Fabricated concrete column-steel beam energy dissipation type panel point connecting device

A concrete column and node connection technology, which is applied in the direction of architecture and building construction, can solve the problems of reducing the collapse resistance of structures, increasing the anti-seismic requirements of columns, and cracking floor slabs, so as to avoid bolt breakage, increase the damage threshold, and Effect of lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

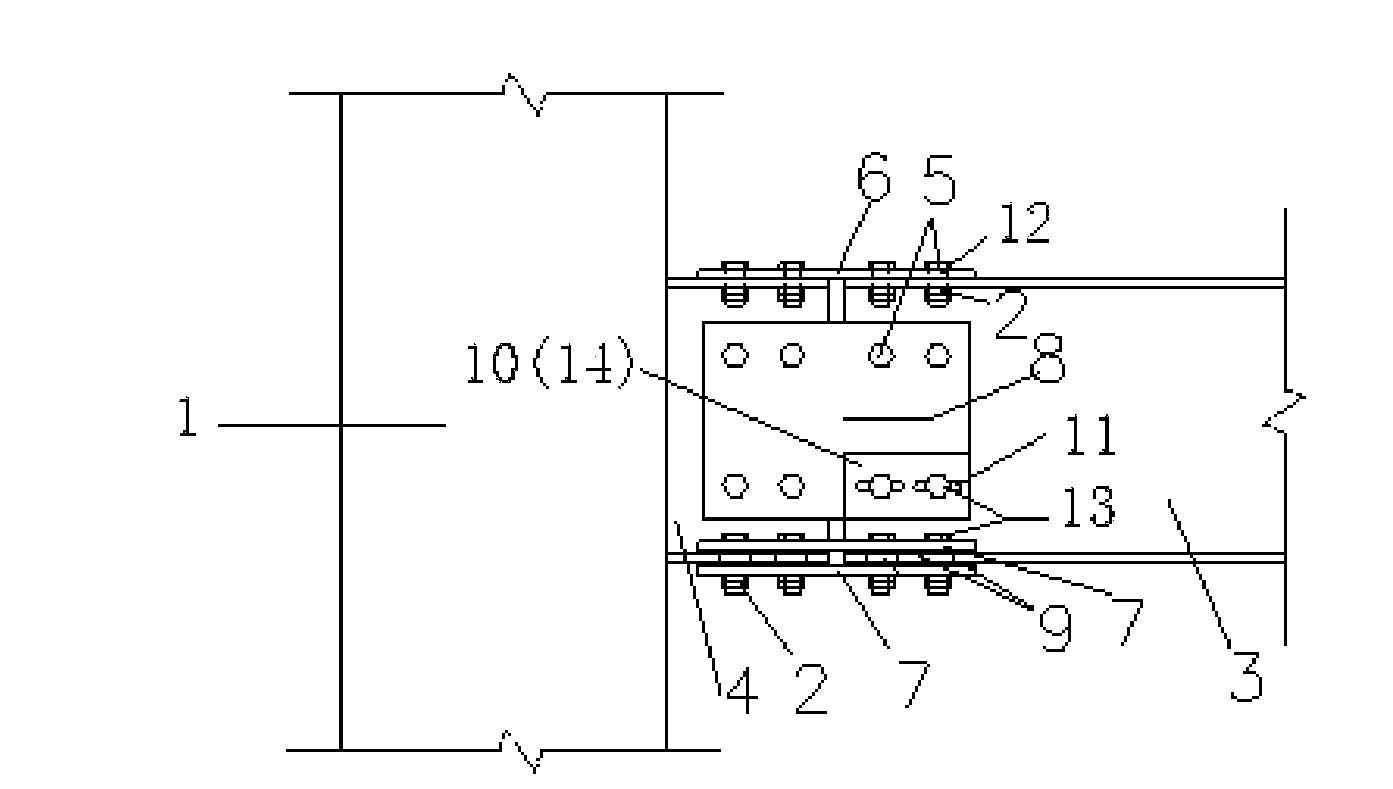

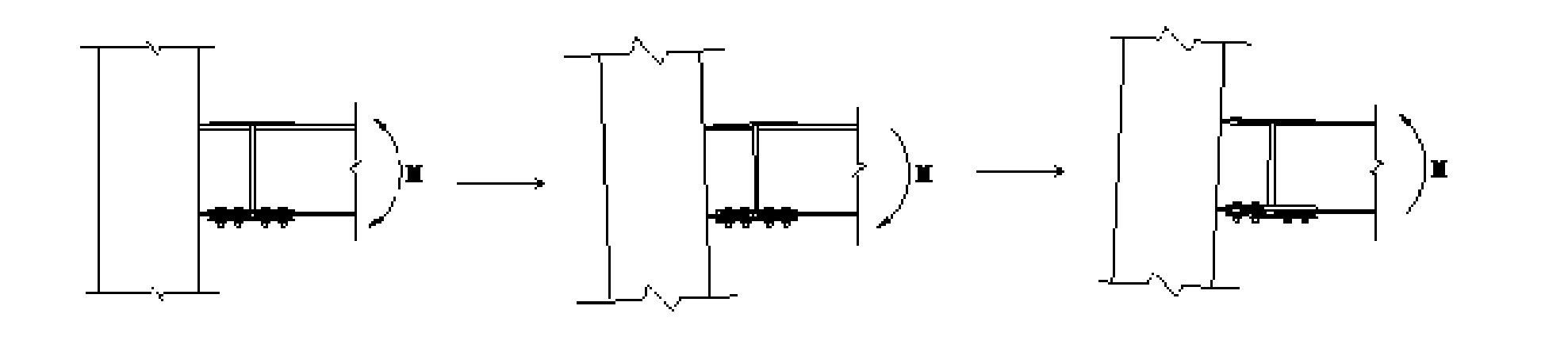

[0041] This embodiment is an asymmetrical frictional connection. Such as figure 1 In the connection form shown, the friction plate 9 is only set at the lower flange, and the web friction plate 14 is set at the web near the lower flange. The web is attached to the inner side of the cover plate 10 . When the joint is in normal use, it behaves as a rigid behavior. The connection between the beam and the column under the strong earthquake generates a relative rotation with the upper flange as the center of rotation through the sliding of the high-strength friction bolts 13 at the lower flange and the bottom of the web, as shown in figure 2 As shown, thereby reducing the impact on the floor. When the contact surface between the friction plate 9 and the lower flange of the steel beam and the web cover plate 8 slips, the seismic energy is dissipated through friction to form a slip hinge. By setting the gap at the beam end, the oblong hole 11 is opened to meet the requirements of ...

Embodiment 2

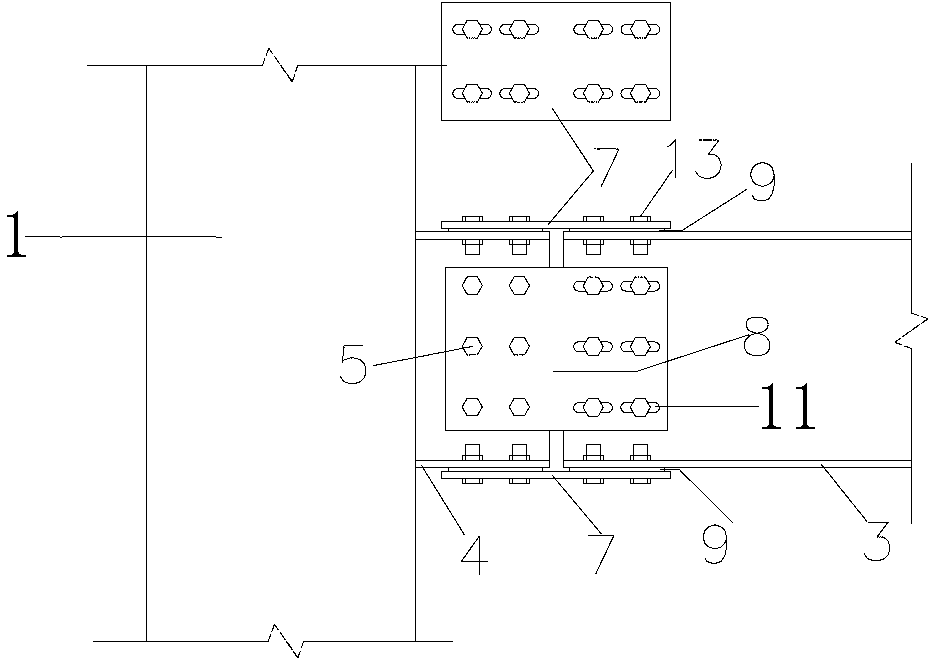

[0043] This embodiment is a symmetrical frictional connection. Such as image 3 As shown, the oblong hole connection cover plate 7 is arranged symmetrically on the upper and lower flanges, and the friction plate 9 is respectively arranged between the oblong hole connection cover plate 7 and the upper and lower flanges. The friction plate 9 is located on the inner side of the oblong hole connection cover plate 7, and the connection cover plate The bolt holes are all oblong holes 11, the bolt holes connecting the web cover plate 8 and the embedded steel beam 4 are opened as circular holes 12, and the bolt holes connecting the web cover plate and the intermediate steel beam 3 are opened as oblong Shaped hole 11.

Embodiment 3

[0045] This embodiment is a connection mode without friction plates. Such as Figure 4 As shown, round hole connecting cover plates 6 are arranged symmetrically on the upper and lower flanges, but there is no friction plate between the round hole connecting cover plate 6 and the flange, and there is no web additional cover plate 10 and web friction plate at the web. 14. Circular holes 12 are provided on the flange and the web, and are connected by high-strength bolts 5 to form a nearly rigid connection.

[0046] To sum up, the fabricated concrete column-steel beam energy-dissipating node connection device of the present invention is mainly composed of beam-beam bolt connection parts and a frictional energy-dissipating device. The invention aims to develop a connecting device matched with the full prefabricated assembly process, reduce the adverse effect on the floor, and improve the energy consumption capacity of the assembled structure. The prefabricated concrete column 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com