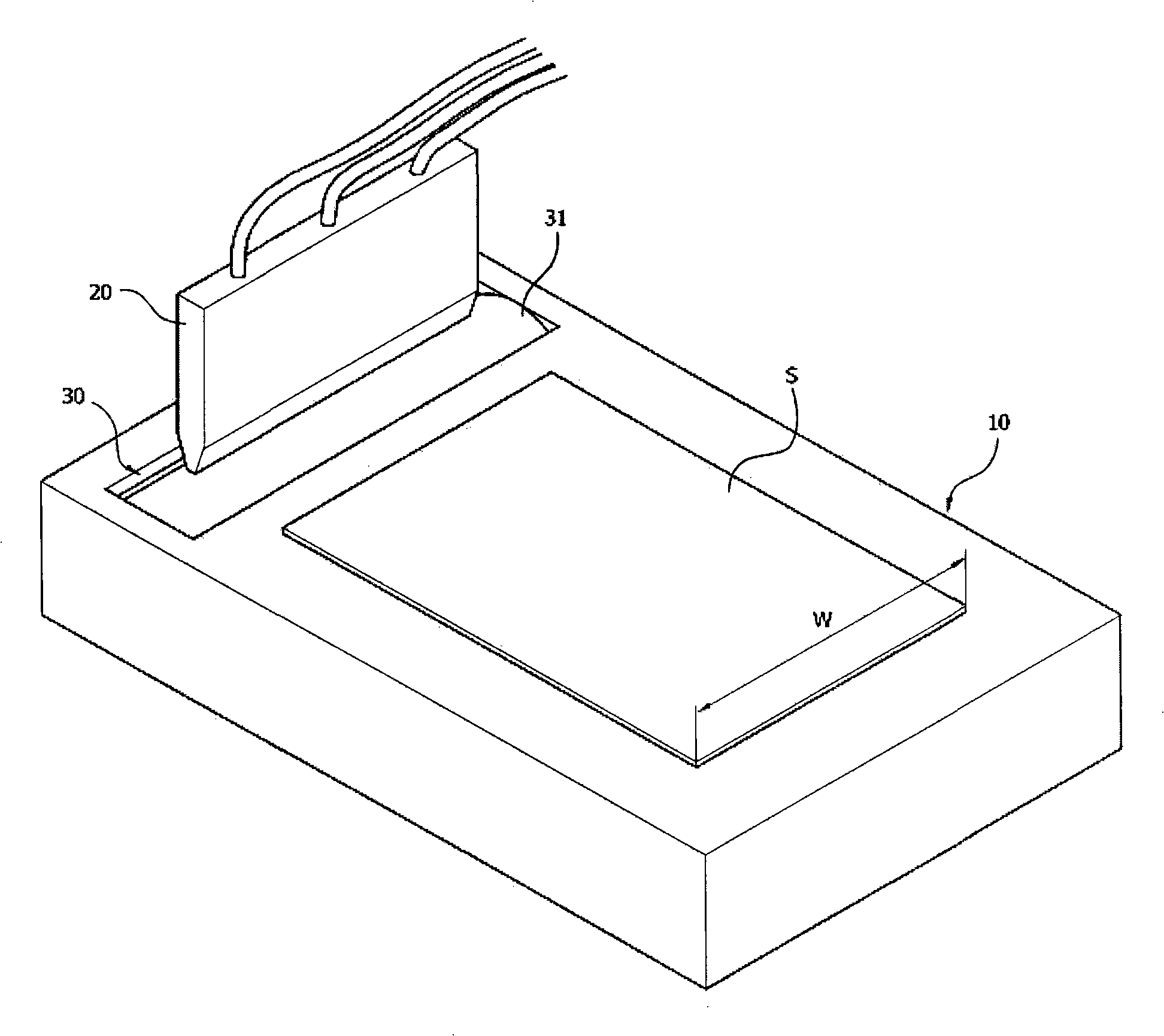

Preparation exhaust device for slit coating machine

A discharge device and coating machine technology, applied to the surface coating liquid device, optical mechanical equipment, photo-plate making process coating equipment, etc., can solve the problems of reduced cleaning efficiency and consumption of solution on the surface of the roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

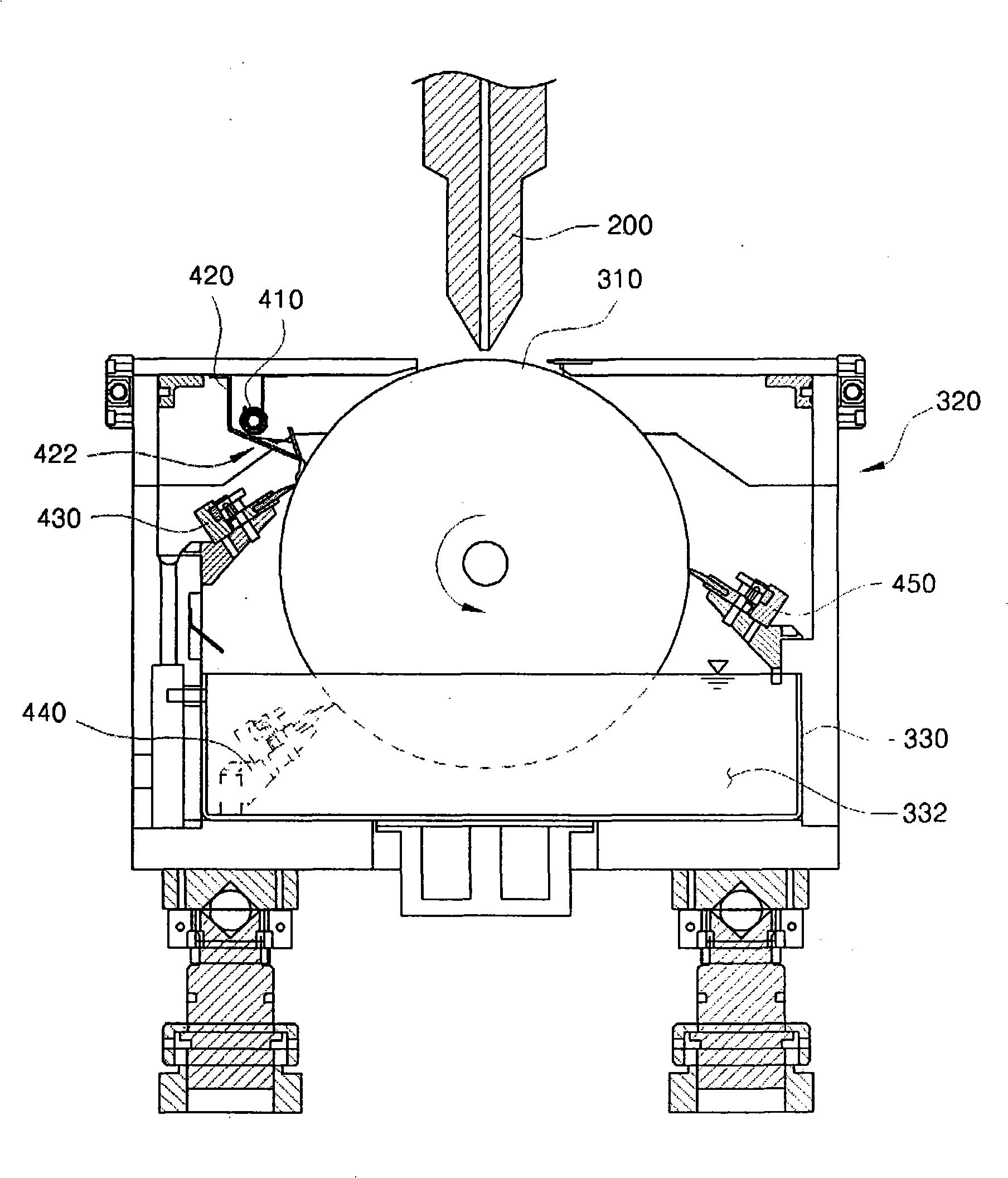

[0025] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

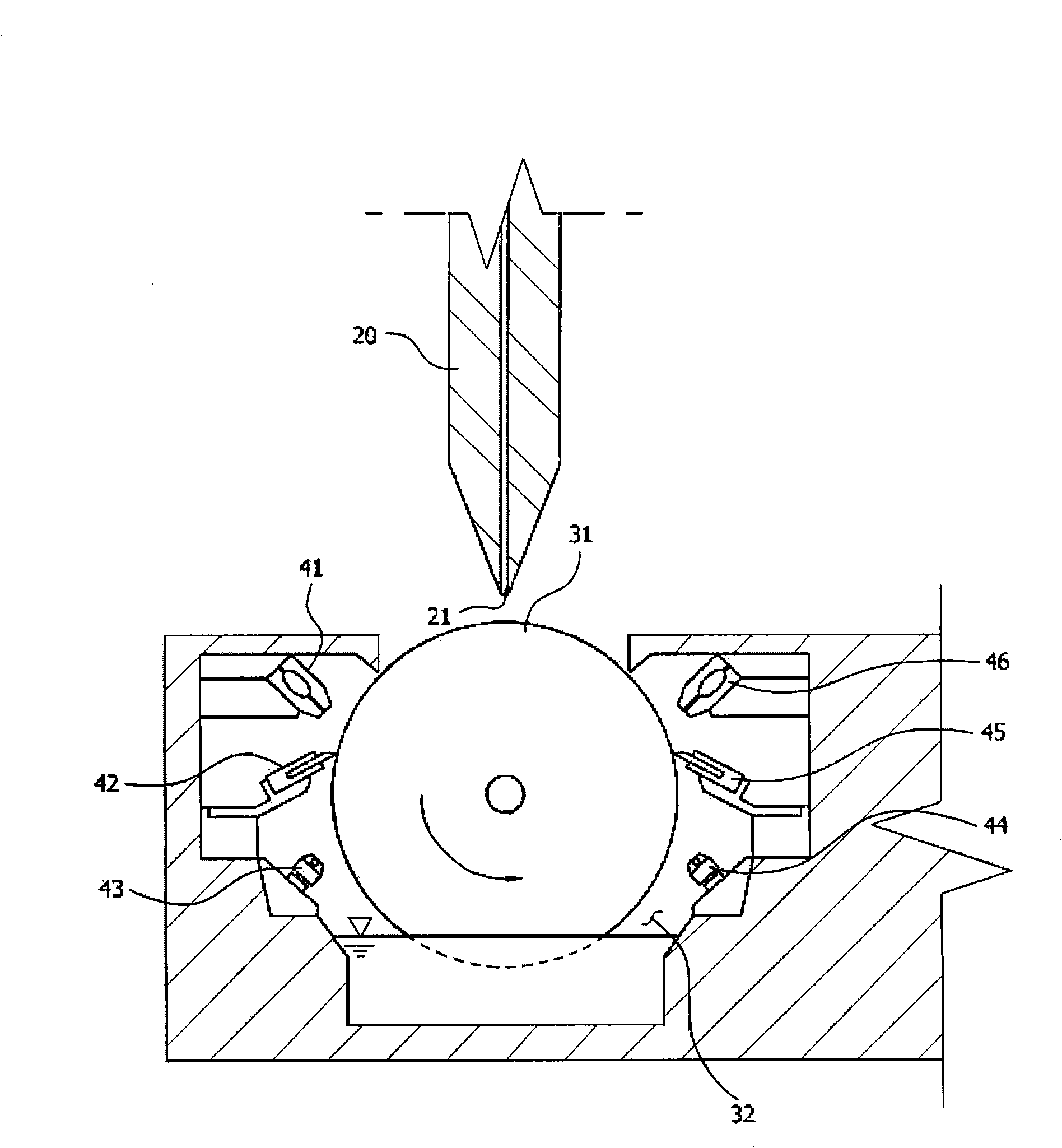

[0026] image 3 is a sectional view of a preliminary discharge device for a slit coater according to an embodiment of the present invention.

[0027] refer to image 3 It can be seen that the pre-discharging device for a slit coater according to the embodiment of the present invention includes: a rotatable roller 310 and an accommodating portion 320 that rotatably supports the roller 310 and exposes a part of the accommodated roller 310 to the outside. The roller 310 receives the photosensitive liquid to be discharged through the slit nozzle 200 , and the storage part 320 is provided with a cleaning tank 330 filled with a cleaning solution 332 in order to clean the surface of the roller 310 receiving the photosensitive liquid.

[0028] At this time, the roller 310 is rotatably installed in the storage part 320 in the form that a part of its outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com