Planet flour mill

A grinding machine and planetary technology, which is applied in the field of planetary grinding machines, can solve the problems of abrasive wear, large floor space, and high noise, and achieve the effects of improved service life, small floor space, and high discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

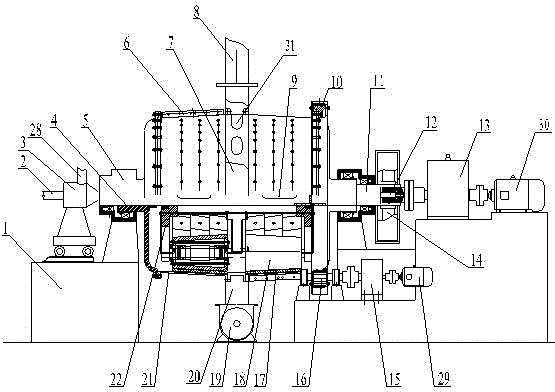

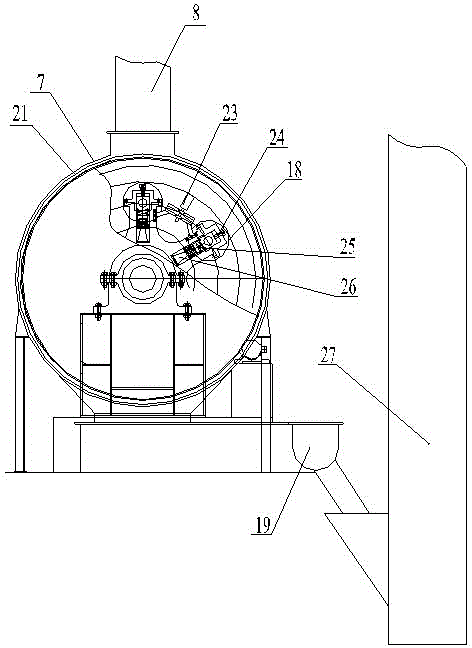

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] refer to figure 1 , the present embodiment includes a horizontally arranged main shaft 11, the interior of the main shaft 11 is hollow, a planetary support 22 is provided in the middle of the main shaft 11, the planetary support 22 is fixedly connected with the main shaft 11, and a group of crushing rollers 18 are arranged on both sides of the planetary support 22. The material rollers 18 are circumferentially distributed in the vertical plane, and the material rollers 18 are in a circular platform structure; The surface is a circular arc surface with a transverse slope that fits closely with the circular table surface of the scrap roller 18; the inner surface of the cylinder 21 is provided with a wear-resistant lining plate 17, and the two ends of the cylinder 21 are provided with a cylinder hollow shaft 4, and the cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com