Moistening device for a roll or a cylinder of an offset press

A technology for offset rollers and offset presses, applied in printing presses, rotary printing presses, offset rotary printing presses, etc., can solve the problems of complex adjustment and unsatisfactory regional wetting setting results, and prevent unprotected operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

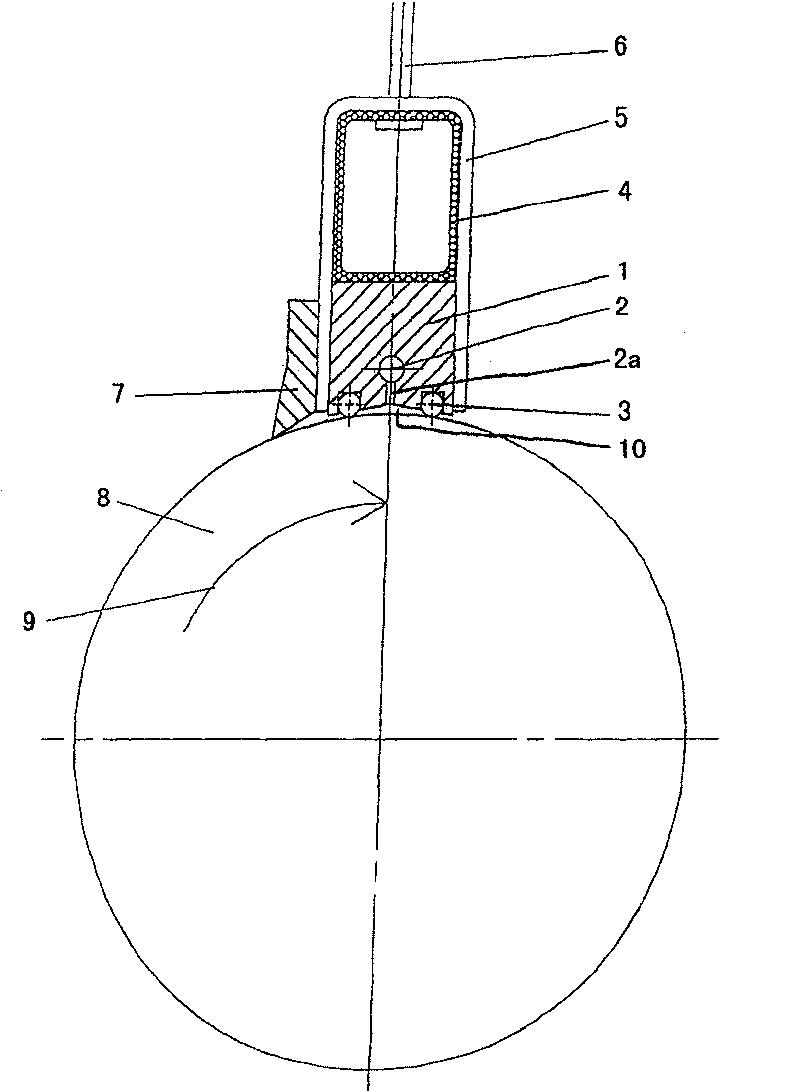

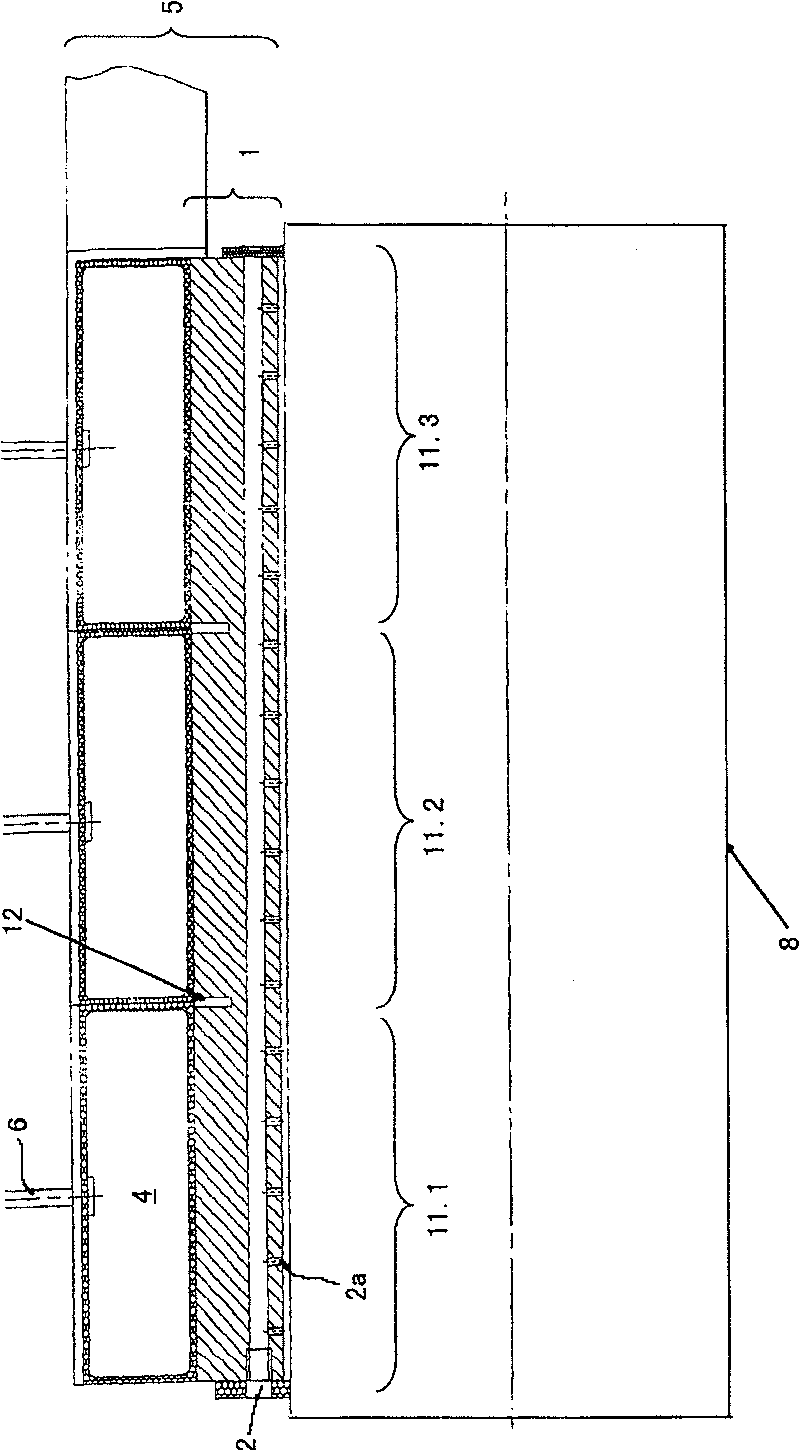

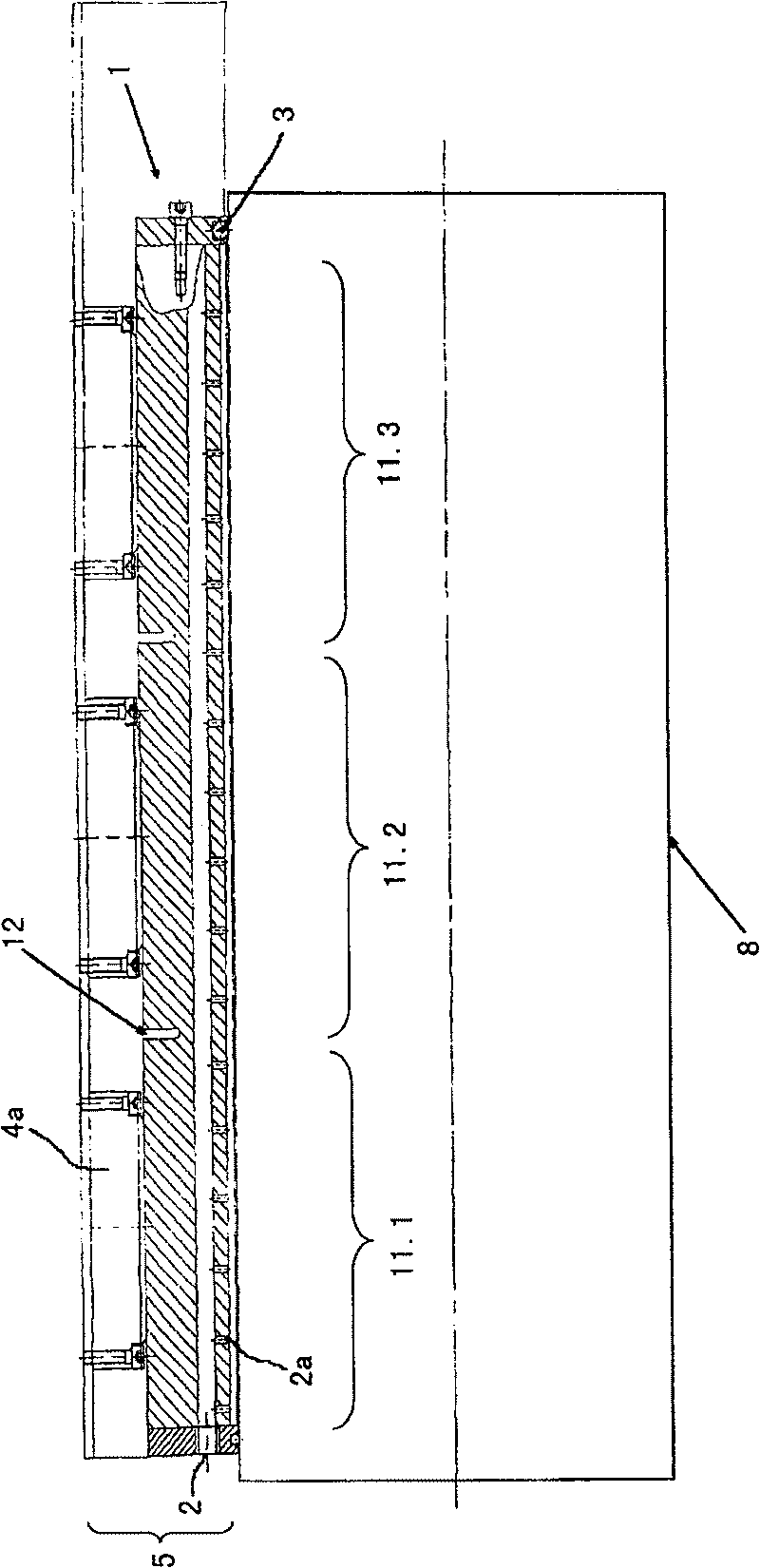

[0032] will be referred to below Figure 1 to Figure 3 The present invention is described in more detail.

[0033] figure 1Represents a section through the cavity scraper 1, through the scraper housing 5 and the ink fountain barrel 8, and perpendicular to the ink fountain barrel 8. The chambered scraper 1 is mounted so that it can move in vertical direction between the two arms of the scraper housing, which in this embodiment are U-shaped. The pressure bellows 4 is located above the cavity scraper 1, the pressure bellows 4 can be selectively filled with a gas or liquid medium through the pressure connection 6 and can also be empty, so the cavity scraper 1 acts on the ink fountain cylinder 8 The contact pressure can vary. This variation of the contact pressure applied by the chambered scraper 1 to the ink fountain cylinder 8 sets the thickness of the wet film on the surface of the ink fountain cylinder, an increase in pressure reduces the thickness of the wet film and vice v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com