A terminal heating method for preventing terminal cracks from fcb welding

A heating method and terminal technology, applied in welding equipment, welding accessories, metal processing, etc., can solve problems such as stress release at unfavorable welds, complicated welding production operations, and arching of welded parts, so as to reduce the bending of the plate surface. Arch phenomenon, improve welding quality and reduce welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment provides a terminal heating method for preventing FCB welding from producing terminal cracks, comprising the following steps:

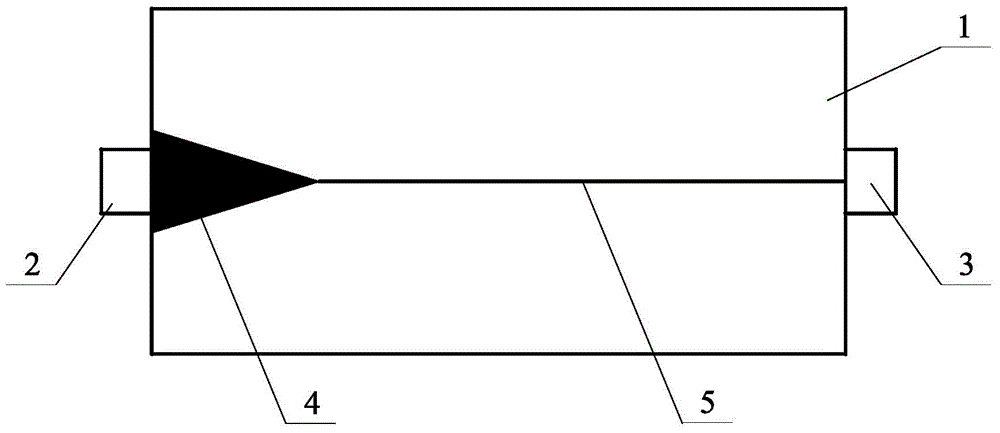

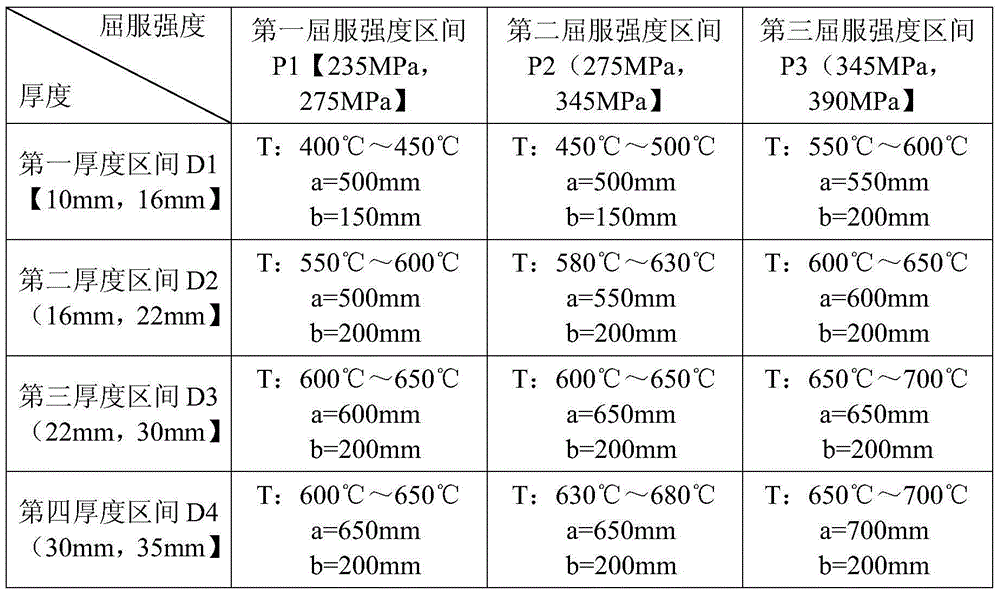

[0065] Step 101, install the arc extinguishing plate 2 on the bottom of the welding end of the longitudinal weld 5 formed by the steel plate 1 to be welded, install the arc starting plate 3 on the bottom of the welding start of the longitudinal weld 5, and preset isosceles in the welding end area In the temperature control zone 4 of the triangle, the apex of the isosceles triangle is located on the longitudinal weld 5 and is far away from the arc extinguishing plate 2, the base of the isosceles triangle is perpendicular to the longitudinal weld 5, the height of the isosceles triangle is a, and the length of the base is is 2b; define three yield strength intervals of steel plate 1 to be welded: P1: [235MPa, 275MPa]; P2: (275MPa, 345MPa]; P3: (345MPa, 390MPa]; define four thickness intervals of steel plate 1 to be welded: D1: [10m...

Embodiment 2

[0071] This embodiment provides a terminal heating method for preventing FCB welding from producing terminal cracks, comprising the following steps:

[0072] Step 201, this step is the same as step 101 in Embodiment 1.

[0073] Step 202, the steel plate selected in this embodiment is Q390 steel, the specification is 10000×2000×25 (length×width×thickness), the yield strength p is 390MPa, and the thickness d is 25mm, which conforms to GB712-2011 "For ships and ocean engineering "Structural steel" requirements, that is, p∈P3, d∈D3, see Table 2, preset a=650mm, b=200mm, T=650~700℃; mark temperature control zone 4 according to a and b.

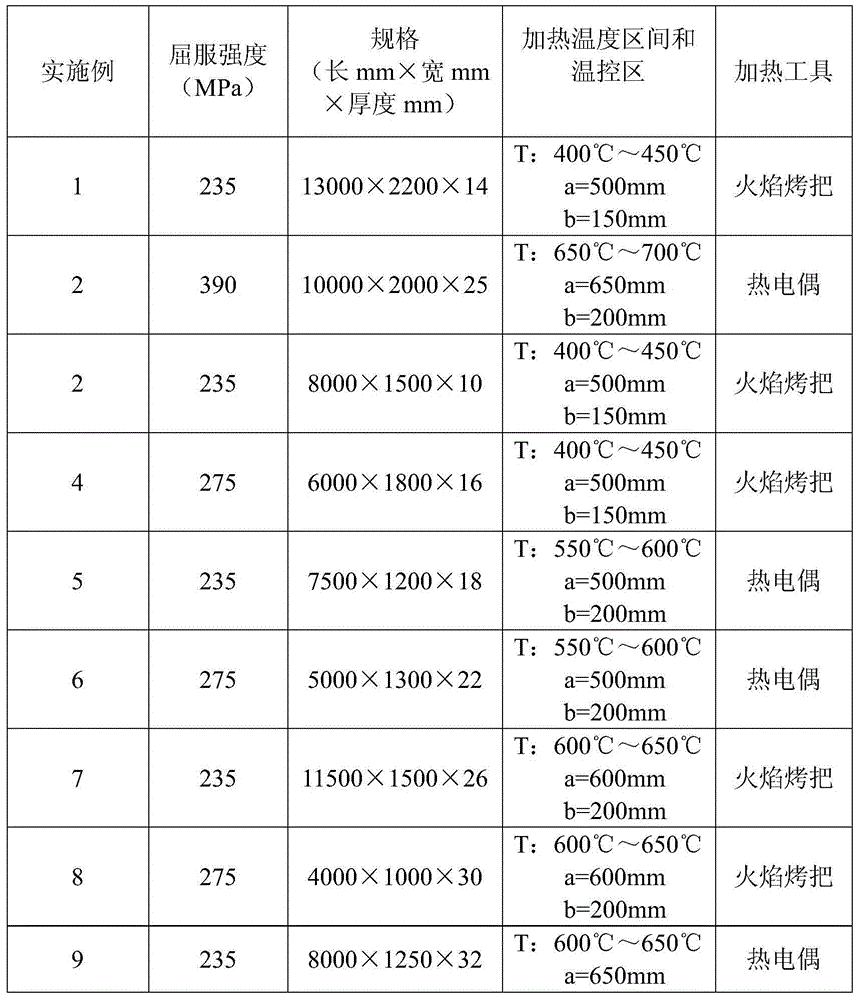

[0074] Step 203, preset the welding speed according to the width of the longitudinal weld 5, measure the welding distance between the welding start of the longitudinal weld 5 and the apex of the isosceles triangle, divide the welding distance by the welding speed, and obtain m1; select a thermocouple as Heating tool, according to the parameters of...

Embodiment 3

[0077] The terminal heating method of embodiment 3 comprises the following steps:

[0078] Step 301, this step is the same as step 101 in Embodiment 1.

[0079] Step 302 , see Table 2 for the yield strength, specifications, heating temperature range, temperature control zone and other parameters of the steel plate in this embodiment, and mark the temperature control zone 4 according to a and b in Table 2.

[0080] Step 303, the heating tools selected in this embodiment are shown in Table 2 for details, m1 and m2 are obtained according to step 103 in embodiment 1, m2 is less than m1, and it is determined to start welding the longitudinal weld 5 first, and then start heating the temperature control zone 4.

[0081] Step 304, first start welding the longitudinal weld 5 by FCB arc welding, then heat the temperature control zone 4, and monitor the surface temperature of the steel plate where the temperature control zone 4 is located by using an infrared thermometer. See Table 3 fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com