Narrow rock wall crane beam excavation method

A technology of crane beams and rock walls, which is applied in excavation, load hanging components, water conservancy projects, etc. It can solve problems such as difficult control of over and under excavation, inability to construct vertical holes in rock platforms, and difficulty in forming rock platforms, so as to reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0022] In conjunction with the accompanying drawings.

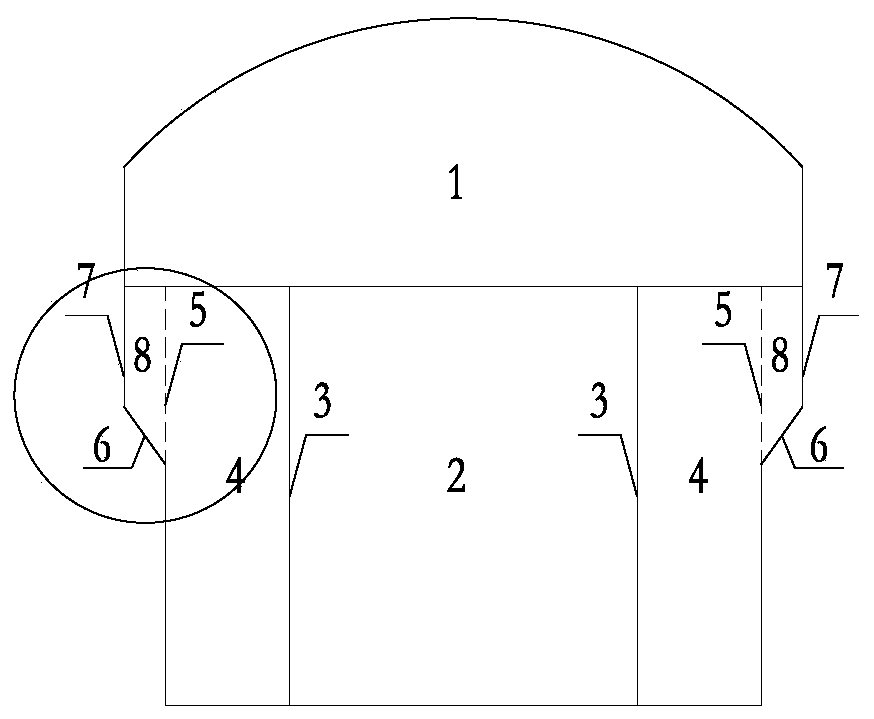

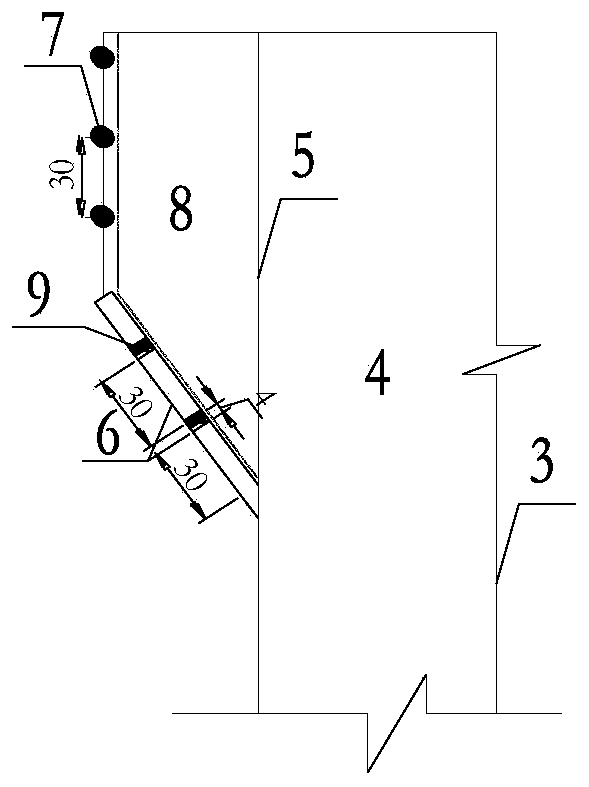

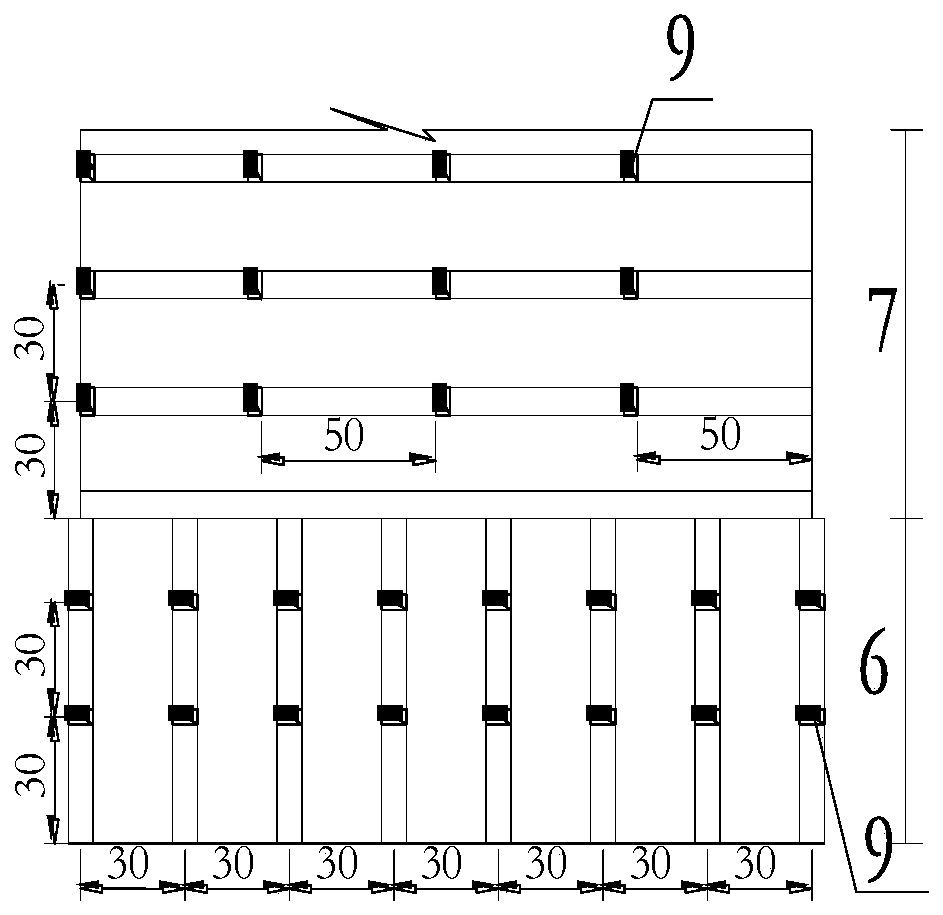

[0023] A method for excavating a crane beam on a narrow rock wall, comprising the following steps:

[0024] After the excavation of the top floor of the cavern is completed, the excavation of the crane beam layer on the rock wall of the cavern is carried out in layers and partitions from the middle to both sides;

[0025] First excavate the middle trench area, using deep hole pre-splitting blasting, the depth is generally 6-8m;

[0026] After the excavation of the middle tank area is completed, the protective layer of the side wall is excavated. Since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com