High-sealing-performance connector used for being connected with fluoroplastic wire

A fluoroplastic and connector technology, which is used in the field of high-sealing connectors to achieve the effect of high-stability sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

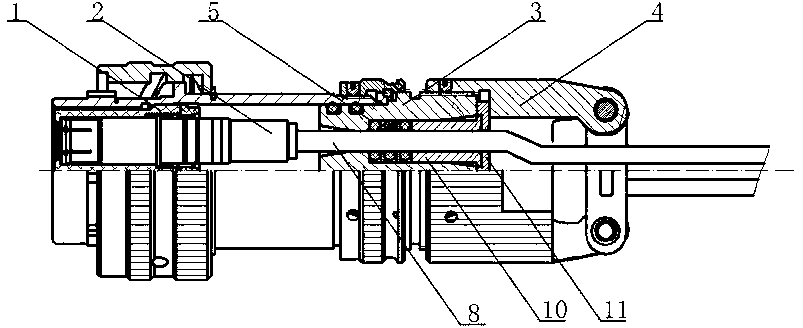

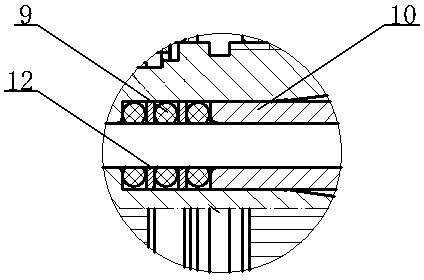

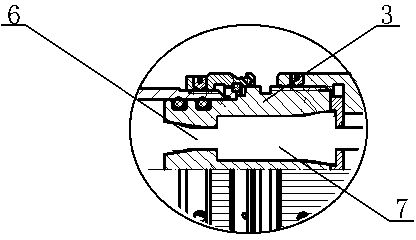

[0018] As shown in the figure, the high-seal connector used to connect fluoroplastic wires includes a connector plug 1 arranged in the housing. In the connector plug 1 of this embodiment, two wire insertion positions 2 are arranged in parallel. The plug-in position 2 is used for inserting the fluoroplastic wire 8 that needs to be connected externally. The tail end of the connector plug 1 is sealed and connected with a connector accessory 3. The connector accessory 3 is used for screwing connection with the nut 4. The connector accessory 3 The outer wall of one end of the housing protruding from the connector plug 1 is provided with external threads, the inner wall of the nut 4 is provided with internal threads, and the connector accessory 3 is screwed and connected with the nut 4 through the threads. Two wire passages 5, two wire passages 5 are arranged corresponding to the two wire insertion positions 2 respectively, and the two wire passages 5 are arranged on the axes of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com