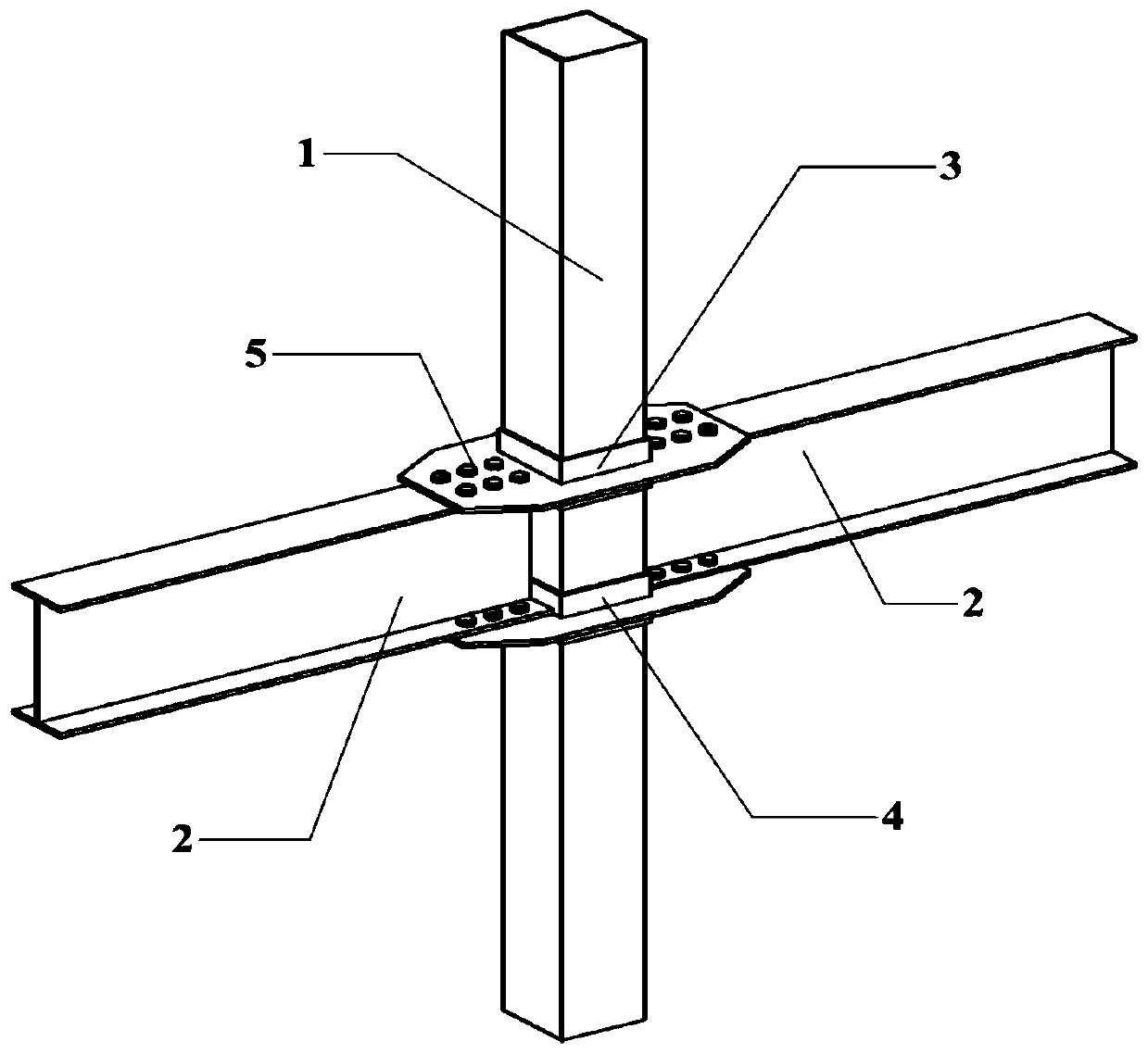

Square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint

A technology of concrete columns and connecting nodes, which is applied in the direction of construction and building construction, can solve the problems of small contact area between the ring plate and the column wall, and the difficulty of setting the inner ring plate, so as to increase the direct contact area, increase the thickness of the column wall, The effect of good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

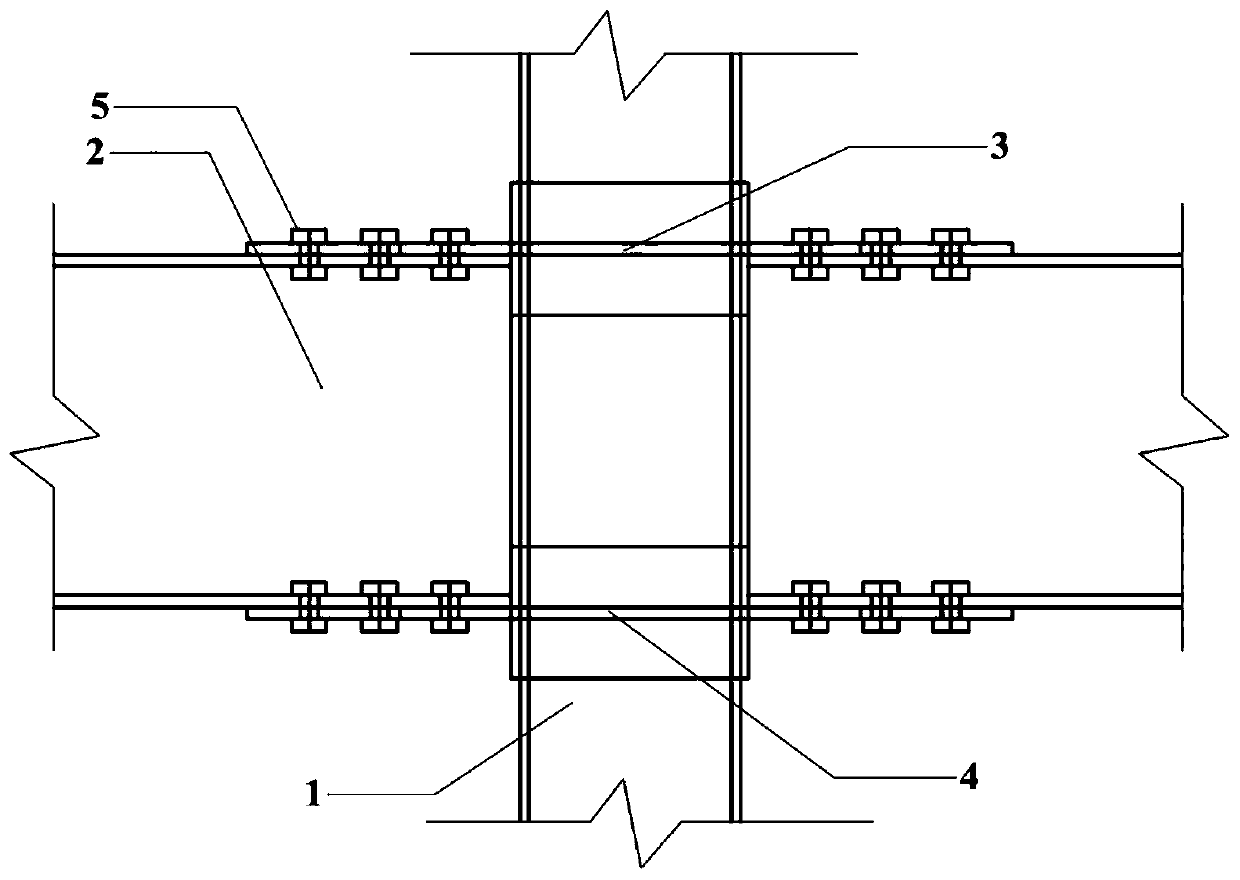

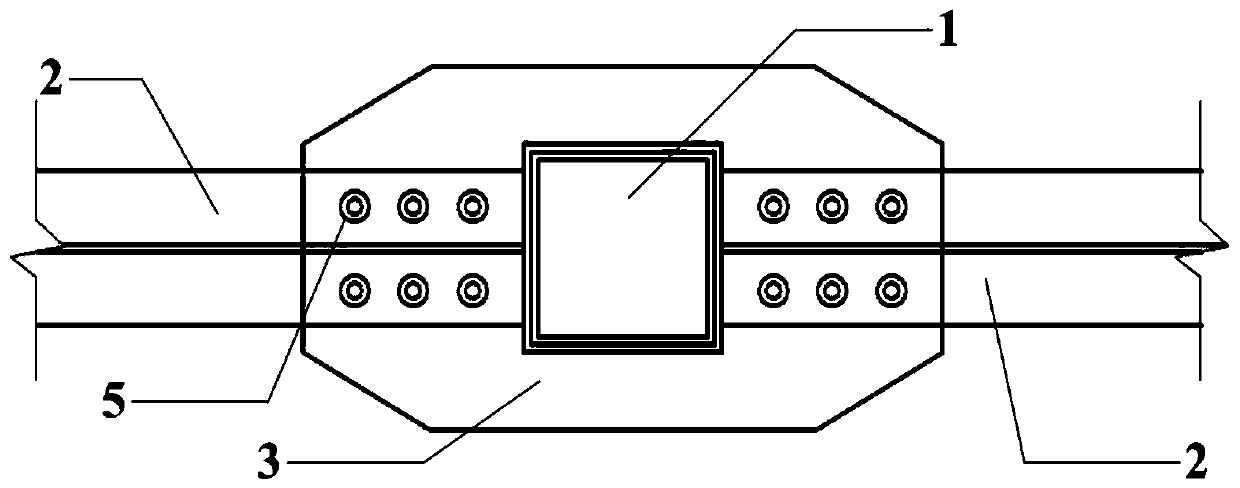

[0044] According to the size of the square steel pipe 1 and the size of the steel beam 2, the outer diameter side length and the inner diameter side length and the ring plate length of the upper short sleeve pipe 31 and the lower short sleeve pipe 41 are determined.

[0045] According to the size of the square steel pipe 1 and the size of the steel beam 2, the upper short casing 31, and the lower short casing 41, the inner diameters of the upper outer ring plate 32 and the lower outer ring plate 42, the minimum width of the ring plate, and the thickness of the ring plate are determined. The section flexural strength of beam 2 determines the number of bolt holes in the beam flange, the spacing and arrangement of bolt holes, and then determines the length of the ring plate.

[0046] The upper short casing 31 and the upper outer ring plate 32 are connected by surrounding welding on all sides to form the upper outer ring casing plate 3 .

[0047] The lower short casing 41 and the ...

Embodiment 2

[0054] The node shear bearing capacity of the present invention will be described below. (The following component dimensions are in mm)

[0055] In order to separately evaluate the effect of short casings on the shear capacity of joints, the square concrete-filled steel tube column-steel beam full-bolt outer ring plate joint without short casings is used as a comparison model to illustrate the mechanical properties of the new type of joints with short casings. Performance, using the finite element analysis software ABAQUS to conduct finite element analysis on the nodes.

[0056] The size of the joint without short casing is as follows: the joint column is a square section of 250×250 square section, the wall thickness is 10, and the height is 3000 square steel tube concrete column; Sectional steel; the length of the outer ring plate is 870, the width of the outer ring plate is 250, the thickness of the outer ring plate is the same as that of the beam flange, the size of the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com