Patents

Literature

98results about How to "Prevent tear damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

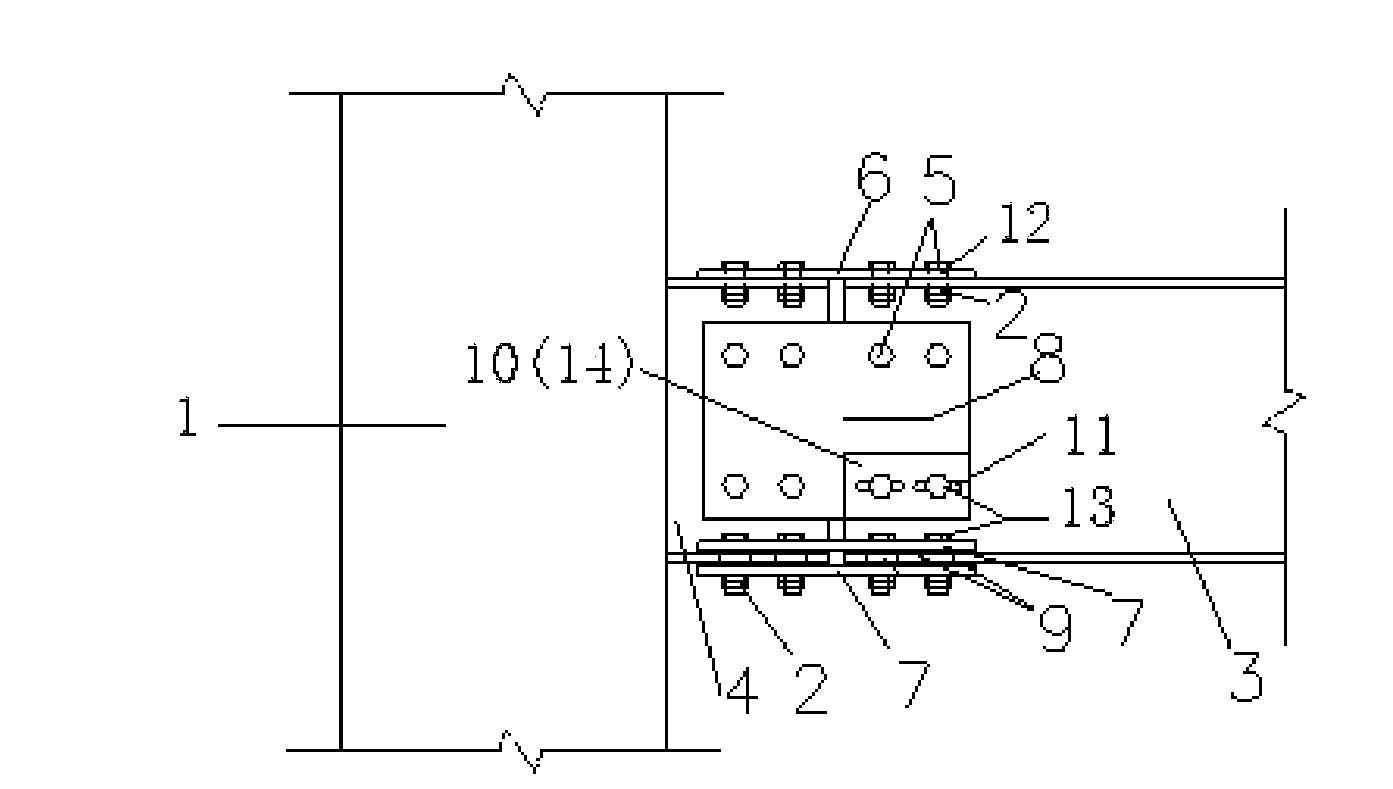

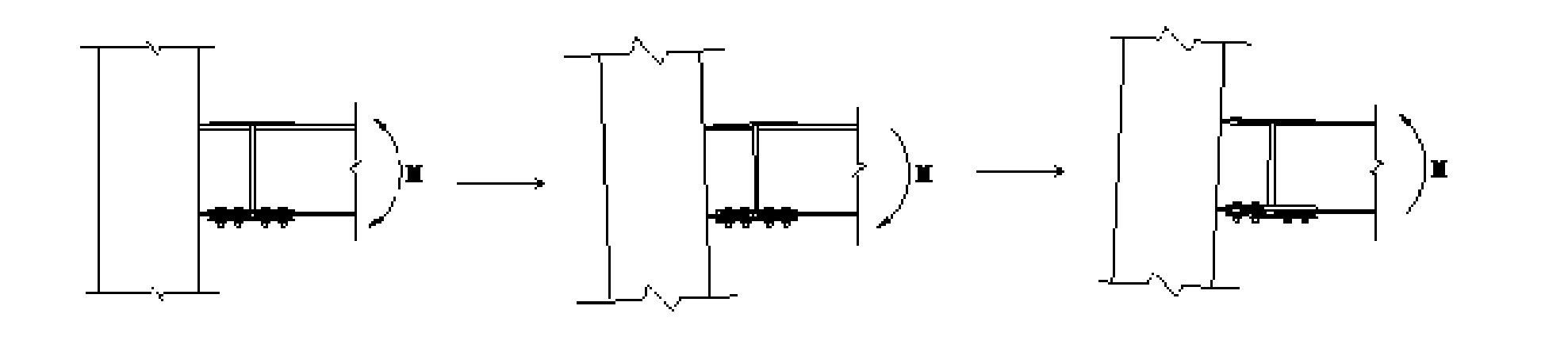

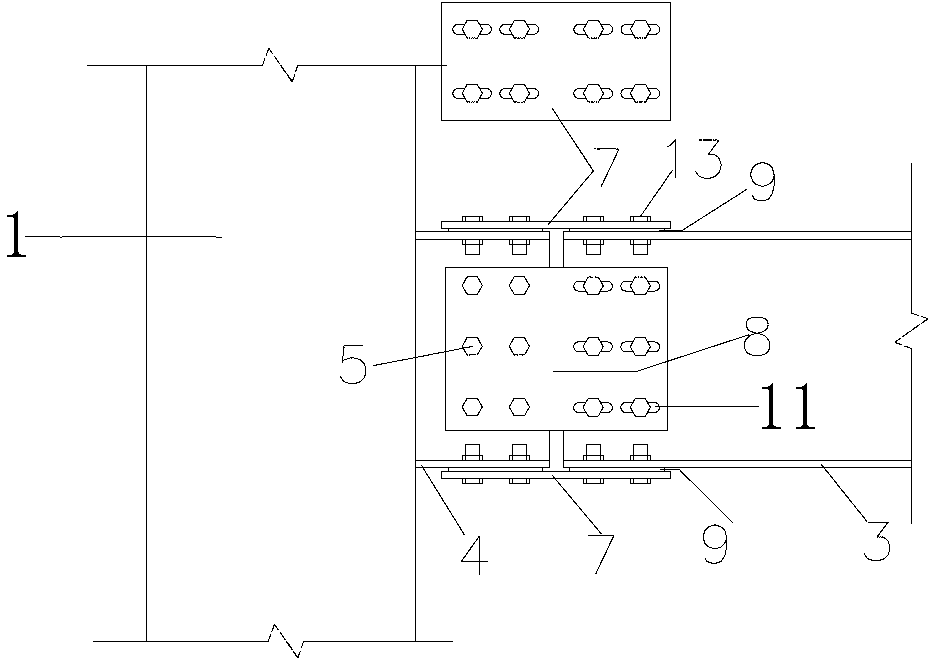

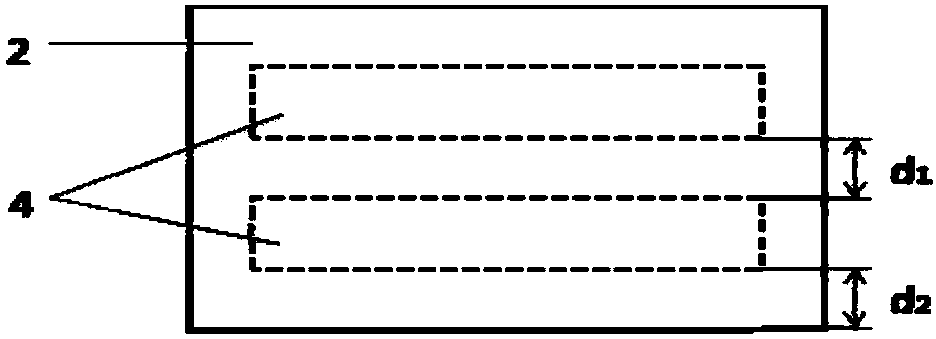

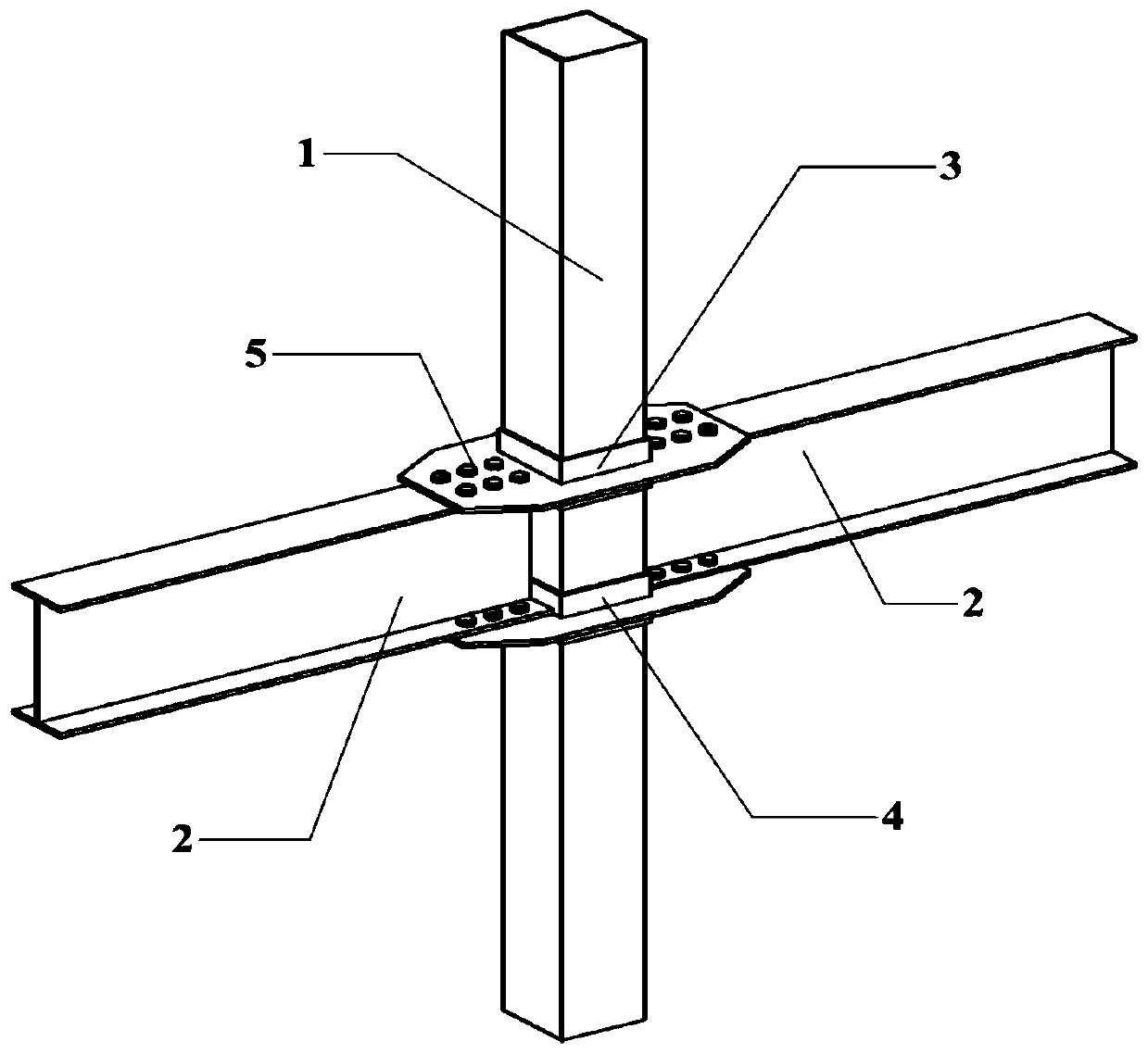

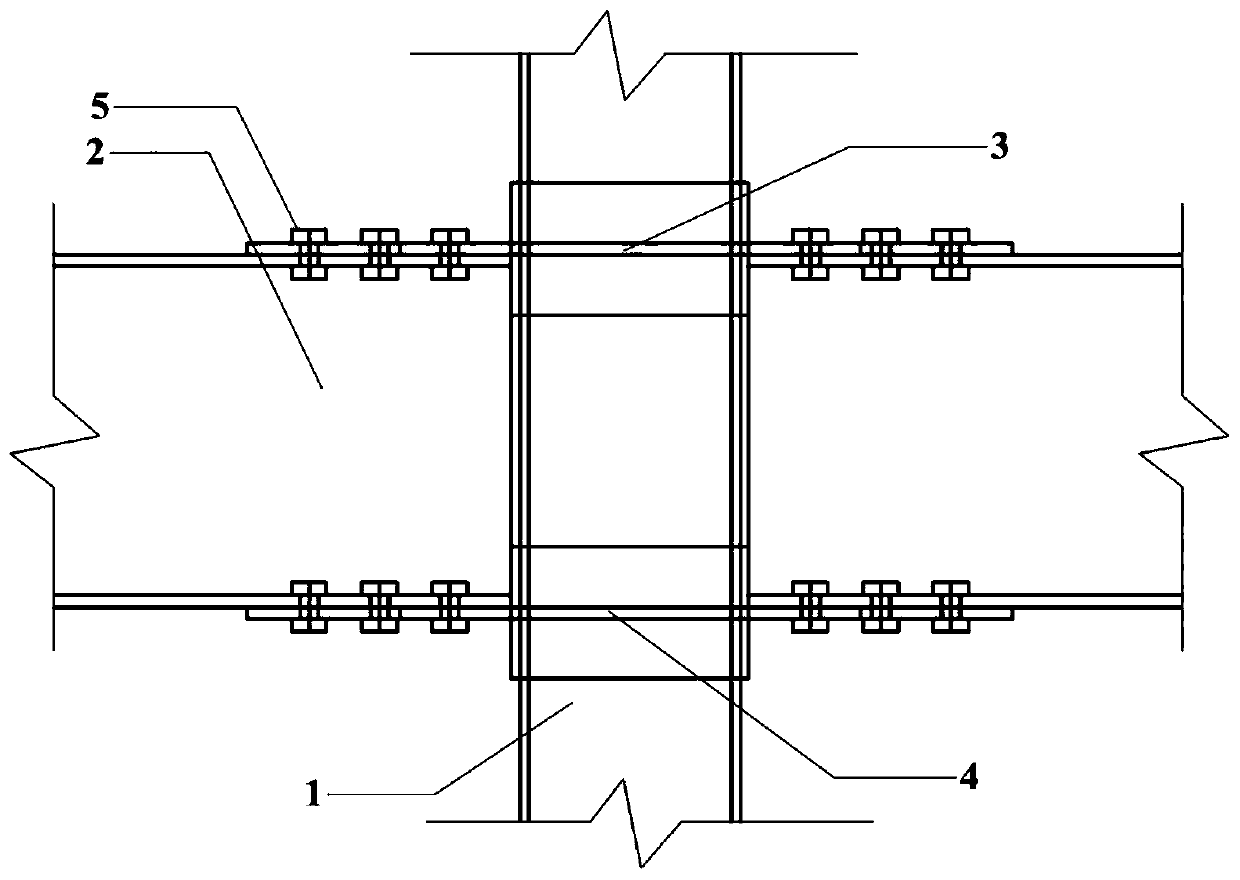

Fabricated concrete column-steel beam energy dissipation type panel point connecting device

ActiveCN103243819ARaise the damage thresholdReduce damageBuilding constructionsStructural elementAdverse effect

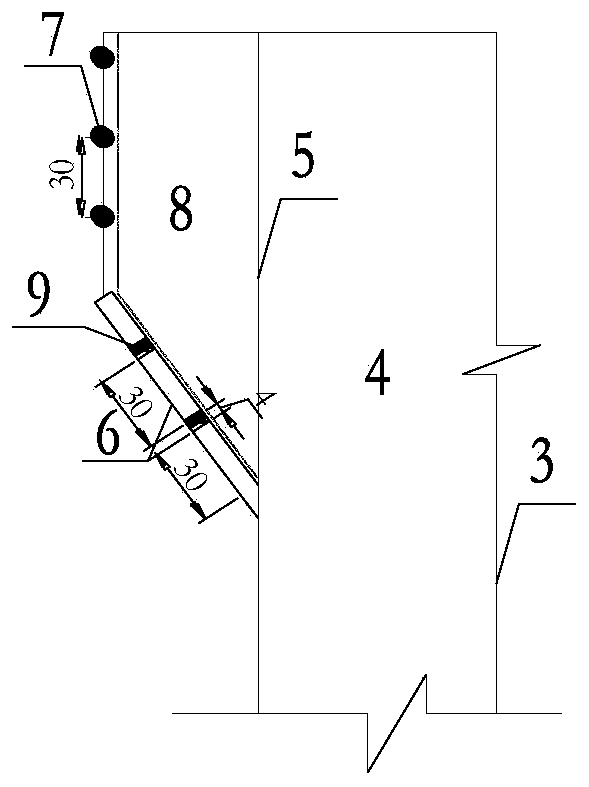

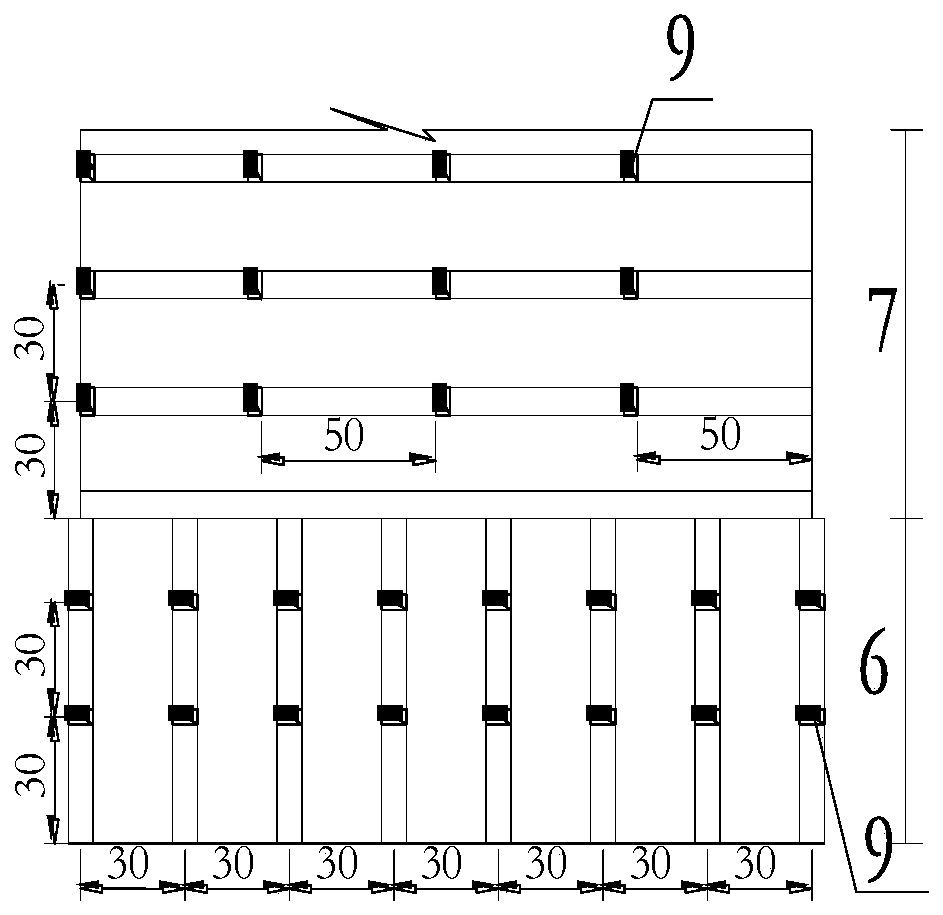

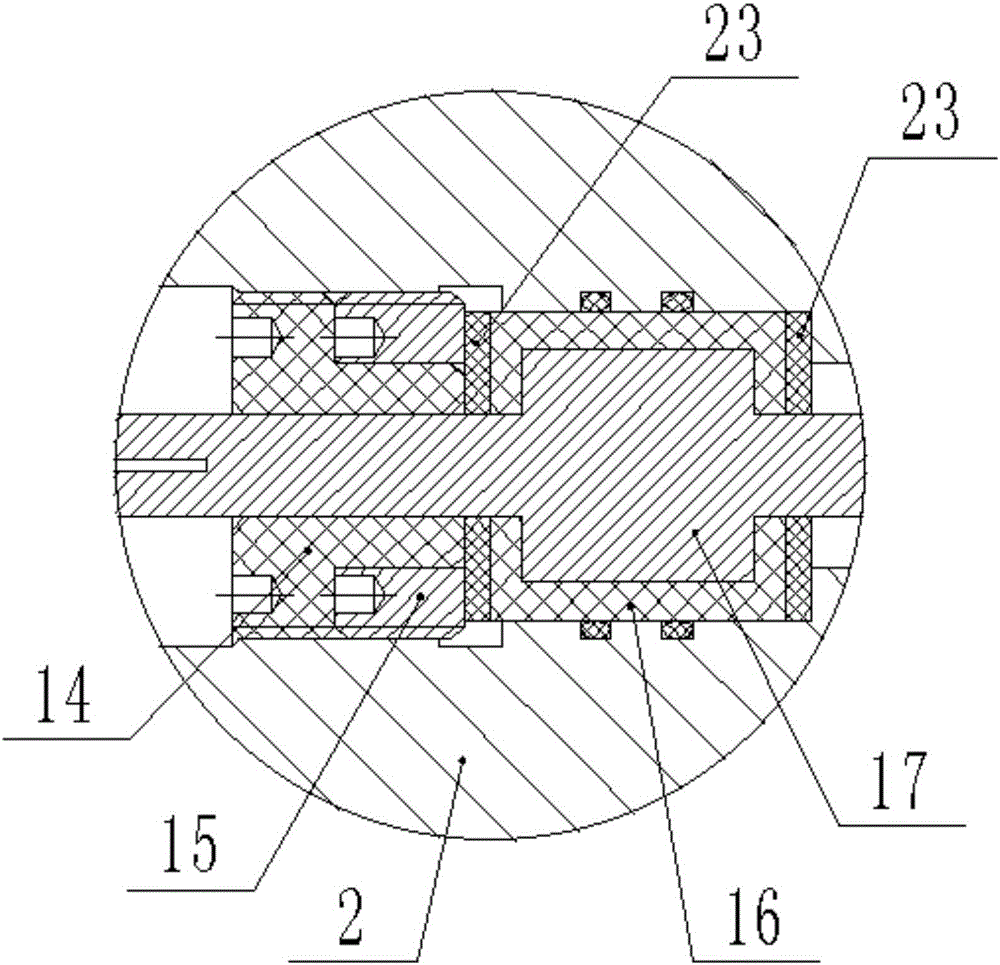

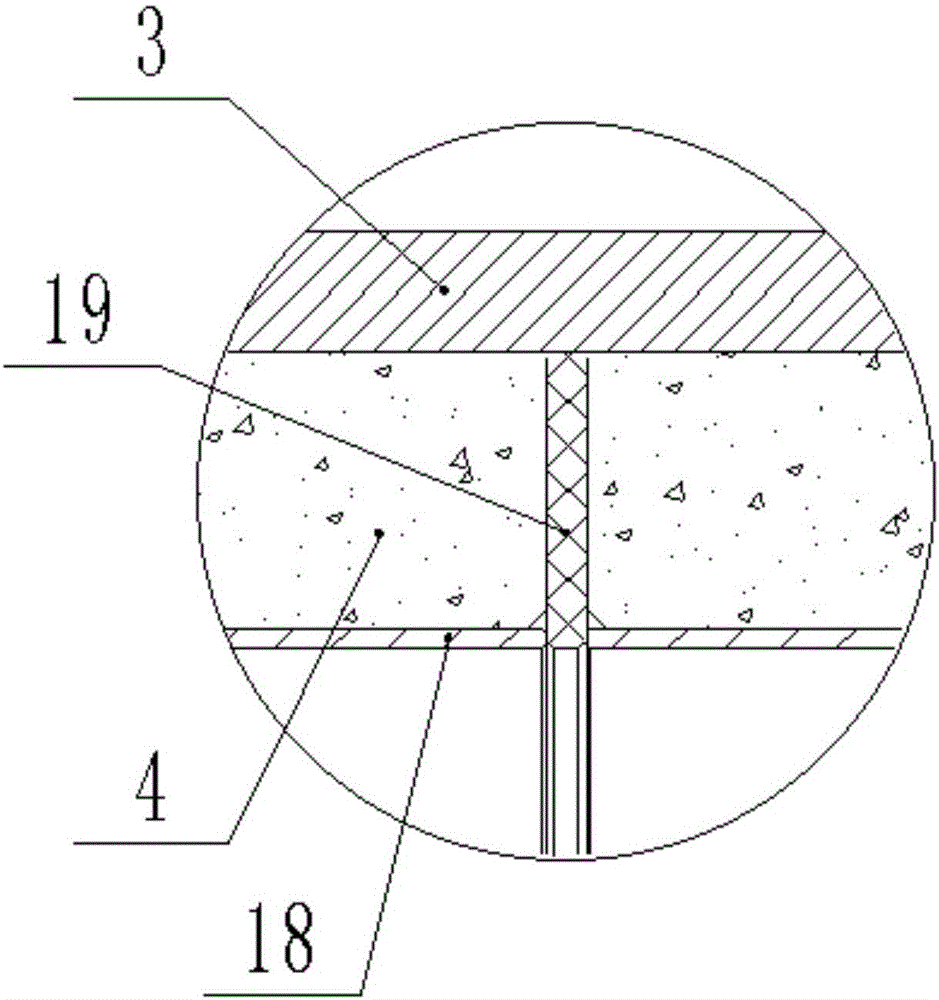

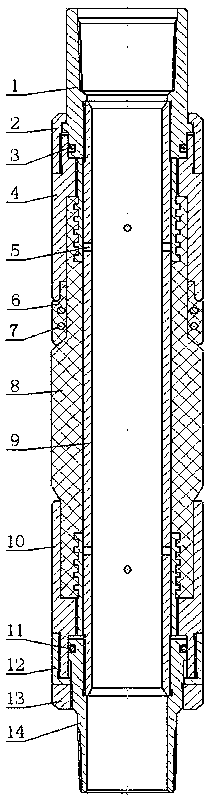

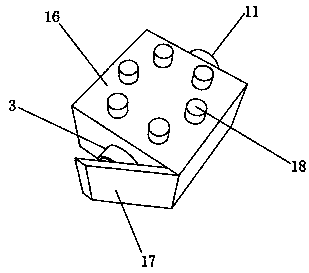

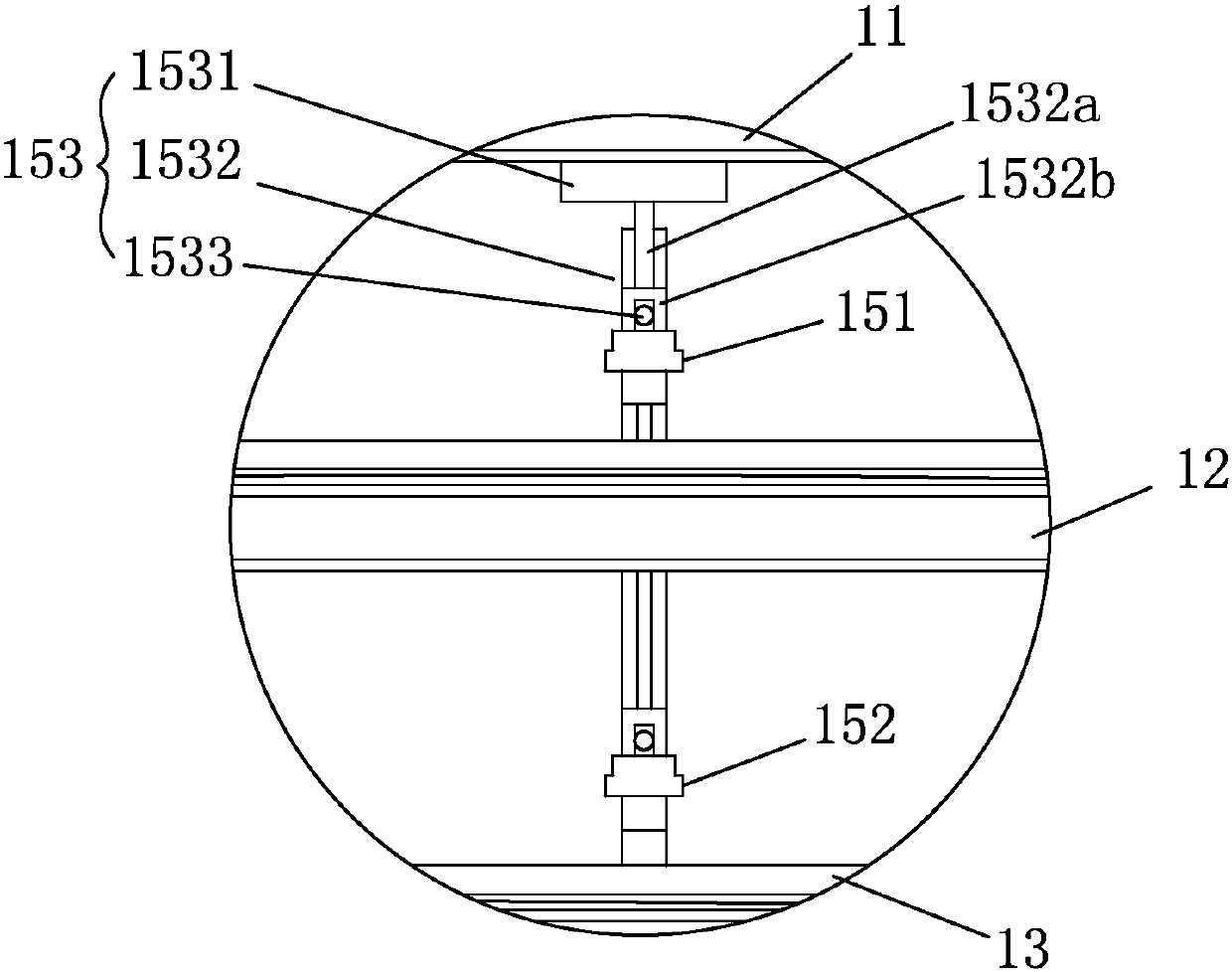

The invention discloses a fabricated concrete column-steel beam energy dissipation type panel point connecting device. The fabricated concrete column-steel beam energy dissipation type panel point connecting device is composed of a beam-beam bolt connection component and a friction energy dissipation device, and comprises a prefabricated concrete column, a pre-buried steel beam, a middle steel beam and a combination connection steel piece, wherein transversal surfaces of the pre-buried steel beam and the middle steel beam are both H-shaped, webs of the pre-buried steel beam and the middle steel beam are connected through a web cover plate, and flanges of the pre-buried steel beam and the middle steel beam are connected through a connection cover plate. Earthquake energy is dissipated by using friction plates attached inside a combination steel piece and through a friction energy dissipation mechanism. Compared with the prior art, the connecting device can reduce adverse effects on a floor and achieve a beam hinge yielding mechanism by moving a plastic hinge outward, the energy dissipation device can improve fabricated structure energy dissipation and reduce damages of main structural members, connection parts and the steel beams can be conveniently maintained, replaced and dismantled for reuse, and simultaneously, the fabricated concrete column-steel beam energy dissipation type panel point connecting device is produced by using a whole prefabricated industrialization standard, and installed only through bolts on site, and has strong engineering practicability.

Owner:江苏德丰建设集团建筑科技有限公司

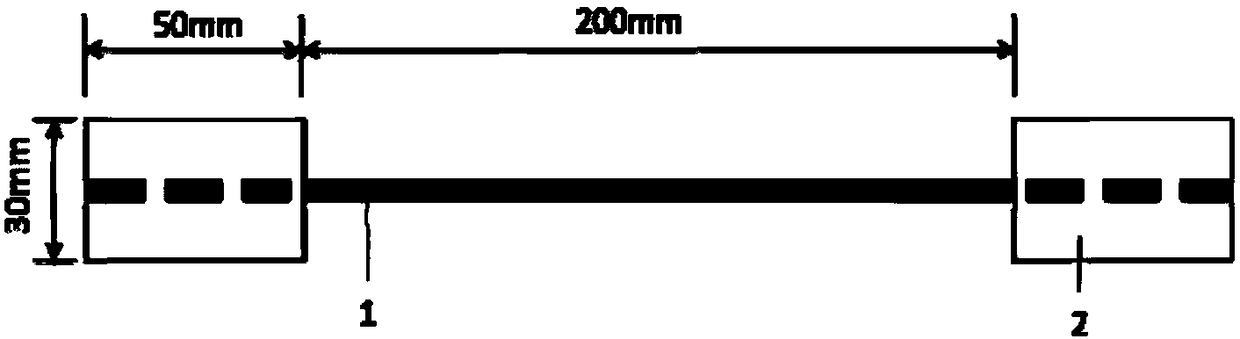

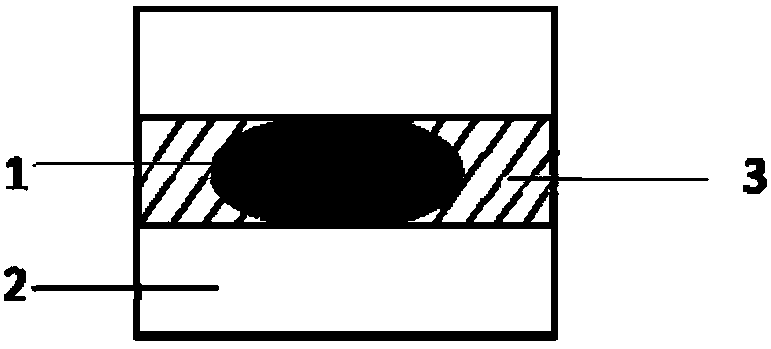

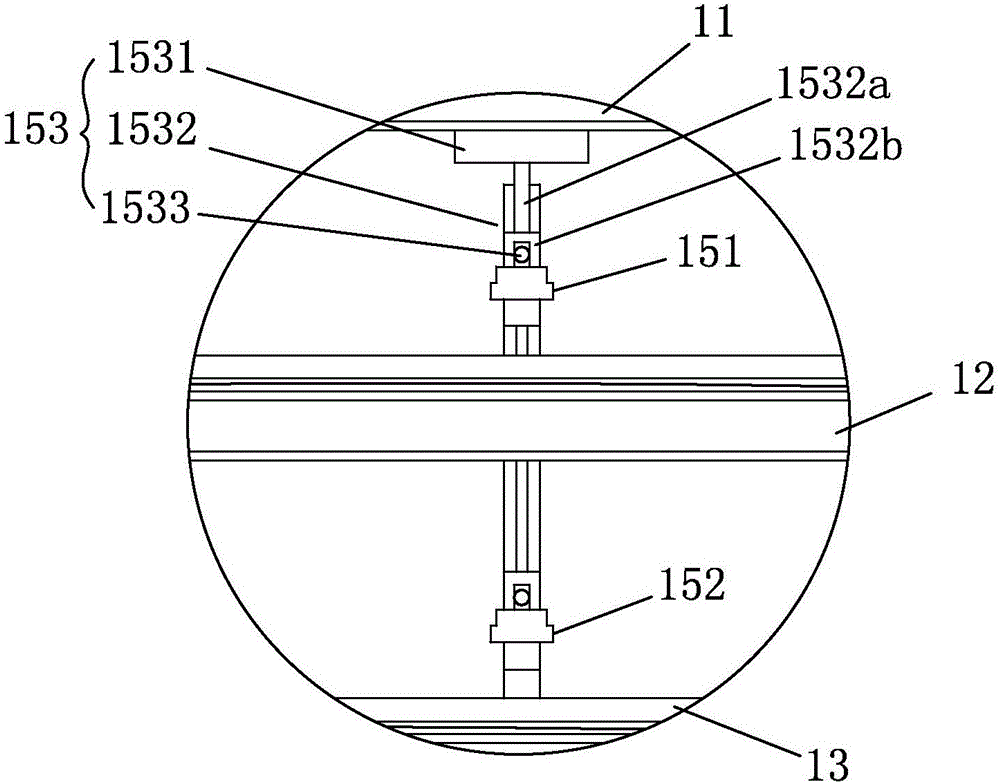

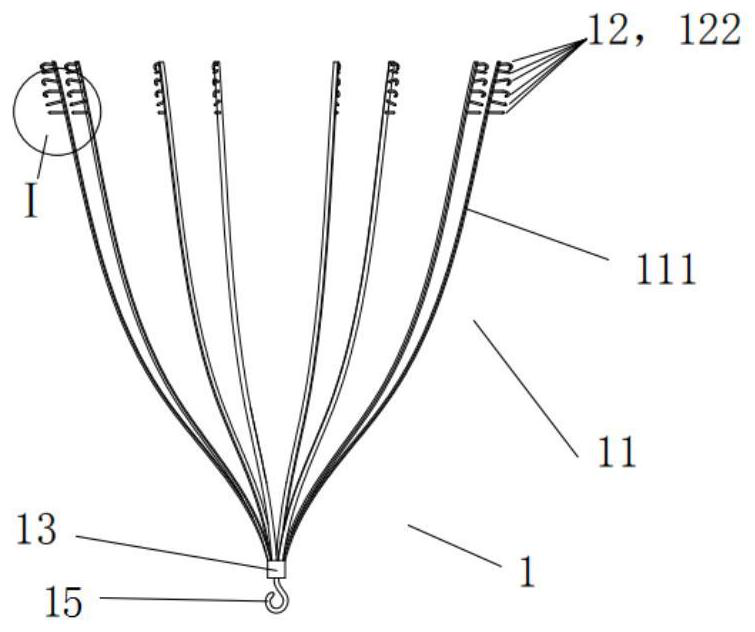

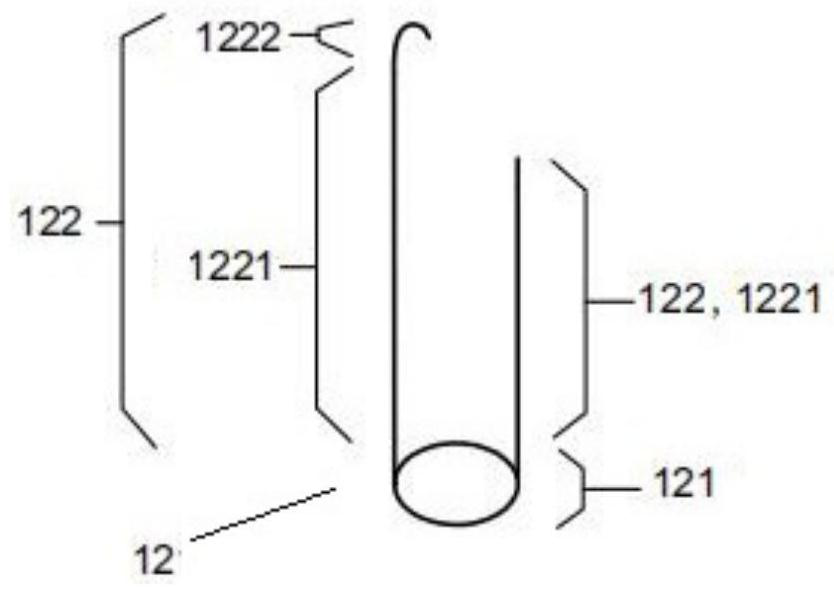

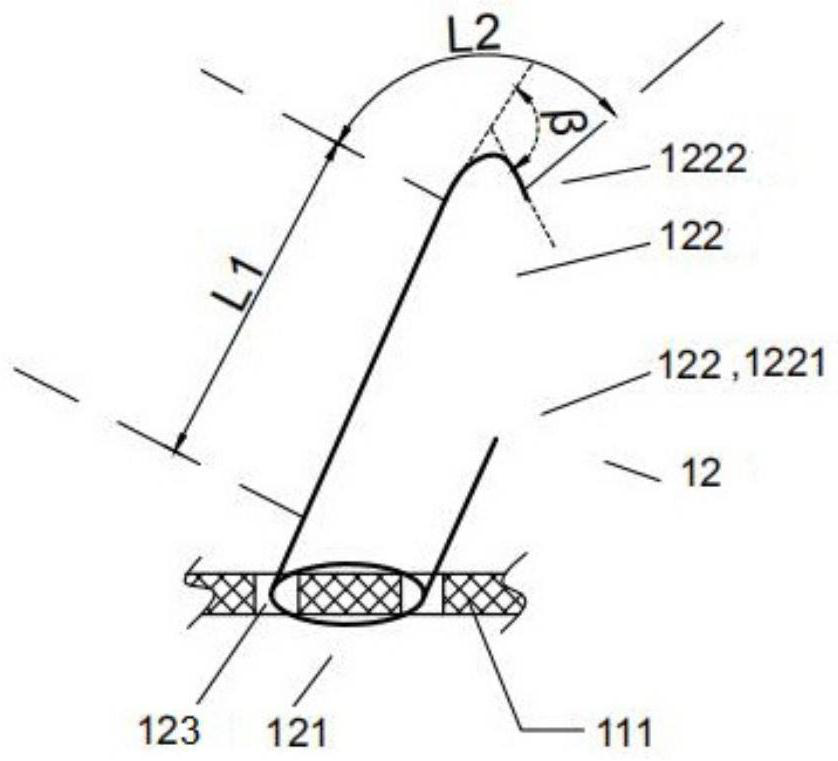

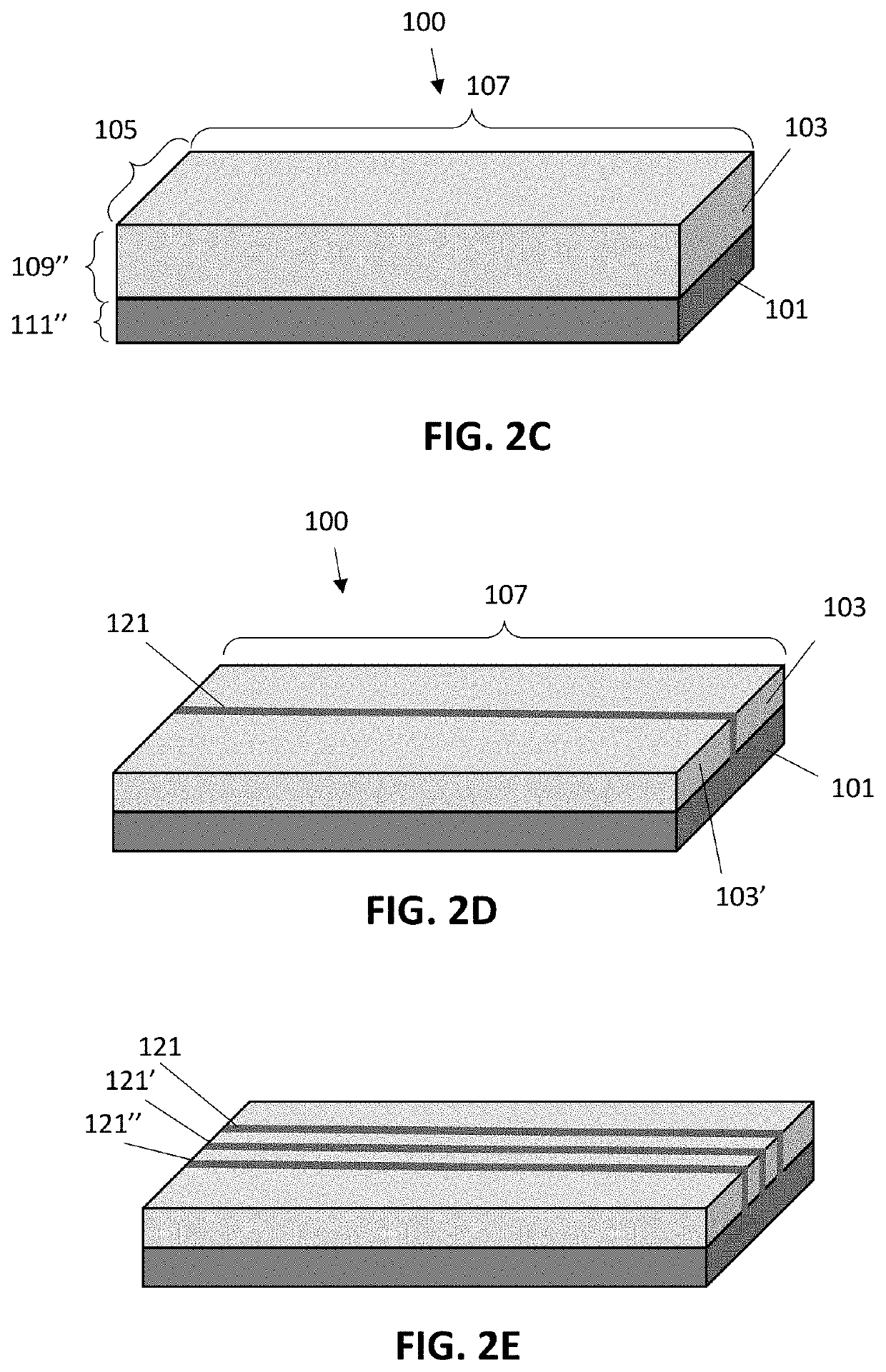

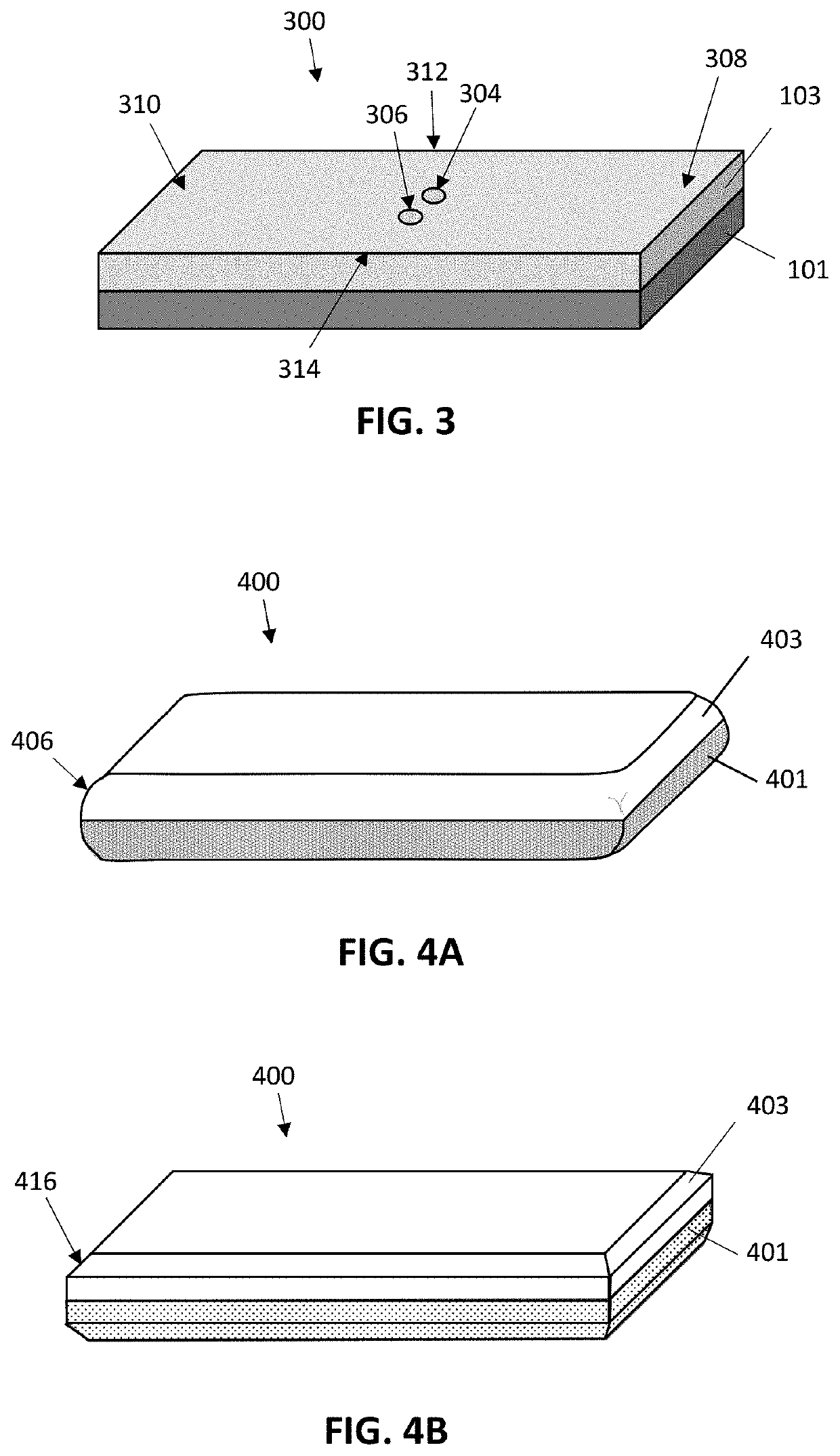

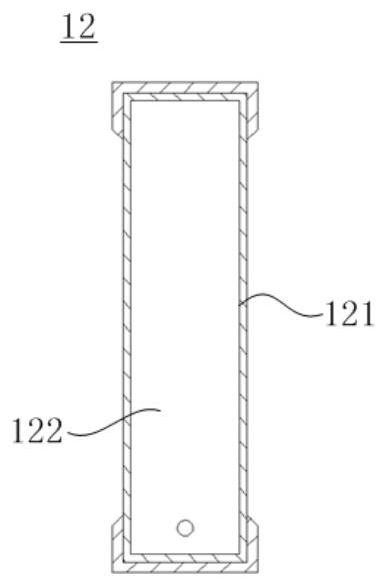

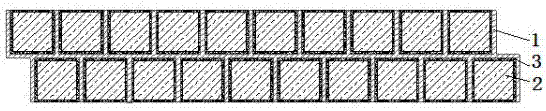

Test sample for tensile properties of large tow carbon fiber multifilament and sample preparation method thereof

ActiveCN108469366AImprove mechanical propertiesPrevent tear damagePreparing sample for investigationFiberTest sample

The invention relates to a test sample for tensile properties of a large tow carbon fiber multifilament and a sample preparation method thereof, and belongs to the field of material property testing.The method comprises the steps that tension is applied to wind the carbon fiber multifilament of not less than 24 k around a frame; gum dipping, gum leaching and heat curing are conducted on the framewound with the multifilament, and the gum-dipped multifilament is cut into multifilament segments after cooling; a set of metal or composite reinforcing sheets are respectively bonded to the two endsof the multifilament segments, wherein each set includes two reinforcing sheets disposed oppositely, a structure glue film is bonded to the inner surface of at least one of the two reinforcing sheets, the middle region and the peripheral edge region of the inner surface are vacated in bonding, and the two ends of the multifilament segments are located in the middle region; the reinforcing sheetsare pressed, heated and cured to obtain the test sample. By adopting the method, the mechanical properties of the reinforcing sheets are improved, the bonding strength between the multifilament and the reinforcing sheets is improved, and the problems of tear damage of the reinforcing sheets and debinding and slippage of fiber when the obtained test sample is used in a tensile test are avoided.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

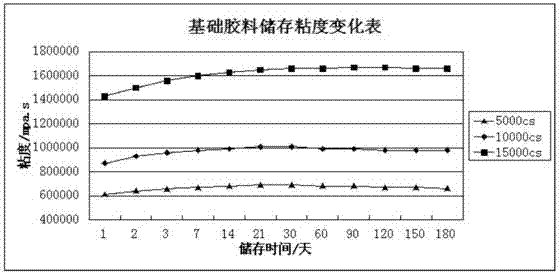

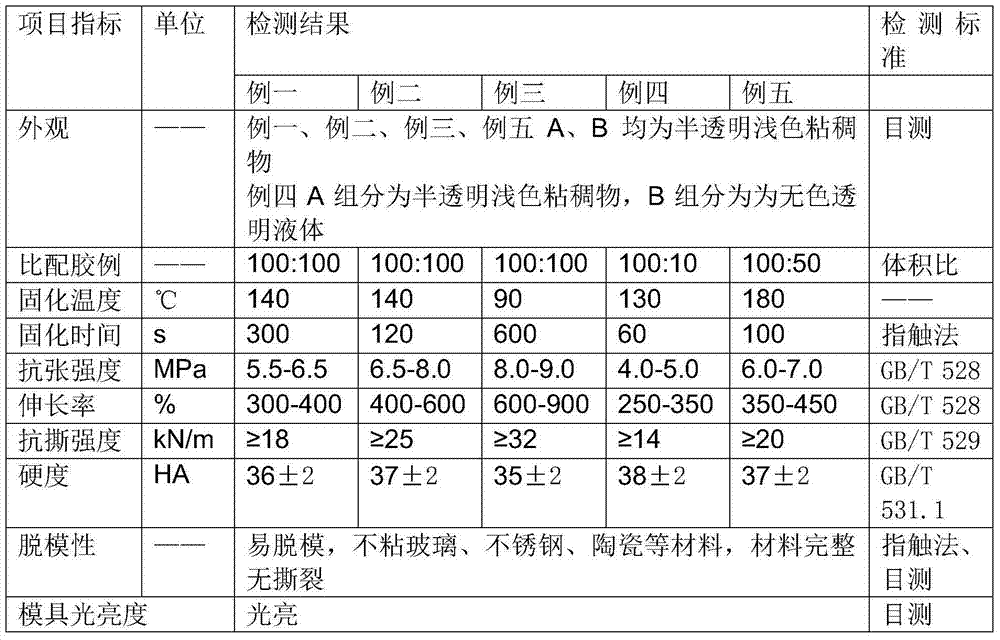

Bi-component addition type mold silicone rubber for injection molding

The invention discloses a bi-component addition type mold silicone rubber for injection molding. The silicone rubber is cured and molded by using A and B components, wherein the A component comprises the following components in parts by mass: 100 parts of base silica gel, 0.1-0.30 part of platinum complex catalyst, 0.1-2.0 part of polymerization inhibitor which is alkynol and vinyl ring-body compound, and 0-10 parts of vinyl silicone oil; the B component comprises the following components in parts by mass: 0-100 parts of vinyl silicone oil, 4-15 parts, preferably 5-10 parts of one or more hydrogen polysiloxanes, and 0-20 parts of vinyl silicone oil. The silicone rubber is used for preparing silicone rubber mold through injection molding and mainly suitable for fast injection molding, the obtained product is good in extrusion property, easy for demolding after being molded, good in mechanical property, free of volatile byproducts in the vulcanizing process, low in shrinkage percentage, internally and externally vulcanized at the same time, good in rebound resilience, wide in application, and can be applied to preparing various injection molded products such as artificial jewelry; the silicone rubber can be reused many times, the higher the reuse frequency is, the better the performance is.

Owner:CHENGDU TALY TECH CO LTD

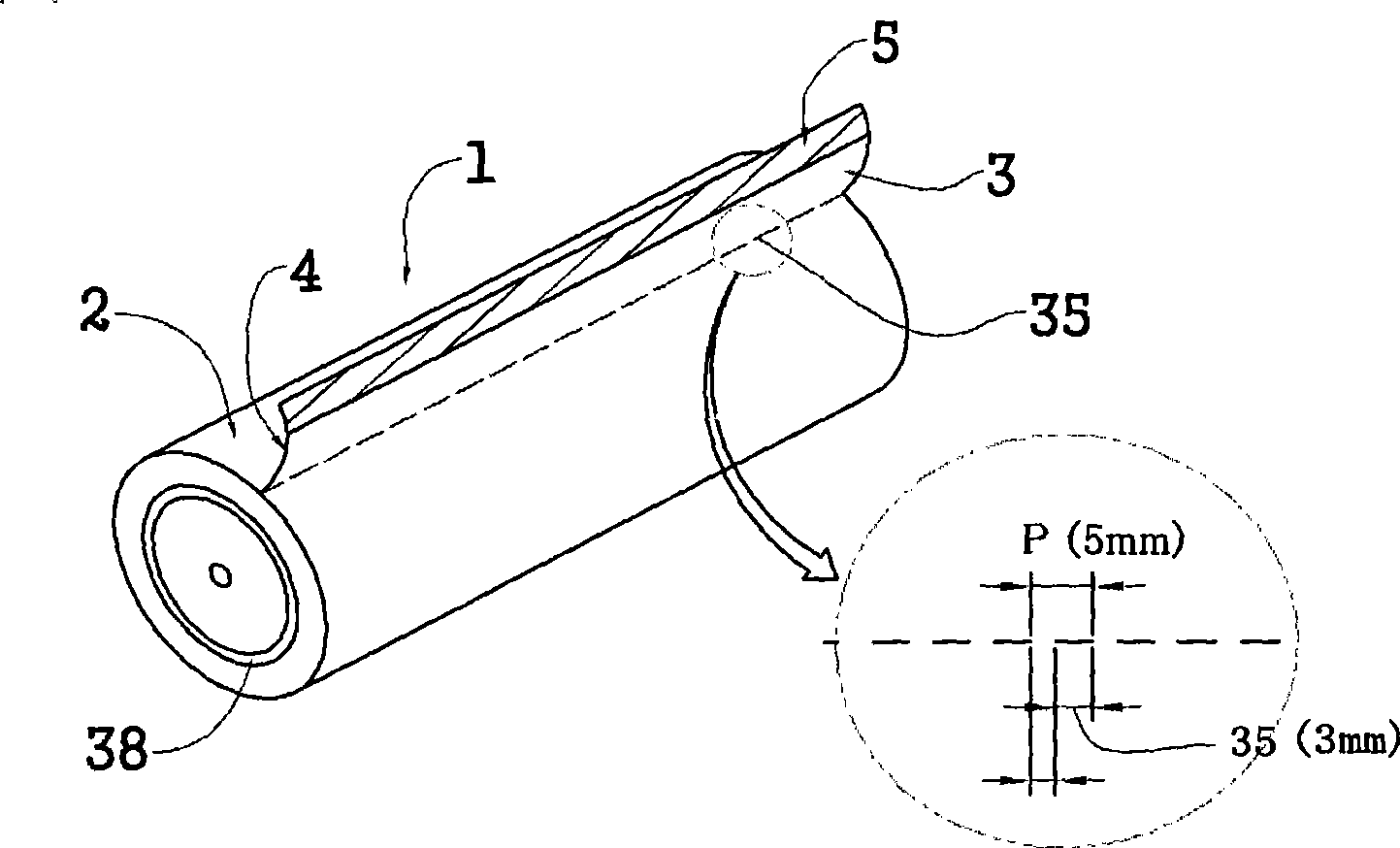

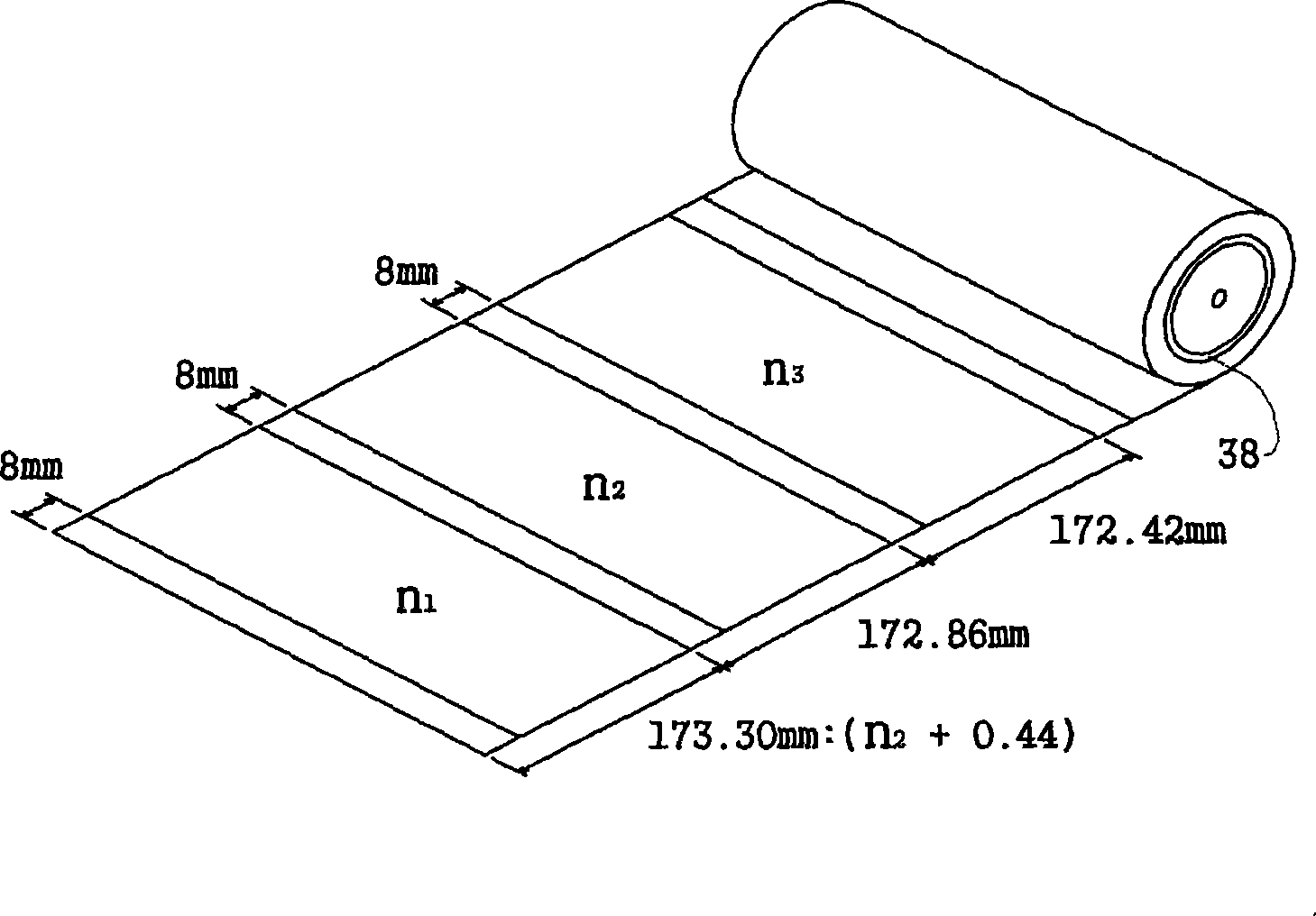

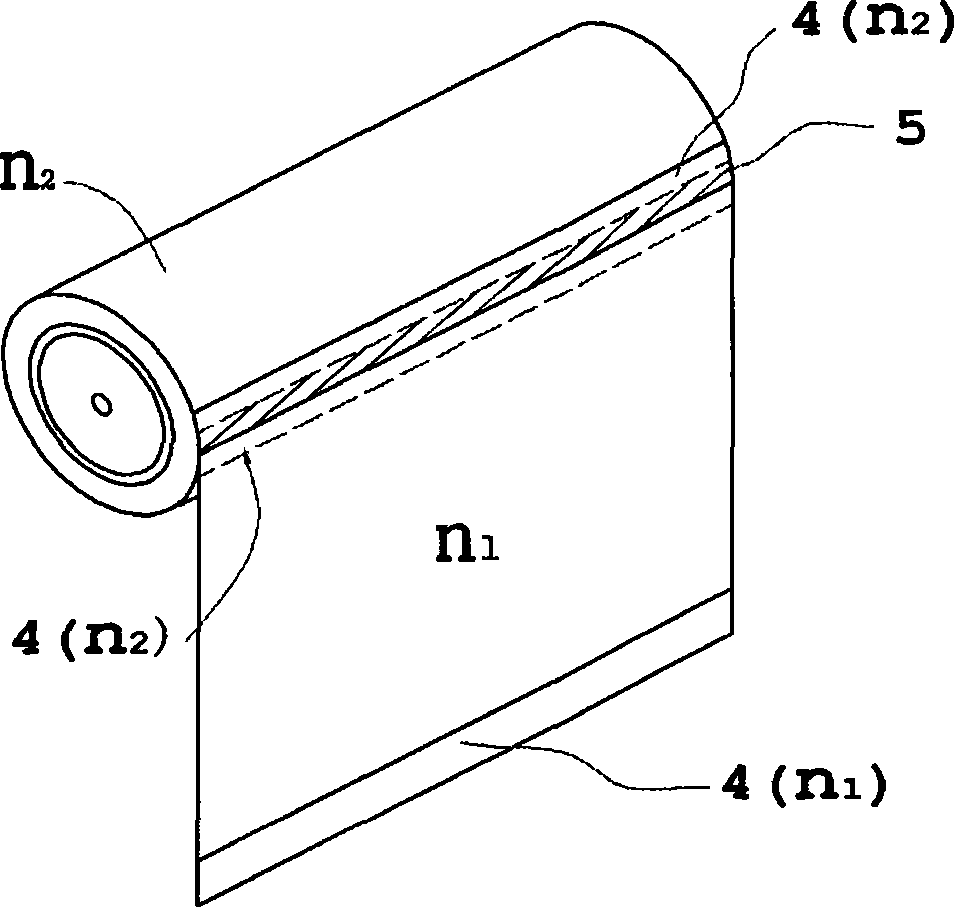

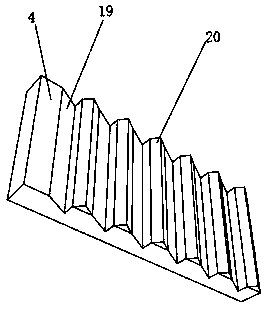

Adhesive roll cleaner, and apparatus for and method of manufacturing the same

InactiveCN101433446APrevent tear damageReduce the difficulty of tearing and replacingNatural cellulose pulp/paperCarpet cleanersAdhesiveEngineering

This invention relates to a cleaning cylinder for cleaning beds or carpets, and apparatus and method for manufacturing cleaning cylinder, providing the cleaning cylinder, in which the adhesive tape is hard to torn even if the hairs or the like are adhered to the winding direction (longitudinal direction) of the adhesive tap, and the smudgy adhesive tape can be easily changed, and apparatus and method for manufacturing cleaning cylinder. In this invention, the cleaning face of the adhesive tape continuously forms the adhesive side of the adhesive layer in the adhesive tapes of multiple layers wound at the outer circumference of the wound roll, inside which is the non-adhesive side. The non-adhesive separating paper having a certain thickness and width and stronger extending intensity is adhered to the transverse direction and longitudinal direction of the adhesive side. The staring position of the separating paper is provided with a tearing opening. An overlapping part is formed at the overlapped part of the width 1 / 2 of the separating paper, thereby easily tearing and changing after being used.

Owner:柳泰铉

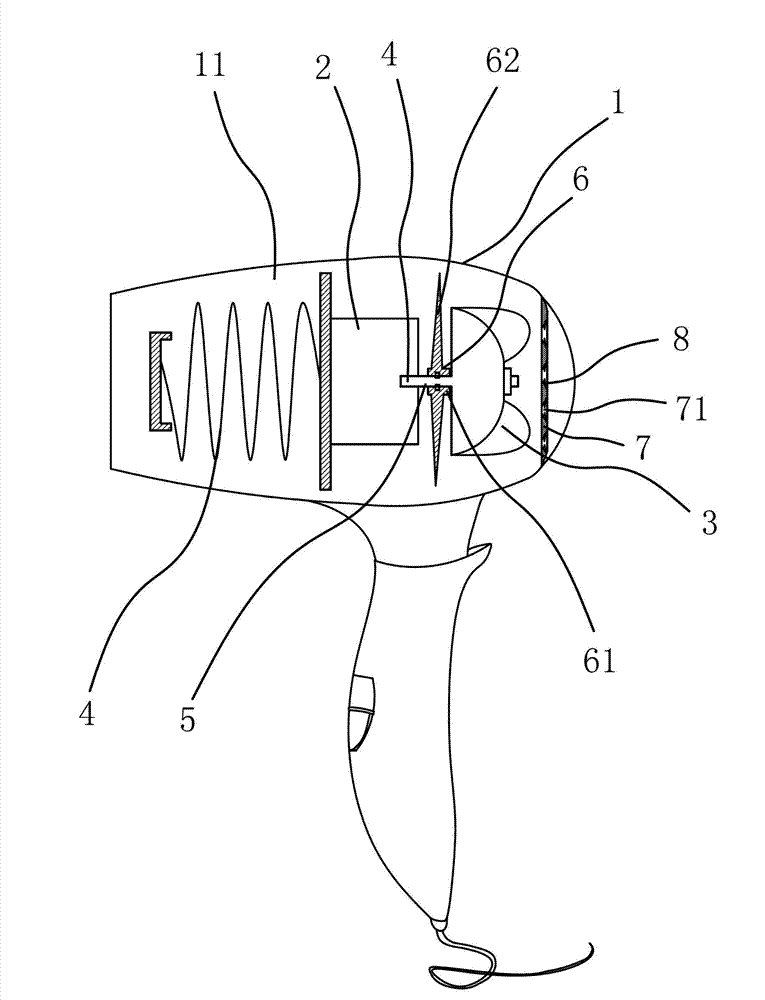

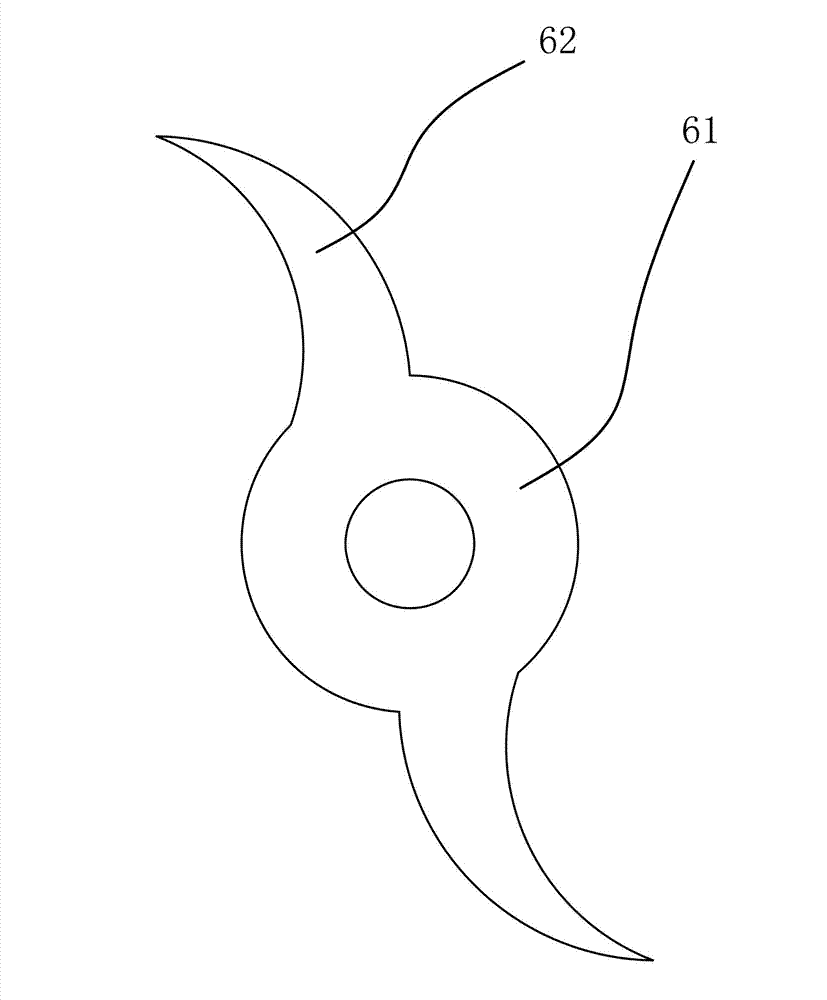

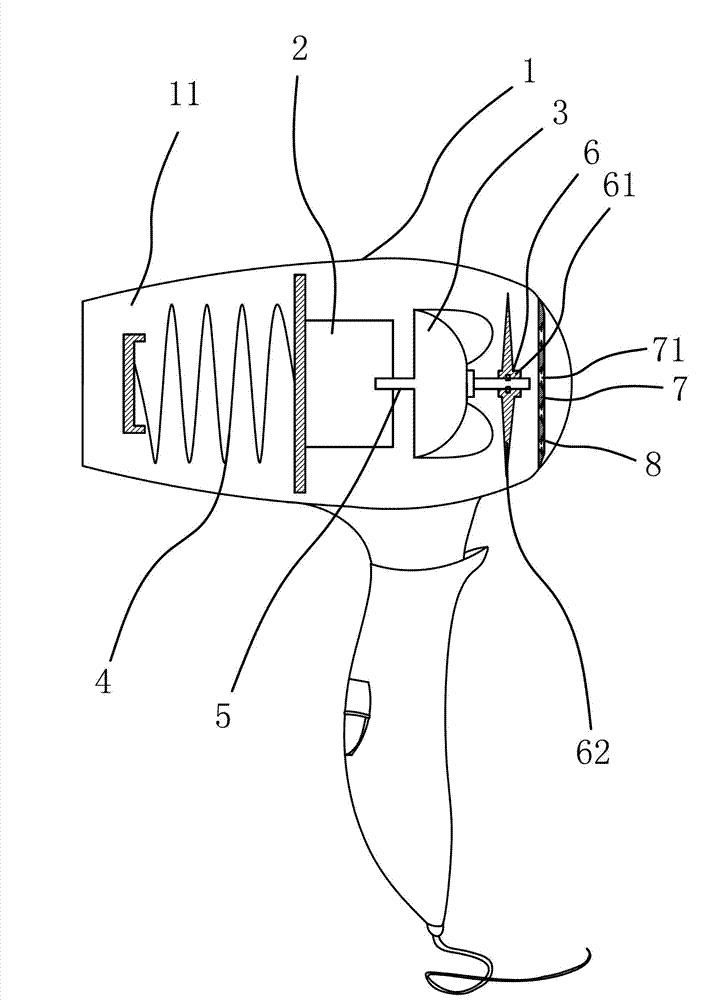

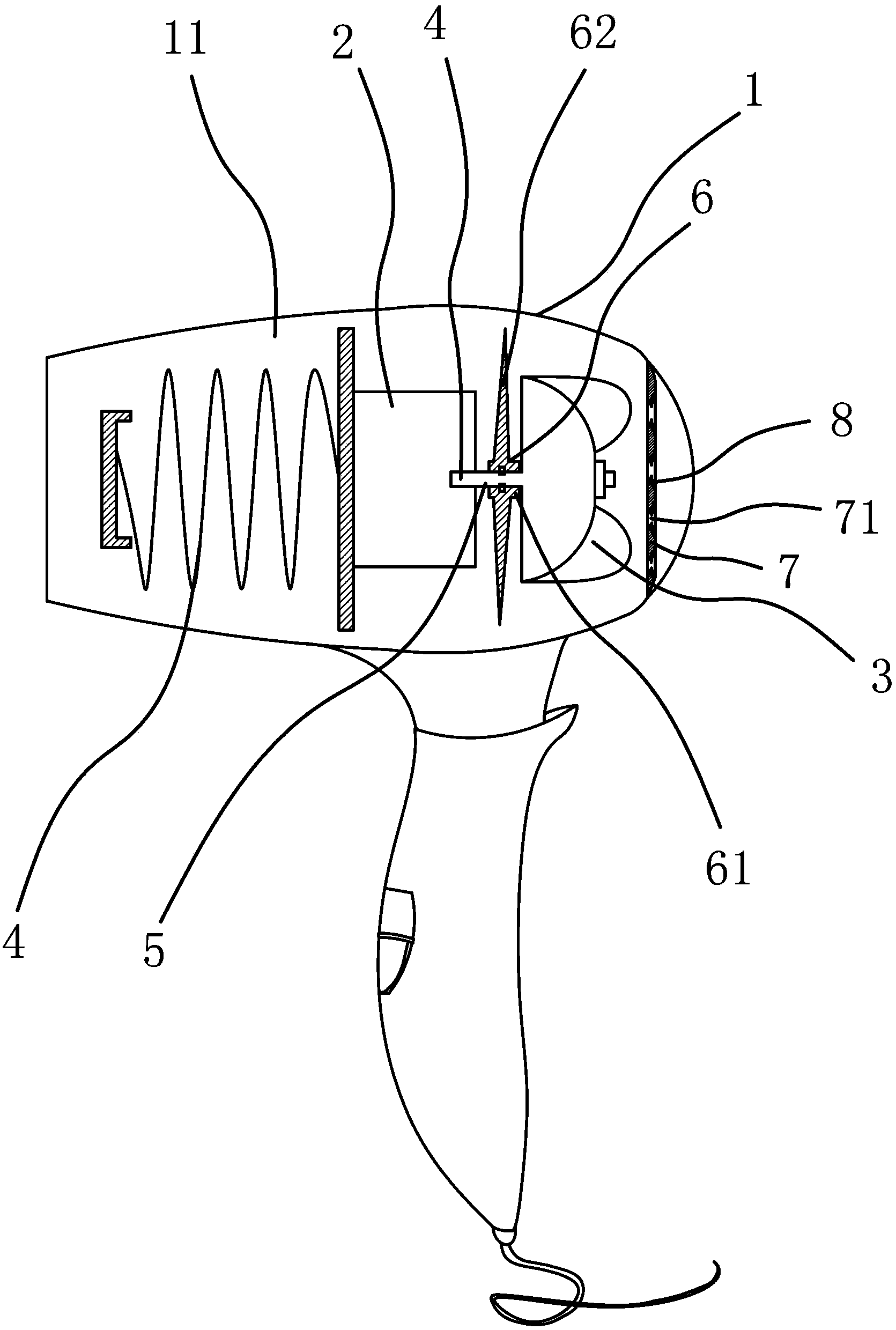

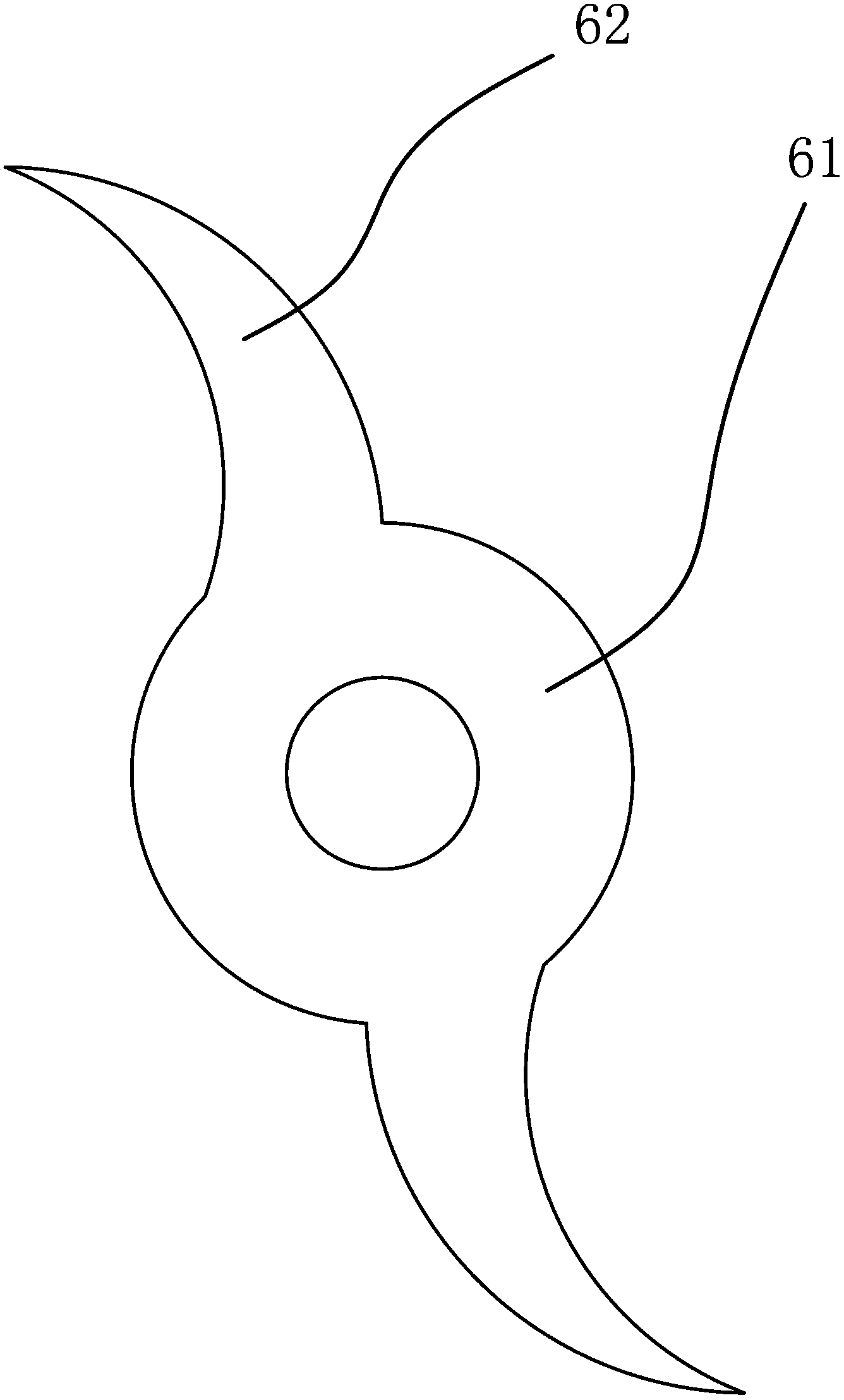

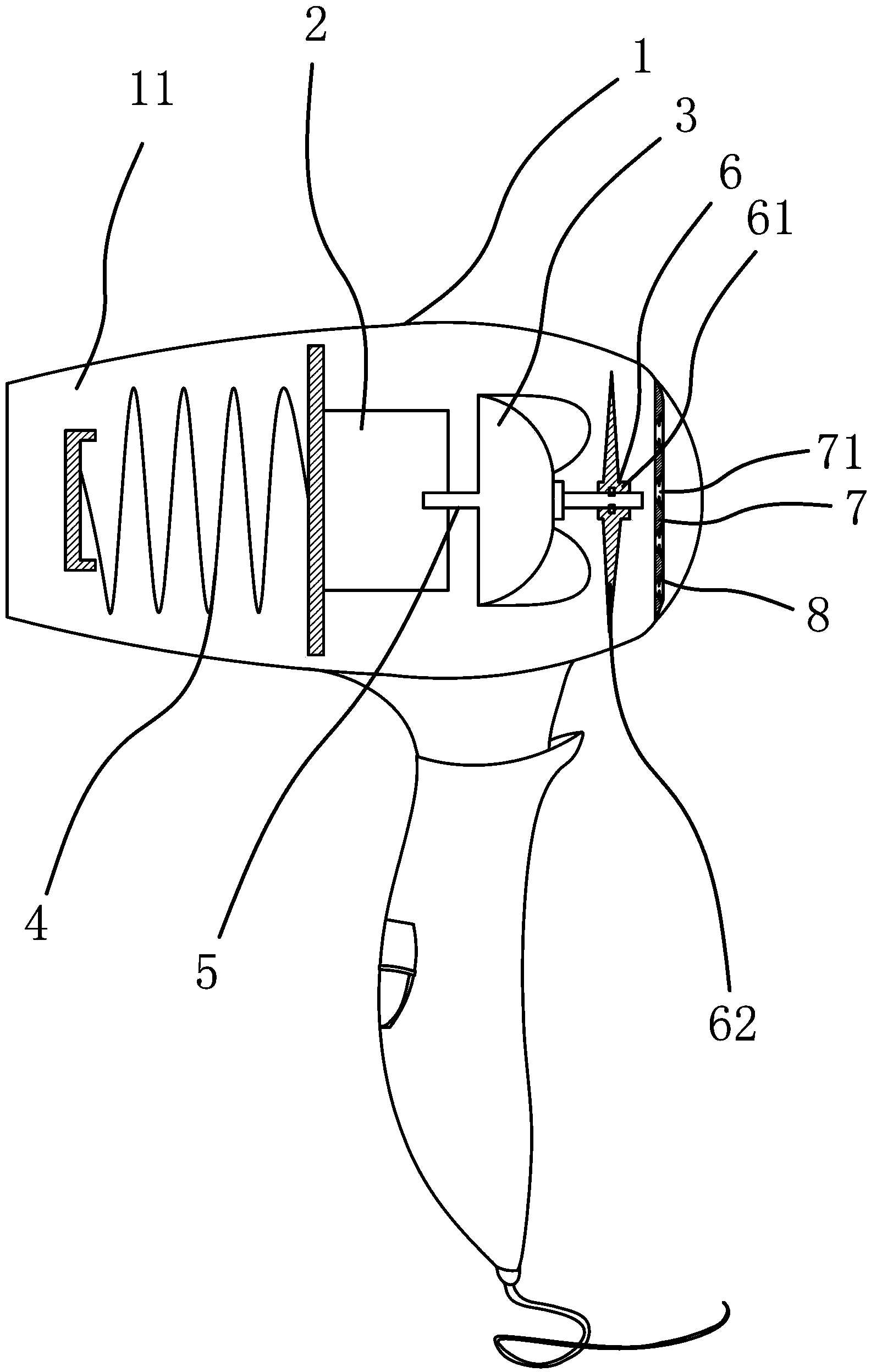

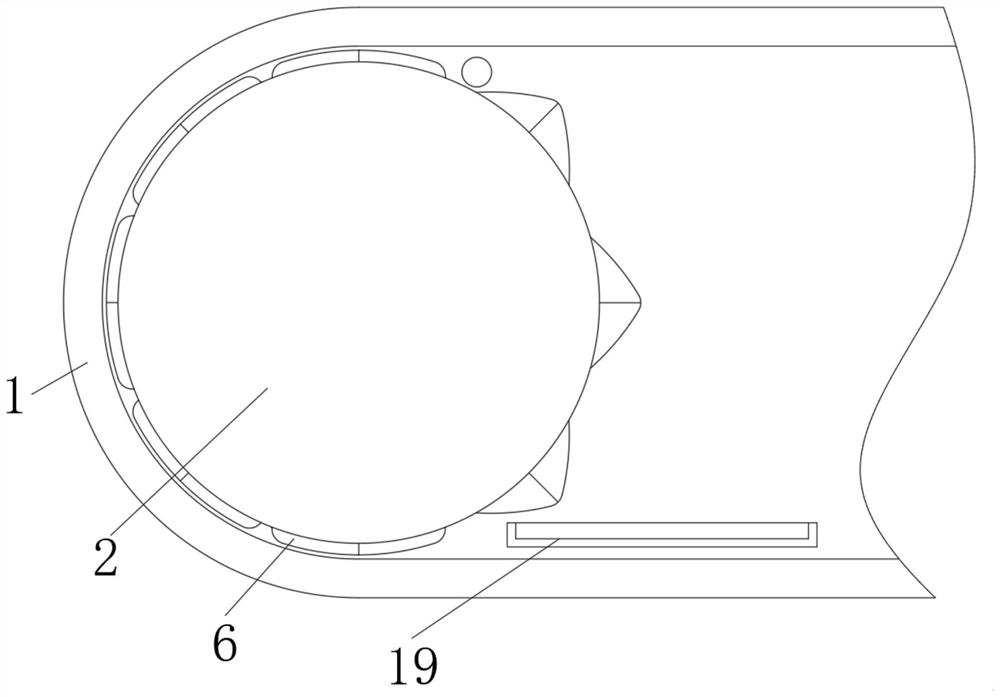

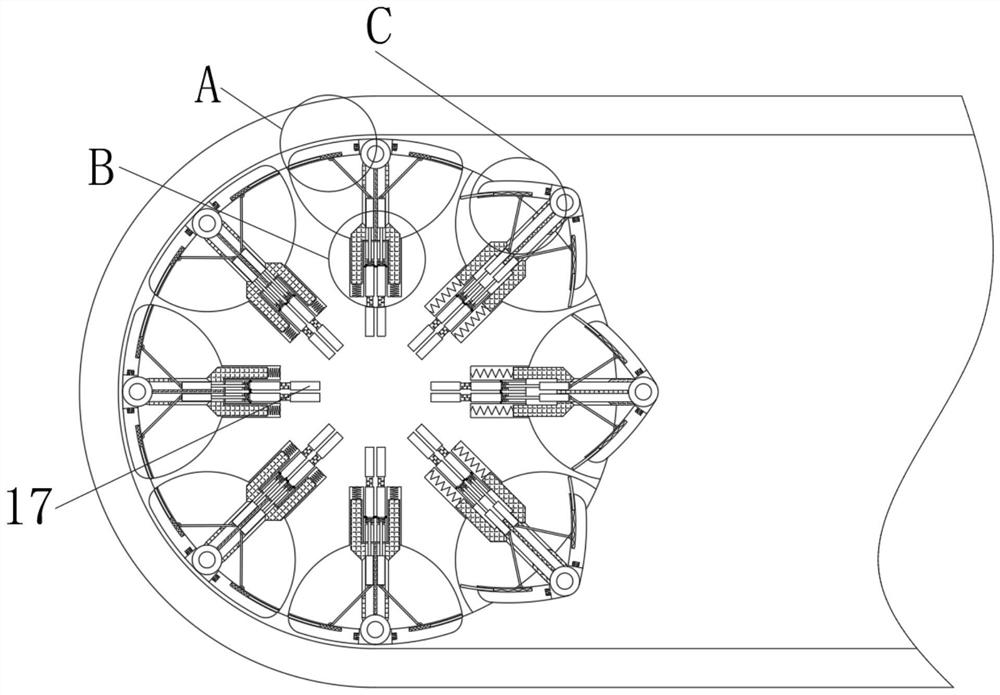

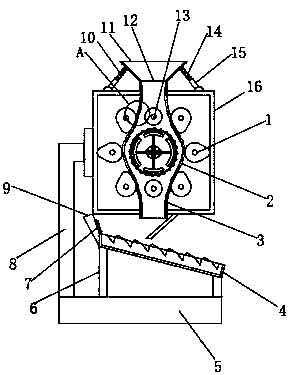

Anti-wind hair drier

The invention provides an anti-wind hair drier, belonging to the technical field of machinery, and aiming at solving the problems that the existing hair drier is easy to wind, low in safety and short in service life. The anti-wind hair drier comprises a housing with an air blowing passage, wherein the air blowing passage of the housing is internally provided with an electric motor, fan blades and an electric heating element; the fan blades are positioned at the inlet section of the air blowing passage and is fixedly connected with the rotating shaft of the electric motor; the inlet section of the air blowing passage is provided with a hair cutting knife capable of cutting the hair sucked in the air blowing passage; and the hair cutting knife is fixedly connected with the rotating shaft of the electric motor. The anti-wind hair drier is capable of cutting the hair sucked in the air blowing passage instantly so that the hair is prevented from being further sucked; and the anti-wind hair drier is good in safety, long in service life and good in comfortableness.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

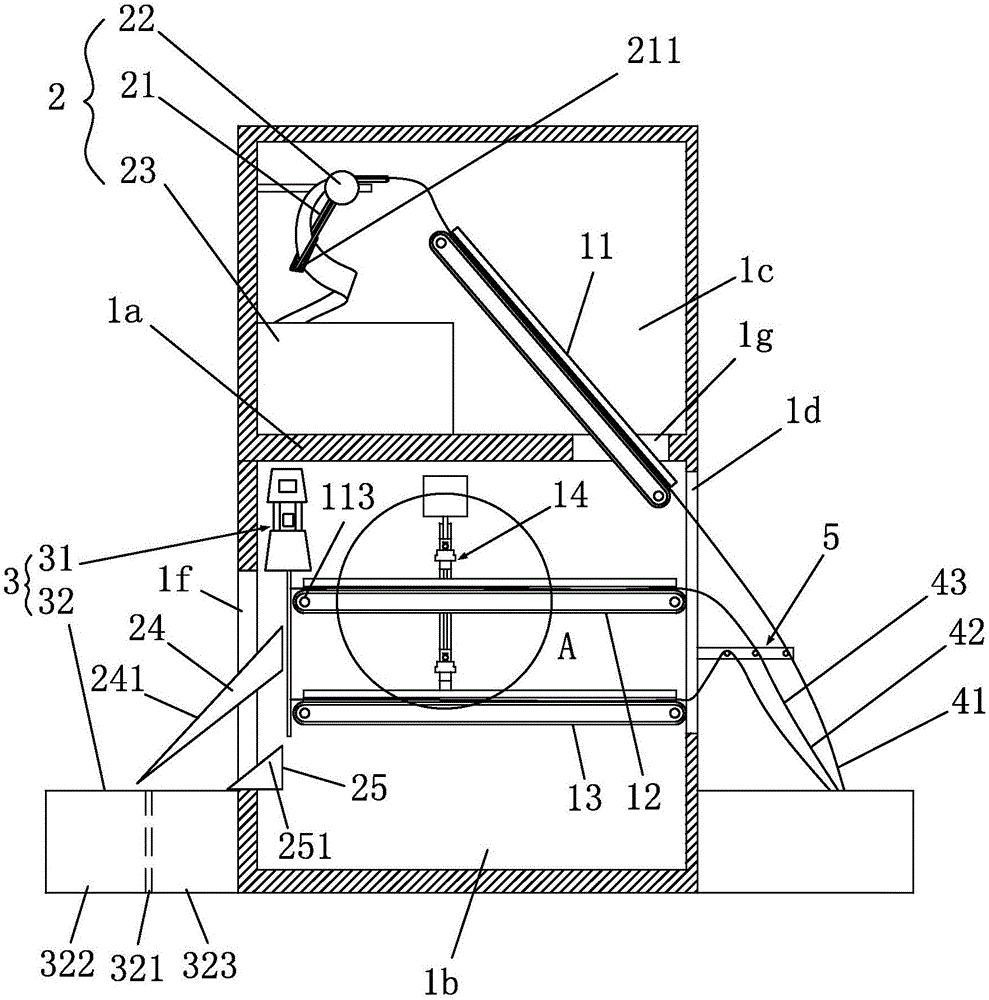

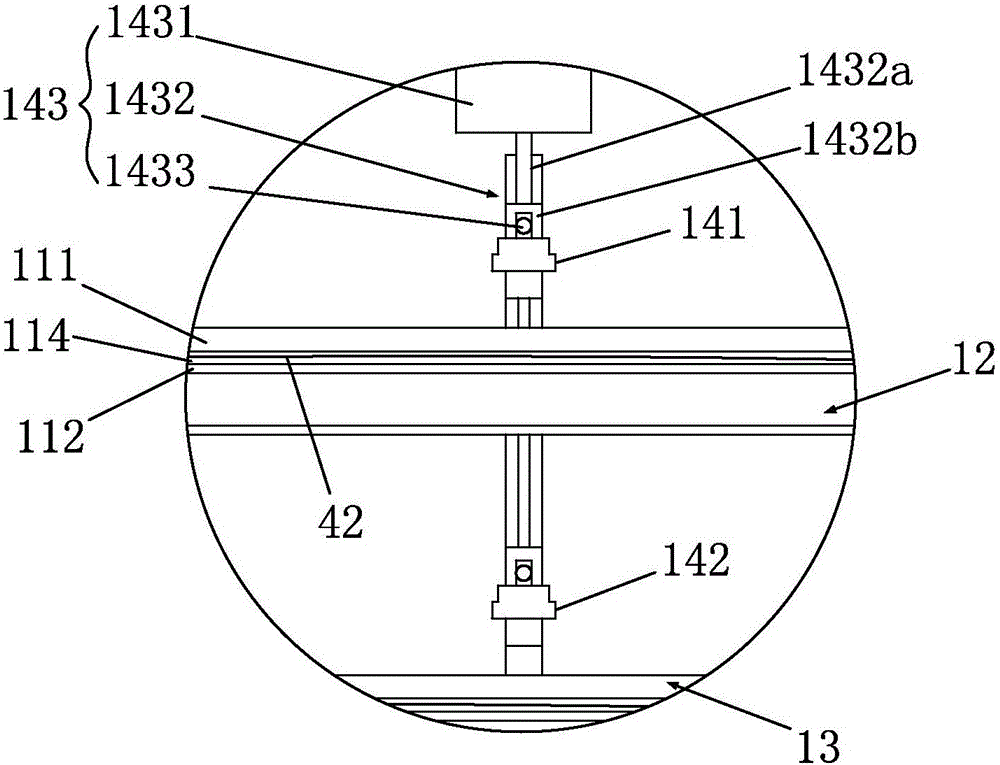

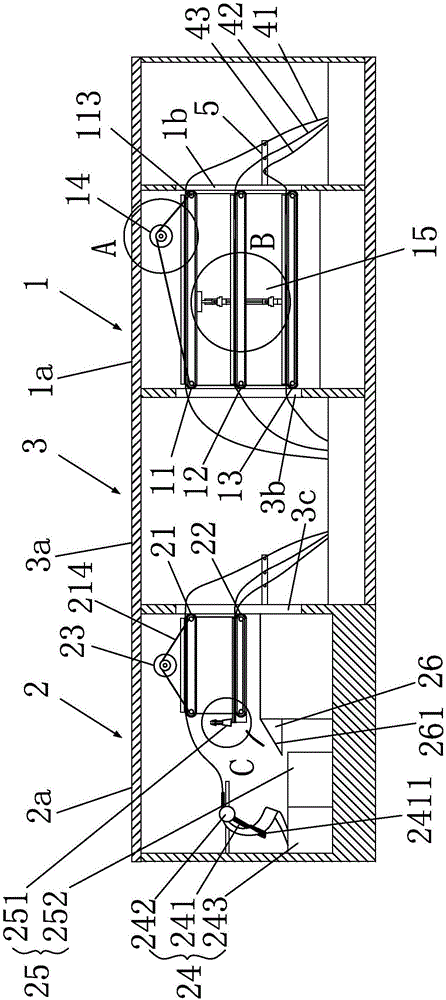

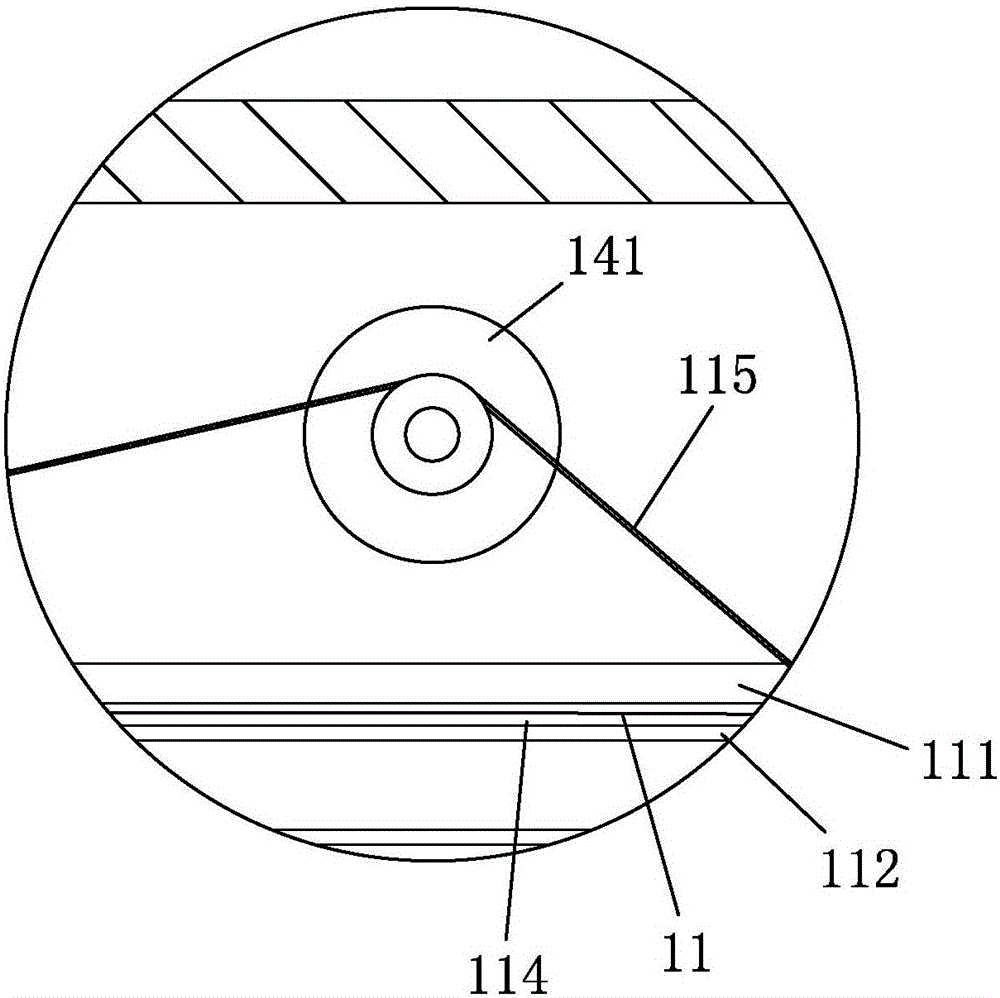

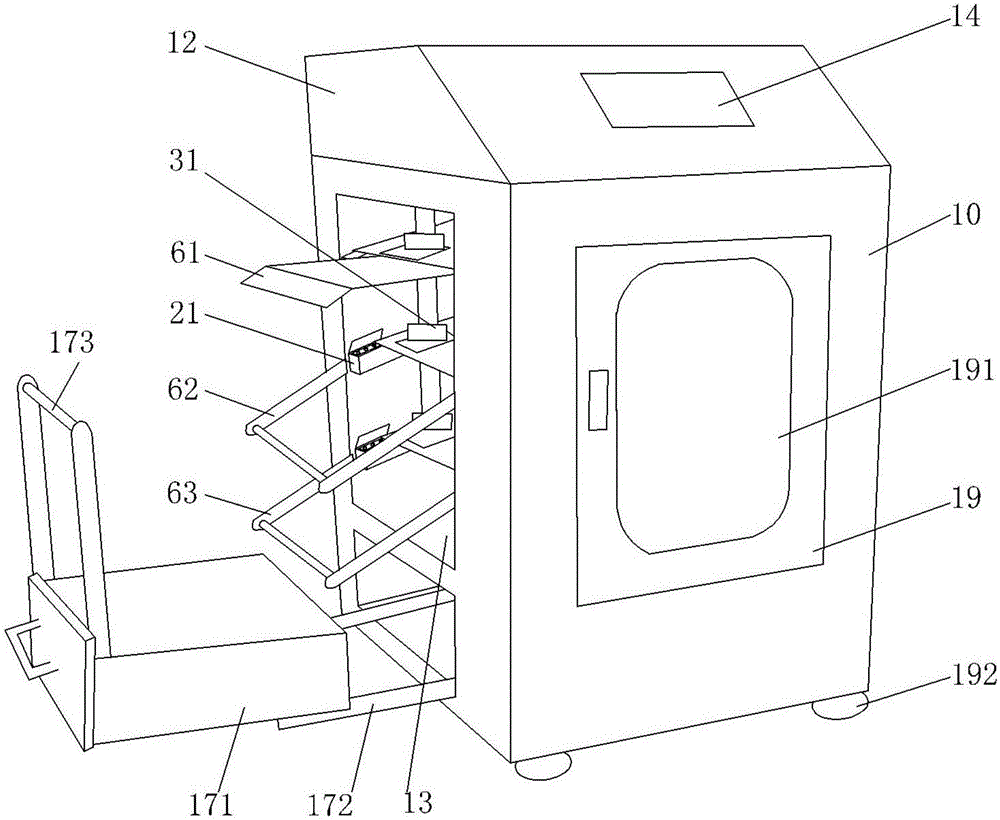

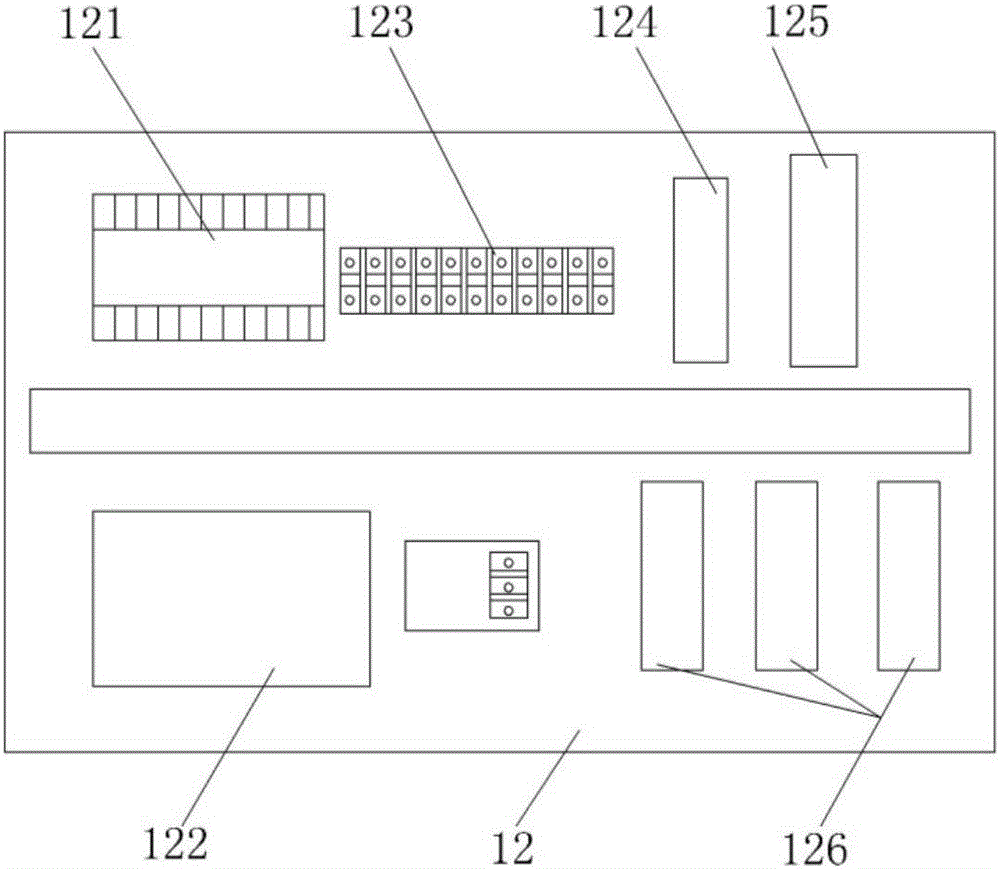

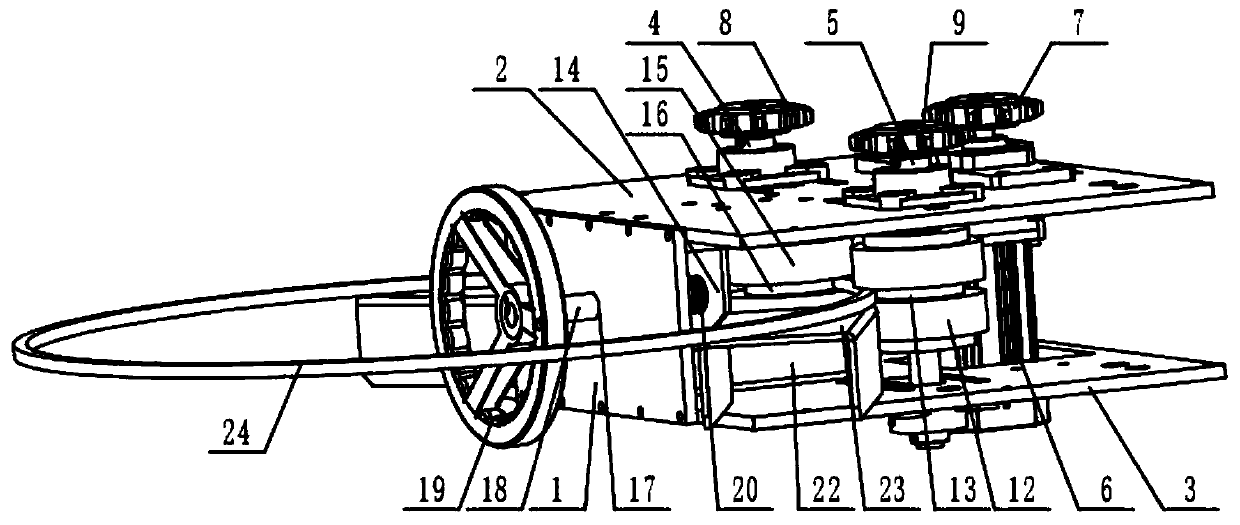

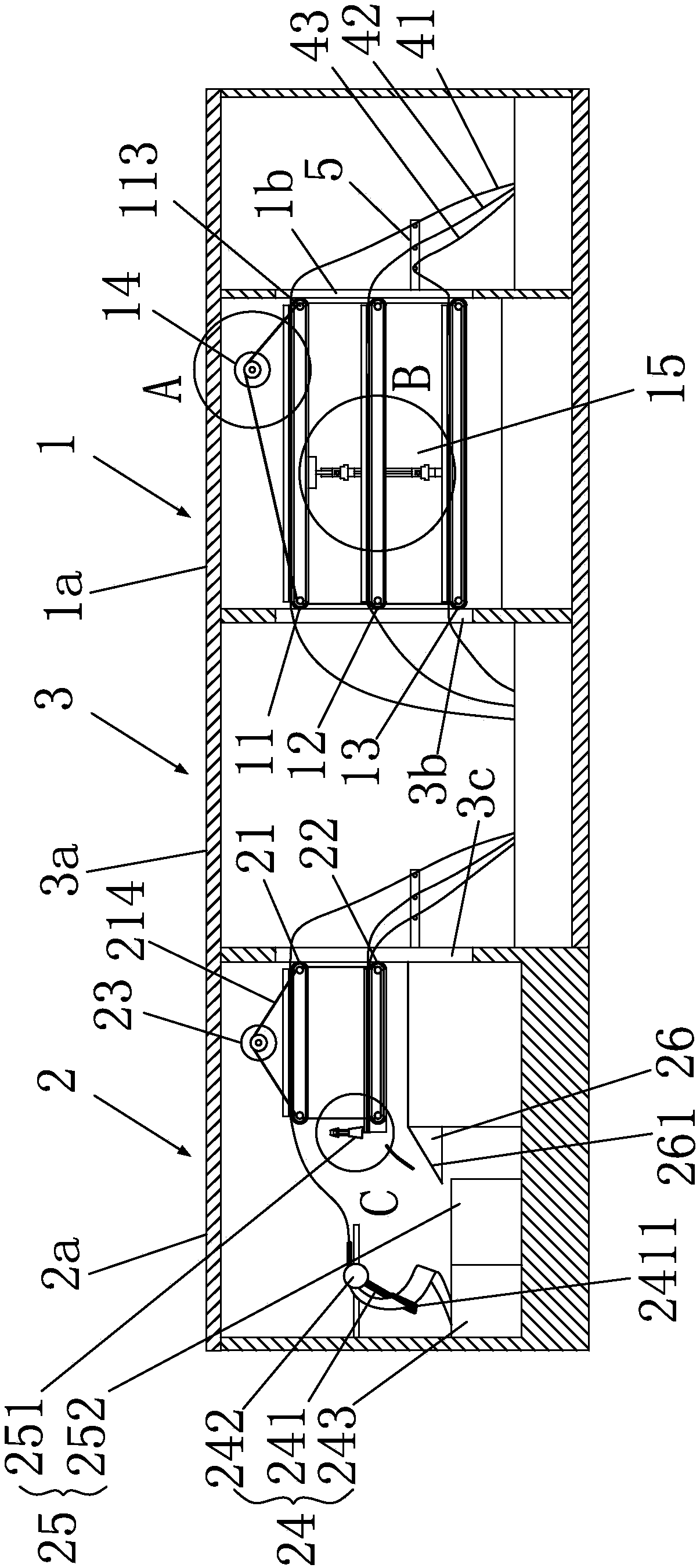

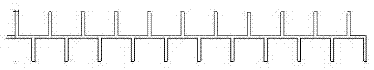

Small invoice sealing machine

ActiveCN106064536ARealize automatic continuous stampingImprove stamping efficiencyStampingInvoiceEngineering

The invention discloses a small invoice sealing machine and belongs to the technical field of automatic office equipment. The technical problems that an existing automatic sealing machine is large in occupied area and assembly and installation are troublesome are solved. The small invoice sealing machine comprises a first conveying mechanism used for conveying first page invoices, a second conveying mechanism used for conveying second page invoices, a third conveying mechanism used for conveying third page invoices, a first diving mechanism used for driving the first conveying mechanism, the second conveying mechanism and the third conveying mechanism, a first control device used for controlling the first diving mechanism to operate intermittently, a sealing mechanism used for sealing the second page invoices and the third page invoices, a first gathering mechanism used for gathering the first page invoices, and a second gathering mechanism used for gathering the second page invoices and the third page invoices. The first gathering mechanism is located above the second conveying mechanism and the third conveying mechanism. The first conveying mechanism is arranged obliquely, and the tail end of the first conveying mechanism is higher than the head end of the first conveying mechanism.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +2

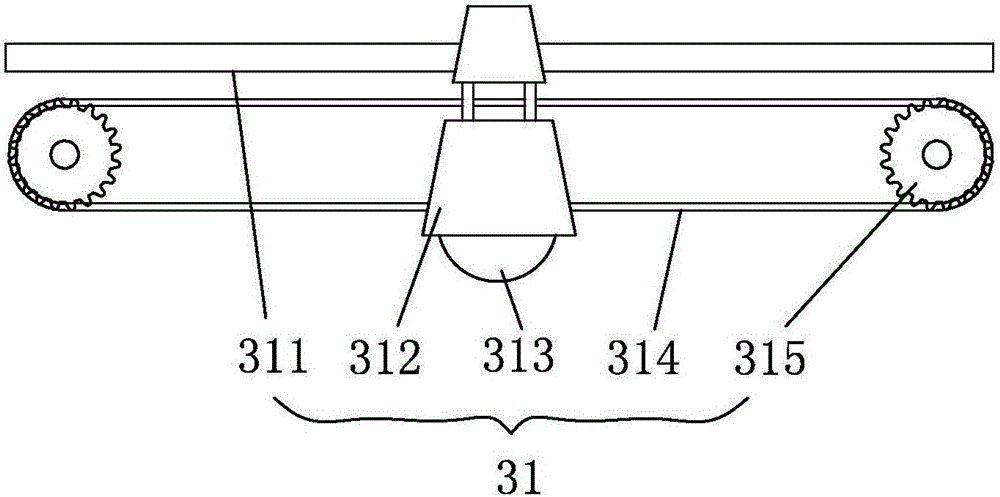

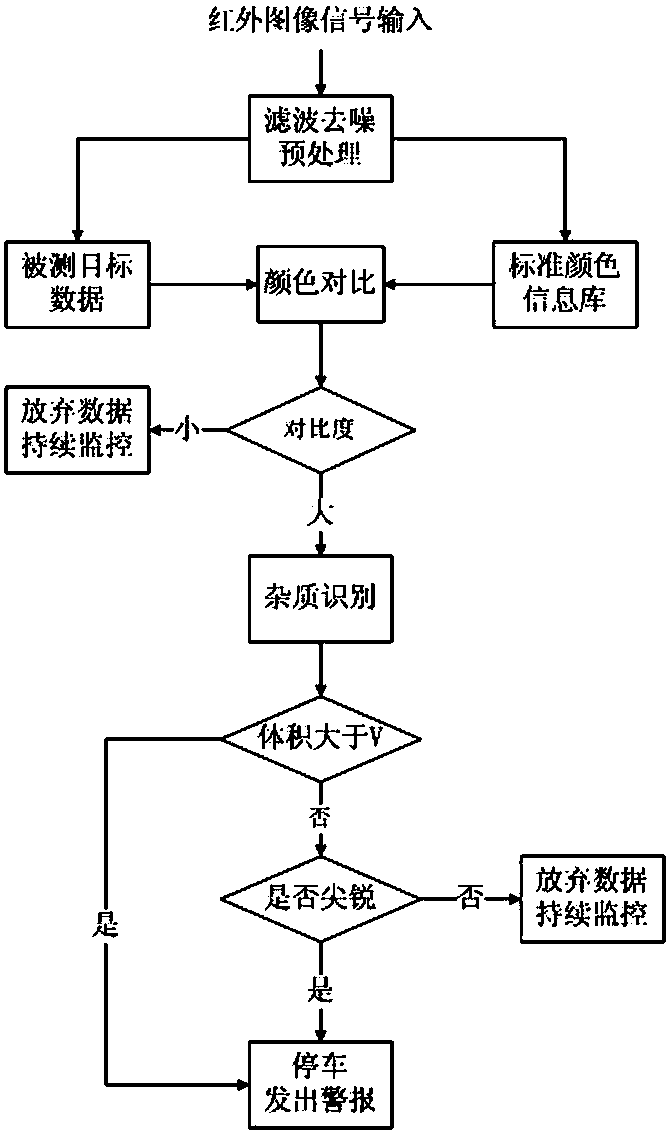

Infrared vision based detection and alarm method for longitudinal adhesive tape tearing

ActiveCN103910181APrevent tear damageLow costControl devices for conveyorsEngineeringInfrared vision

The invention relates to an infrared vision based detection and alarm method for longitudinal adhesive tape tearing and belongs to the technical field of automatic detection. The infrared vision based detection and alarm method for longitudinal adhesive tape tearing can be widely applied to belt-type conveyors used by industrial and mining enterprises in coal mines, power plants, wharfs and the like. The infrared vision based detection and alarm method for longitudinal adhesive tape tearing is realized by imaging target adhesive tape in real time via a CCD (charge coupled device), analyzing an image and alarming. The infrared vision based detection and alarm method has the advantages that deficiencies in an existing adhesive tape tearing detection method are overcome, actions can be taken when a danger source occurs on the adhesive tape and before the danger source damages the adhesive tape, tearing damage of the adhesive tape is completely avoided, cost on maintenance and replacement of the adhesive tape and economic loss caused by long-time production halt can be reduced to a great extent.

Owner:TAIYUAN UNIV OF TECH

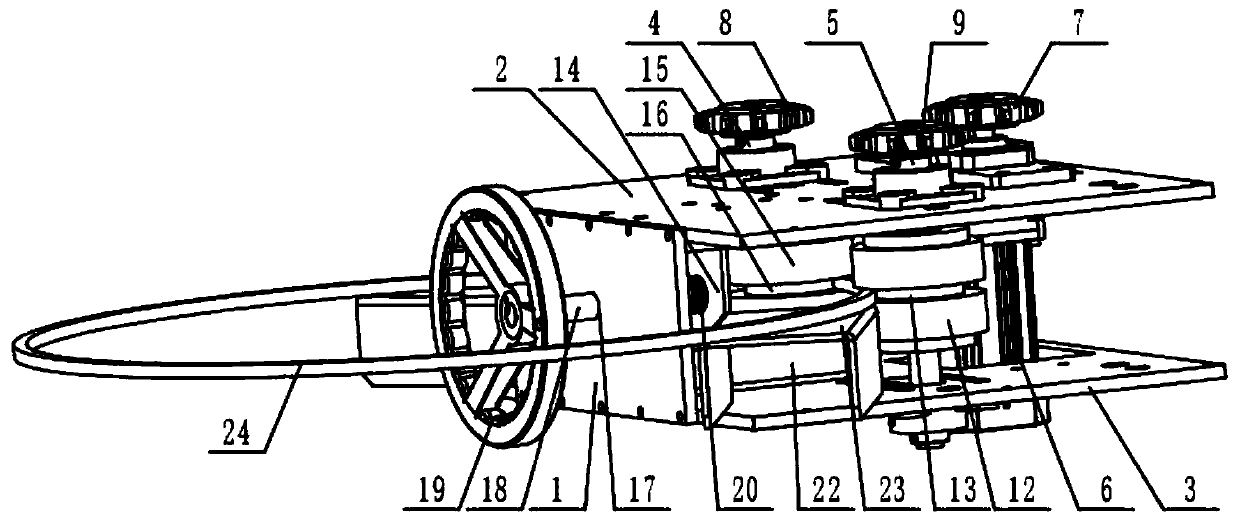

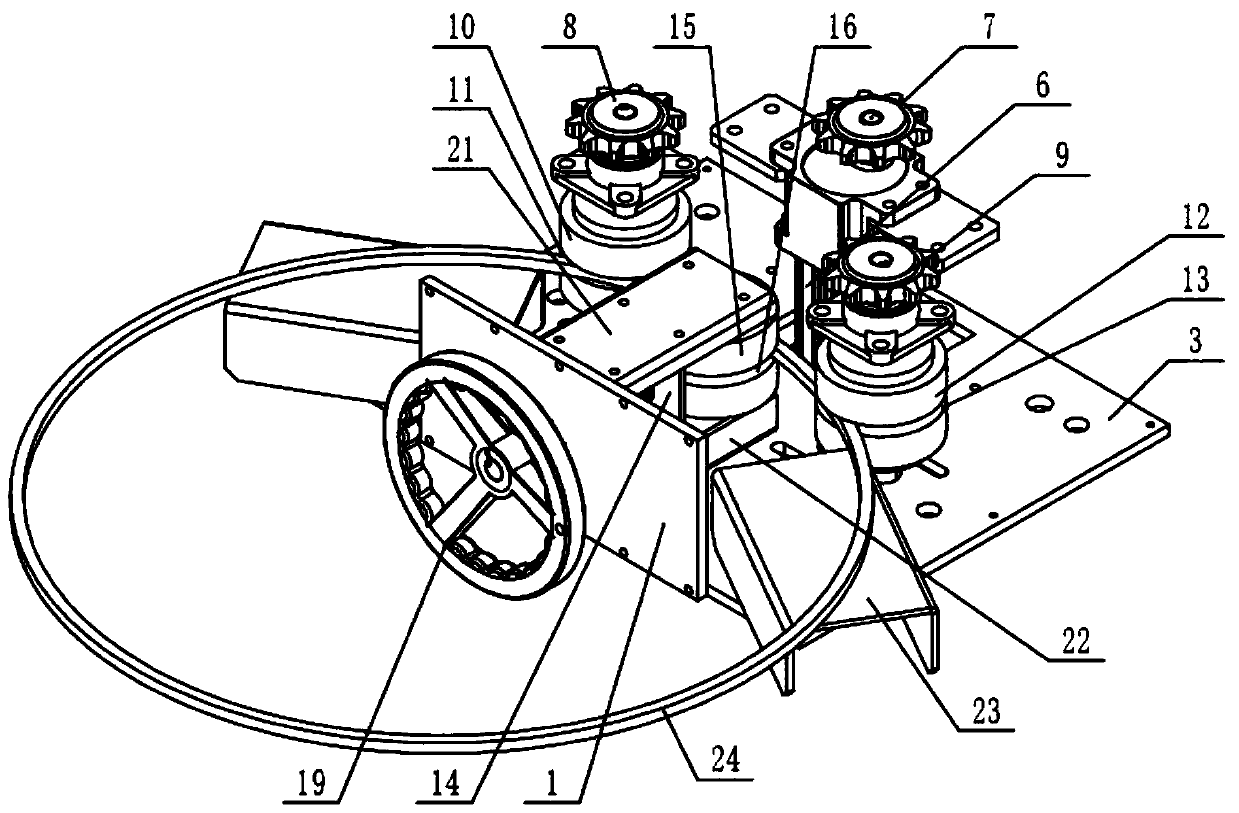

Invoice collecting device

ActiveCN106006153AImprove collection efficiencyRealize automatic collection and sortingPile receiversGear driveInvoice

The invention discloses an invoice collecting device, belongs to the technical field of automated office equipment, and solves the technical problem that an existing automatic stamping machine cannot automatically collect ply invoices. The invoice collecting device comprises a fourth conveying mechanism, a fifth conveying mechanism, a third driving mechanism, a second control device, a first collecting mechanism and a second collecting mechanism, wherein the fourth conveying mechanism is used for conveying first invoices; the fifth conveying mechanism is used for conveying second invoices and third invoices; the third driving mechanism is used for driving the fourth conveying mechanism and the fifth conveying mechanism; the second control device is used for controlling a second driving mechanism to run intermittently; the first collecting mechanism is used for collecting the first invoices; the second collecting mechanism is used for collecting the second invoices and the third invoices; each of the fourth conveying mechanism and the fifth conveying mechanism comprises a baffle, a conveying belt and at least one gear driving the conveying belt; and the third driving mechanism synchronously drives the gears of the fourth conveying mechanism and the gears of the fifth conveying mechanism to rotate.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +2

Invoice stamping, cut-off and storage machine

The invention discloses an invoice stamping, cut-off and storage machine comprising a shell body and a partition plate. The partition plate divides an inner cavity of the shell body into a control cavity and a work cavity. A feeding mechanism and a stamping mechanism for at least one invoice and a cut-off mechanism and a storage mechanism are arranged in the work cavity, wherein the cut-off mechanism and the storage mechanism are used for sequentially cutting off and storing all the stamped invoices correspondingly. The control cavity is provided with a control mechanism for controlling the feeding mechanism, the stamping mechanism, the cut-off mechanism and the storage mechanism. The structure is compact, using is convenient, and the automation degree is high; and by means of coordination of the feeding mechanism, the stamping mechanism, the cut-off mechanism, the storage mechanism and the control mechanism, continuous stamping, cutting, and classified storing of triple invoices can be achieved, and labor intensity of operating personnel is reduced greatly.

Owner:JIAXING HENGCHUANG ELECTRIC POWER DESIGN & RES INST CO LTD +2

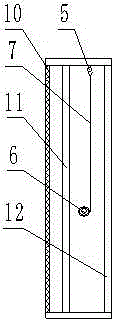

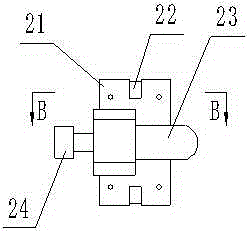

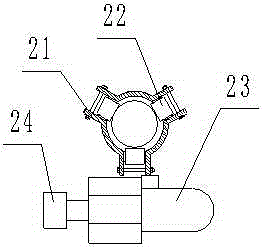

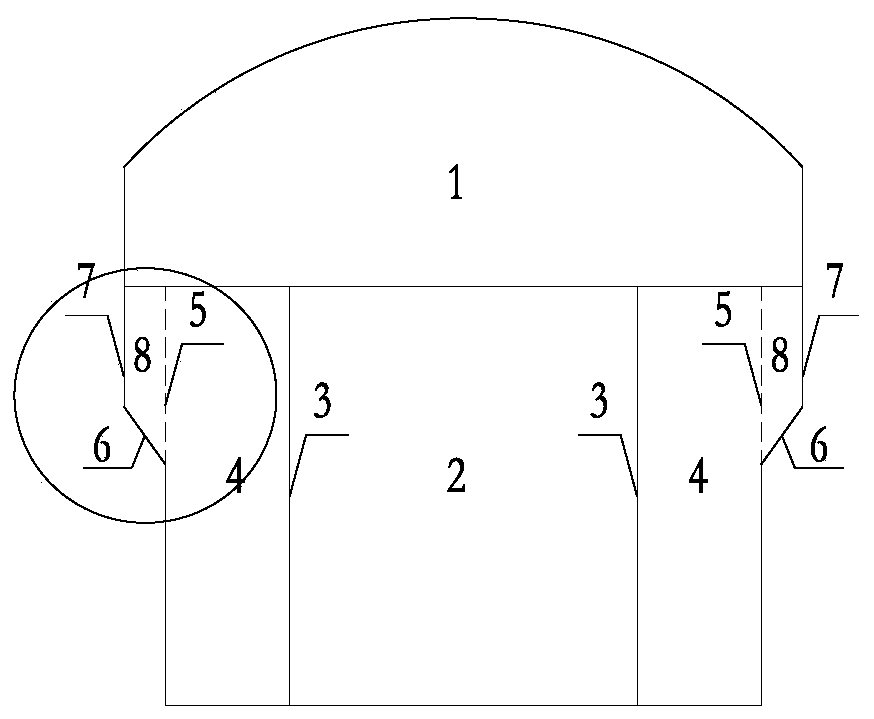

Integrally lifting type curtain of pig house

The invention discloses an integrally lifting type curtain of a pig house. The integrally lifting type curtain comprises the pig house. The upper half portion of the pig house is provided with ventilating windows, a lifting and pulling beam is arranged above the ventilating windows, the inner side of each ventilating window is fixedly provided with a mosquito prevention mesh, the outer side of each ventilating window is provided with 1-3 curtain bodies, each curtain body is provided with a corresponding curtain lifting device, each curtain lifting device comprises fixing rails vertically arranged at the two ends of the pig house, shutter devices are arranged on the fixing devices, each shutter device comprises three supporting seats which are movably arranged in the peripheral direction of the fixing rails, and the supporting seats are clamped to the fixing rails. A drive device is connected outside each supporting seat, each drive device is connected with a coupling, the other end of each coupling is connected with a reelpipe, and the outer side of each reelpipe is fixedly provided with the corresponding curtain body. The integrally lifting type curtain is simple in structure, convenient to operate, proper to store and not prone to being damaged; even strong wind blows, sun shielding and wind blocking can be well achieved, and the living conditions required by living pigs are met.

Owner:云南东恒经贸集团猪育种有限公司

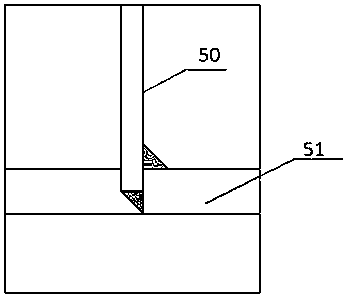

Narrow rock wall crane beam excavation method

InactiveCN111236240AImprove molding qualityPrevent tear damageArtificial islandsLoad-engaging girdersStructural engineeringDrill hole

The invention discloses a narrow rock wall crane beam excavation method. The method comprises the steps that after excavation of a cavern top layer is completed, excavation of a cavern rock wall cranebeam layer is conducted in a partitioned mode from the middle to the two sides; firstly, a middle groove area is excavated, protective layers on the two sides are stripped at a time, and after supporting is completed, pre-splitting blasting excavation is conducted on inclined face holes of a rock table, and blasting holes are drilled and blasted from a side wall of a cavern along a designed inclined face of the rock table and perpendicular to the trend axis of the cavern for drilling hole blasting; and then horizontal smooth blasting of a straight side wall on the rock table is conducted, andthe blasting holes are horizontally drilled and blasted in the direction parallel to the excavation direction of the cavern for horizontal drilling hole blasting. According to the narrow rock wall crane beam excavation method, pre-splitting blasting is carried out on the inclined surface in advance, inclined surface cracks and turning points of a rock wall crane beam are formed in advance, the situation that horizontal smooth blasting must be adopted to tear and damage a rock mass when side wall vertical smooth blasting cannot be implemented can be avoided, rock table forming quality is improved, and meanwhile rock table rock mass quality is improved; and in addition, vertical holes and inclined holes do not need to be aligned one by one, and only the depth needs to be strictly controlled, so that the workload of surveying, setting-out and checking is reduced.

Owner:中国水利水电第七工程局有限公司

Implanting instrument with bionic micro-thorn attachment structures

PendingCN112022260AReduce retraction and release resistanceImprove fatigue durabilityStentsOcculdersClassical mechanicsStructural engineering

The invention relates to an implanting instrument with bionic micro-thorn attachment structures. The implanting instrument at least comprises an attachment frame, wherein the attachment frame is a self-expanding type support or a ball-expanding type support and comprises a plurality of frameworks and a plurality of bionic micro-thorn attachment structures; the bionic micro-thorn attachment structures are arranged on the outer surfaces of the frameworks; the bionic micro-thorn attachment structures are in the form of bionic plant surface sparse micro-thorns; each bionic micro-thorn attachment structure comprises a thorn root and a micro-thorn; each micro-thorn is composed of a thorn body and a thorn tip; each micro-thorn is linear or J-shaped or the combination of the linear micro-thorn andthe J-shaped micro-thorn; and the thorn bodies and / or the thorn tips of the micro-thorns can touch cavity tissue to achieve an attachment type anchoring function. The implanting instrument is wide inapplication range, free of anchoring damage, firm and high in safety.

Owner:NINGBO DIOCHANGE MEDICAL TECH CO LTD

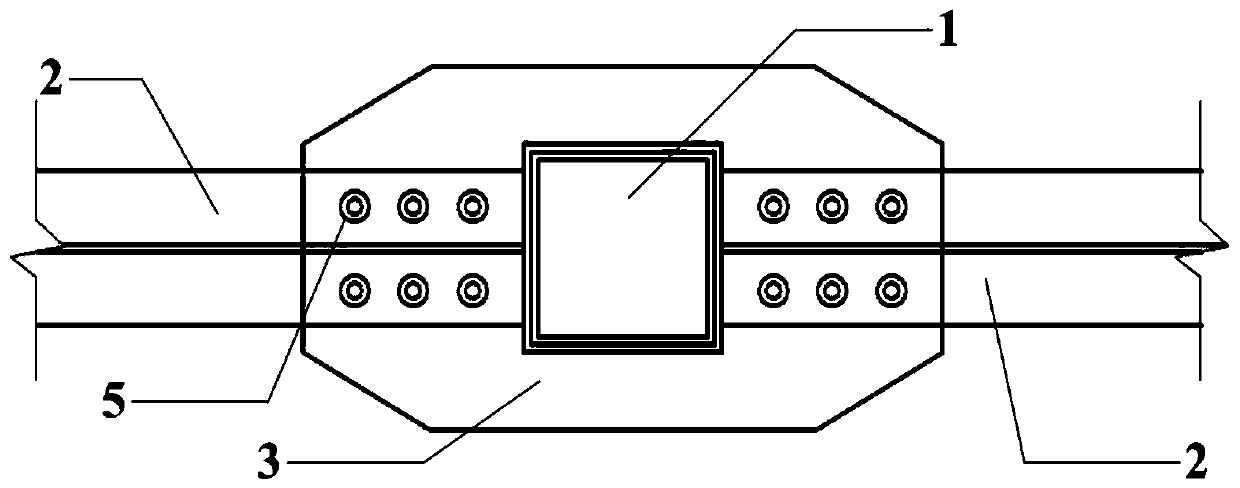

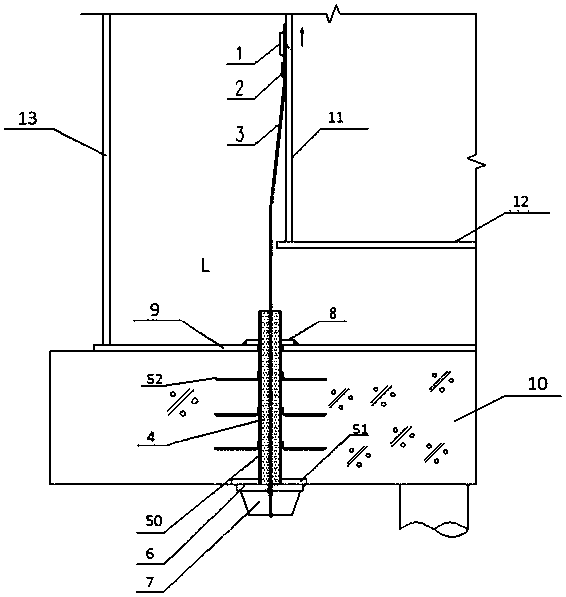

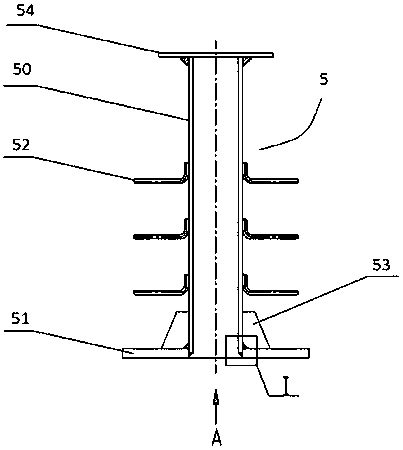

Square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint

InactiveCN111456235AIncrease the direct contact areaImprove distributionBuilding constructionsBoard structureSteel tube

The invention discloses a square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint. The square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint comprises a square steel tube, the square steel tube is sleeved with an upper outer ring sleeve plate and a lower outer ring sleeve plate, the upper outer ring sleeve plate comprises an upper short sleeve, an inner surface of the upper short sleeve is connected with the square steel tube, an outer surface of the upper short sleeve is connected with an upper outer ring plate, the lowerouter ring sleeve plate and the upper outer ring sleeve plate are of the same structure, the lower outer ring sleeve plate comprises a lower short sleeve and a lower outer ring plate, and a steel beam is connected between the upper outer ring sleeve plate and the lower outer ring sleeve plate. The distribution of a column wall yield line is expanded, the column wall rigidity of a joint domain isimproved, and the contribution of an outer ring plate to the joint bearing capacity under the action of external load is increased; the defect that the rigidity at the joint is insufficient due to thefact that an inner ring plate is not arranged is overcome; by adopting the method, the field operation amount is small, the steel structure construction efficiency is improved, the material utilization rate is increased, and good economic benefits and social benefits are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

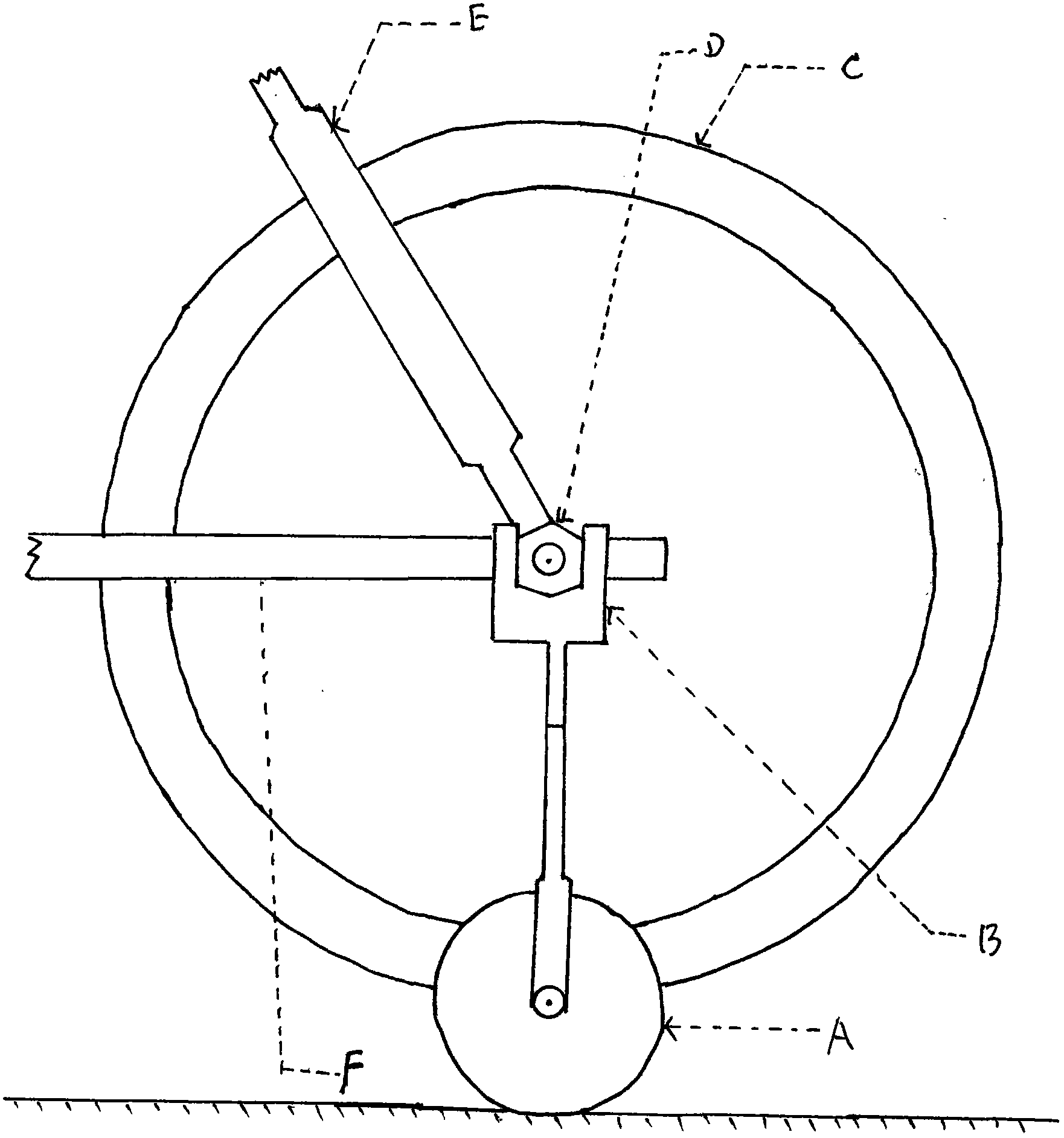

Sectional material side bending and rounding machine

The invention relates to a sectional material side bending and rounding machine. The sectional material side bending and rounding machine comprises a side plate, a top plate and a bottom plate, wherein one side of the top plate and one side of the bottom plate are connected with the upper end and the lower end of the side plate respectively, a first rotating shaft, a second rotating shaft and a rotating shaft driving device which is used for driving the first rotating shaft and the second rotating shaft to rotate are arranged between the top plate and the bottom plate, a first roller is arranged on the first rotating shaft, an annular first notch is formed in the middle of the first roller, a second roller is arranged on the second rotating shaft, an annular second notch is formed in the middle of the second roller, a U-shaped support and a pressing wheel movably arranged in the U-shaped support are further arranged between the top plate and the bottom plate, an annular third notch isformed in the middle of the pressing wheel, and a pressing wheel driving device used for driving the U-shaped support to move is arranged on the side plate. According to the machine, sectional materials with various arc degrees can be bent, moreover, the arc degree and the length size of a prepared product can be guaranteed, tearing damage to the sectional materials can be avoided, and the qualityof the product is ensured.

Owner:张家港市文锋机械有限公司

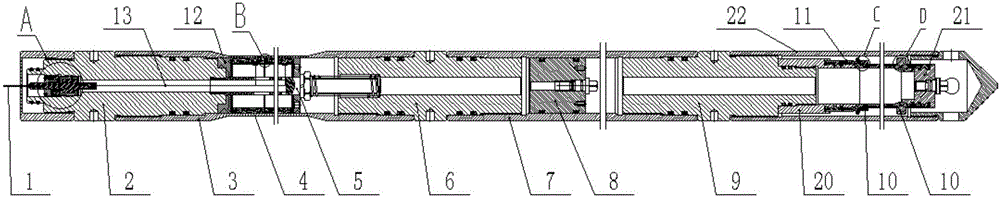

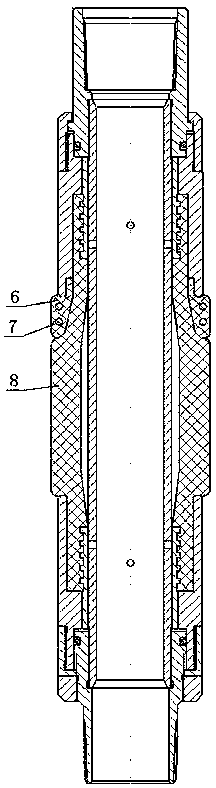

Ultrasonic variable-frequency blockage removing, oil outlet increasing and injection increasing device

ActiveCN106246139AIncrease the effective radius of actionReduce acoustic lossCleaning apparatusElectricityCopper

The invention belongs to the technical field of oil production, and particularly relates to an ultrasonic variable-frequency blockage removing, oil outlet increasing and injection increasing device. The ultrasonic variable-frequency blockage removing, oil outlet increasing and injection increasing device comprises a cable, a cable connecting body, a protection cylinder, piezoelectric ceramic and a pressure balance rubber cylinder and further comprises a sealing piston. The cable is connected to the upper side of the cable connecting body through a cable connector assembly. The protection cylinder is fixedly connected to the outer side of the lower end of the cable connecting body. The piezoelectric ceramic is pre-tightened and fixed to the inner side of the protection cylinder through a gland, and copper skin is attached to the inner wall of the piezoelectric ceramic and connected with the cable through a wire and the cable connector assembly, so that power supply is achieved. A wire passing pipe is mounted in the center of the lower end of the cable connector body. The wire penetrates through the center of the wire passing pipe and a wire passing hole in the pipe wall of the wire passing pipe. The sealing piston is mounted in a piston sleeve and can slide in the piston sleeve, and the piston sleeve is connected to the lower end of the protection cylinder through a middle connecting body. The pressure balance rubber cylinder is of a cylindrical structure with the two ends being open.

Owner:HEILONGJIANG EAIEN NEW MATERIAL TECH DEV CO LTD

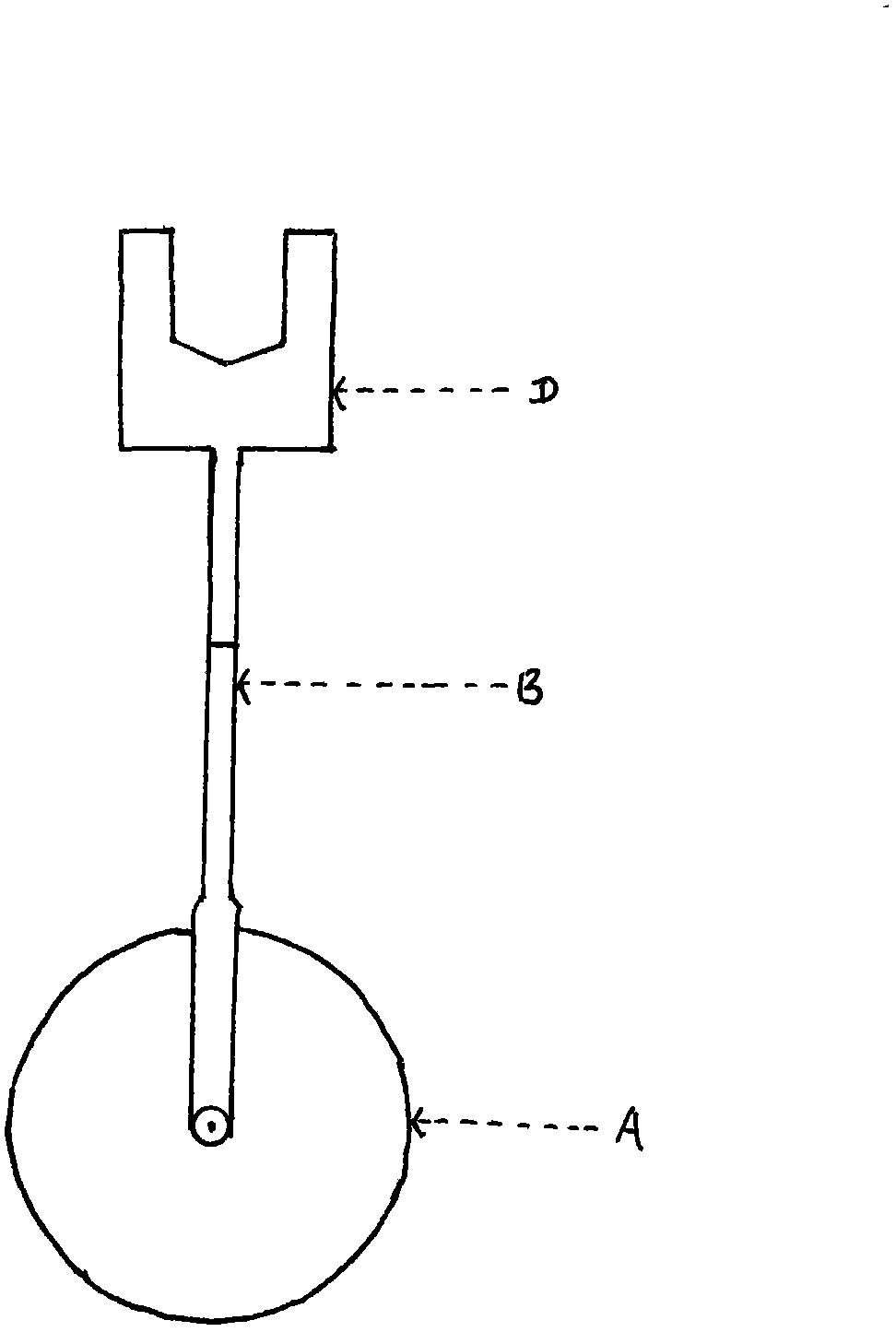

Expansion type water injection packer with shoulder pad sleeve on upper part of rubber barrel

PendingCN111075387AIncrease the lengthReduce stress concentrationFluid removalSealing/packingComposite materialMechanical engineering

The invention discloses an expansion type water injection packer with a shoulder pad sleeve on upper part of a rubber barrel. The water injection packer comprises a central tube and a rubber barrel assembly sleeved on the outer wall of the central tube, a radially penetrating pressure transmission hole is formed in the central tube, the rubber barrel assembly comprises an upper rubber barrel section, a middle rubber barrel section and a lower rubber barrel section, wherein the outer diameter of the middle rubber barrel section is larger than the outer diameter of the upper rubber barrel section, meanwhile, the outer diameter of the middle rubber barrel section is larger than the outer diameter of the lower rubber barrel section, an upper shoulder platform is formed at the joint of the middle rubber barrel section and the upper rubber barrel section, a lower shoulder platform is formed at the joint of the middle rubber barrel section and the lower rubber barrel section, the shoulder padsleeve is sleeved on the outer wall of the upper rubber barrel section, and the lower end of the shoulder pad sleeve resists on the upper shoulder platform. According to the invention, the shoulder protection of the rubber barrel is increased; when the expansion type packer is sealed, the shoulder pad sleeve can be driven to expand, so that the stress concentration on the shoulder of the rubber barrel is reduced, the service life of the packer can be prolonged, and the benefits of oil field layered water injection and oil extraction are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

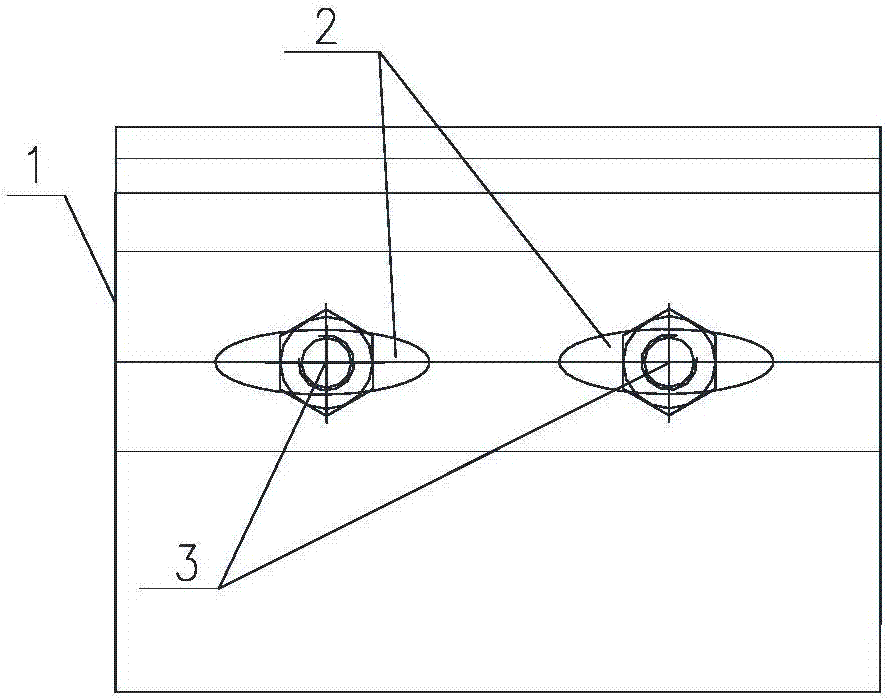

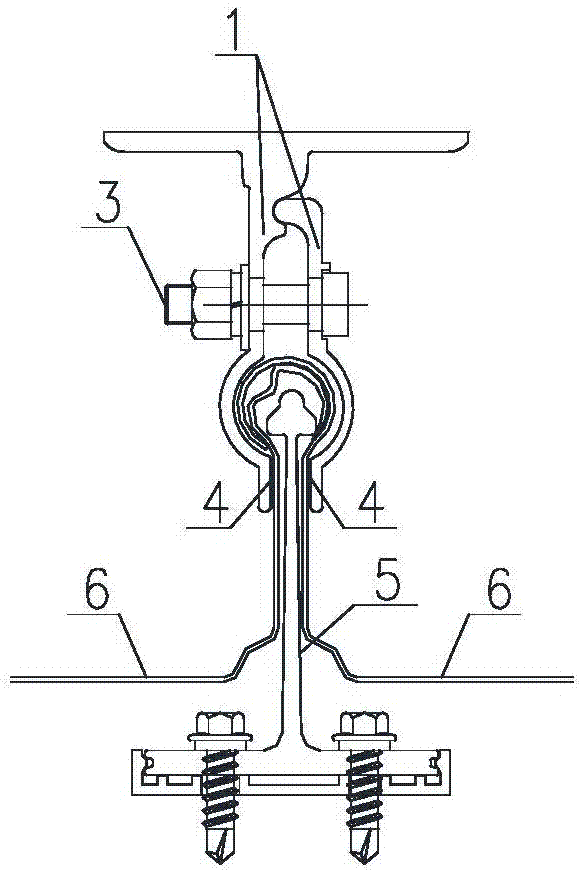

Wind resistant clamp allowing upright lockrand roofing boards to move longitudinally

PendingCN106939673APrevent tear damageAnti-wind effectRoof covering using slabs/sheetsBuilding constructionAerospace engineering

The invention discloses a wind resistant clamp allowing upright lockrand roofing boards to move longitudinally. The wind resistant clamp comprises two fixing clamp pieces. Bolt holes are formed in the upper portions of the two fixing clamp pieces; locking bolts are mounted in the bolt holes correspondingly in a penetrating mode; a tong opening is formed in the lower portion of the two fixing clamp pieces; elastic gaskets are fixed on the inner sides of the lower portions, corresponding to the tong opening, of the two fixing clamp pieces; and the bolt holes are long circular holes extending in the longitudinal direction of the upright lockrand roofing boards. By arranging the elastic gaskets at the tong opening, while the roofing boards of the upright lockrand roofing boards at lockrands are limited to open transversely to take the wind resistant effect, the roofing boards at the lockrands are allowed to slide longitudinally; and by adopting the long circular holes to serve as the bolt holes, the roofing boards at the lockrands can be staggered in the longitudinal direction. Therefore, longitudinal constraint force of the fixing clamp pieces to the upright lockrand roofing boards can be released, tearing and destroying of the roofing boards are avoided, and the wind resistant clamp can resist wind and prevent leakage, construction is convenient, and the economic effect is good.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING

Aseismic structure in double-shell low-temperature in-tank tank

ActiveCN108861170AAvoid the problem of low temperature damageAvoid lift-off damageLarge containersStructural engineering

The invention provides an aseismic structure in a double-shell low-temperature in-tank tank. The aseismic structure comprises an anchor belt box, a cover body and an anchor belt, wherein the anchor belt box is arranged in a bearing table foundation, the top end is exposed out of the upper surface of the bearing table foundation and penetrates through an outer tank base plate to be in sealed welding to the outer tank base plate, the cover body is exposed out of the lower surface of the bearing table foundation and seals the bottom end of the anchor belt box, the lower end of the anchor belt penetrates the anchor belt box to be connected with the cover body, and the upper end of the anchor belt is movably connected with an inner tank wall. According to the aseismic structure, the anchor beltpenetrates the anchor belt box in the concrete bearing table foundation to be connected with the exposed cover body, the anchor belt is not in contact with the anchor belt box and is not in contact with the outer tank base plate, and the problem of low-temperature damage of the outer tank and the bearing table foundation due to the fact that cold of a low-temperature inner tank is transmitted toan outer tank and the bearing table foundation is solved; tearing force damage caused by the anchor belt to the outer tank base plate during an earthquake is avoided; the inner tank wall is movably connected to the upper end of the anchor belt, additional tension generated by the anchor belt to the inner tank wall can be avoided, the low-temperature inner tank is fixed during the earthquake, the earthquake force of a tank body is directly transmitted to a pressure bearing platform, and lift-off damage is prevented from being generated on the low-temperature inner tank during the earthquake.

Owner:SINOPEC ENG +1

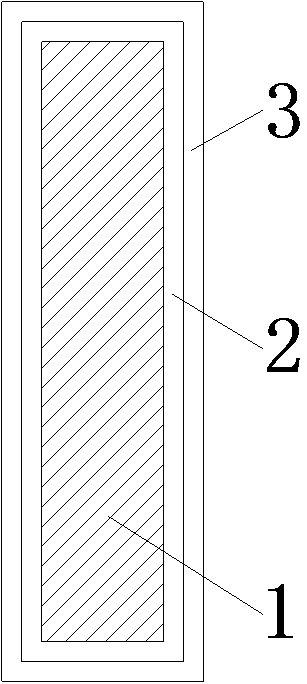

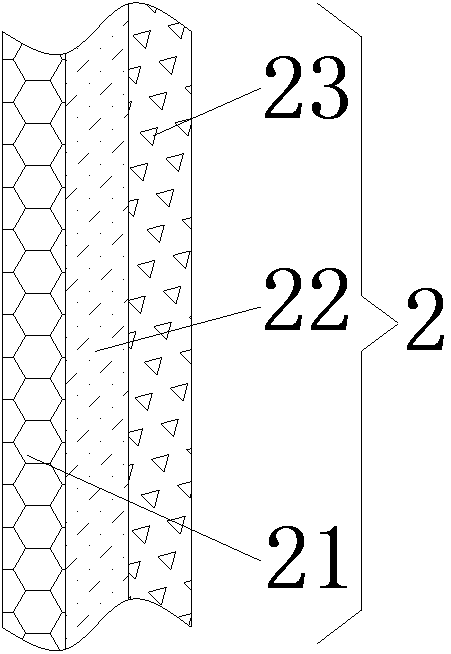

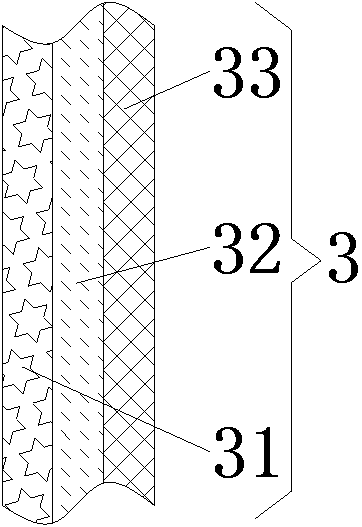

Fabric with good wear-resisting effect

InactiveCN111559147AImprove wear resistanceImprove tear resistanceSynthetic resin layered productsGlass/slag layered productsPolyesterGlass fiber

The invention discloses a fabric with good wear-resisting effect. The fabric with the good wear-resisting effect comprises a fabric body, wherein an anti-breakage layer is arranged on the surface of the fabric body, and a wear-resisting layer is arranged on the surface of the anti-breakage layer; the anti-breakage layer comprises a nylon fiber layer; a carbon fiber layer is connected to the surface of the nylon fiber layer in an interwoven mode; and a glass fiber layer is connected to the surface of the carbon fiber layer in an interwoven mode. According to the invention, the anti-breakage layer, the nylon fiber layer, the carbon fiber layer, the glass fiber layer, the wear-resisting layer, a polypropylene fiber layer, a vinylon fiber layer and a polyester fiber layer cooperate with each other, so the advantages of improved tear resistance and improved wear resistance of the fabric are achieved; when the anti-tearing fabric is used for a long time, the anti-tearing performance of the fabric can be effectively improved, and the fabric is prevented from being torn and damaged, so the service life of the fabric is prolonged; and the wear resistance of the fabric can be effectively improved, and the fabric is prevented from being rubbed and damaged, so the service life of the fabric is prolonged.

Owner:SUZHOU SENCHUANG TEXTILE TECH CO LTD

Anti-wind hair drier

The invention provides an anti-wind hair drier, belonging to the technical field of machinery, and aiming at solving the problems that the existing hair drier is easy to wind, low in safety and short in service life. The anti-wind hair drier comprises a housing with an air blowing passage, wherein the air blowing passage of the housing is internally provided with an electric motor, fan blades and an electric heating element; the fan blades are positioned at the inlet section of the air blowing passage and is fixedly connected with the rotating shaft of the electric motor; the inlet section of the air blowing passage is provided with a hair cutting knife capable of cutting the hair sucked in the air blowing passage; and the hair cutting knife is fixedly connected with the rotating shaft of the electric motor. The anti-wind hair drier is capable of cutting the hair sucked in the air blowing passage instantly so that the hair is prevented from being further sucked; and the anti-wind hair drier is good in safety, long in service life and good in comfortableness.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

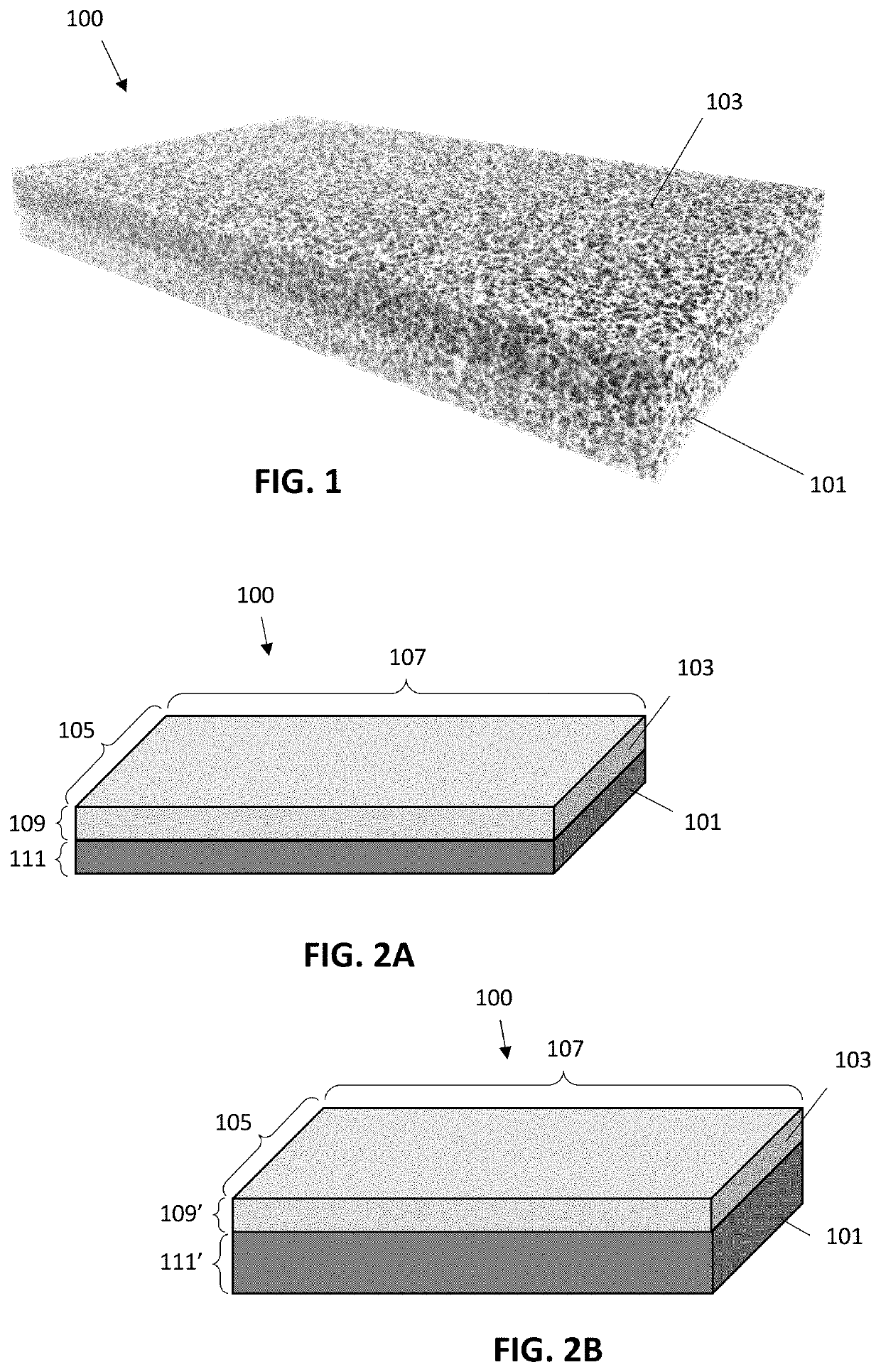

Connective tissue to bone interface scaffolds

ActiveUS10966816B1Avoid occlusionHigh porosityBone implantLigamentsConnective tissue fiberEngineering

Owner:SPARTA BIOPHARMA LLC

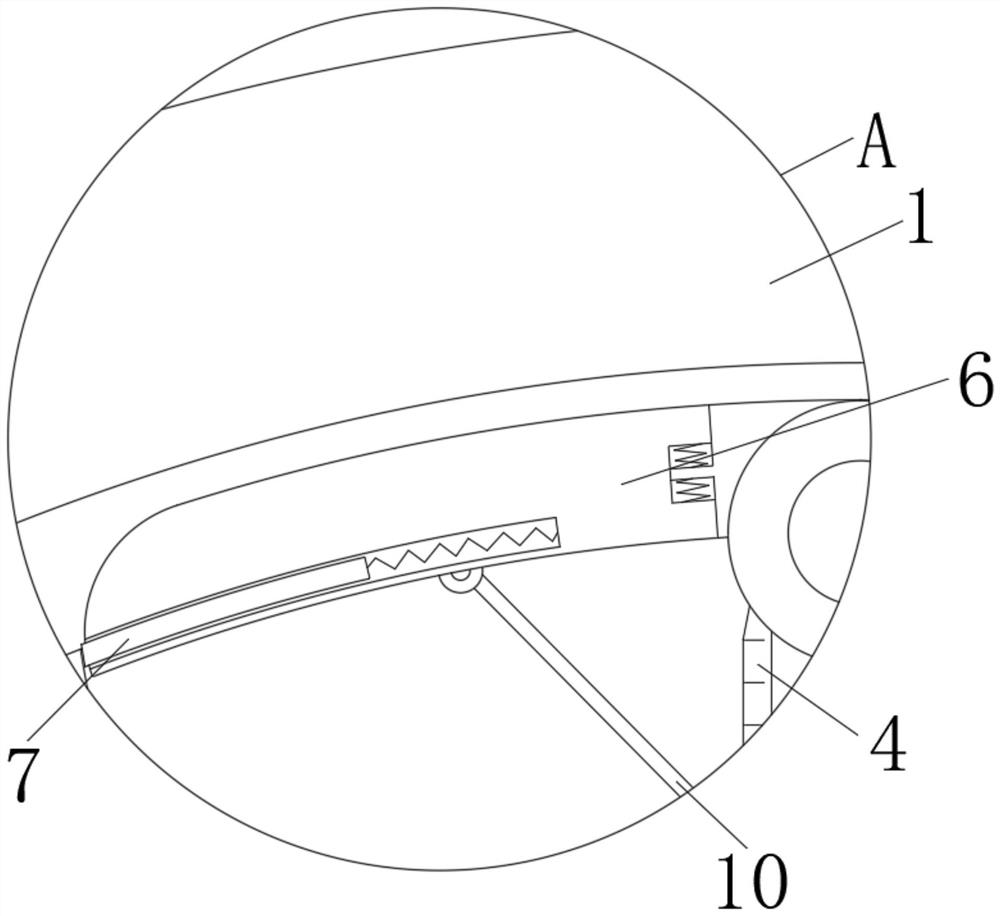

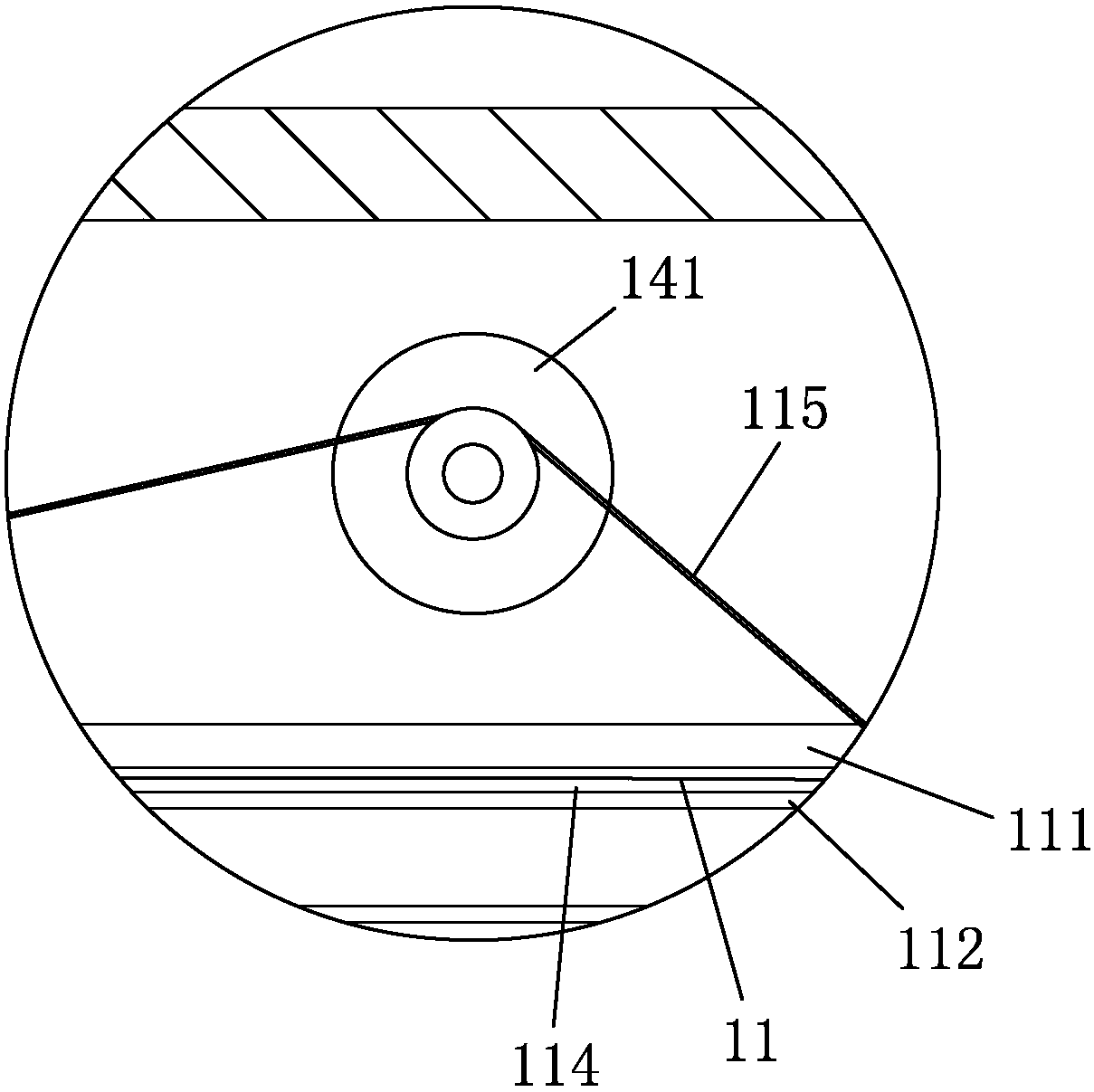

Roller mechanism capable of preventing belt from being torn and damaged

InactiveCN113998390APrevent tear damagePrevent slippingConveyorsRollersClassical mechanicsEngineering

The invention relates to the technical field of belt conveying, and discloses a roller mechanism capable of preventing a belt from being torn and damaged, the roller mechanism comprises the belt, and a roller is movably mounted on the inner side of the belt. Through the arrangement of telescopic rods and deflection plates, the belt makes contact with the roller, so that the belt exerts extrusion force on the deflection plates, then the telescopic rods are driven to inwards compress the large elastic pieces, the extruded deflection plates form protrusions on the surface of the roller, and the protrusions are attached to the belt all the time due to the elastic force of the large elastic pieces, so friction force between the roller and the belt is increased, and the belt is prevented from slipping and the working efficiency of the belt is prevented from being affected. Then, when the deflection plates are separated from the belt, the large elastic pieces drive the telescopic rods to reset, then the deflection plates are made to move outwards, the materials in the area are pushed into a collecting groove through the deflection plates moving outwards, the materials are prevented from entering the position between the roller and the belt for the second time, and meanwhile, the reset telescopic rods can drive the piston rod to reset, so that recycling of the device is achieved.

Owner:常赫男

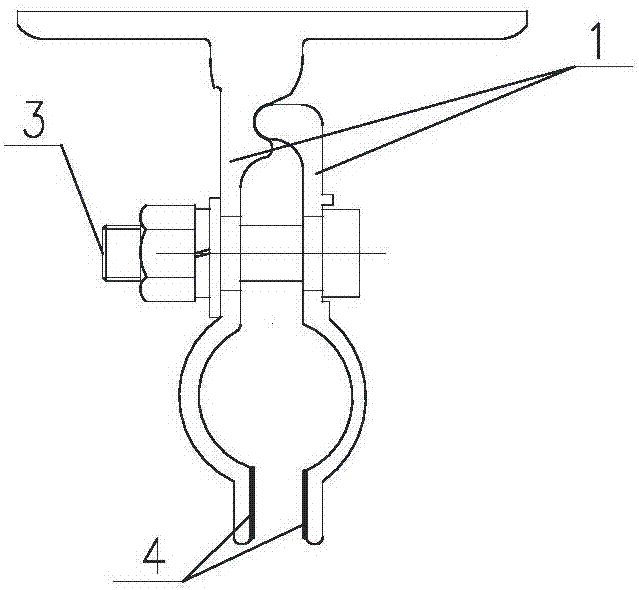

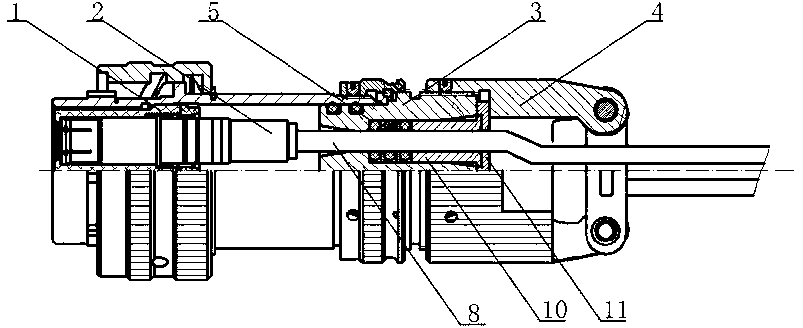

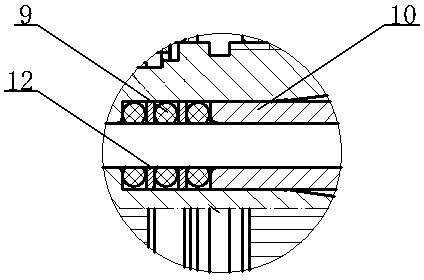

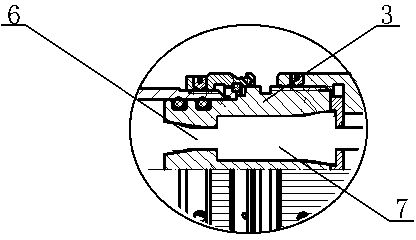

High-sealing-performance connector used for being connected with fluoroplastic wire

InactiveCN103346439APrevent tear damageImprove stabilityCouplings bases/casesStructural engineeringMechanical engineering

The invention relates to a high-sealing-performance connector used for being connected with a fluoroplastic wire. The connector comprises a connector plug, wherein the tail end of the connector plug is connected with a connector accessory connected with a nut in a screwing mode, the inside of the connector accessory is provided with a wire channel, the wire channel comprises a small-diameter portion and a large-diameter sealing portion, the fluoroplastic wire is arranged in the nut in a protruding mode, one end of the fluoroplastic wire penetrates through the wire channel to be inserted into a wire insertion position in the connector plug, an O-type ring is sleeved on the wire body, located in the large-diameter sealing portion, of the fluoroplastic wire, a sleeve is sleeved on the fluoroplastic wire between the O-type ring and the nut, and the nut squeezes the sleeve through a pressing plate. According to the high-sealing-performance connector, a traditional glue sealing processing method is changed, the O-type sealing ring is arranged in the wire channel, by means of squeezing force of the nut on the O-type sealing ring in screwing, the O-type ring fills a gap between the wire and a shell body, and accordingly high and stable sealing performance of the tail end of the connector connected with the fluoroplastic wire externally is achieved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

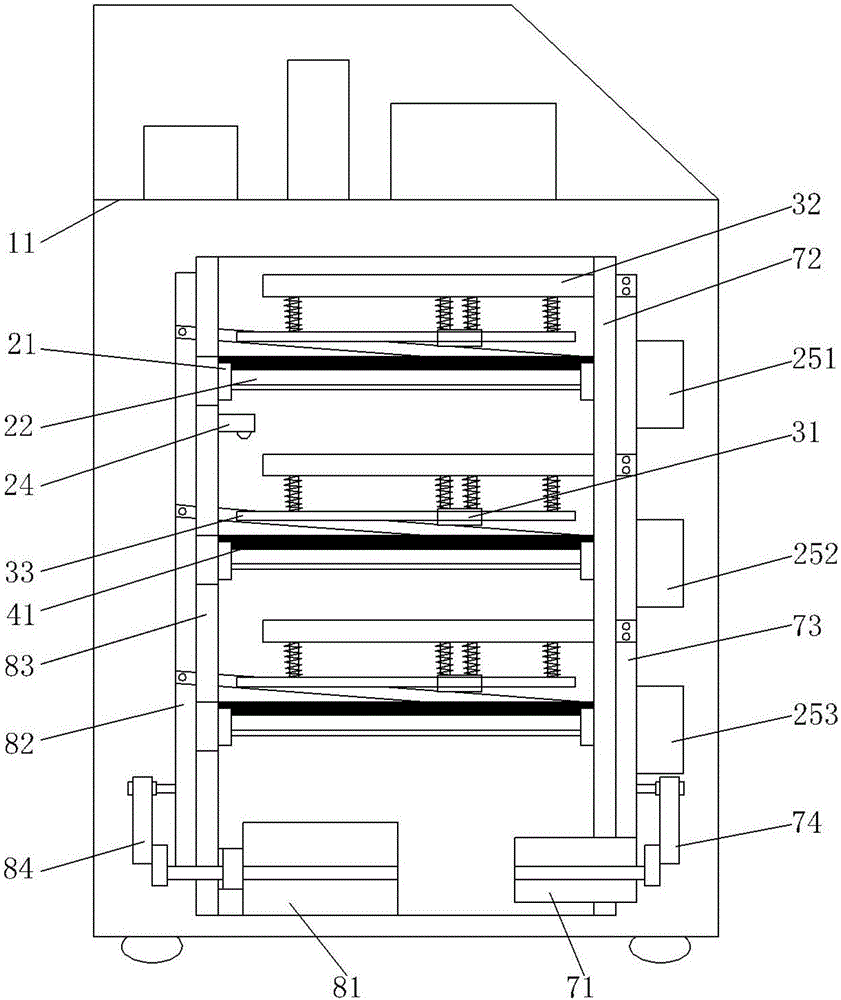

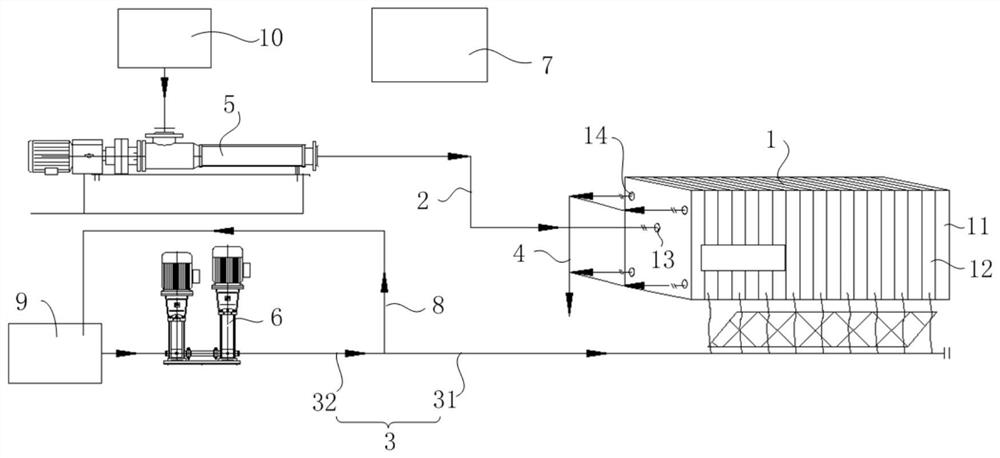

Diaphragm filter pressing equipment, diaphragm filter pressing system and diaphragm filter pressing method

PendingCN112174480AGuaranteed filter press effectReduce moisture contentSludge treatmentProcess engineeringEnvironmental geology

The invention relates to membrane filter pressing equipment, a membrane filter pressing system and a membrane filter pressing method. The membrane filter pressing equipment comprises a filter press, asludge inlet pipeline, a squeezing pipeline and a water outlet pipeline,a filter pressing cavity of the filter press comprises a sludge inlet, a water outlet, a plurality of van-type plates and diaphragm plates, the van-type plates and the diaphragm plates are sequentially arranged at intervals in a staggered mode, a filtering cavity is formed between the adjacent van-type plates and diaphragm plates, and the filtering cavity is communicated with the sludge inlet and provided with a water filtering hole communicated with the water outlet. The sludge inlet pipeline is communicated with the sludge inlet and can be used for introducing sludge into the filtering cavity, the sludge inlet pipeline is provided with a first flow control part, the water outlet pipeline is communicated with the water outlet, the diaphragm plate comprises a diaphragm cavity and a diaphragm arranged on the side wall of the diaphragm cavity, the squeezing pipeline is communicated with the diaphragm cavity and canintroduce a squeezing medium into the diaphragm cavity, and the squeezing pipeline is provided with a second flow control part. The sludge filter pressing effect can be guaranteed, the water content of a filter cake is reduced, meanwhile, the situation that a membrane is torn and damaged due to excessive stretching is avoided, and the cost is reduced.

Owner:深圳包清天环保有限公司

Red-skin peanut peeling device for agricultural production

InactiveCN111358015AImprove buffering effectAvoid damageHuskingHullingMechanical engineeringHorticulture

The invention belongs to the technical field of peeling devices and particularly discloses a red-skin peanut peeling device for agricultural production. For the problems that a peeling device in a patent is poor in peeling effect, pulp of a peanut is easily damaged in a peeling process and the peeling efficiency is low, now a scheme is proposed as follows: the red-skin peanut peeling device comprises a base, wherein a support post is fixed at one side of an outer wall at the top of the base through screws; a shell is arranged on an outer wall at one end, far away from the base, of the supportpost; a same fixed block is fixed on inner walls at two sides of the shell through the screws; grooves are formed in the outer walls on the periphery of the fixed block; and a retraction cylinder is arranged on the inner wall of each groove. According to the red-skin peanut peeling device, peanut kernels can be peeled under the frictional force of outer drawer cloth and inner drawer cloth and thecommon action of barbs; in a kneading peeling process, springs can play a good buffer role, the damage to the peanut kernels caused by excessive extrusion force can be prevented; the peeling effect isgood; and the peeling quality and efficiency of the peanut kernels are significantly improved.

Owner:陈克勤

Smart stamping machine for electricity bills

ActiveCN106004134BRealize automatic continuous stampingImprove stamping efficiencyStampingStampingIndustrial engineering

The invention discloses an intelligent stamping machine for an electric charge invoice, and belongs to the technical field of automatic office equipment. The technical problem that an existing automatic stamping machine cannot automatically finish triplicate invoice stamping or triplicate invoice collecting is solved. The intelligent stamping machine for the electric charge invoice comprises an automatic invoice stamping machine and an invoice collecting device. The automatic invoice stamping machine comprises a first conveying mechanism used for conveying a first invoice sheet, a second conveying mechanism used for conveying a second invoice sheet, a third conveying mechanism used for conveying a third invoice sheet, a first drive mechanism used for driving the first conveying mechanism, the second conveying mechanism and the third conveying mechanism, a first control device used for controlling the first drive mechanism to intermittently run, and a stamping mechanism used for stamping the second invoice sheet and the third invoice sheet. The invoice collecting device comprises a fourth conveying mechanism used for conveying the first invoice sheet, and a fifth conveying mechanism used for conveying the second invoice sheet and the third invoice sheet.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +2

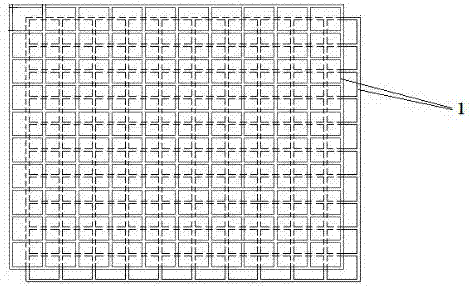

Staggered distribution plate type composite missile shielding structure

PendingCN108005453AImprove performanceEnhance penetration resistanceBuilding constructionsProtective buildings/sheltersHardnessEngineering

The invention belongs to the technical field of engineering protection and discloses a staggered distribution plate type steel-based composite missile shielding structure. The staggered distribution plate type steel-based composite missile shielding structure is of a plate type structure constituted in the mode that high-hardness core bodies are embedded into thin-wall box grid metal base bodies;a plurality of metal box grids on each layer are continuously arranged and distributed; the metal box grids on the upper layer and the lower layer are arranged and distributed in a staggered mode; thethin-wall metal box grids are overall of a vertical staggered distribution plate type structure formed by integral casting; the upper end faces of the thin-wall metal box grids on the upper layer areopen, and the lower end faces of the thin-wall metal box grids on the lower layer are open; each thin-wall metal box grid is internally provided with the corresponding high-hardness material servingas a missile-shielding structure filling core body; and the high-hardness materials and the staggered distribution metal box grids are bonded into a whole through adhesion agents to form the plate type composite structure. The staggered distribution plate type composite missile-shielding structure has the characteristics of being high in anti-impact force, good in impact toughness, excellent in performance, reliable, practical, convenient and rapid to construct, capable of resisting repeated strike, replaceable, easy to repair and the like.

Owner:UNIT 61489 OF PLA

Catheter with sleeve film capable of protecting tissue and preparation method and application thereof

The invention discloses a catheter with sleeve film capable of protecting tissue, a preparation method and application thereof. The material is composed of a catheter core and the sleeve film wrappedaround the outer portion of the catheter, wherein the sleeve film comprises an outer layer anti-adhesion layer and an inner layer lubricating layer, and the outer layer anti-adhesion layer and the inner layer lubricating layer are both made from a biomedical material. The catheter with the sleeve film capable of protecting the tissue and the preparation method and application thereof have the advantages that the outer layer anti-adhesion layer of the sleeve film is made from the water-soluble biomedical material, the outer layer can play an anti-adhesion role when the catheter is implanted into the body, and the inner layer material can exert a plasticizer function and a lubrication function after being dissolved by a tissue fluid, so that the tear damage caused by adhesion when tube taking can be reduced, the catheter is suitable for being used as a component material of the lacrimal duct intubation, and the anti-adhesion performance of an existing materials is improved.

Owner:GUANGZHOU YUEQING REGENERATION MEDICINE TECH CO LTD

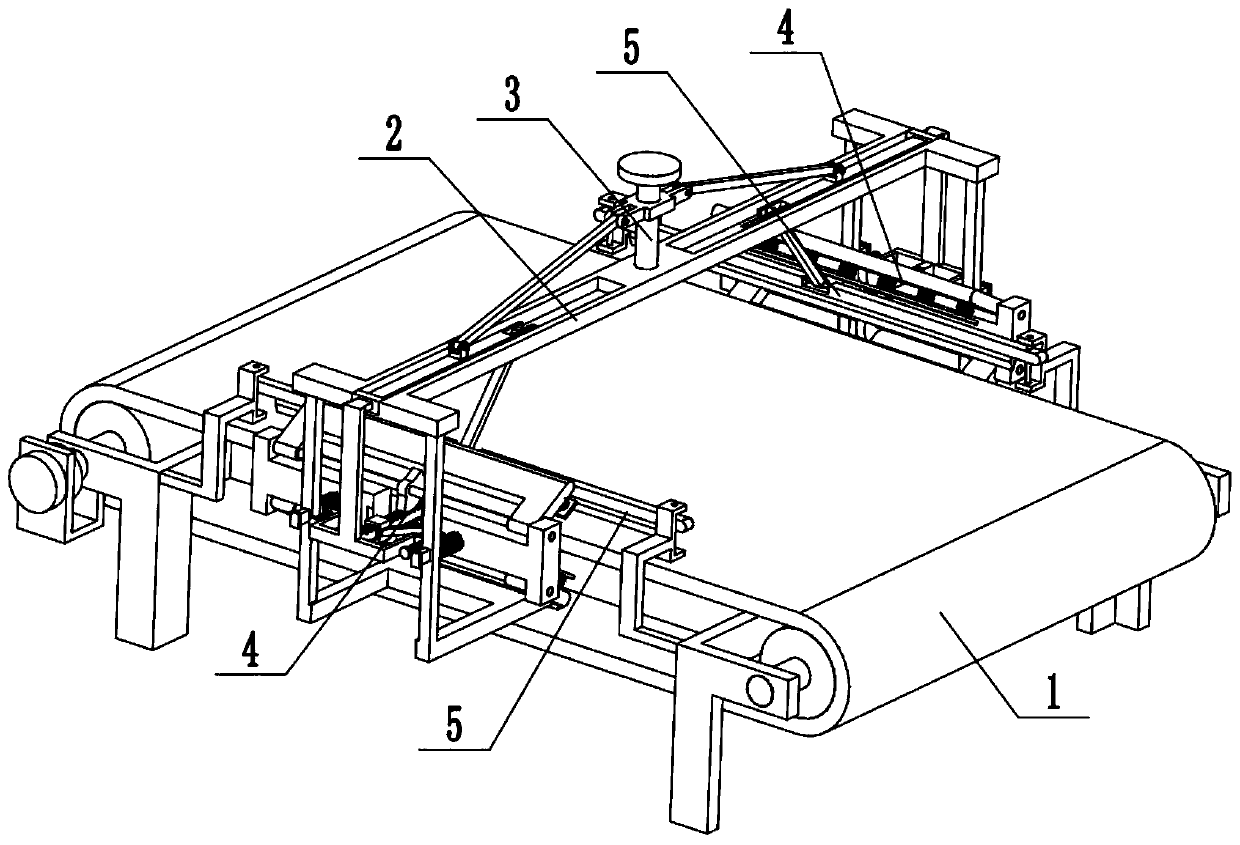

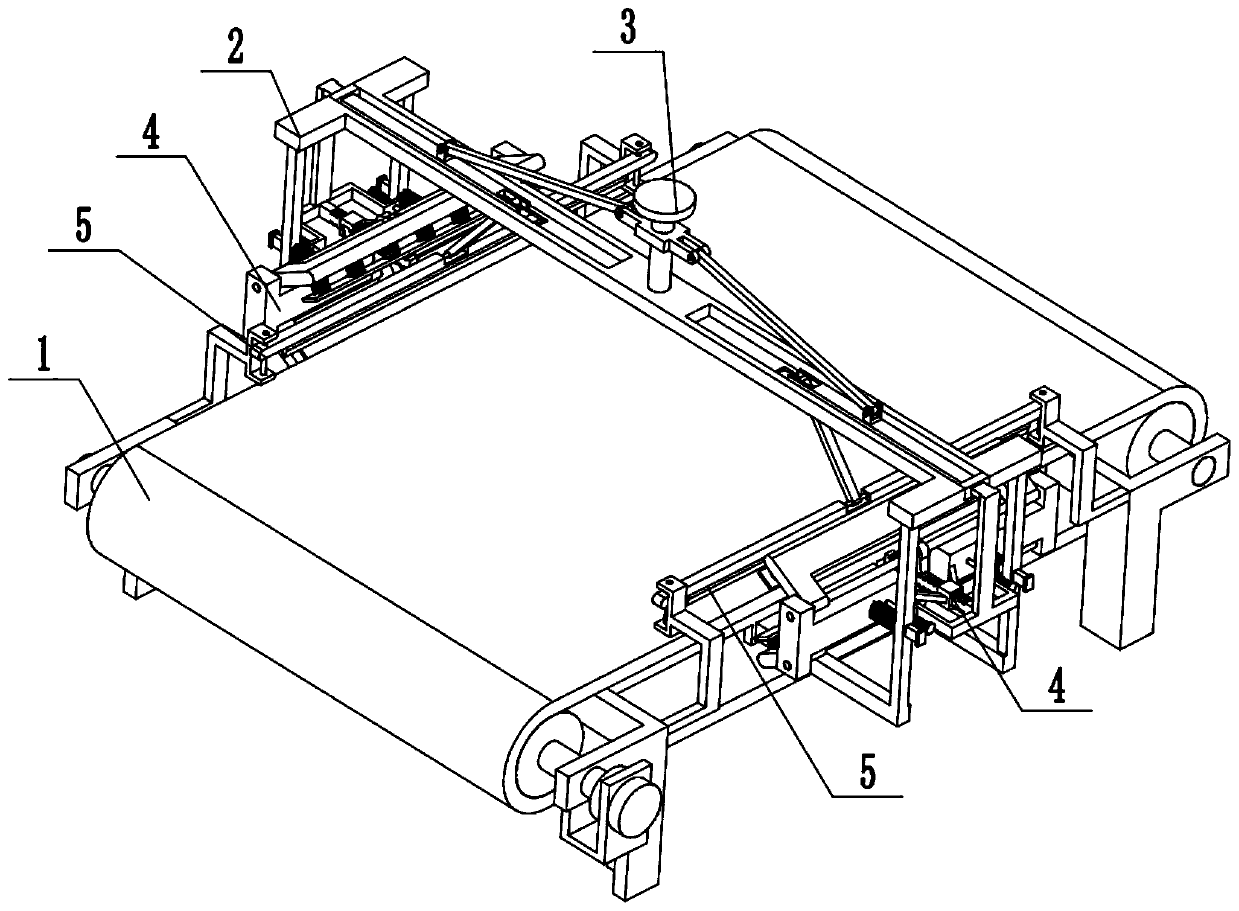

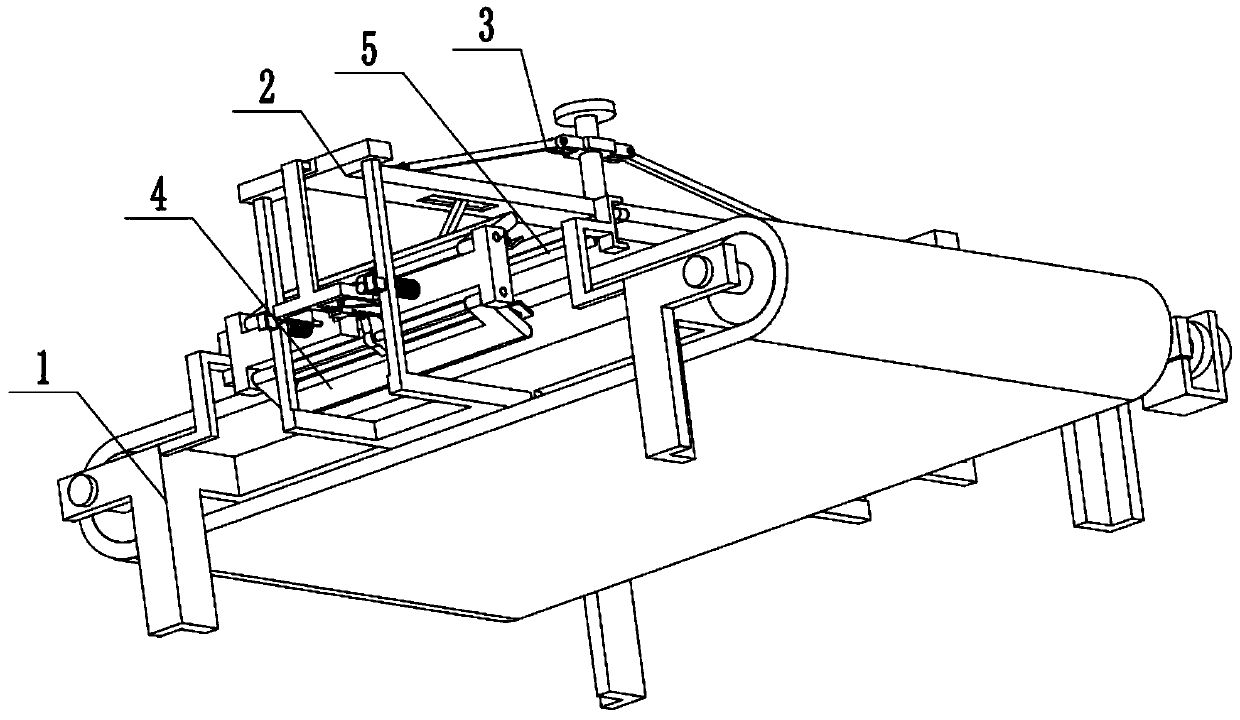

Greenhouse film stretching device

ActiveCN111037899APrevent tear damageEliminates the need to pick and place multiple filmsFlat articlesArticle deliveryThin membraneMechanical engineering

The invention discloses a greenhouse film stretching device and belongs to the technical field of film processing. The device comprises a film conveying mechanism, a supporting frame assembly, a stretching adjusting mechanism, grabbing mechanisms and edge cutting mechanisms. According to the greenhouse film stretching device of the invention, a film clamping mode is adopted, so that the phenomenonthat a film is unevenly pulled and stressed during stretching is avoided, the film is prevented from being damaged due to stress concentration; and the unstretched edge part of the film can be automatically cut off after the film is stretched. The supporting frame assembly is arranged on the film conveying mechanism. The stretching adjusting mechanism is connected with the supporting frame assembly in a matched mode. The number of the grabbing mechanisms is two. The two grabbing mechanisms are symmetrically arranged on the supporting frame assembly. The two grabbing mechanisms are both connected with the stretching adjusting mechanism. The number of edge cutting mechanisms is two. The two edge cutting mechanisms are symmetrically arranged on the film conveying mechanism. The two edge cutting mechanisms are both connected with the stretching adjusting mechanism in a matched mode. The stretching adjusting mechanism drives the two grabbing mechanisms to clamp a film, and meanwhile the stretching adjusting mechanism drives the two edge cutting mechanisms to cut the film.

Owner:恩施市来发塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com