Method for correcting star wheel dental plate rack circle curve

A star gear tooth and curve technology, which is applied in the field of tooth profile correction of the tooth plate, can solve the problems of falling, increased load on the wheel bearing of the trolley, air leakage, etc., and achieves the effect of eliminating and reducing the phenomenon of arching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

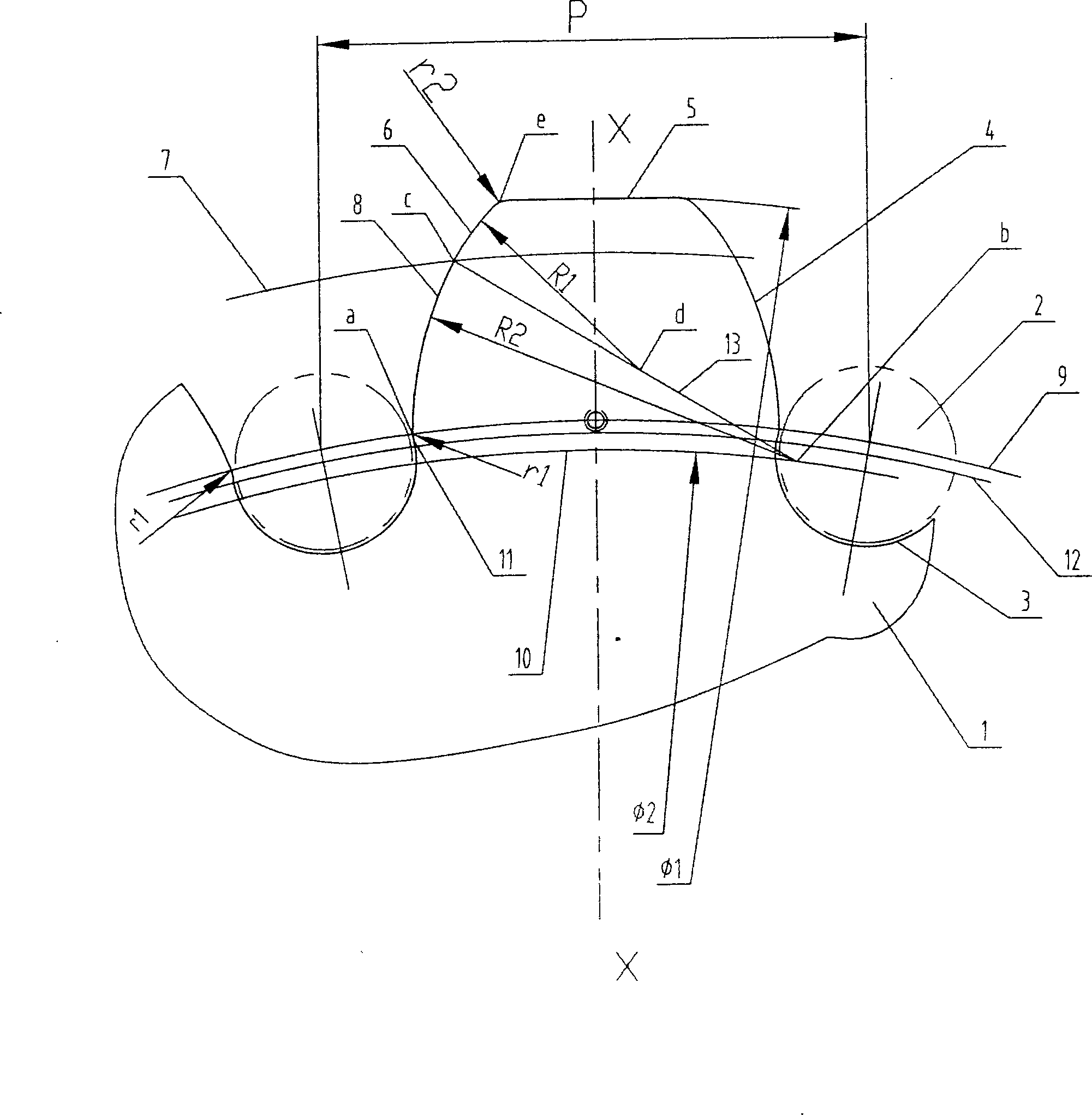

[0013] The value range of Φ1 is 4716~4736, and Φ2 is 4056~4116.

[0014] R1 is 200-230, and R2 is 560-610.

[0015] r1 is 80-110, and r2 is 70-150.

Embodiment 2

[0017] Preferable: Φ1 is 4725, Φ2 is 4080. R1 is 210 and R2 is 580. r1 is 100 and r2 is 100.

[0018] 2. Star wheel tooth plate with a pitch circle of Φ3098.52

Embodiment 3

[0020] The value range of Φ1 is 3436~3456, and Φ2 is 3018.52~3078.52.

[0021] R1 is 90-120, and R2 is 360-410.

[0022] r1 is 80-110, and r2 is 50-130.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch circle diameter | aaaaa | aaaaa |

| Pitch circle diameter | aaaaa | aaaaa |

| Pitch circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com