A planetary gear CNC lathe discharge device

A technology for CNC lathes and planetary gears, which is applied in the direction of automatic in/out of workpieces, metal processing equipment, metal processing machinery parts, etc., and can solve the problems of low discharge efficiency of CNC lathes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

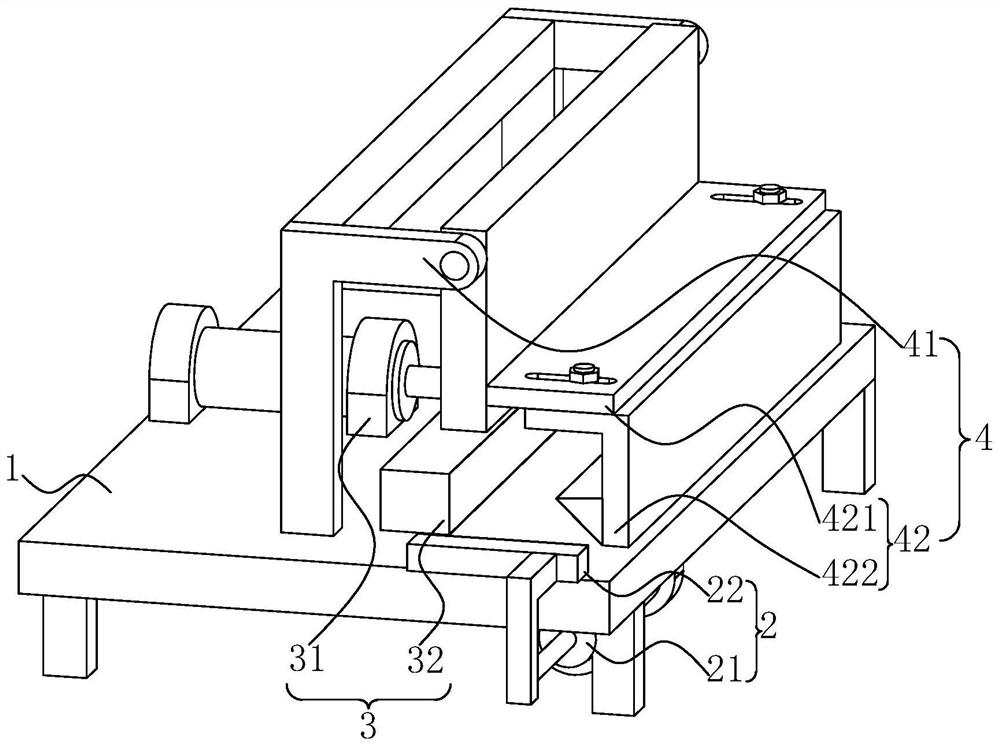

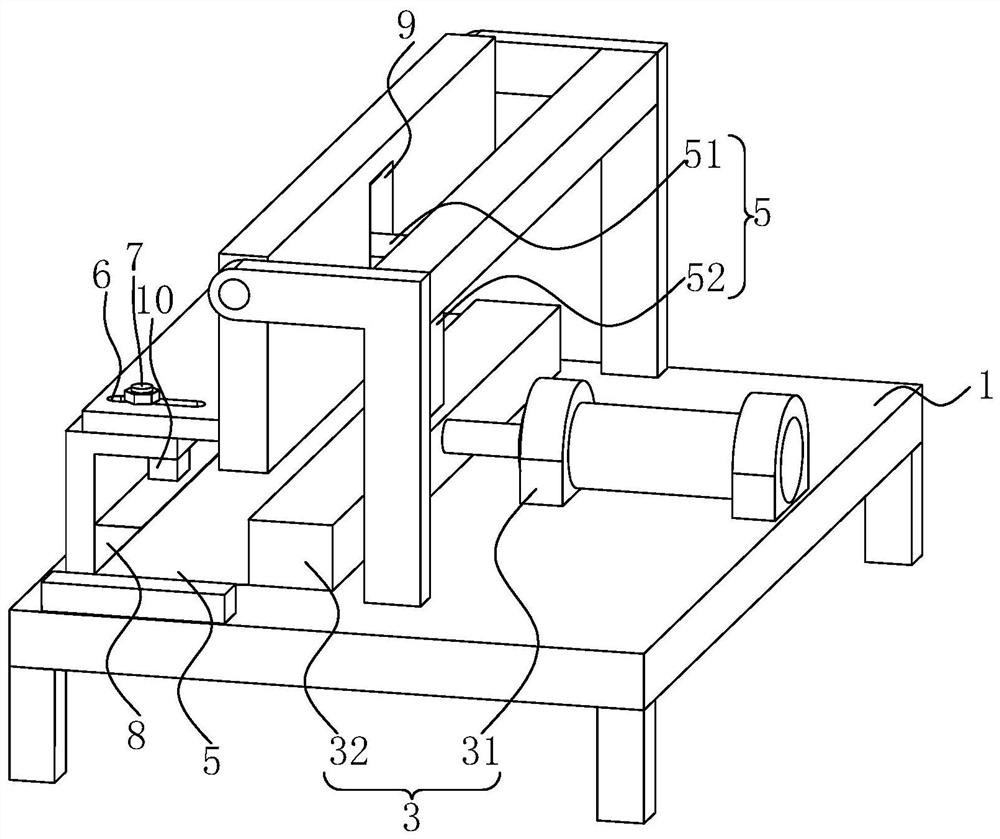

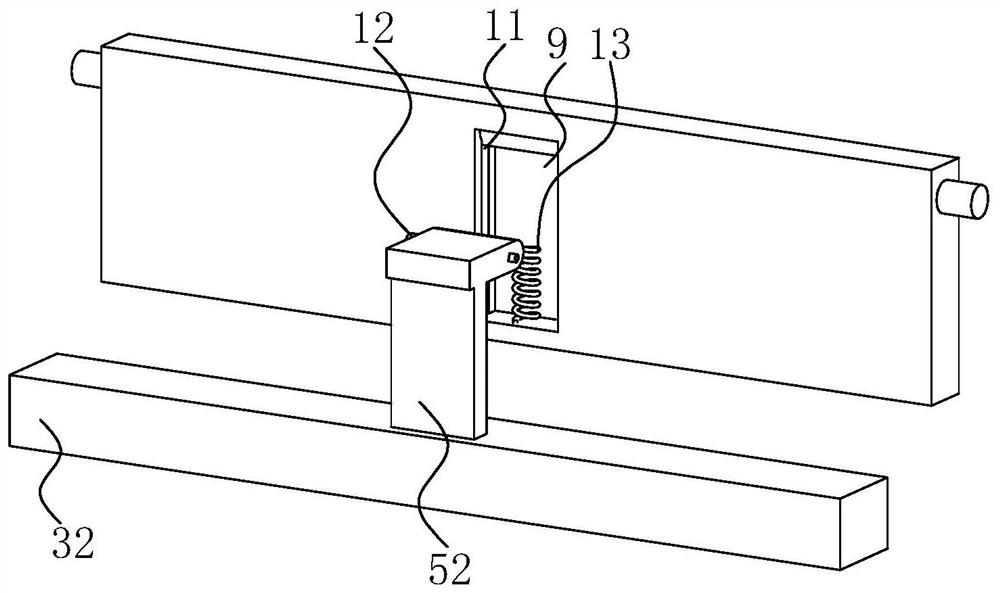

[0033] The following is attached Figure 1-3 The application is described in further detail.

[0034] A planetary gear CNC lathe discharge device, refer to figure 1 with figure 2 , including a cuboid-shaped workbench 1, a first pusher unit 2 positioned on the workbench 1, a second pusher unit 3, and a regularizing unit 4, and the movement direction of the second pusher unit 3 is perpendicular to the first pusher unit 2, the regularizing unit 4 is located at the end of the push-out stroke of the second pushing unit 3, the first pushing unit 2 is located between the starting end and the end of the pushing-out stroke of the second pushing unit 3, and the regularizing unit 4 is hinged to the workbench 1 Connected, the regularizing unit 4 is connected with an opening and closing unit 5 .

[0035] The first pushing unit 2 includes a first driving cylinder 21 and a rectangular parallelepiped first pushing block 22 connected to the end of the piston rod of the first driving cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com