A single-sided floating fixture for plowing furrows on slabs

A floating fixture and plowing technology, which is applied in clamping, manufacturing tools, supports, etc., can solve the problems affecting the plowing depth and tool setting accuracy, the quality of micro-groove processing, and the increase of flat plate width, etc., to achieve simple structure, reduce The effect of arching and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

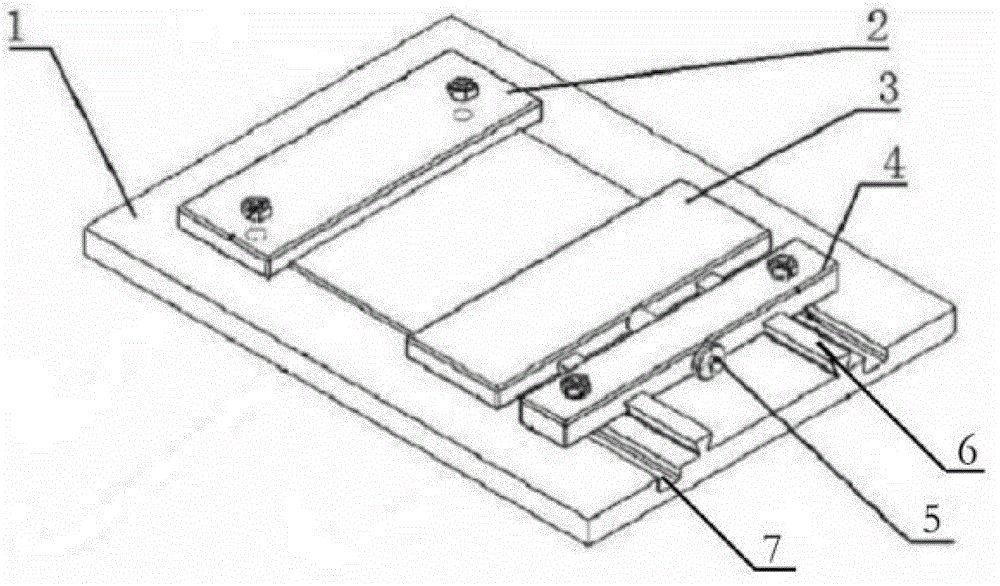

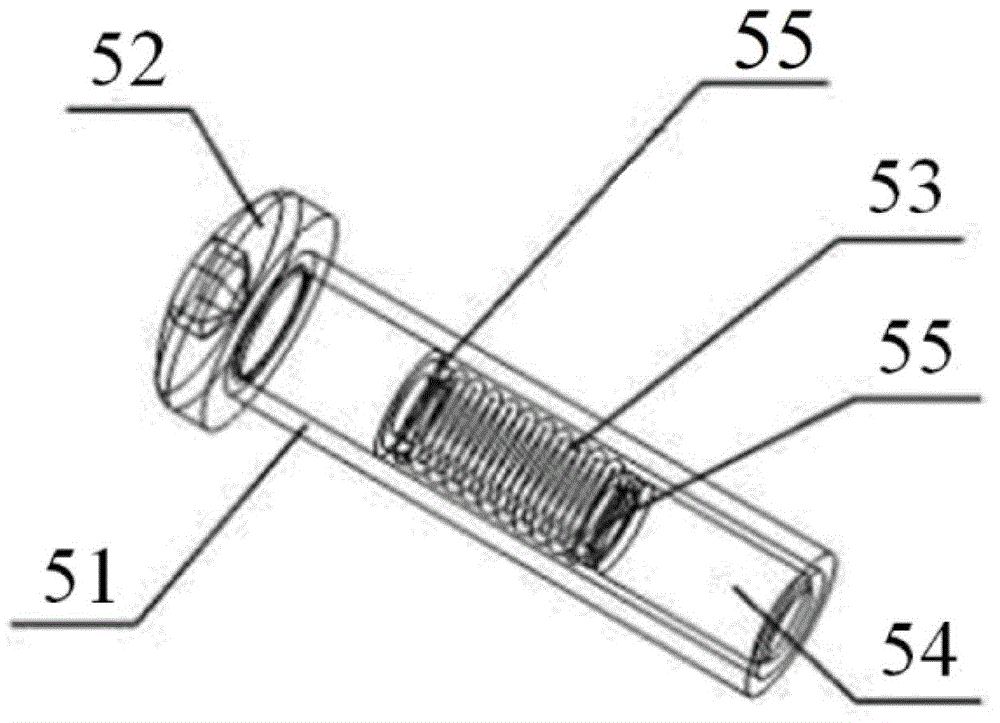

[0024] Such as figure 1 Shown is a structural schematic diagram of the present invention, a kind of unilateral floating fixture for plowing grooves on a flat plate, including a base 1 and a fixed splint 2 installed on the base, a movable splint 3, a movable baffle 4, a spring adjustment Force mechanism 5, the fixed splint 2 is fixed on the left side of the base 1 by two hexagonal bolts, the movable splint 3 and the movable baffle 4 are installed on the right side of the base 1 through the dovetail guide rail 6, and the movable baffle 4 is installed on the side of the movable splint 3 On the right side, the movable splint 3 is aligned with the fixed splint 2 through the dovetail guide rail 6, and the spring force regulating mechanism 5 is installed in the middle of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com