Infrared vision based detection and alarm method for longitudinal adhesive tape tearing

A technology of longitudinal tearing and tape, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of tape damage, tape repair and replacement that consume a lot of manpower and financial resources, lack of real-time and accuracy, etc. Achieve the effect of avoiding tearing, reducing maintenance and replacement tape costs, and avoiding tear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

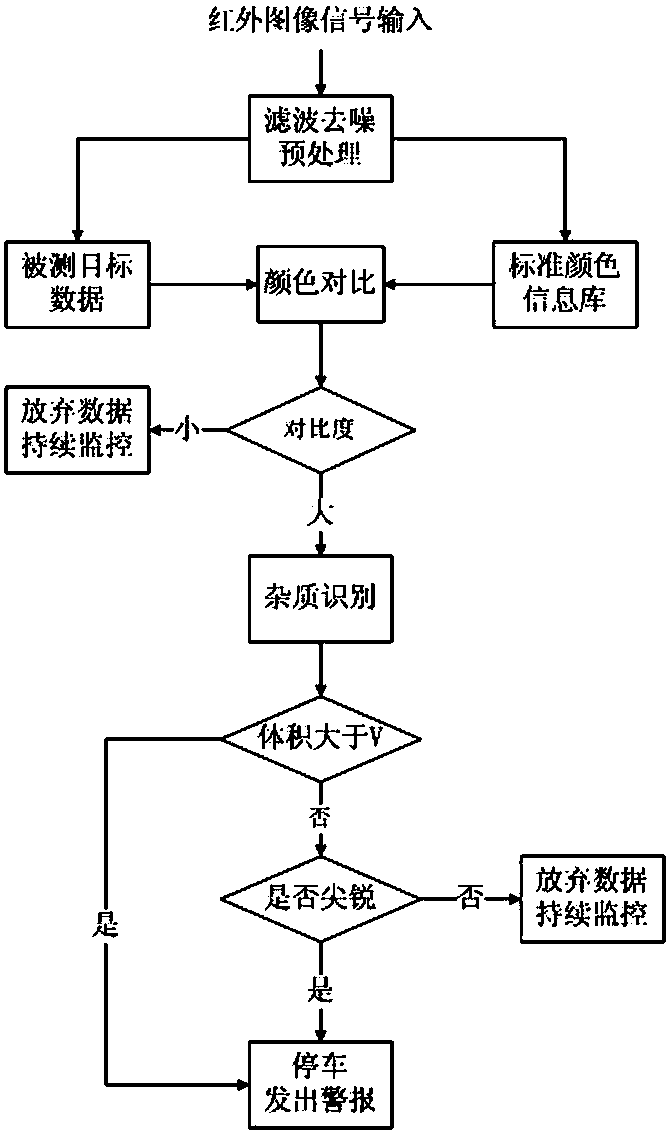

[0031] Such as figure 1 As shown, the infrared camera (German OPTRIS thermal imaging camera PI160+) is vertically installed directly above the transport tape (target tape), and the transport material from the surface of the tape is exactly the focal length of the camera. Using optical means, by installing and adjusting the lens, it is determined that the focal length of the camera is 1 meter and the field of view is 90°. Assuming that the conveying speed of the tape is 2m / s, at the speed of one picture per second, it can be ensured that there is no missing part on the tape. The specific shooting frequency is reset by the corresponding tape transport speed.

[0032] In the first 5 to 10 minutes after the equipment is started, use the self-learning function to store the correct color information. At this stage, staff must be present to monitor to prevent impurities from passing through. When the correct color information is stored, it enters the monitoring mode for the substa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com