Staggered distribution plate type composite missile shielding structure

A distributed plate and staggered-layer technology, applied in the field of staggered-layer distributed plate-type composite bullet-shielding structures, can solve problems such as difficulties in production and matching of bullet-shielding structures, reduction of effective penetration depth, and failure of incoming weapons to hit, so as to reduce the effective Penetration depth, reduced penetration depth, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

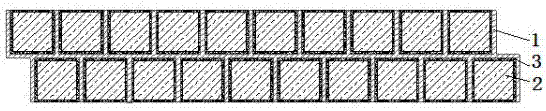

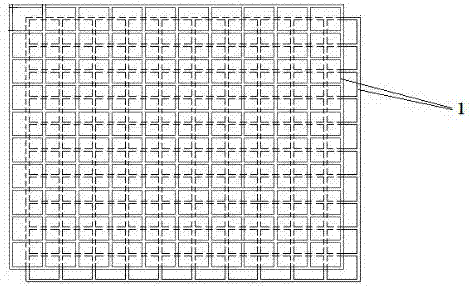

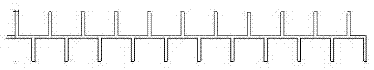

[0018] like figure 1 As shown, a kind of staggered distribution board type composite bomb shelter structure, the described composite bomb shelter structure has two layers of thin-walled metal boxes 1 arranged up and down; in this embodiment, the described staggered distribution of thin-walled steel base boxes is ZG45 cast carbon steel is poured by lost foam casting process; figure 2 , image 3 , the thin-walled metal box 1 on each layer is composed of a plurality of thin-walled metal box units arranged continuously; the size of each thin-walled metal box unit is 55×55×55 (mm), and the wall The thickness is 6mm; the plurality of thin-walled metal box cells in the upper layer are misplaced and interlaced with the plurality of thin-walled metal box cells in the lower layer; the opening direction of the plurality of thin-walled metal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com