Method for conveying demolition waste materials obtained through overhaul of dry quenching boiler

A technology of CDQ coke oven and transportation method, which is applied in the directions of transportation, packaging, sled, etc., can solve the problem of inconvenient transportation of CDQ coke oven demolition waste, and achieve the goal of shortening the demolition period, ensuring quality and safety, and improving demolition efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

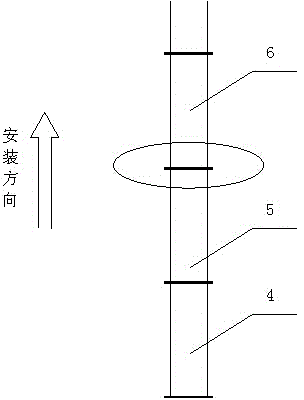

[0027] The method for transporting CDQ coke oven overhaul and dismantling waste of the present invention is characterized in that it comprises the following steps:

[0028] a. Make the feeding chute

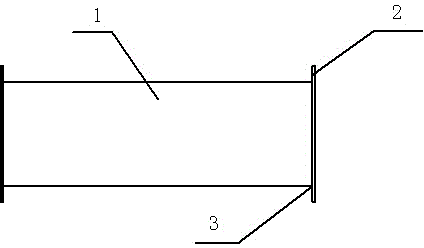

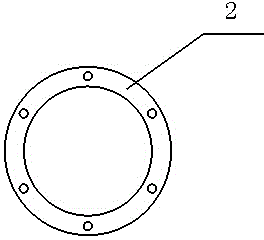

[0029] see now Figure 1-2 , figure 1 It is a schematic structural view of a single-section chute in an embodiment of the present invention, figure 2 for figure 1 side view.

[0030] The chute is made with a pipe with an inner diameter of 500mm. The length of each section of the chute is 2.0m. The pipe section is welded with a flange plate of a corresponding diameter. The flange plate is made of a 10mm steel plate, and a bolt with a diameter of 20mm is opened on the flange plate. hole;

[0031] b. Set up the overall scaffolding operation platform

[0032] According to the characteristics of the main body structure, it is carried out by erecting a full frame, and the scaffolding should be carried out around the circumference of the main body. The support of the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com