A recycling process for construction, demolition and decoration waste

A treatment process and waste technology, which is applied in the field of recycling treatment process of demolition and construction and decoration waste, can solve the problems of treatment and recycling, high equipment investment cost, complicated process flow, etc., and achieve high sorting Efficiency and resource utilization, saving floor space, and simplifying the effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

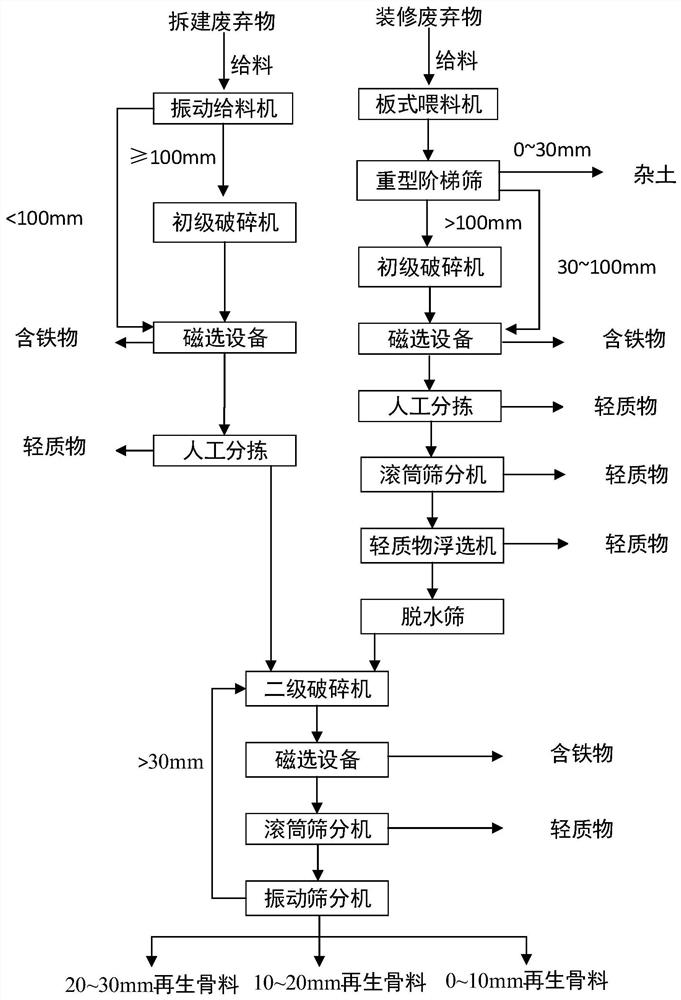

[0032] like figure 1 As shown, a recycling process for demolition and decoration waste provided by the embodiment of the present invention includes the following steps:

[0033] S1, classification

[0034] Divide construction waste into two categories, demolition and construction waste and decoration waste, and stack them according to category.

[0035] S2, iron removal

[0036] The construction and demolition waste to be processed in step S1 is screened into two parts with a particle size D<100mm and a particle size D≥100mm through a vibrating feeder; the part with a particle size D<100mm is transported to the magnetic separation equipment by a belt conveyor Iron removal; the part with a particle size D≥100mm is transported to the primary crusher through a belt conveyor to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com