Automatic tapping assembly line

An assembly line and automatic technology, which is applied in the field of assembly line, can solve the problems such as the lack of improvement in the efficiency of automatic tapping and drilling, and achieve the effect of stable spatial position, continuous and efficient method, and guaranteed positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

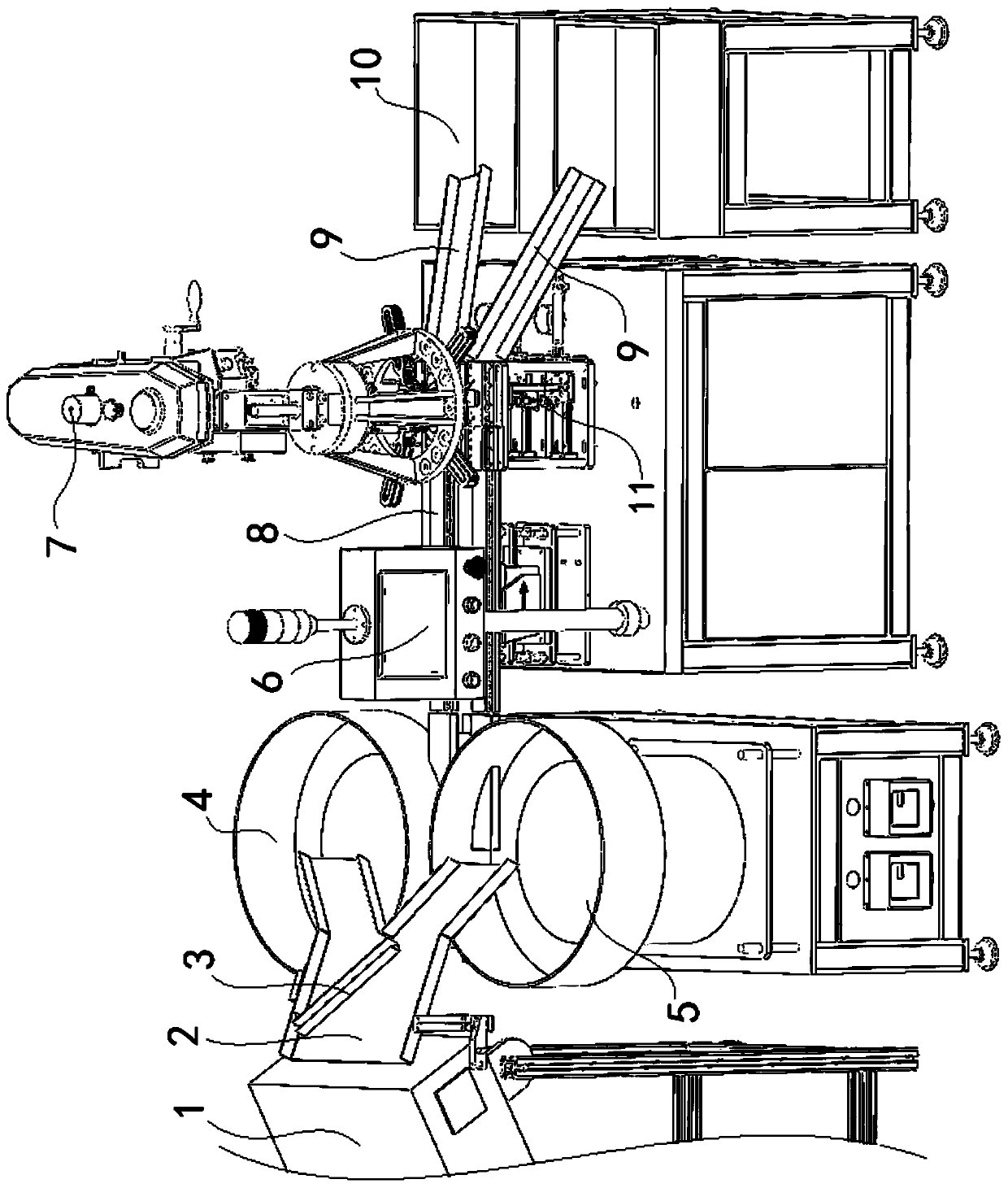

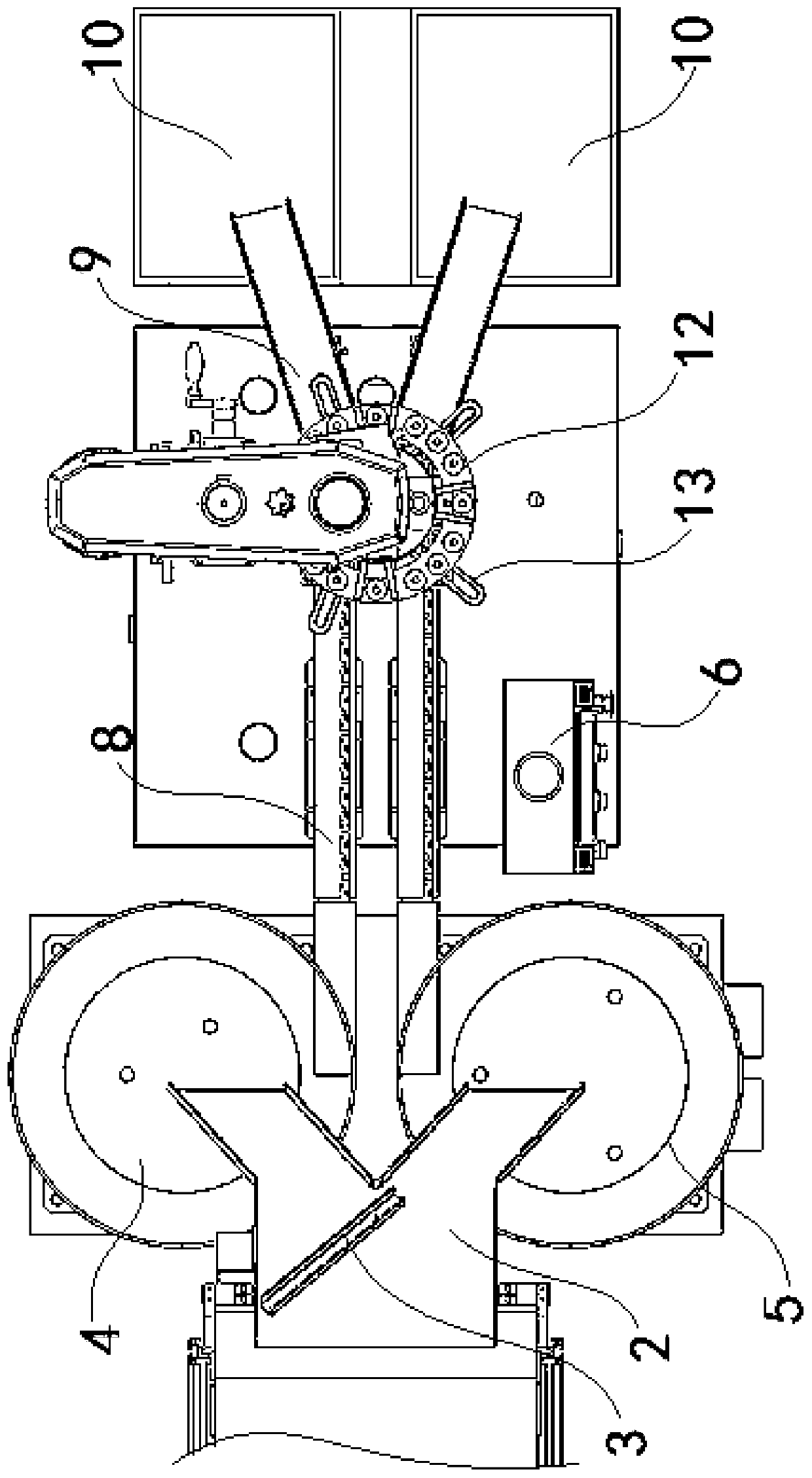

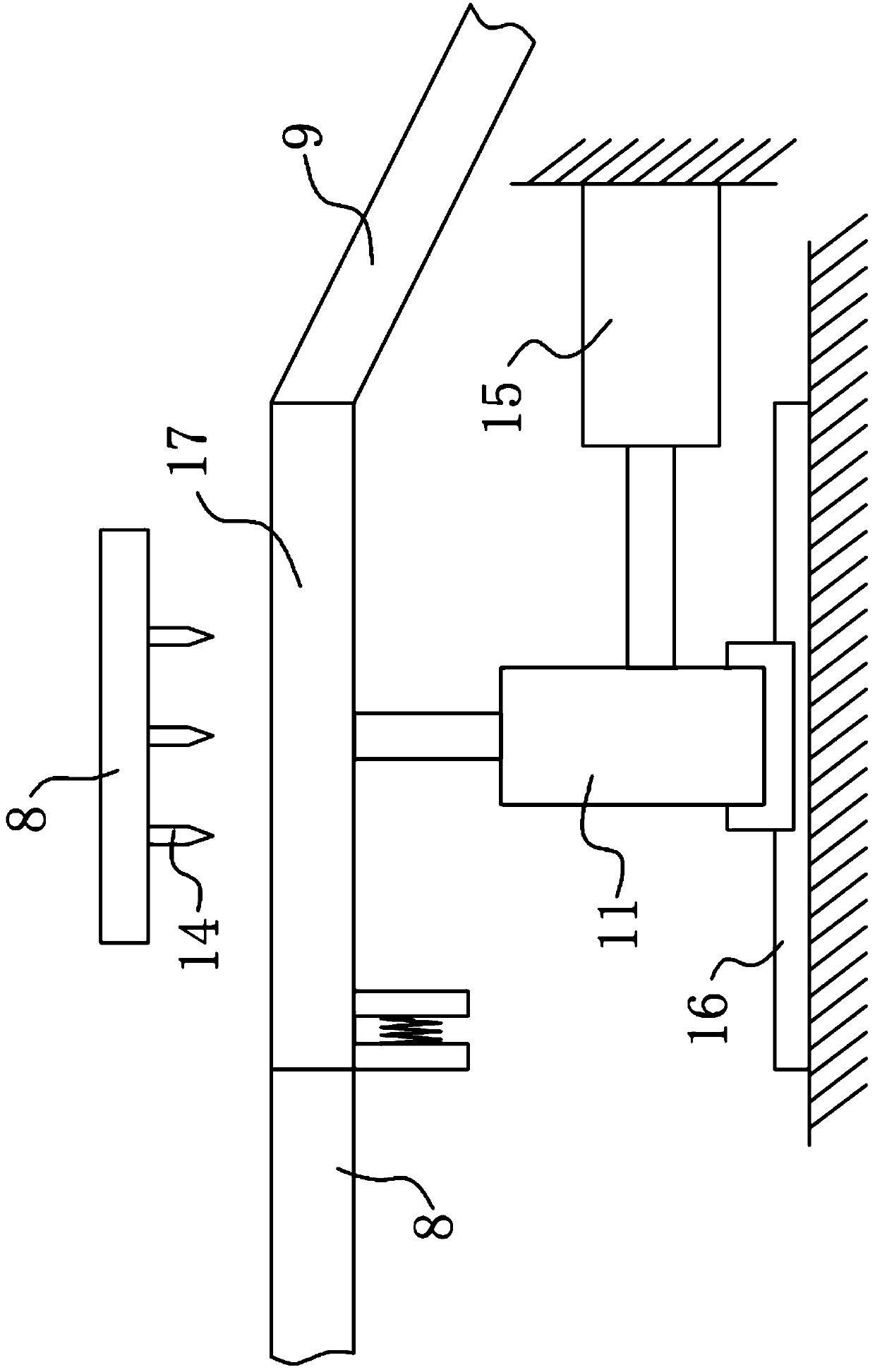

[0029] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0030] In order to achieve the purpose of the present invention, an automatic tapping assembly line includes: a feeding mechanism, including a Y-shaped slideway 2 and a vibrating plate whose height gradually decreases along the feeding direction, and the bottom of the Y-shaped slideway 2 is provided with two bifurcated Slideway, Y-shaped slideway 2 is movably connected with a lever 3 that moves the workpiece 23. The lever 3 has a degree of freedom of swinging against the Y-shaped slideway 2. The rotation center of the lever 3 is located at the junction of the two slideways. place; the vibrating plate includes the first vibrating plate 4 and the second vibrating plate 5 respectively located under the two slideways, and the outlets of the first vibrating plate 4 and the second vibrating plate 5 are respectively connected with a horizontal and parallel straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com