Enclosing purlin protection pretreatment method before demolition blasting of deep foundation pit supporting beam

A technology for deep foundation pits and supporting beams, which is applied in protection devices, excavation, and infrastructure engineering, etc. It can solve the problems of prolonging the construction period, affecting the effect of blasting fragmentation, and increasing the cost of demolition, so as to reduce hazards, effectively use explosive energy, and improve construction efficiency. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

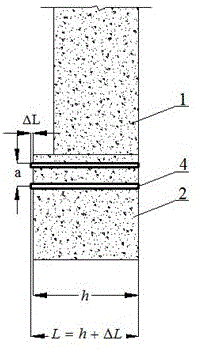

[0033] A pretreatment method for purlin protection before blasting demolition of support beams in deep foundation pits. In this embodiment, the deep foundation pit horizontal support beam (1) has foot supports and truss supports, and the length of the connecting surface of the deep foundation pit horizontal support beam (1) and the purlin (2) is 2200mm; Section size is: height h=1000mm, width A=1200mm.

[0034] The concrete steps of the technical solution adopted in this embodiment are:

[0035] Step 1. Determination of reserved area

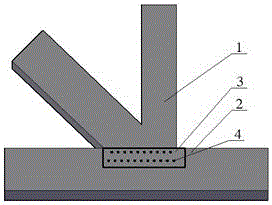

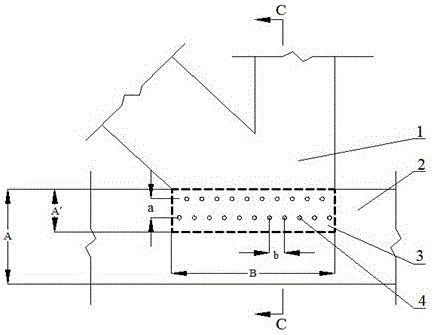

[0036] The structure and size of the horizontal support beam (1) and purlin (2) of the deep foundation pit to be demolished provided according to the design drawing of the support beam in the deep foundation pit, such as figure 1 and figure 2 As shown, a reserved area (3) is provided on the upper surface of the purlin (2).

[0037] Such as figure 1 and figure 2 As shown, the reserved area (3) is rectangular, and the length B of the reser...

Embodiment 2

[0056]A pretreatment method for purlin protection before blasting demolition of support beams in deep foundation pits. Present embodiment except following technical parameters, all the other are with embodiment 1:

[0057] In this embodiment, the horizontal support beam (1) of the deep foundation pit has foot supports and truss supports, and the length of the connecting surface of the horizontal support beam (1) and the purlin (2) of the deep foundation pit is 2500mm; Section size is: height h=1400mm, width A=1400mm.

[0058] The length B=2200mm of reserved area (3) described in the present embodiment, the width of reserved area (3) is A'

[0059] A'=0.4~0.5A (1)

[0060] From: A=1400mm;

[0061] Then: A'=560~700mm.

[0062] The pre-embedded PVC pipes (4) in this embodiment are 3-4 rows, and the distances between the outer two rows of pre-embedded PVC pipes (4) and the respective adjacent long sides of the reserved area are 80-90 mm. The row spacing of each row is a=220~2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com