Test sample for tensile properties of large tow carbon fiber multifilament and sample preparation method thereof

A technology of tow carbon fiber and tensile properties, which is applied in the field of large tow carbon fiber multifilament tensile properties test specimens and sample preparation, can solve the problems of test result gap, tear damage, fiber tow slippage, etc. Achieve the effects of avoiding tear damage, increasing interface bonding force, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

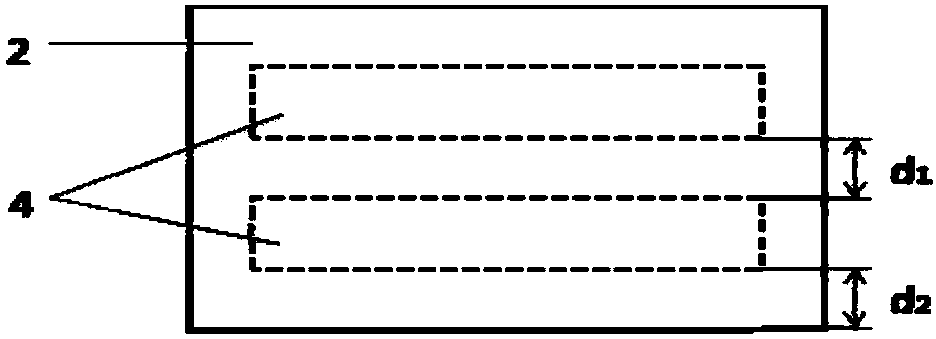

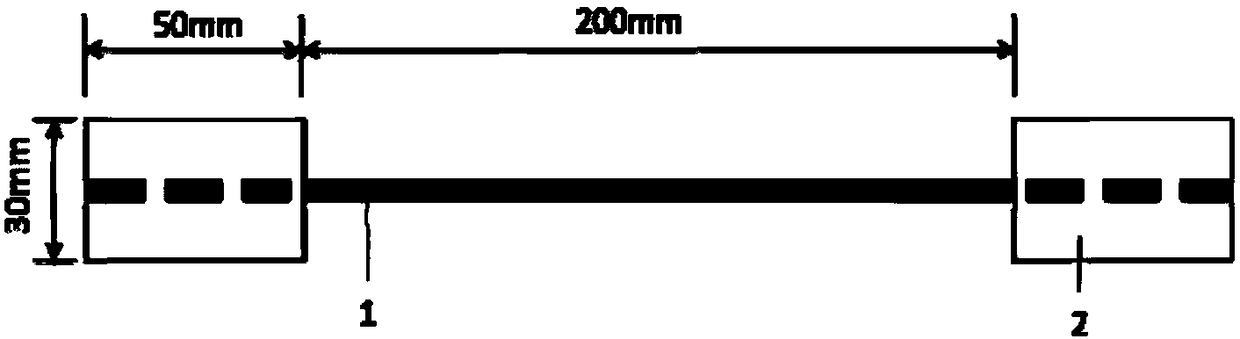

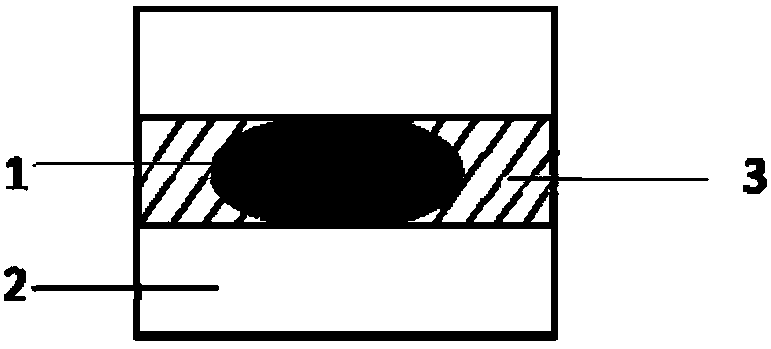

[0054] Use 5N tension to wind T700S-24K carbon fiber multifilament from Toray Corporation of Japan on the frame; add 100 parts by mass of diglycidyl phthalate, 50 parts by mass of tetrahydrophthalic anhydride and 0.5 parts by mass of N ,N-Dimethylbenzylamine, then add 100 parts of acetone and stir for 5 minutes, pour into the dipping tank; immerse the frame of the winding multifilament in the dipping tank for 1 minute, take it out and let it dry for 1 minute, then put it in the drum Dry and solidify in an air oven. The multifilament curing process is (140°C / 0.5h)+(180°C / 1.5h). After cooling, it is cut into a 30cm multifilament section. The two sections of the multifilament section are flat and about 5cm in length. , the middle part is cylindrical; a group of aluminum alloy reinforcing sheets (single sheet thickness 1mm) are attached to both ends of the multifilament section, and four layers of J-47A structural adhesive film (single sheet thickness 1mm) are attached to the upper...

Embodiment 2

[0056] Wind the X720S-36K carbon fiber multifilament of Toray Corporation of Japan on the frame with a tension of 10N; add 100 parts by mass of 3,4-epoxycyclohexyl 3',4'-epoxycyclohexyl methyl ester, 60 parts by mass to a 5L measuring cup Part of methyl nadic anhydride and 2 parts by mass of 2,4,6-tris(dimethylaminomethyl)phenol, then add 120 parts of toluene and stir for 5 minutes, pour into the dipping tank; immerse the frame of winding multifilament After 2 minutes of dipping, take it out of the dipping tank and let it dry for 2 minutes, then place it in a blast oven to dry and solidify. The multifilament curing process is (150°C / 1h)+(200°C / 3h). After cooling, it is cut into 30cm multifilament segments , the two sections of the multifilament section are flat, and the length is about 5cm, and the middle part is cylindrical; a group of aluminum alloy reinforcement sheets (single sheet thickness 3mm) are respectively attached to the two ends of the multifilament section, and th...

Embodiment 3

[0058] Use 10N tension to wind STS-48K carbon fiber multifilament of Japan Toho Co., Ltd. on the frame; add 100 parts by mass of 3,4-epoxycyclohexyl 3',4'-epoxycyclohexyl methyl ester, 100 parts by mass to a 5L measuring cup Parts of hexahydrophthalic anhydride and 3 parts by mass of 2-ethyl-4-methylimidazole, then add 150 parts of xylene and stir for 5 minutes, pour into the dipping tank; dip the frame of the winding multifilament into the dipping tank After 3 minutes, take it out and let it dry for 3 minutes, then place it in a blast oven to dry and solidify. The multifilament curing process is (150°C / 2h)+(200°C / 3h). After cooling, it is cut into 30cm multifilament segments. The two sections of the section are flat, and the length is about 5cm, and the middle part is cylindrical; a group of glass fiber reinforced plastic reinforcement sheets (single piece thickness 2mm) are respectively attached to the two ends of the multifilament section, and the upper and lower inner surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com