Dismounting method for basic steel pipe pile of offshore wind turbine

A technology for offshore fans and steel pipe piles, which is applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of complex construction conditions, hidden dangers of blasting construction safety, difficult management and coordination, etc., to achieve high demolition efficiency and ensure safety. sex, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

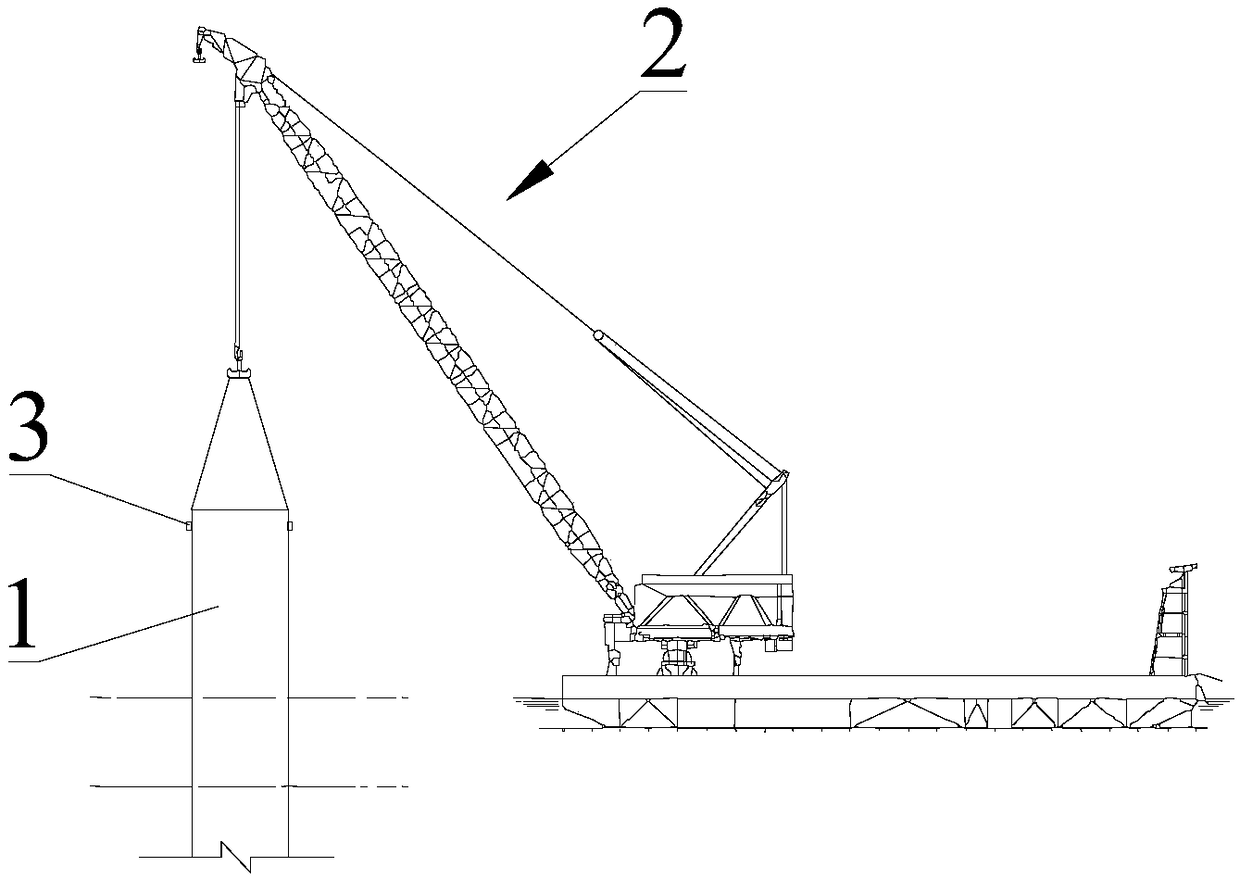

[0023] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0024] A method for removing steel pipe piles for foundations of offshore wind turbines, comprising the following processing steps:

[0025] 1) Fix the steel pipe pile 1 to be removed. In this embodiment, the steel pipe pile 1 to be dismantled is suspended and fixed by the floating crane 2 , and a lifting lug 3 is provided on the top of the steel pipe pile 1 , and the floating crane 2 is detachably connected to the lifting lug 3 .

[0026] 2) Reinforcing the soil around the fixed steel pipe pile 1 . Preferably, the soil around the steel pipe pile 1 is reinforced by using the high-pressure rotary grouting pile construction method, which can prevent sand turning.

[0027] 3) Cleaning the inside of the steel pipe pile 1 . Generally, there will be impurities such as concrete inside the steel pipe pile 1. Therefore, a drill bit with a small diameter can be used to clean the inside of the steel pipe pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com