Feed storage bin

A technology for storing silo and feed, applied in the directions of container, packaging, transportation and packaging, can solve the problem of easy arching of feed, and achieve the effect of promoting the flow of feed and reducing the phenomenon of arching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

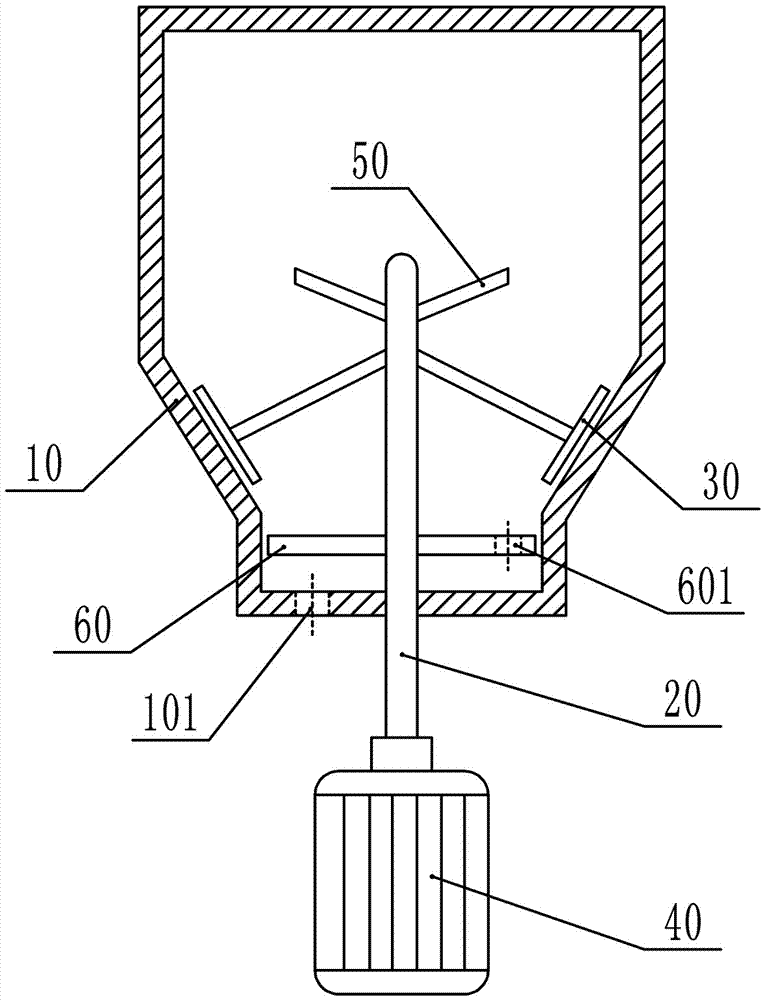

[0014] The reference numerals in the drawings of the description include: storage box 10 , discharge port 101 , rotating shaft 20 , scraper 30 , motor 40 , stirring rod 50 , baffle plate 60 , and discharge port 601 .

[0015] like figure 1 As shown, the feed storage bin includes a storage box 10 provided with an outlet 601 , a motor 40 , a rotating shaft 20 , a scraper 30 and a baffle 60 . The bottom of the material storage box 10 is funnel-shaped. The rotating shaft 20 is coaxially connected with the output shaft of the motor 40 . The scraper 30 is welded on the rotating shaft 20 and fits in clearance with the inner wall of the material storage box 10 . That is, the scraper 30 is close to the inner wall of the material storage box 1010, and the distance between the scraper 30 and the inner wall is about 0.5 cm. The baffle 60 is located in the storage box 10 and insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com