Excavator protecting method for mine cave

A technology for excavators and caverns, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of high rigidity of the backing plate, increase of backing plate thickness, and cracking of the surrounding welds, so as to reduce the amount of materials and reduce the distortion. Twisting deformation, avoiding the effect of tearing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

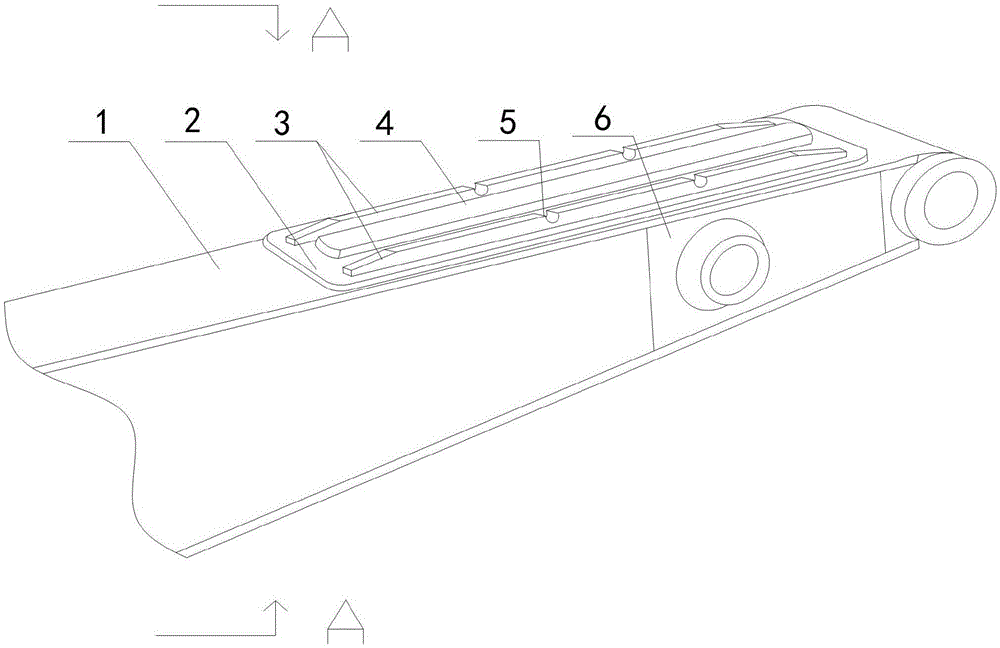

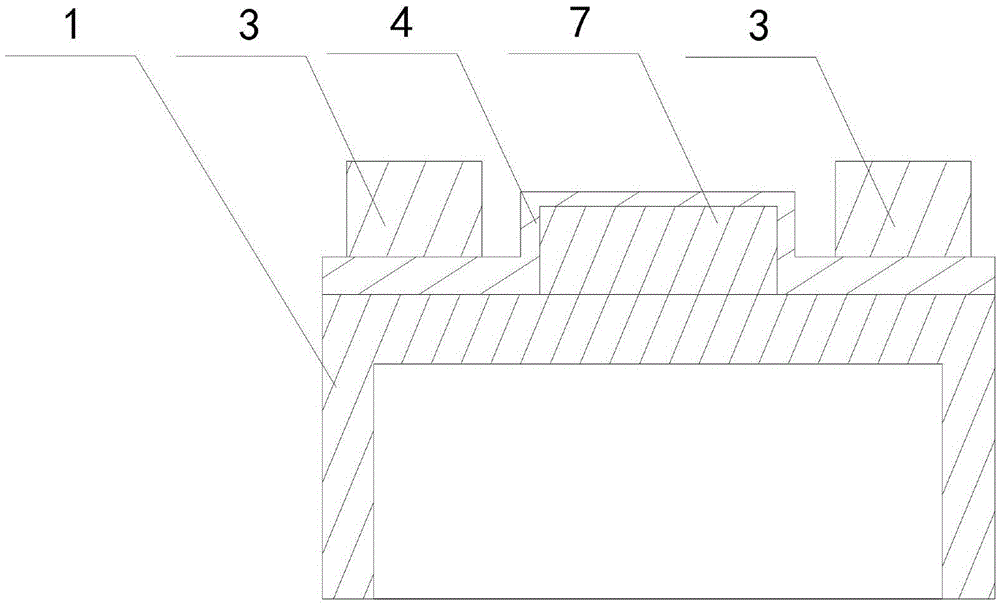

[0021] Such as figure 1 and figure 2 As shown, this embodiment includes a stick body 1 and a backing plate 2 welded on the inner wall of the stick body 1, and two strip-shaped strips are welded on the backing plate 2 along the axial direction of the backing plate 2. Reinforcing ribs 3, and stamping and forming a rectangular protrusion 4 parallel to the reinforcing ribs 3 in the middle of the backing plate 2 and along its bottom surface vertically pointing to the upper surface, the protrusion 4 is placed between the two reinforcing ribs 3 , and the horizontal height of the protrusion 4 on the upper surface of the backing plate 2 is less than the horizontal height of the reinforcing rib 3; a limit block 7 is also installed on the outer wall of the stick body 1, and the limit block 7 is connected to the The protrusion 4 fits inside.

[0022]When working, the stick body 1 bends, and the upper surface of the stick body 1 directly contacts or collides with the material to be exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com