Anti-theft door breaking method by using freezing pressure of water and low-temperature cold brittleness of steel plate

An anti-theft door, steel plate technology, applied in the direction of preventing theft, anti-war damage, special equipment for doors/windows, etc., can solve problems such as hidden safety hazards, increased difficulty in demolition by firefighters, difficulty in rapid fire rescue work, etc., to improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] A method for demolition of an anti-theft door utilizing the freezing pressure of water and the cold and brittle properties of steel plates, comprising the following steps:

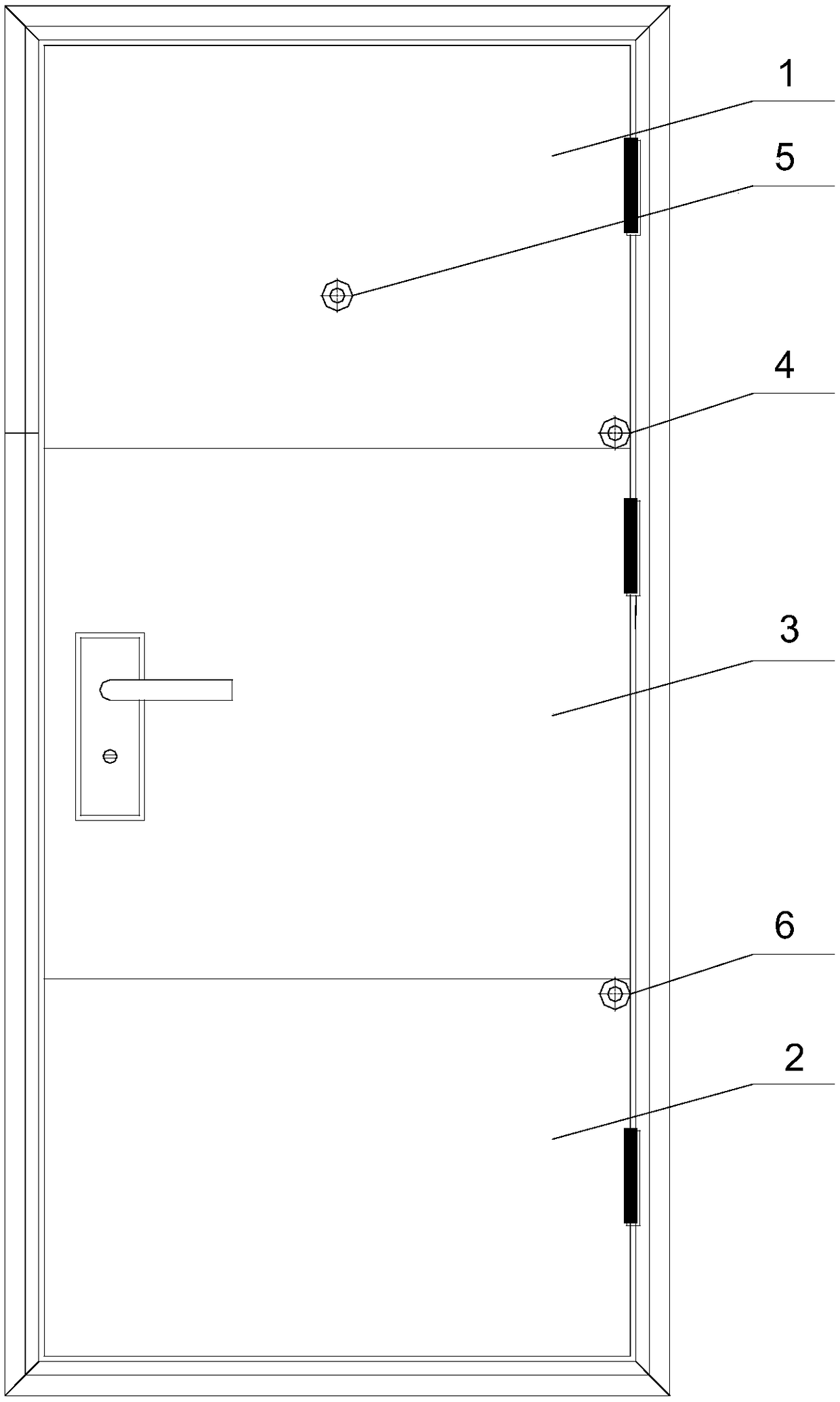

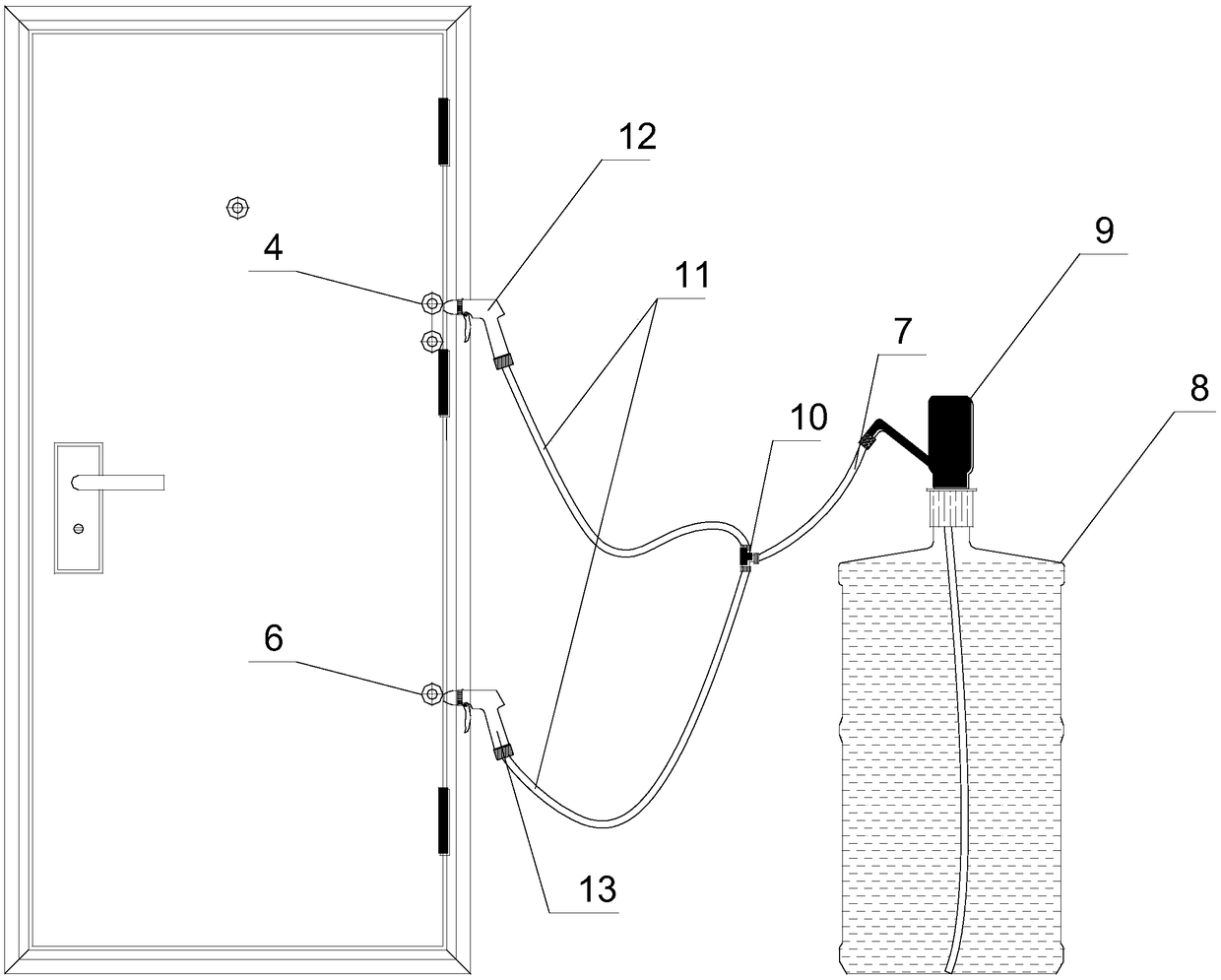

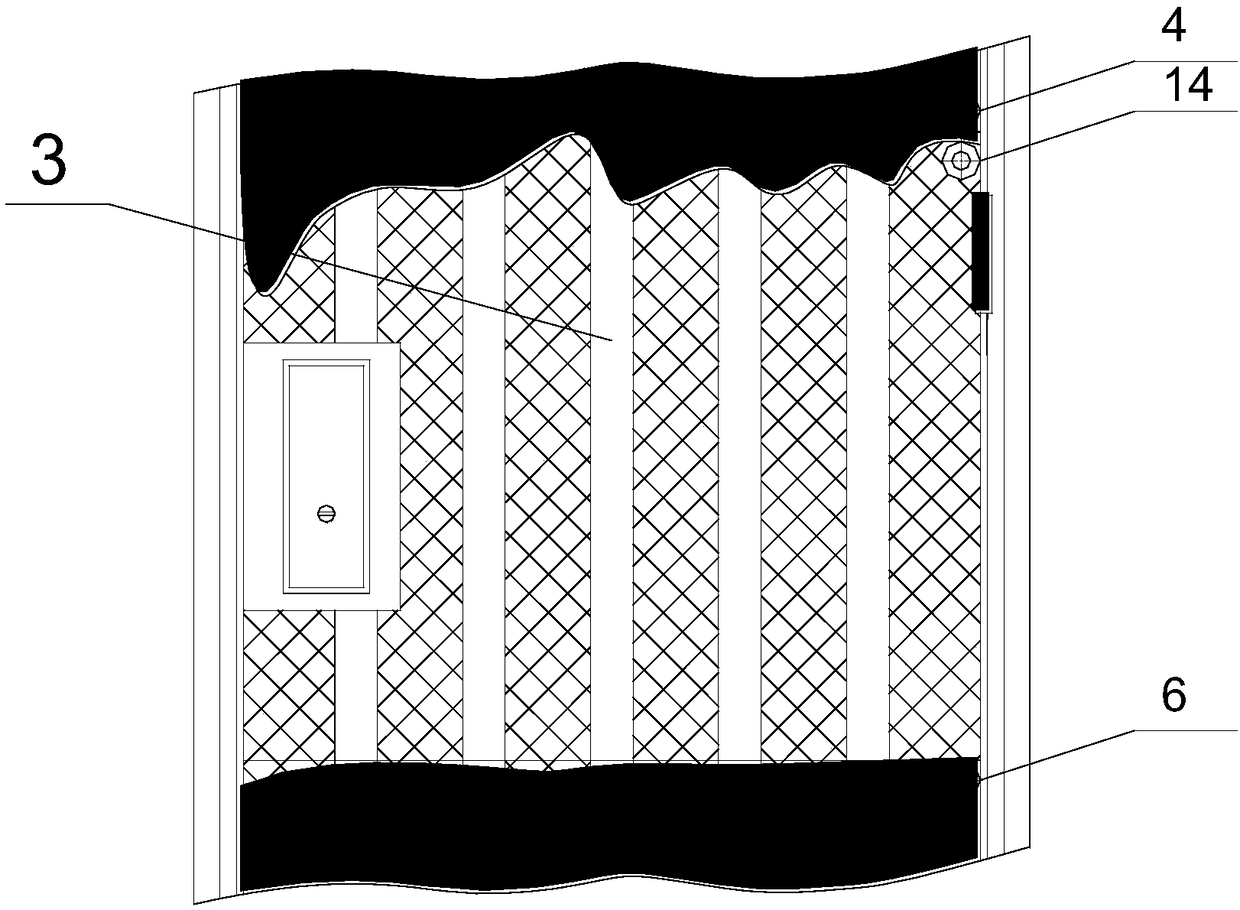

[0027] Such as figure 1 As shown, the first step is to determine the reasonable position of water injection and form strong constraints in the door body, as follows: divide the door panel into three parts from top to bottom and inject water respectively, in which the areas of the upper part 1 and the lower part 2 are equal, and Both are smaller than the area of the middle part 3; the upper water injection hole 4 is opened at the lowermost end of the divided upper part 1 and close to the door hinge, and the lower water injection hole 6 is opened at the uppermost end of the divided lower part 2 and close to the door hinge. The middle position of the upper part 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com