Hot air drying device for fat powder

A technology of hot air drying and fat powder, which is applied in the direction of edible oil/fat, drying, drying machine, etc. It can solve the problems of mutual coagulation of fat powder particles, the quality reduction of fat powder, and the easy deterioration of fat powder, so as to speed up the flow performance, improvement of drying efficiency, and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

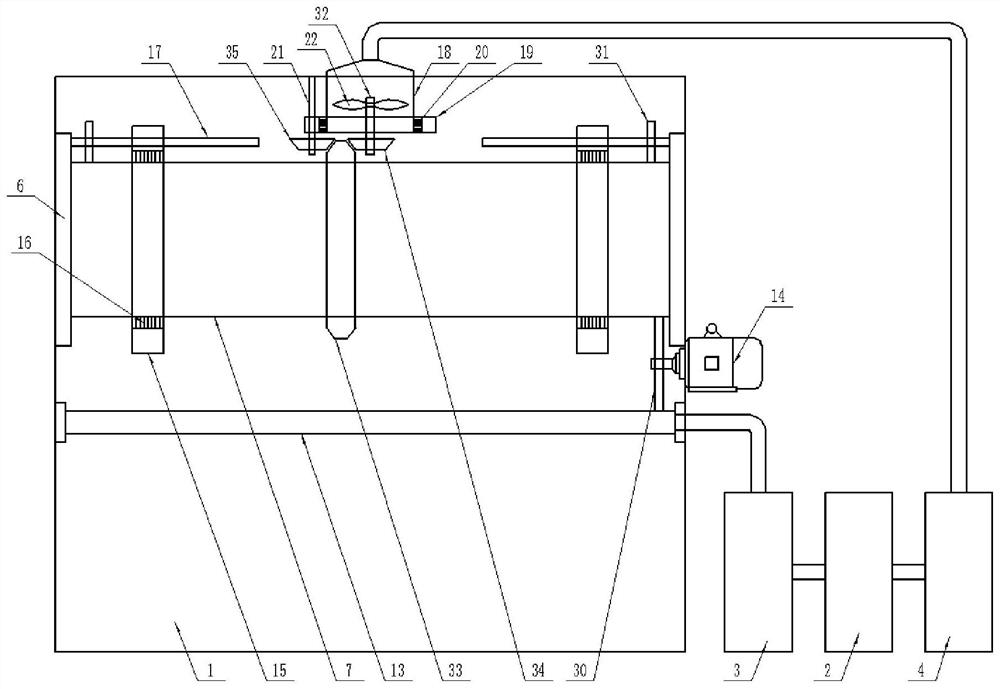

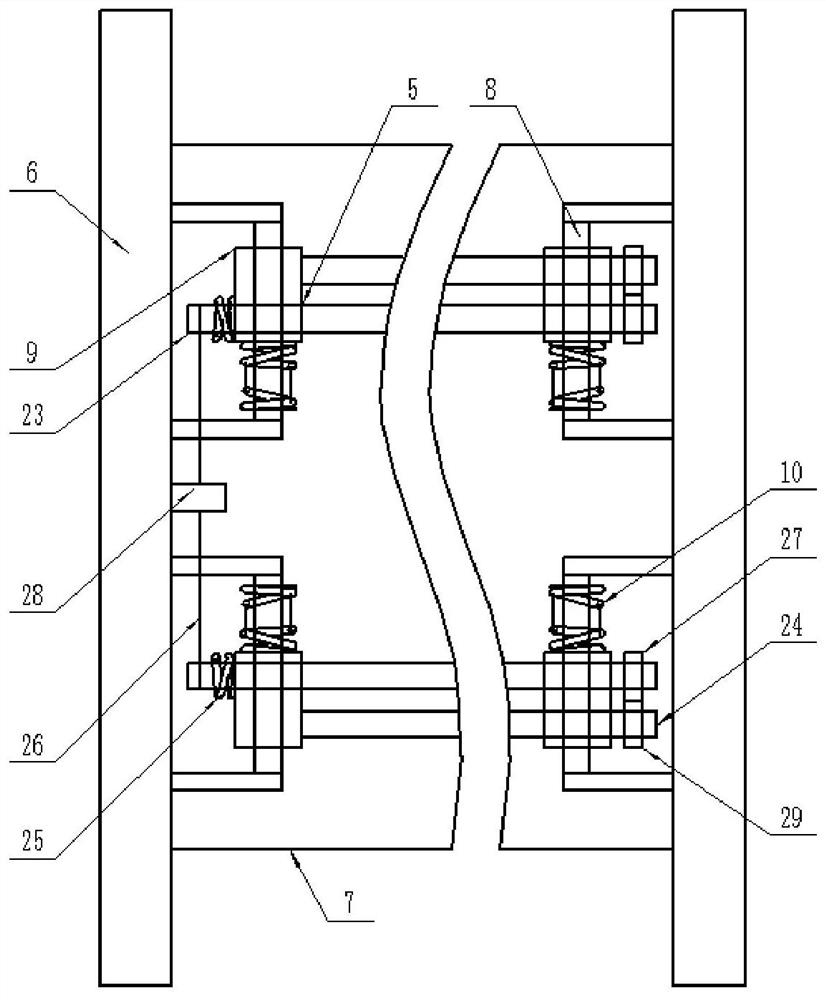

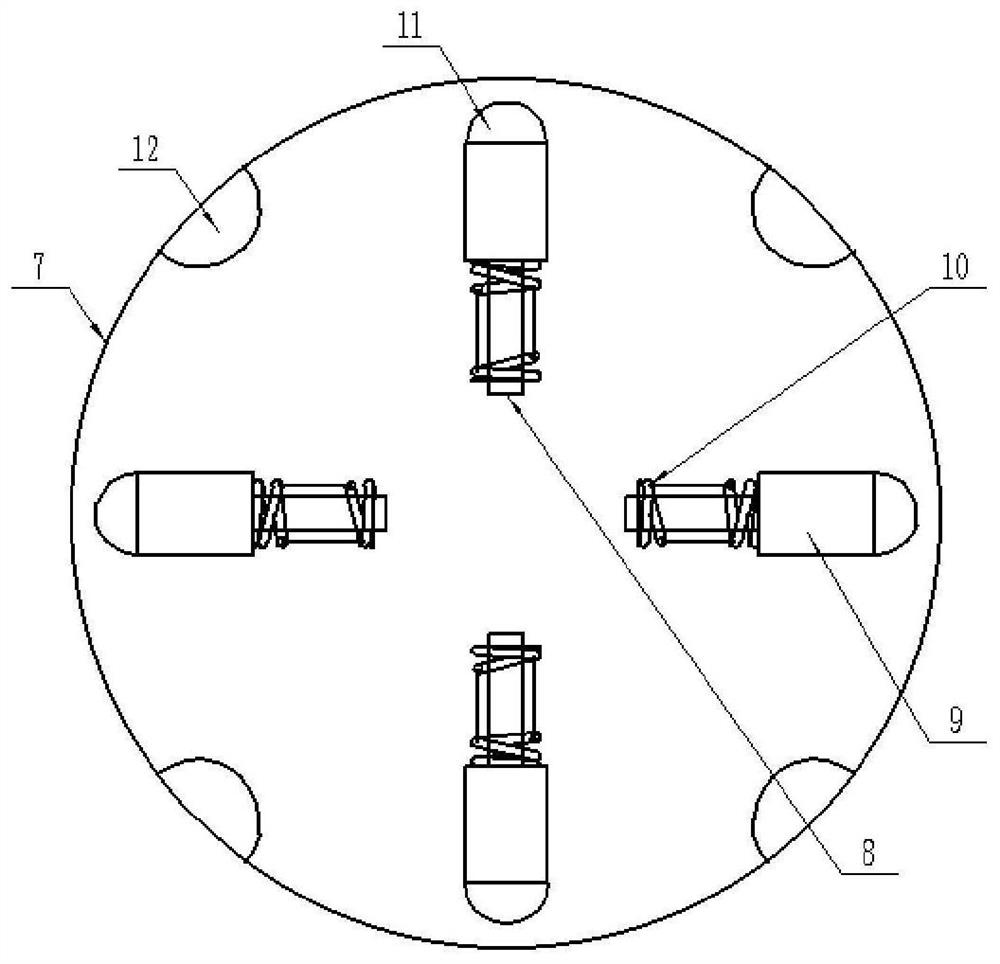

[0022] Embodiment 1: see figure 1 , figure 2 , image 3Now, a kind of hot air drying device for fat powder provided by the present invention is described, including a drying box 1, a fan 2, a heater 3 and a filter 4, and the upper side of the drying box 1 is provided with a Grinding and sieving mechanism 5 is arranged, and described grinding and sieving mechanism 5 comprises the installation bracket 6 that is vertically fixed on the inner end walls of the left and right sides of the drying box 1, and the horizontal movement between the installation brackets 6. The first cylindrical filter holder 7 and the mounting bracket 6 correspond to the other side of the fixed end position and are located on the inside of the first cylindrical filter holder 7. The radial shaft 8 is uniformly provided with an equal arc, and the outside of the radial shaft 8 is covered with The radial slider 9 and the spring 10, the grinding parts provided at the inner edge end of the first cylindrical f...

Embodiment 2

[0023] Example 2: see figure 1 , figure 2 , image 3 , a kind of hot air drying device for fat powder provided by the present invention is now described, the other side of the mounting bracket 6 corresponding to its fixed end position is correspondingly provided with an annular slot, and the first cylindrical filter Both ends of the frame 7 in the length direction are movably embedded in the annular slot, and the radial shaft 8 is arranged along the diameter direction of the inner port of the first cylindrical filter frame 7, and is located at the left and right sides of the drying box 1. The positions of the radial shafts 8 on both sides of the direction are set in one-to-one correspondence, and the radial slider 9 is movably sleeved outside the radial shaft 8, and it can slide freely along the length direction of the radial shaft 8. The spring 10 is sheathed on the outside of the shaft 8 near the center of the mounting bracket 6, one end of the spring 10 is fixedly connec...

Embodiment 3

[0024] Embodiment 3: see figure 2 , image 3 Now, a kind of hot air drying device for fat powder provided by the present invention is described, and the grinding parts all include a driving grinding shaft 23 and a driven grinding shaft 24, and the driving grinding shaft 23 and the driven grinding shaft 24 are arranged in parallel at intervals along the diameter direction of the inner port of the first cylindrical filter holder 7, and both ends of the length direction of the active grinding shaft 23 are movable through the radial slider 9 to protrude, and the average length of the active grinding shaft 23 is One side of the extension end of the direction is covered with a torsion spring 25 and is wound with a transmission rope 26, and the outside of the extension end of the other side is covered with a driving gear 27. The outer end wall is fixedly connected, and the other end is fixedly connected with the outer end wall of the protruding end of the active grinding shaft 23, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com