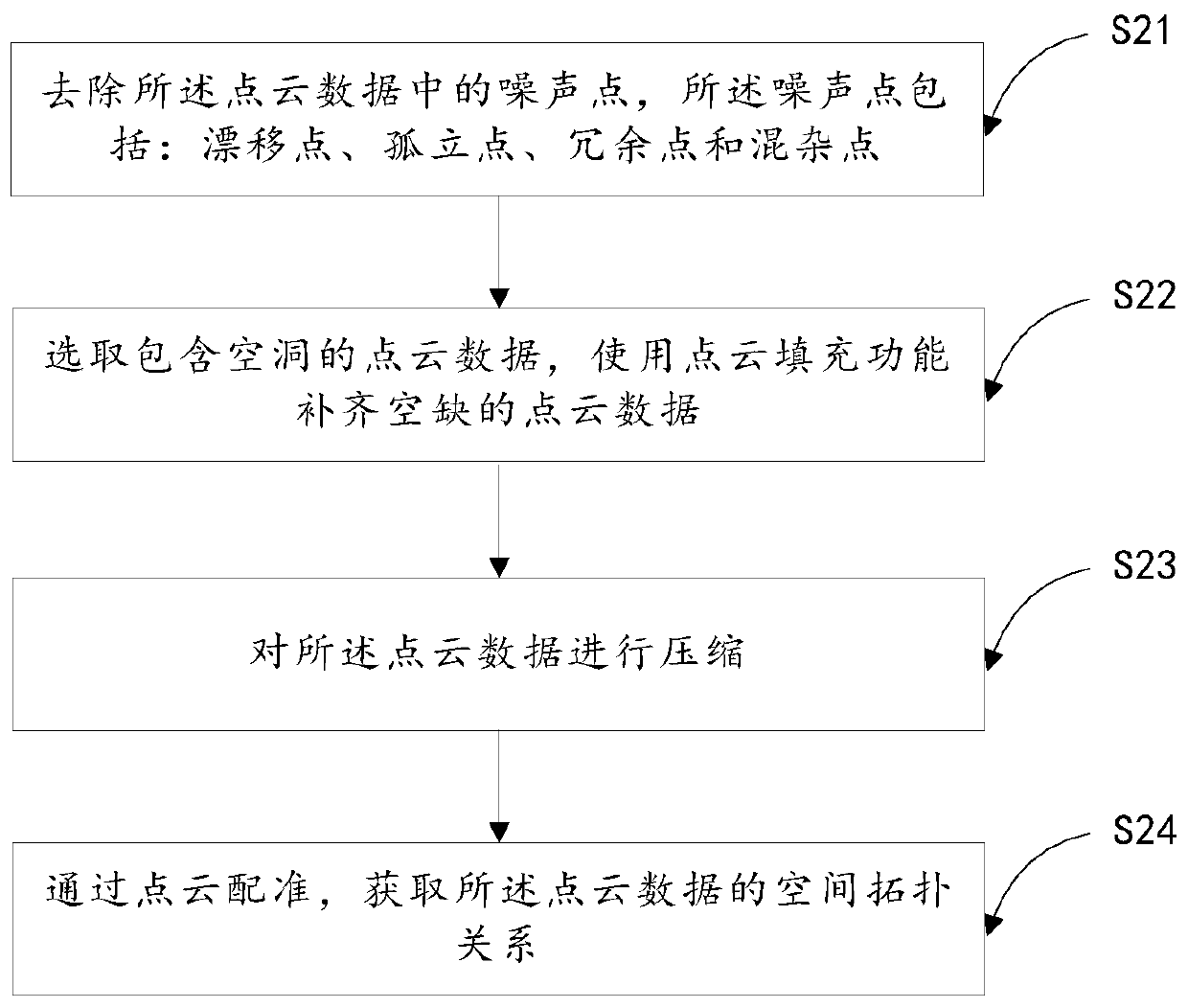

Enclosing purlin protection pretreatment method before demolition blasting of deep foundation pit supporting beam

InactiveCN106759526ASimple manufacturing methodEfficient use ofProtective foundationExcavationsPurlinDemolition waste

The invention relates to an enclosing purlin protection pretreatment method before demolition blasting of a deep foundation pit supporting beam. The technical scheme is that the upper surface of an enclosing purlin (2) is provided with a rectangular reserve zone (3), and the length B of the reserve zone (3) is a horizontal length of a connecting face of the enclosing purlin (2) and a horizontal supporting beam (1); a long side of the reserve zone (3) is overlapped with the connecting side of the enclosing purlin (2) and the horizontal supporting beam (1). 2-4 lines of embedding PVC pipes (4) are arranged at the reserve zone (3), and the line space a of every line is equal to 200-250 mm, and the hole space b is equal to 140-160 mm. The embedding PVC pipe (4) is embedded in the form of quincunx, and the embedding PVC pipe (4) is perpendicular to the reserve zone (3). Before pouring the reinforcement concrete to the foundation pit supporting beam, the embedding PVC pipe (4) is fixed in the reserve zone (3), and the lower end of the embedding PVC pipe (4) is located at the bottom part of a template of the enclosing purlin (2); the upper end of the embedding PVC pipe (4) is 40-80 mm higher than the upper surface of the enclosing purlin (2). The enclosing purlin protection pretreatment method is featured by low construction cost, good safety, short construction cycle, good breaking effect and resource saving.

Owner:WUHAN UNIV OF SCI & TECH

Demolition waste recovering and using method of earth pressure balance shield machine

The invention discloses a demolition waste recovering and using method of an earth pressure balance shield machine. The earth pressure balance shield machine comprises a cutter head and a digging cabin arranged behind the cutter head. The demolition waste recovering and using method comprises the following steps of 1, starting the cutter head for digging the stratum, and conveying demolition wastes obtained through digging to the digging cabin; 2, sieving the demolition wastes in the digging cabin to obtain first demolition wastes and second demolition wastes, wherein the grain diameter of the first demolition wastes is greater than the grain diameter of the second demolition wastes; and 3, stirring the second demolition wastes with slurry, and conveying the mixture back into the digging cabin. According to the demolition waste recovering and using method provided by the invention, the sieved second demolition wastes and the slurry are stirred and mixed; the mixture is conveyed back into the digging cabin again; and a mud film is formed on the digging surface by using the rotation of the cutter head. Gaps among the particles in the stratum can be filled; the particle gradation condition of the stratum is improved, so that the stratum settlement in the digging process can be effectively controlled; and the self stability of the digging surface can be enhanced.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Overhead hoist for demolition blasting of large-sized bridge

PendingCN108086173AGuaranteed stabilityAvoid leaningBridge erection/assemblyBridge strengtheningDemolition wasteEngineering

The invention discloses an overhead hoist for demolition blasting of a large-sized bridge. The overhead hoist comprises a bottom plate, four sets of vertical columns are perpendicularly arranged at the top of the bottom plate, a top plate is perpendicularly connected to the ends, away from the bottom plate, of the four sets of vertical columns, a guardrail is arranged between the ends, close to the bottom plate, of every two adjacent sets of vertical columns, a buffer plate is arranged on the side, away from the guardrails, of the bottom plate, four sets of supporting rods are arranged on theside, close to the bottom plate, of the buffer plate, telescopic channels matched with the four sets of supporting rods are formed in the bottom plate, and the bottoms of the telescopic channels are connected with the supporting rods through springs. A central groove is formed in the side, close to the buffer plate, of the bottom plate, a gravity sensor is arranged at the center of the bottom of the groove, two sets of adjusting devices are arranged in the groove, and each adjusting device comprises a fixing plate, a rotating screw rod, a balancing weight and a sliding rod. The overhead hoistis simple in structure, and can effectively ensure the stability after a hanging basket is hoisted, thus the hanging backset is prevented from tilting, meanwhile, the borne impact force is relieved when a sudden falling emergency situation occurs, and the safety of working personnel is protected.

Owner:贵州贵安新联爆破工程有限公司

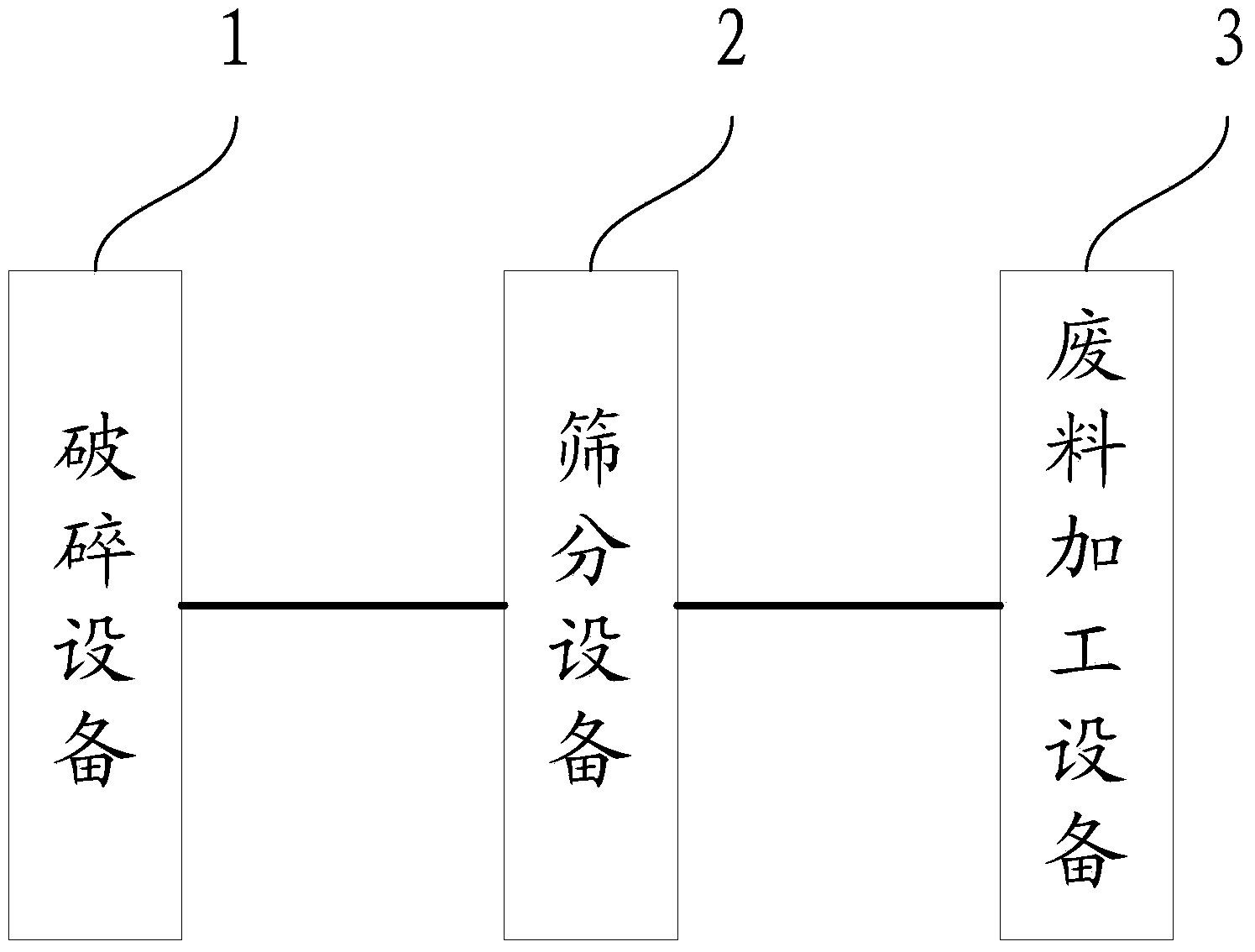

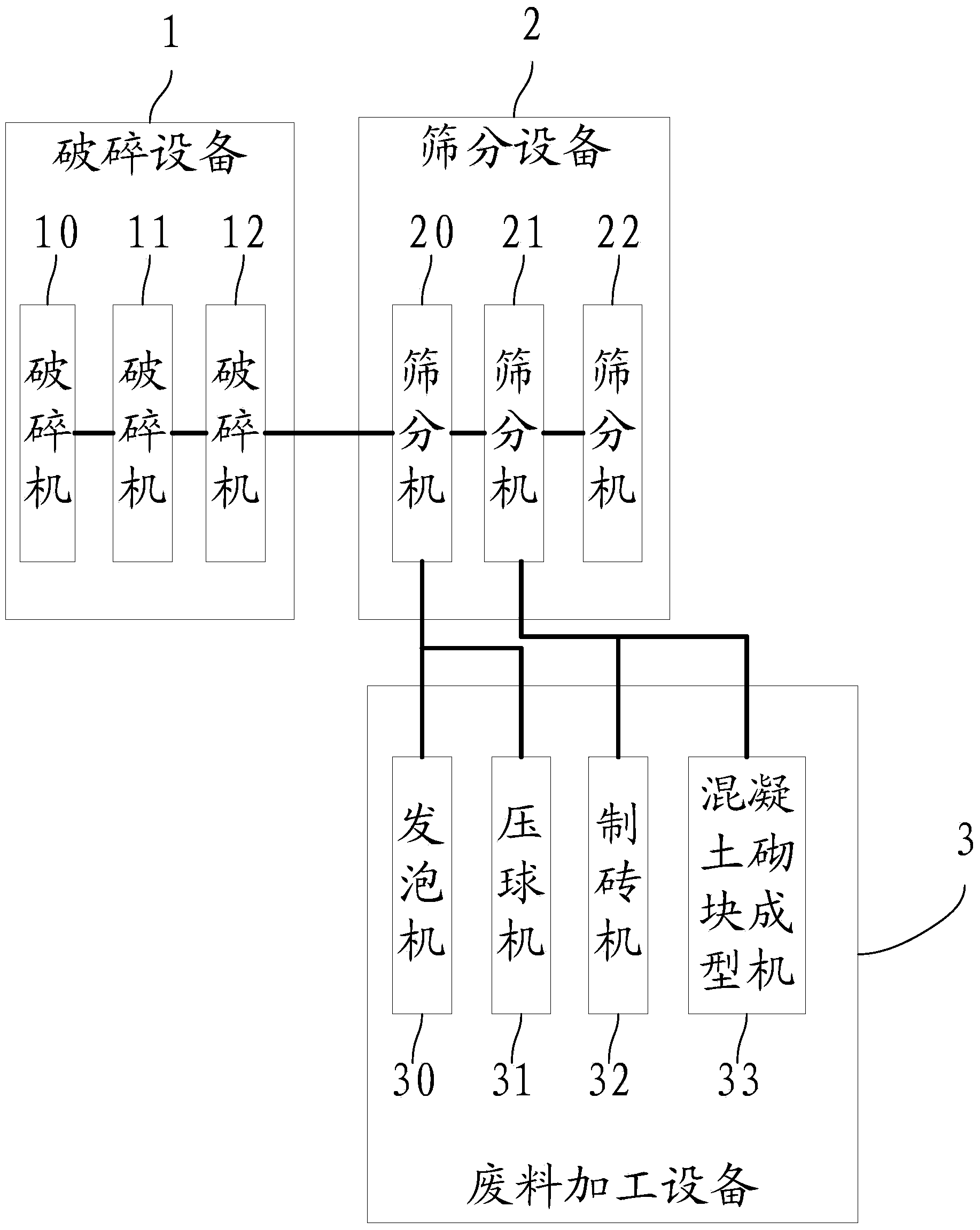

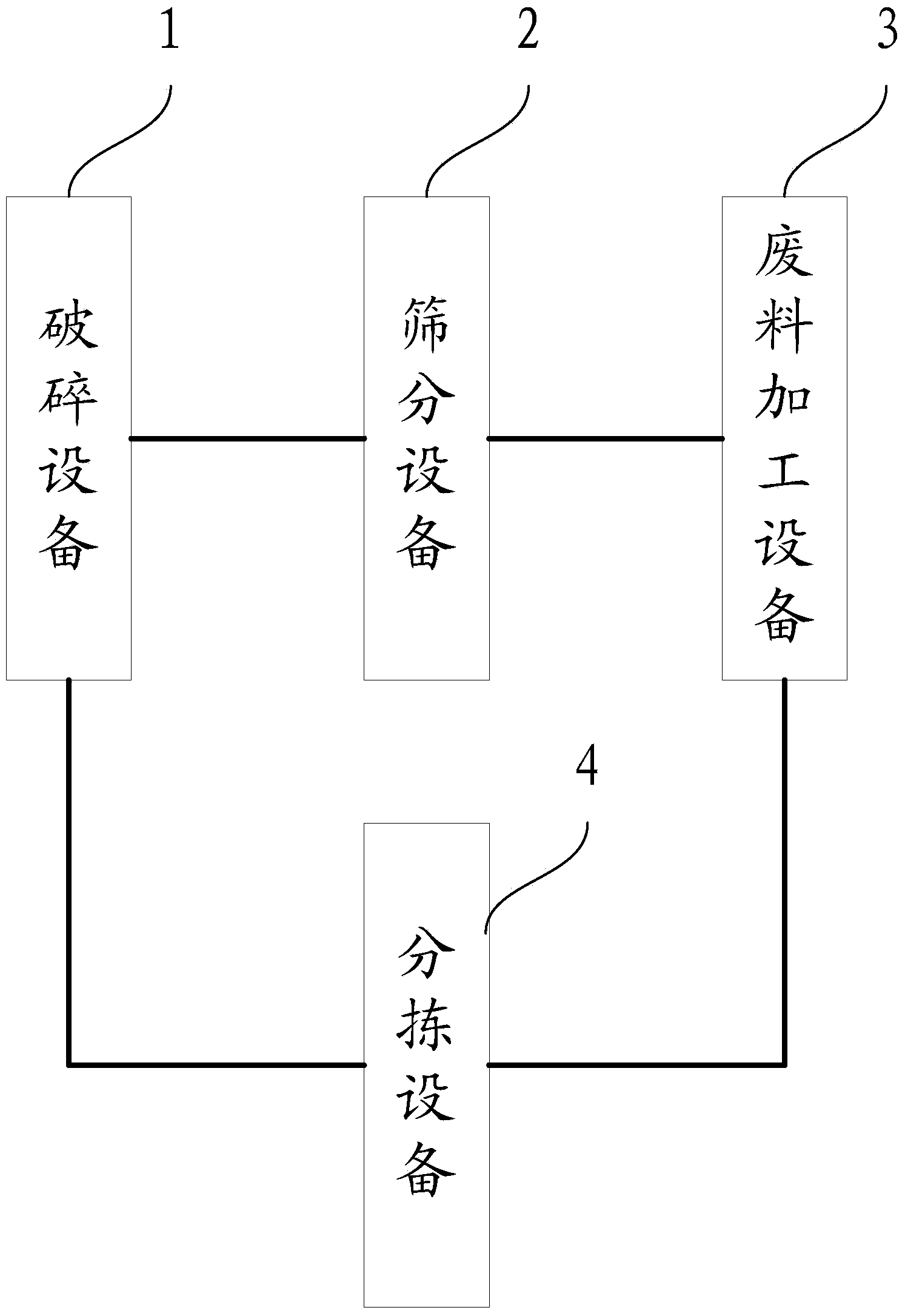

Mobile combination treatment station and method for repeated use of demolition waste

InactiveCN104043635ATake advantage ofReduce pollutionConstruction waste recoverySolid waste disposalWaste processingBrick

The invention discloses a mobile combination treatment station and a method for repeated use of demolition waste. The mobile combination treatment station suitable for repeated use of the demolition waste includes a crushing device, wherein the crushing device can be connected to a screening device of the crushing device in a dismantling mode and also can be connected to a waste processing device of the screening device in a dismantling mode; the crushing device includes at least one crusher, the crusher can crush the demolition waste to obtain a crushed material, and the crushed material obtained from crushing is transported to the screening device; the screening device can screen the crushed material according to the particle size, and the crushed material obtained from screening and having a certain particle size and suitable for manufacture of building materials is transported to the waste processing device; the waste processing device includes at least one of the following machines: a ball pressing machine, a brick preparing machine, a foaming machine, and a concrete block molding machine. The mobile combination treatment station and the method for repeated use of the demolition waste can reduce pollution to the environment, make full use of the demolition waste, and reduce the resource consumption and the engineering cost.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD +2

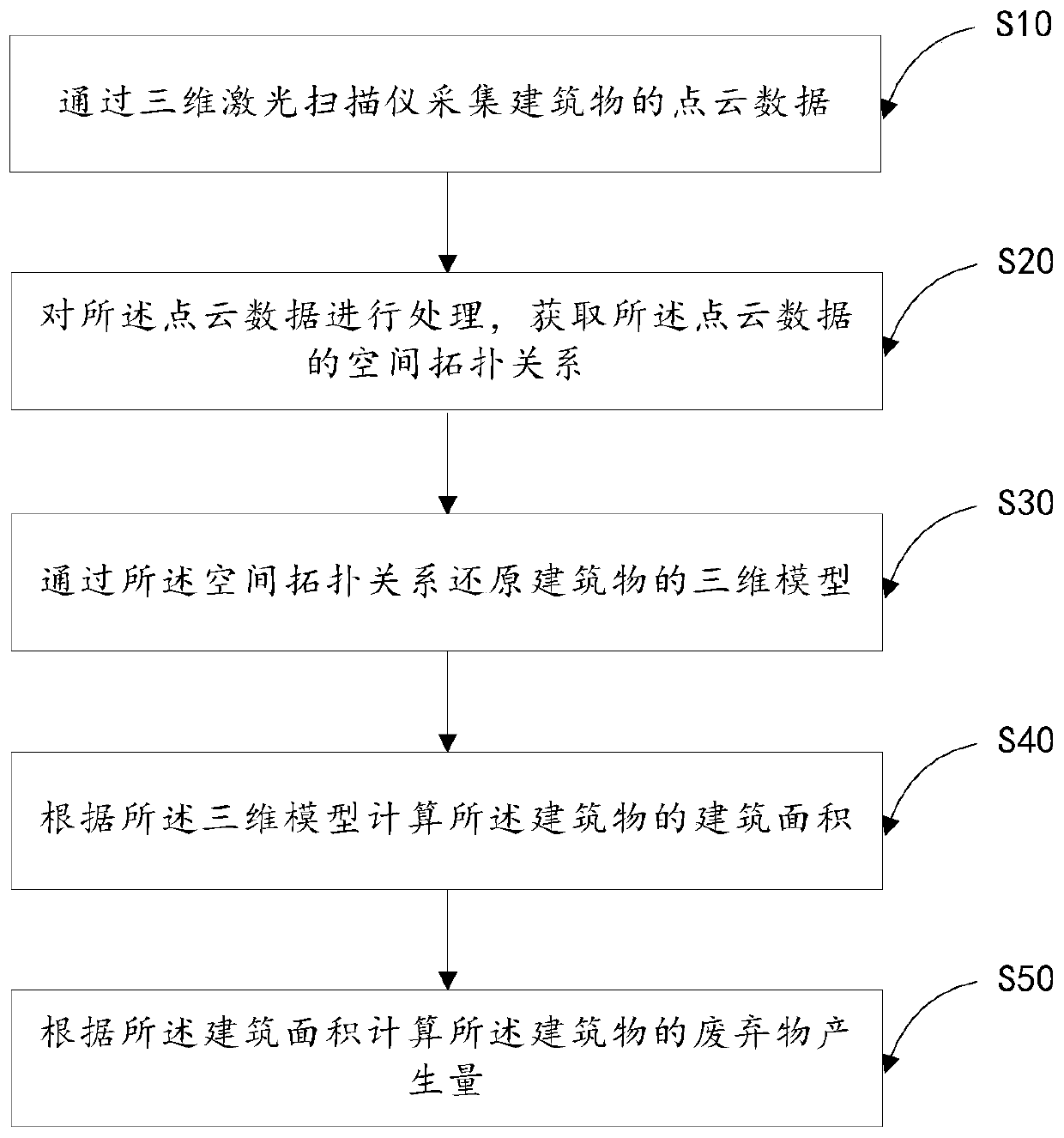

Building demolition waste yield prediction method and device based on laser scanning

InactiveCN110348620AEasy to remove intelligentlyImage enhancementForecastingDemolition wastePoint cloud

The invention relates to the technical field of intelligent buildings, and discloses a building demolition waste output prediction method and device based on laser scanning. The building demolition waste output prediction method comprises the steps: collecting the point cloud data of a building through a three-dimensional laser scanner; processing the point cloud data to obtain a spatial topological relation of the point cloud data; restoring a three-dimensional model of the building through the spatial topological relation; calculating the building area of the building according to the three-dimensional model; calculating the waste output of the building according to the building area; and predicting the existing building demolition waste yield through the three-dimensional laser scanningtechnology, thus facilitating intelligent demolition.

Owner:SHENZHEN UNIV +1

A method for transporting dry quenching coke oven overhaul demolition waste

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

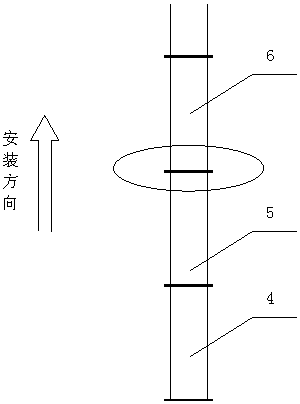

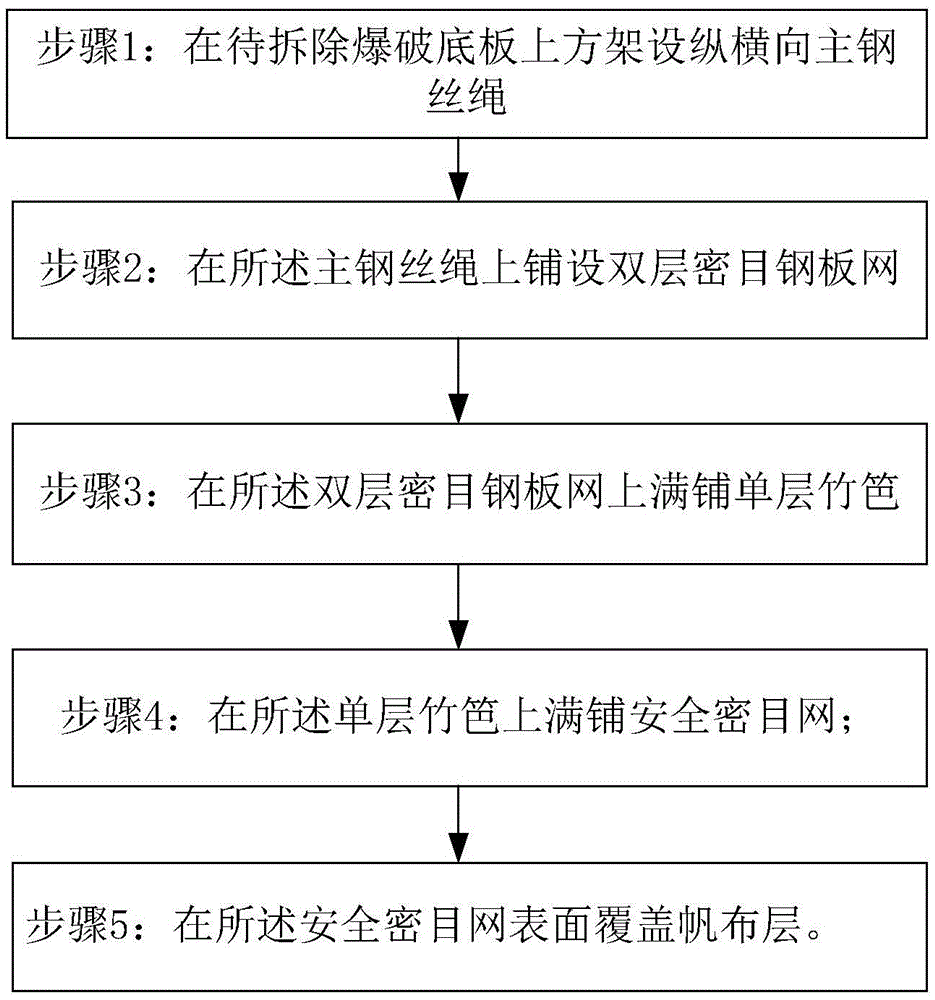

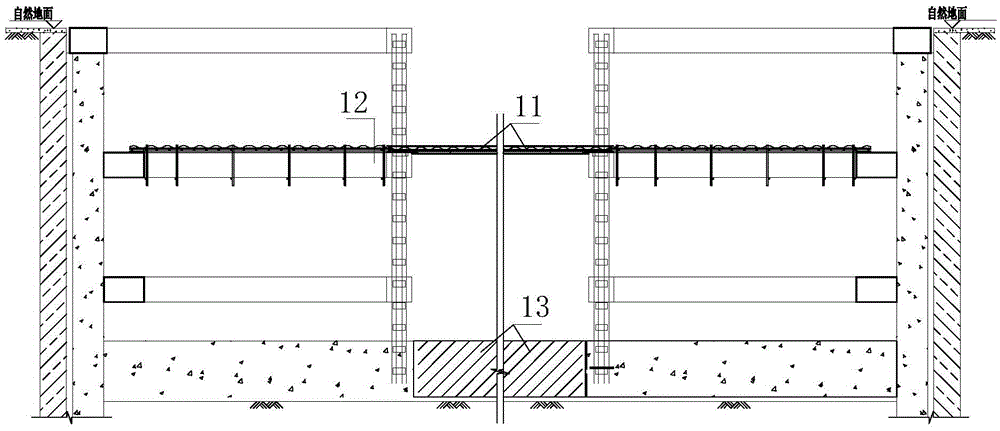

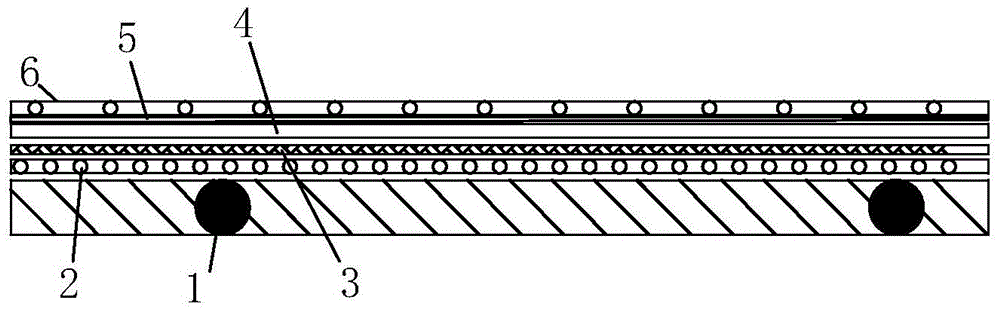

Overhead protection method

InactiveCN105569365AReusableNot easy to wear and tearBuilding repairsBlastingSheet steelDemolition waste

The invention discloses an overhead protection method. The overhead protection method comprises the following steps: step 1, vertical and horizontal main steel wire ropes are erected above a bottom plate to be subjected to demolition blasting; step 2, double dense expanded steel mesh layers are laid on the main steel wire ropes; step 2, a single bamboo sheathing layer is laid fully on the double dense expanded steel mesh layers; step 4, safety dense meshes are fully laid on the single bamboo sheathing layer; step 5, the surface of the safety dense meshes is covered with a canvas layer. According to the method, the vertical and horizontal main steel wire ropes are erected above the bottom plate to be subjected to demolition blasting, by means of the principle of repeated energy absorption from swinging of the steel wire ropes, the main steel wire ropes are matched with the double dense expanded steel mesh layers on the main steel wire ropes, the bamboo sheathing and the safety dense meshes are laid on the double dense expanded steel mesh layers, dustproof canvas is used for covering finally, then the overhead safety protection frame is formed, and flying stone and dust generated in blasting of the bottom plate can be blocked effectively. Repeated and continuous blasting can be implemented with the overhead protection method, the construction cost is low, and the materials used in the method all have the characteristics of recyclability and low probability of loss.

Owner:SHANGHAI NO 7 CONSTR

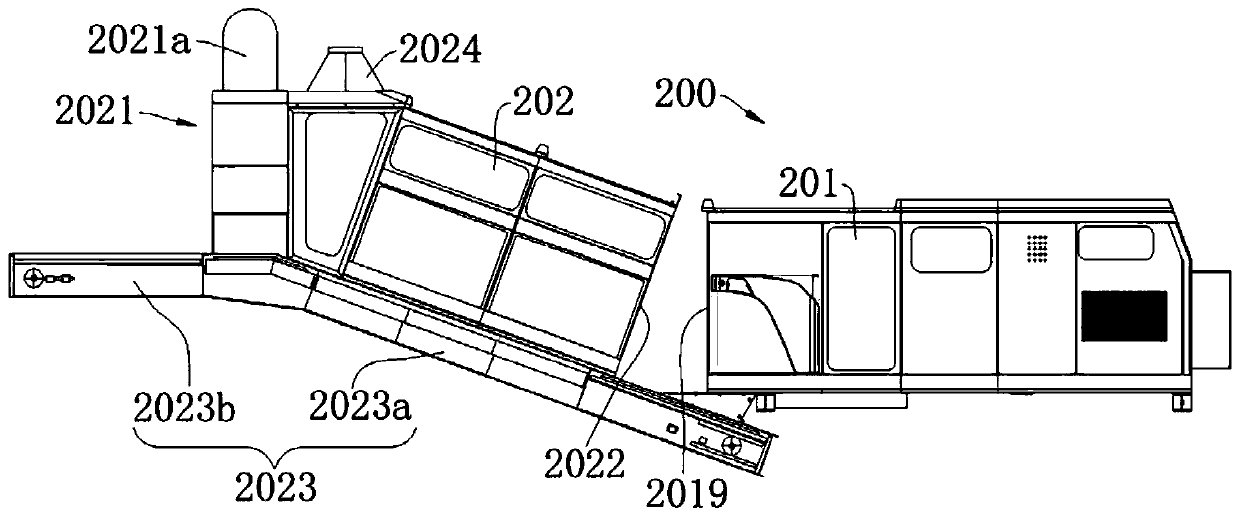

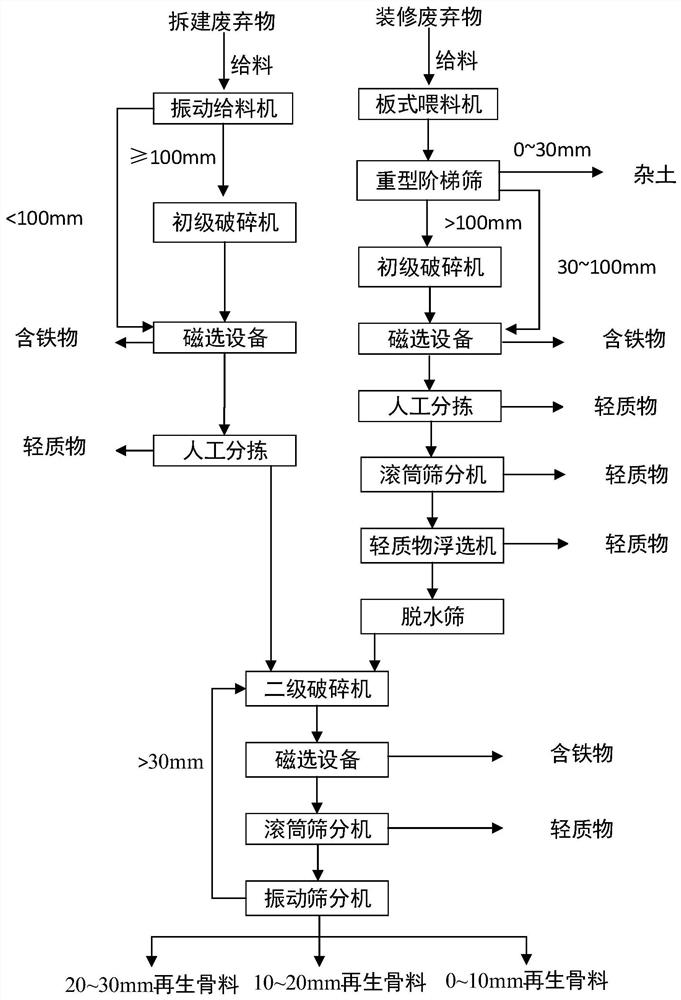

A recycling process for construction, demolition and decoration waste

ActiveCN110976478BImprove efficiencyImprove resource utilizationConstruction waste recoverySolid waste disposalDemolition wasteEnvironmental engineering

A recycling process for demolition and decoration waste, including: dividing construction waste into two types: demolition and construction waste and decoration waste; separating iron-containing materials and light materials in the demolition and construction waste; Separation of miscellaneous soil, iron-containing materials and light materials in the decoration waste; combining the pre-treated demolition and construction waste and decoration waste, and crushing them into recycled aggregate; separating the iron-containing material in the recycled aggregate Separation of waste and light matter; sieve the processed recycled aggregate into recycled aggregate with different particle size ranges. Reasonably combine the separation process of construction and demolition waste and decoration waste. Firstly, the demolition and construction waste and decoration waste undergo different pretreatment processes to make the two properties and components the same, and then crush the two into recycled aggregates. , and finally select the recycled aggregates to make the recycled aggregates of high quality; it not only ensures high sorting efficiency and resource utilization of demolition and construction waste and decoration waste, but also reduces equipment investment and saves floor space.

Owner:SHENZHEN WEIHAI BUILDING MATERIAL

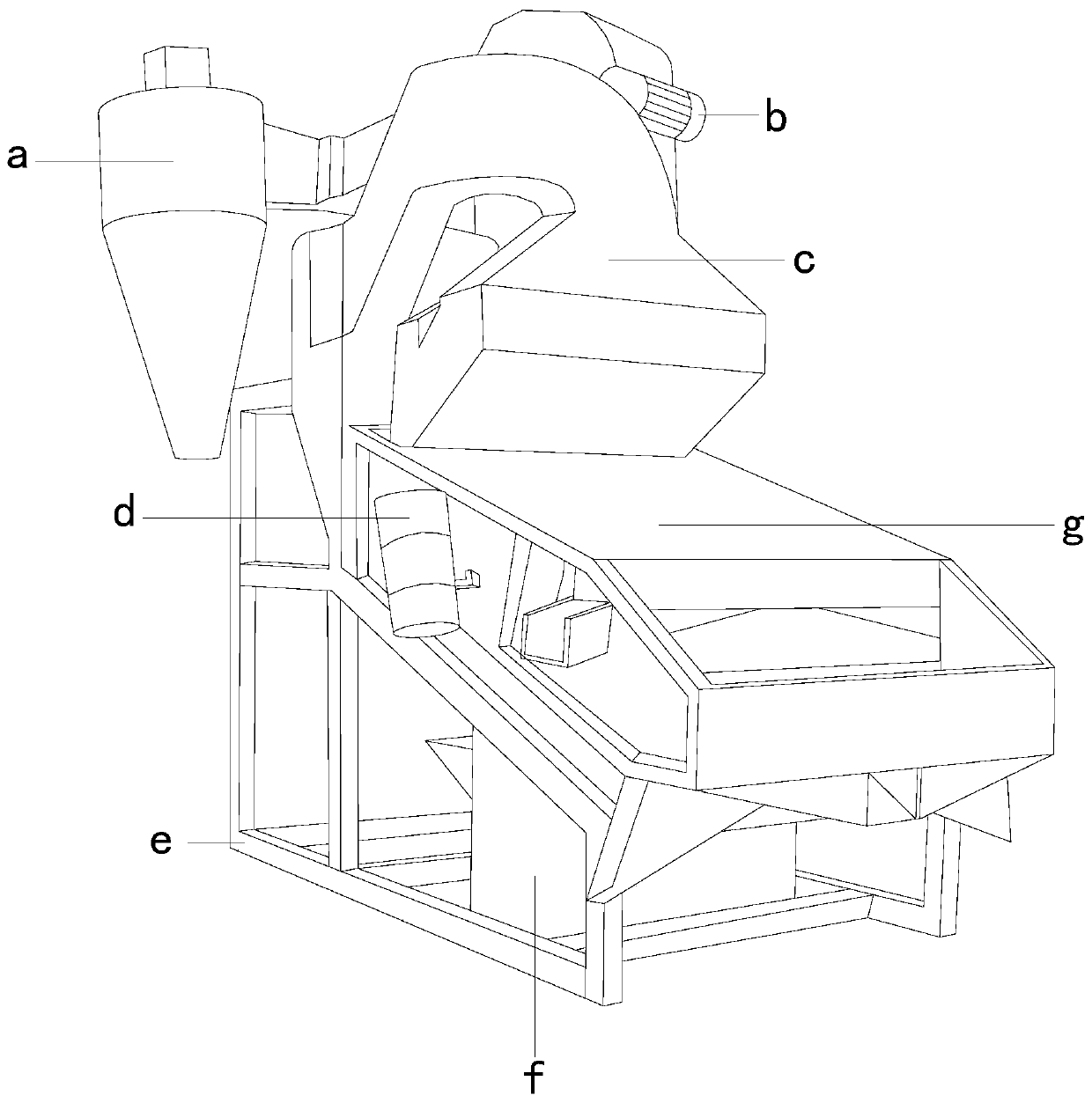

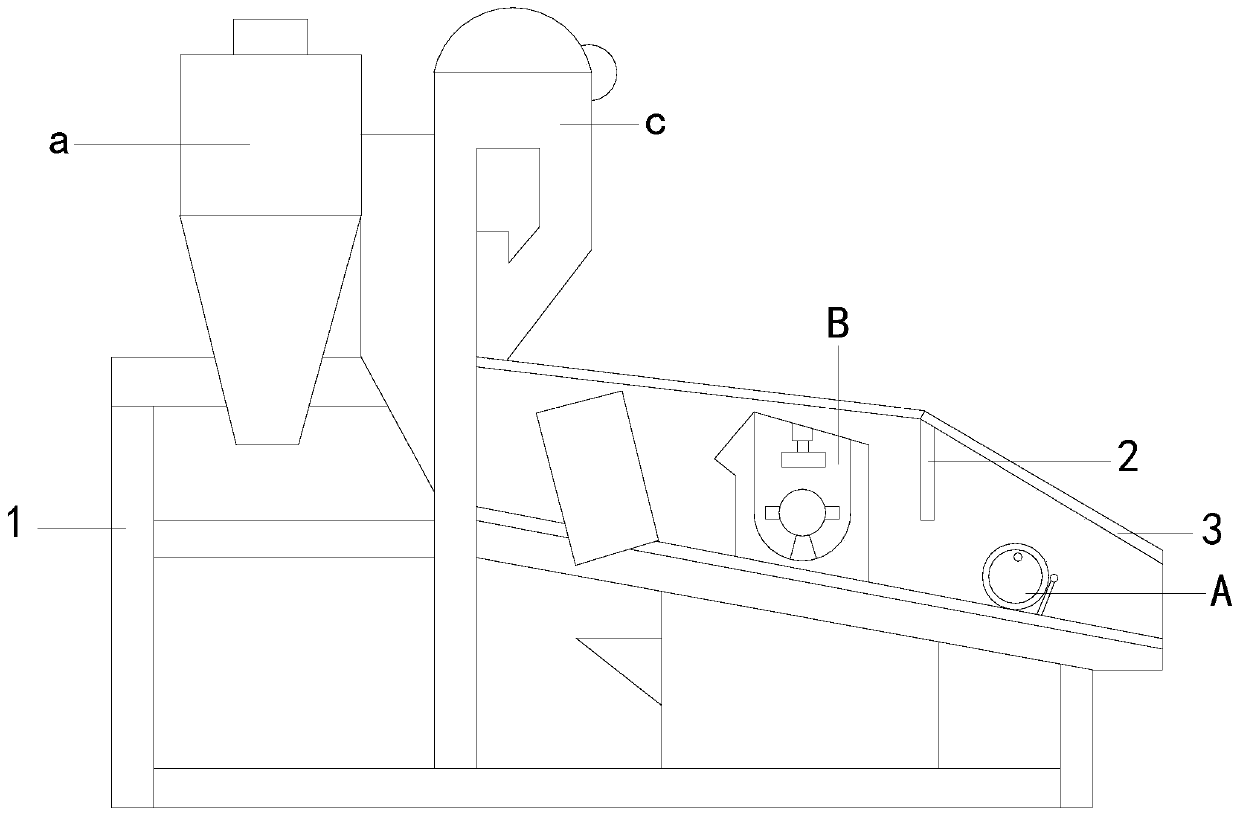

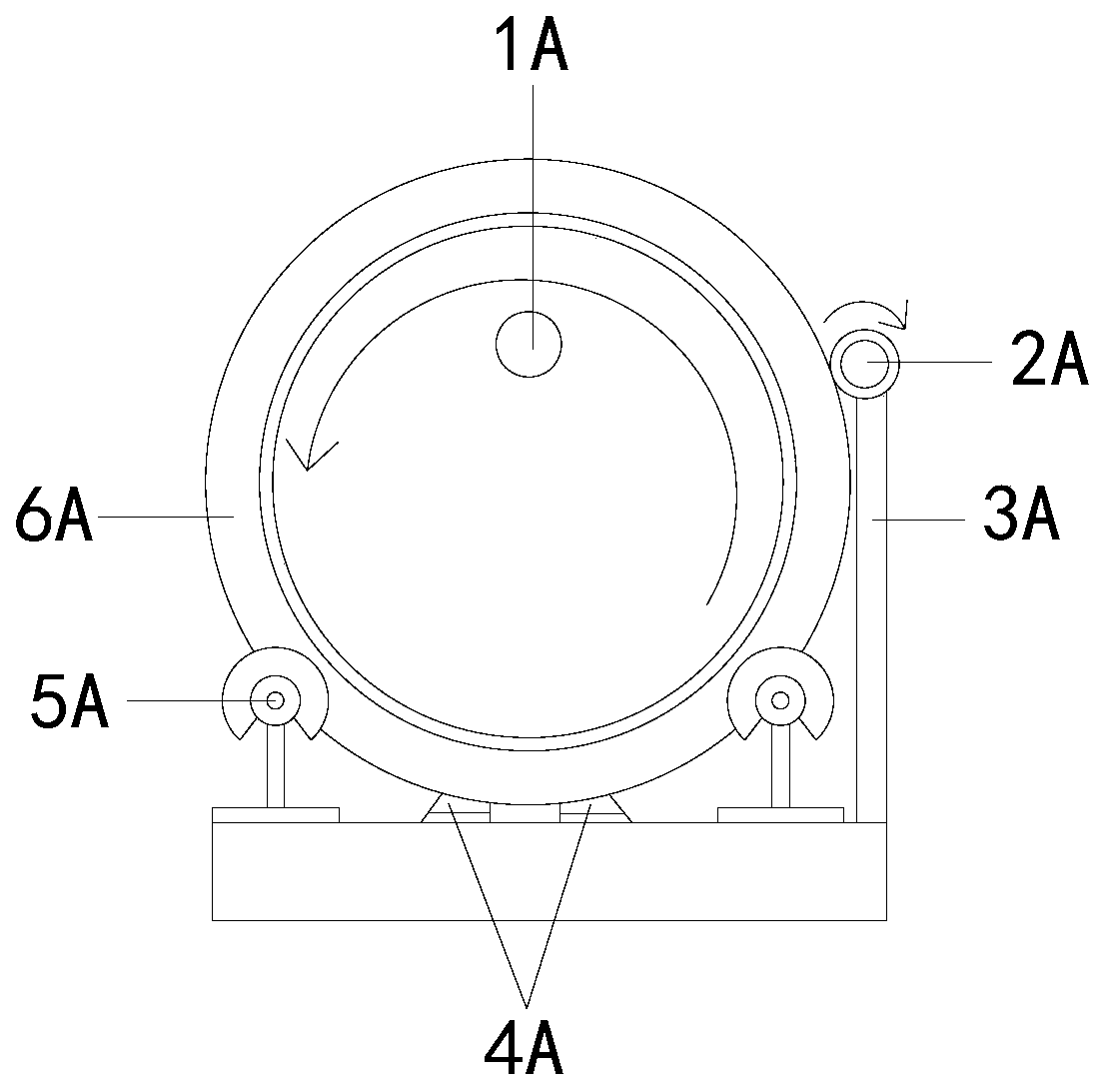

Winnowing machine for recycling indoor decoration waste

ActiveCN110496690AAvoid secondary pollutionAvoid accumulationGrain treatmentsDrive wheelDemolition waste

The invention discloses a winnowing machine for recycling indoor decoration waste. The winnowing machine structurally comprises a discharging hopper, a motor, an air pipe, a driving wheel, a rack, a storage box and a crushing mechanism. The winnowing machine has the beneficial effects that construction waste generated by decoration is classified and treated through the arranged crushing mechanism,and a crushing device is mainly used for treating softer construction waste; the waste is broken through traction force, and prevented from being agglomerated and stacked on a crushing cutter in bags; different thicknesses are formed through regulation, and then the formed rotary cutting effect and force are changed, so that the crushing effect is optimal; the crushing device can be used for crushing all hard masonry construction waste through an alloy hammer of the crushing device and high strength impact, and the volume and shape of the construction waste are changed, so that unified collection and bagging of the construction waste are facilitated; a refuse sack can not be broken by the crushed waste due to friction, and accordingly the refuse sack does not spill or leak; and secondarypollution caused by the decoration waste is eliminated effectively.

Owner:安徽国祯环卫科技有限公司

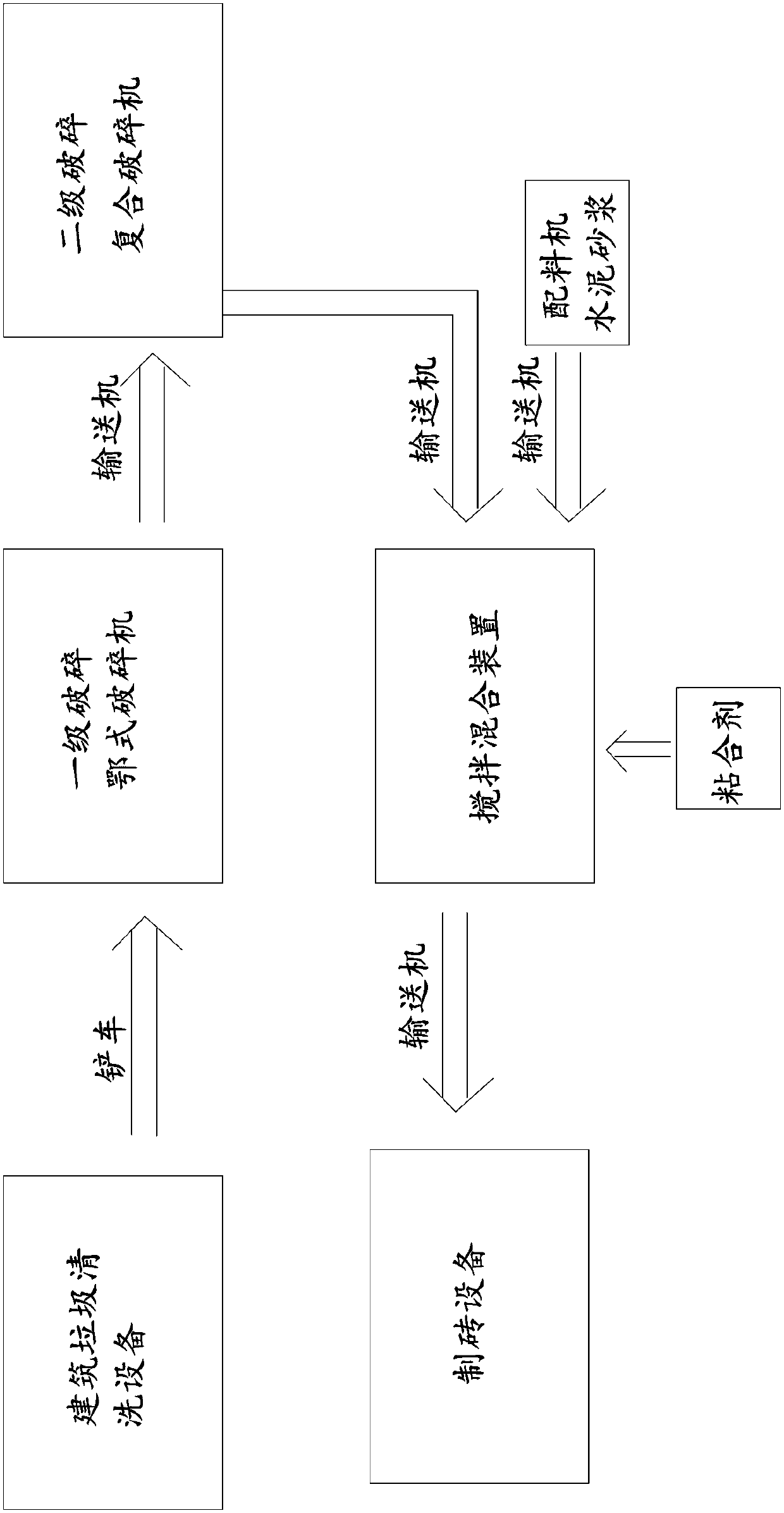

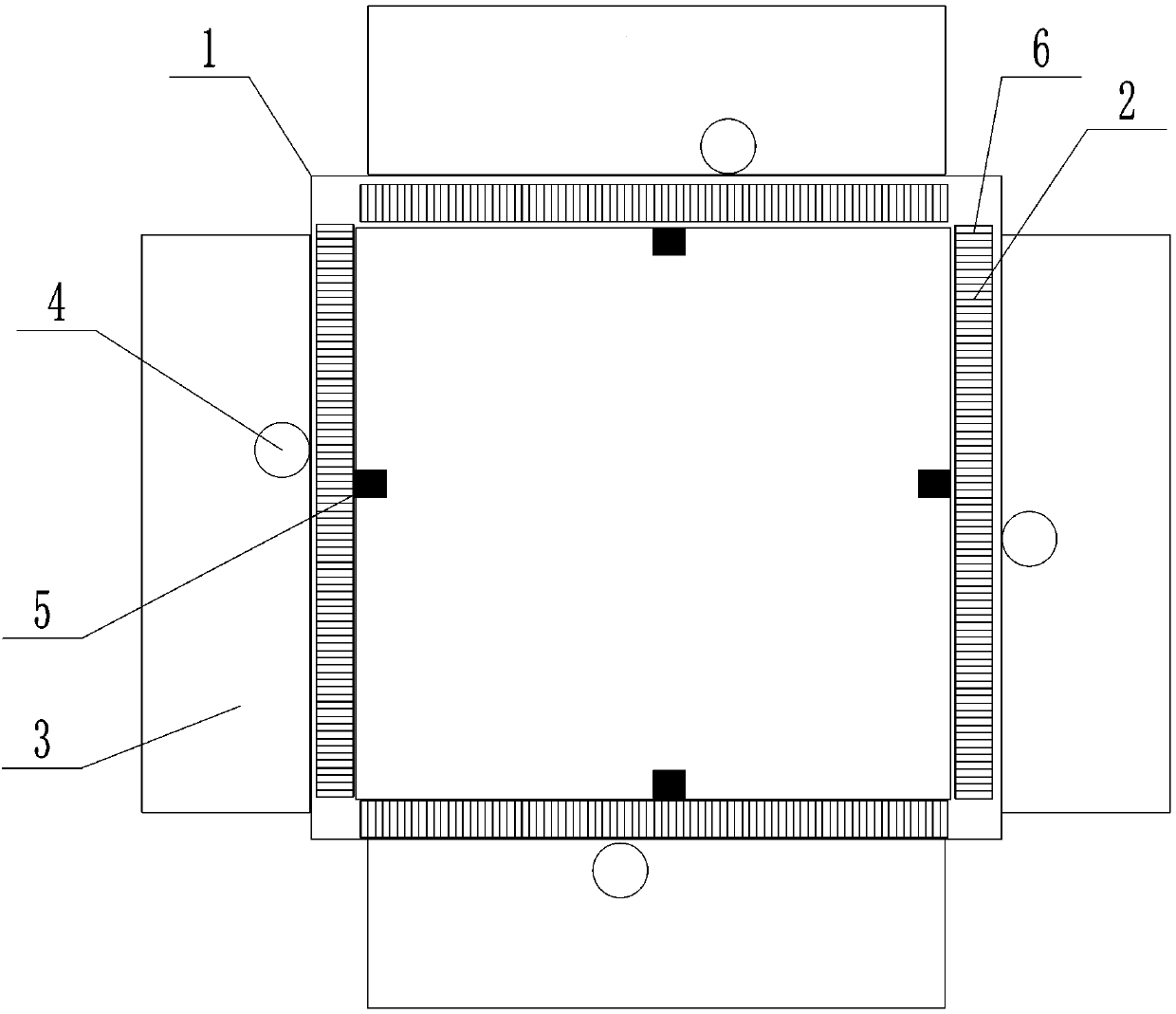

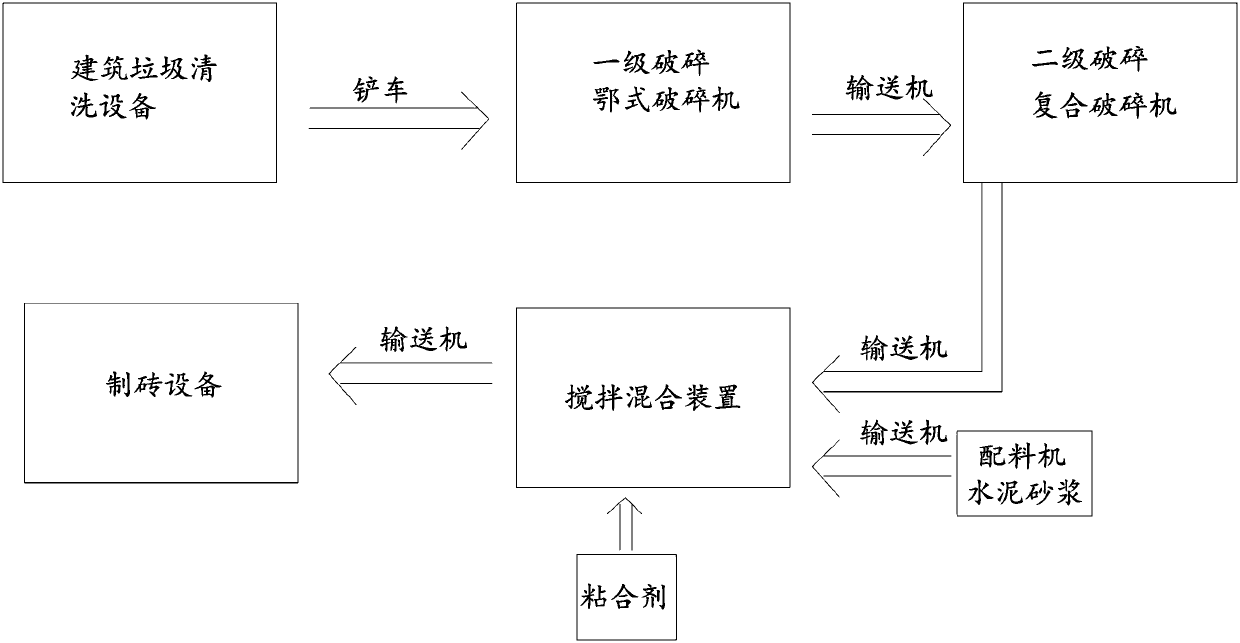

System and method for recycling of building demolition waste

PendingCN109970396APromote fragmentationReduce pollutionSolid waste managementBuilding materialDemolition waste

The invention relates to the technical field of construction and building material equipment, in particular to a system and method for recycling of building demolition waste. The system for recyclingof building demolition waste includes: a) building demolition waste cleaning equipment; b) primary crushing equipment; c) secondary crushing equipment; d) mixing equipment; and e) brick-making equipment. The method for recycling of building demolition waste includes the steps of: 1: building demolition waste cleaning step; 2. primary crushing step; 3. secondary crushing step; 4. mixing step; and 5. brick-making step.

Owner:孟杨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com