Lift system, load-bearing mechanism for such a lift system and method for assembly of such a load-bearing mechanism

A support device, elevator technology, applied in elevators, applications, textile cables, etc. in buildings, can solve the problems of low lateral stability and wear resistance on the back side of the belt, and achieve excellent sliding properties, low wear resistance, The effect of reducing stress

Inactive Publication Date: 2011-01-05

INVENTIO AG

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The specification therefore also proposes an elastomeric carrier belt reinforced with tire cords and satisfactorily connected with elastomeric wedge ribs, but with only low lateral stability and wear resistance on the back side of the belt

Thus, the belt known from US3996813 is not suitable for use in elevator installations with a long running area between the drive pulley and the deflection pulley, the variable running length and the simultaneous deflection on the back side of the belt have a negative effect on the lateral stability of the belt and wear resistance put forward higher requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

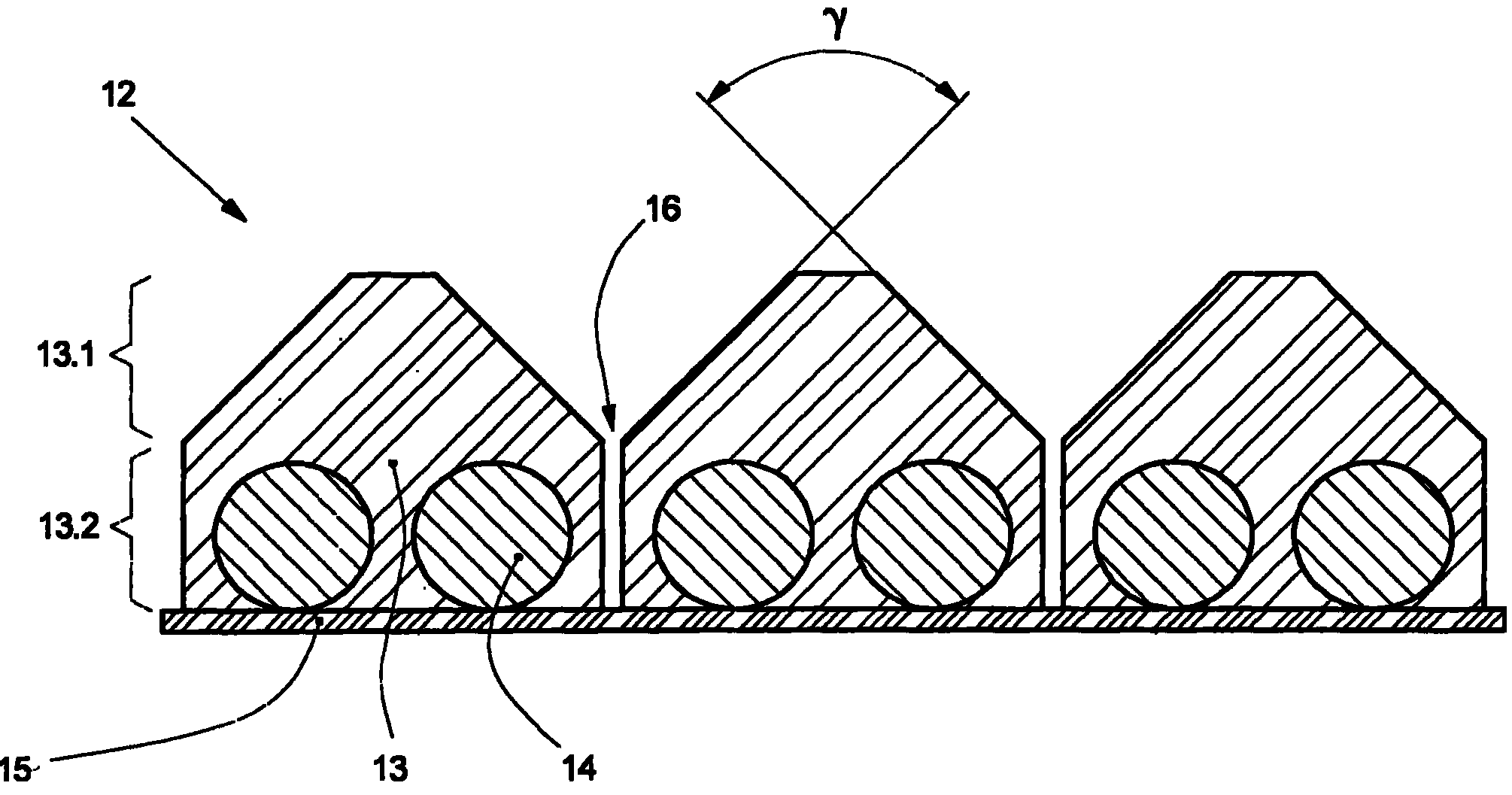

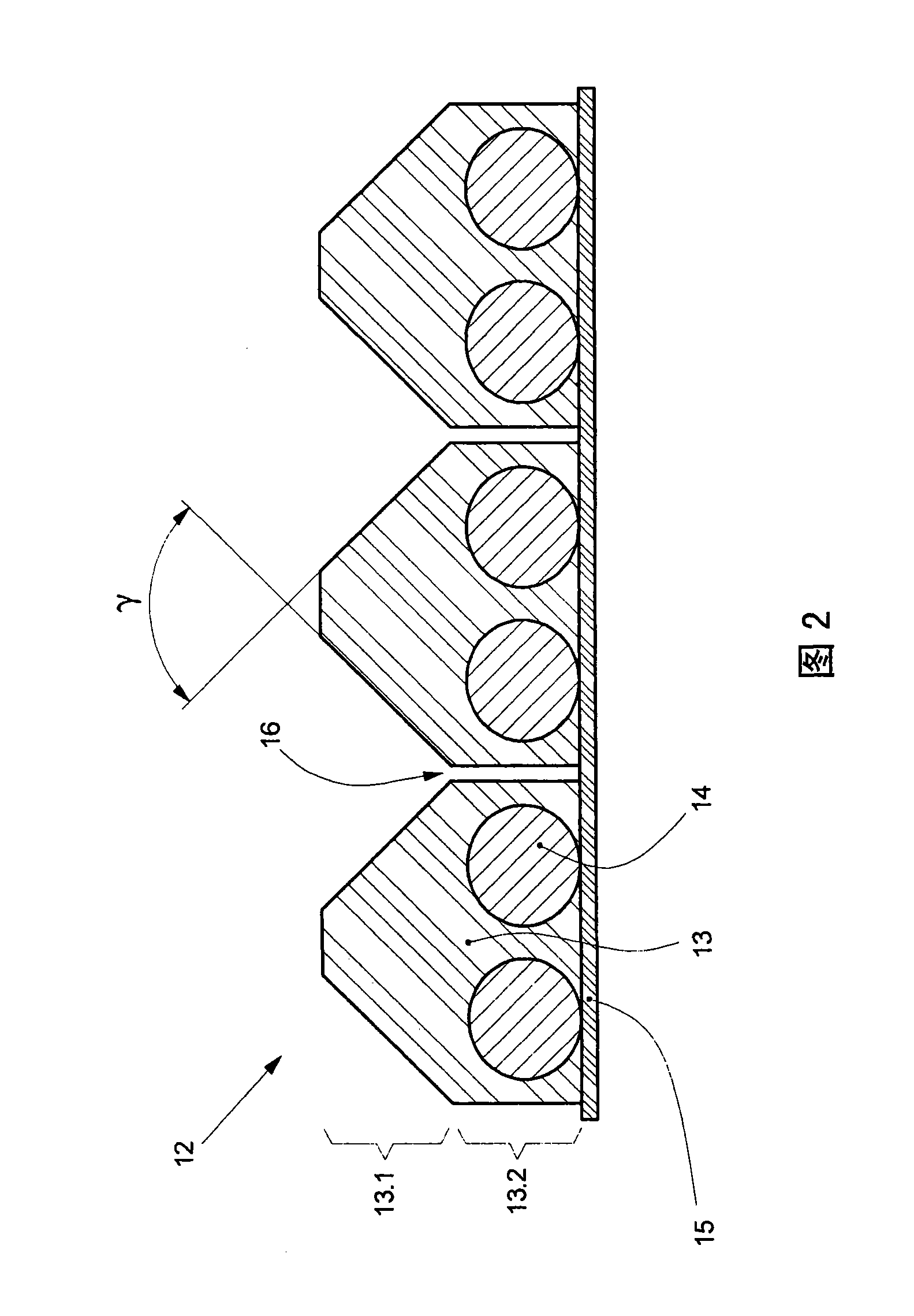

A lift belt (12) for a lift installation comprises a wedge rib arrangement (15) with at least two wedge ribs (15.1) which extend in longitudinal direction of the lift belt an d form a contact side for engagement with a drive wheel (4.1) of the lift installation, a tensile carrier arrangement (14) with at least two tensile carriers (14.1, 14.2) arranged in two mutually adjacent wedge ribs of the wedge rib arrangement, and a back layer (13) whic h forms a rear side, which is opposite the contact side, of the lift belt. The back layer has a profile with at least one web (13.1) projecting into the wedge rib arrangement towar ds the contact side. <SDOCL LA=EN> 13 Claims 1. Lift belt (12) for a lift installation, with a wedge rib arrangement (15) with at least two wedge ribs (15.1) which extendin longitudinal direction of the lift bel t and which form a contact side for engagement with a drive wheel (4.1) of the lift installatio n, a tensile carrier arrangement (14) with at least two tensile carriers (14.1, 14.2) arranged in two mutually adjacent wedge ribs of the wedge rib arrangement, and a back layer (13) whic h forms a rear side, which is opposite the contact side, of the lift belt(12), characterised in that the back layer (13) forms a flat profile with at least one web (13.1) projecting into the wedge rib arrangement (15) towards the contact side. 2. Lift belt according to claim 1, characterised in that the back layer (13) is produced from a thermoplastic synthetic material, particularly from polyamide (PA), polyethylene (PE), polyester, particularly polyethyleneterephthalate (PET), polycarbonate (PC), polypropylene (PP), polybutyleneterephthalate (PBT), polyethersulfone (PES), polytetrafluorethylene (PTFE), polyvinylchloride (PVC) or from polyblend and / or a fabric ofsuch a thermoplastic synthetic material. 3. Lift belt according to any one of the preceding claims.

Description

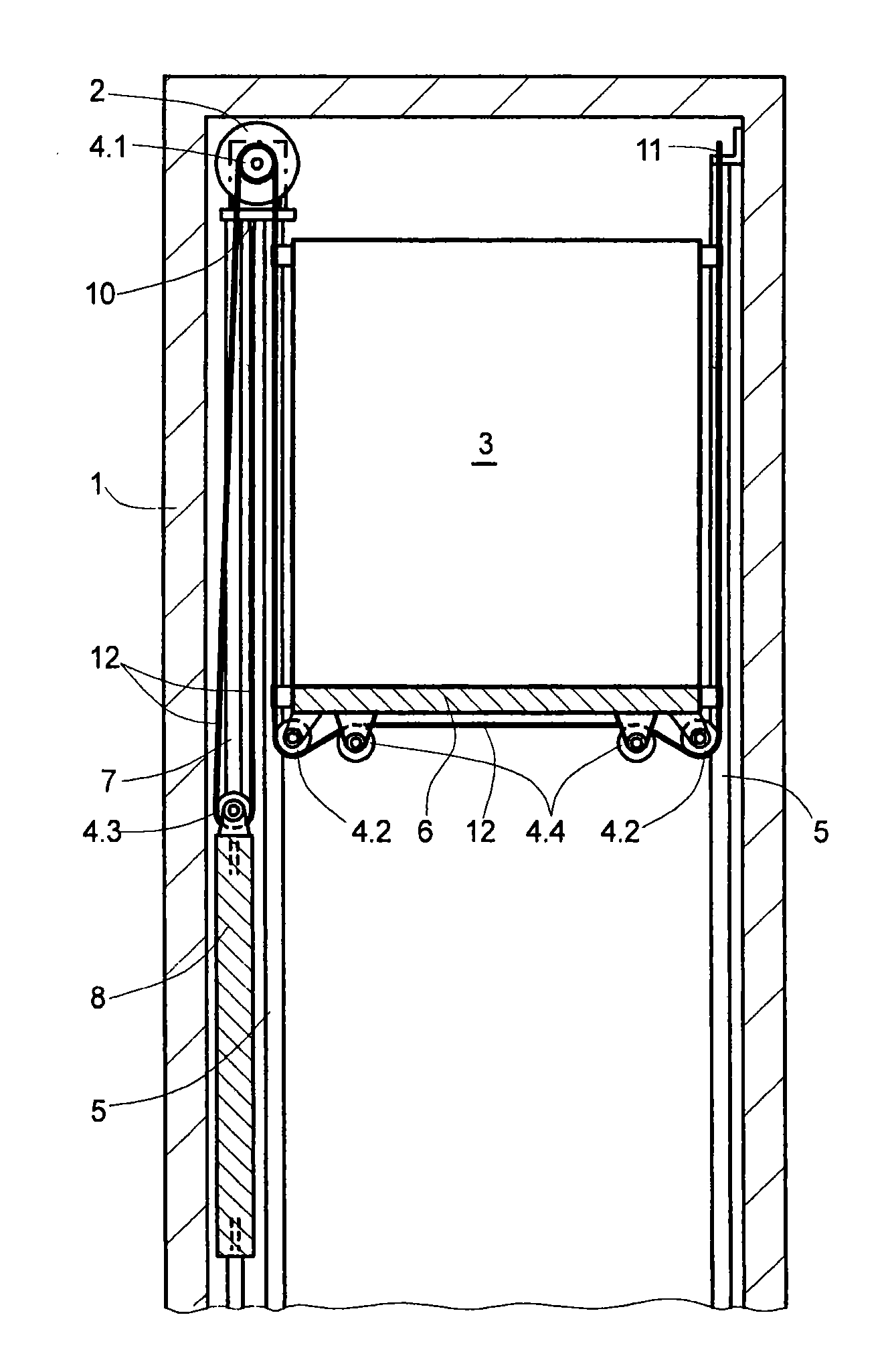

Elevator installation, elevator support device for elevator installation and production method thereof technical field The invention relates to an elevator installation with a support device, an elevator support device for such an elevator installation, and a method for producing such an elevator support device. Background technique An elevator installation includes an elevator car and usually a counterweight, which can be moved in the elevator shaft or along self-supporting guides. In order to generate the motion, the elevator installation comprises at least one drive unit with at least one drive pulley, which supports the elevator car and the counterweight via one or more elevator support devices in the form of belts and / or transfers the required drive The force is transmitted to the elevator car and counterweight. From EP1555234B1 is known an elevator installation according to which the belt, on the traction side facing the drive pulley, has a rib arrangement with a p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B66B11/08D07B1/00D07B1/16

CPCB29D29/103B66B7/062D07B1/22D07B2201/2087D07B2501/2007B66B7/06B66B7/00

Inventor 厄恩斯特·阿赫

Owner INVENTIO AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com