Connection shaft and uniaxial eccentric screw pump

A technology for connecting shafts and shafts, used in pumps, pump components, rotary piston pumps, etc., can solve the problems of shape and volume change, pulsation, and poor ejection accuracy, achieving low bending rigidity and improving conveying efficiency. , the effect of high torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, the connecting shaft 10 according to one embodiment of the present invention will be described in detail with reference to the drawings.

[0056] The connecting shaft 10 of the present invention is used to connect a first member and a second member in various devices and mechanisms such as various pumps and compressors, and to transmit power of a power source from the first member to the second member. Among other things, the coupling shaft 10 of the present invention is suitable for transmitting eccentric motion from a first part to a second part.

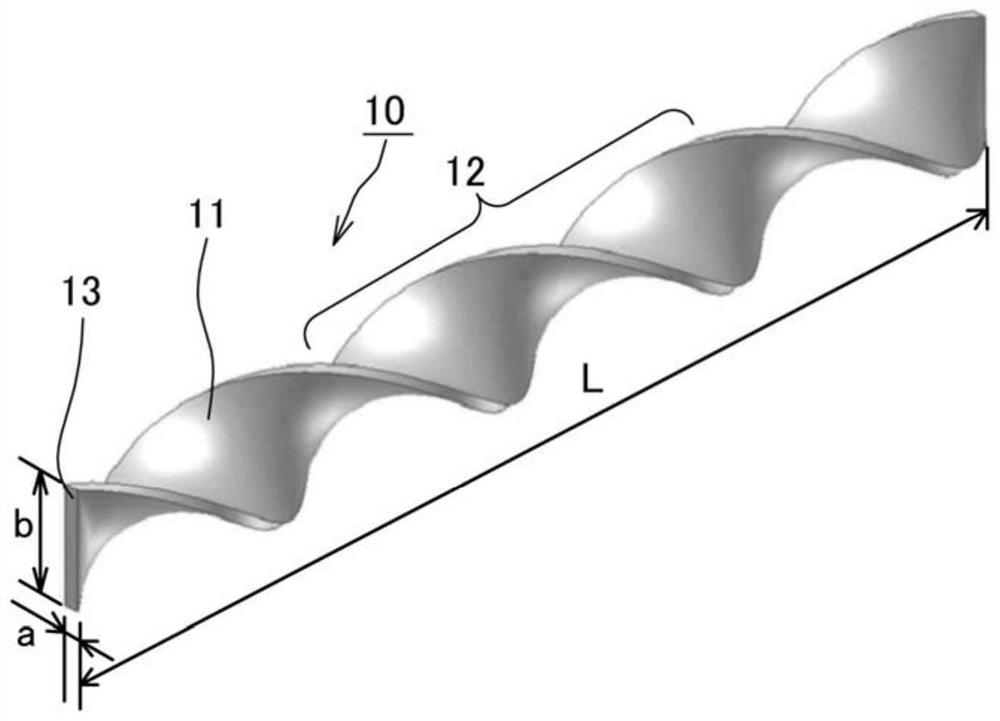

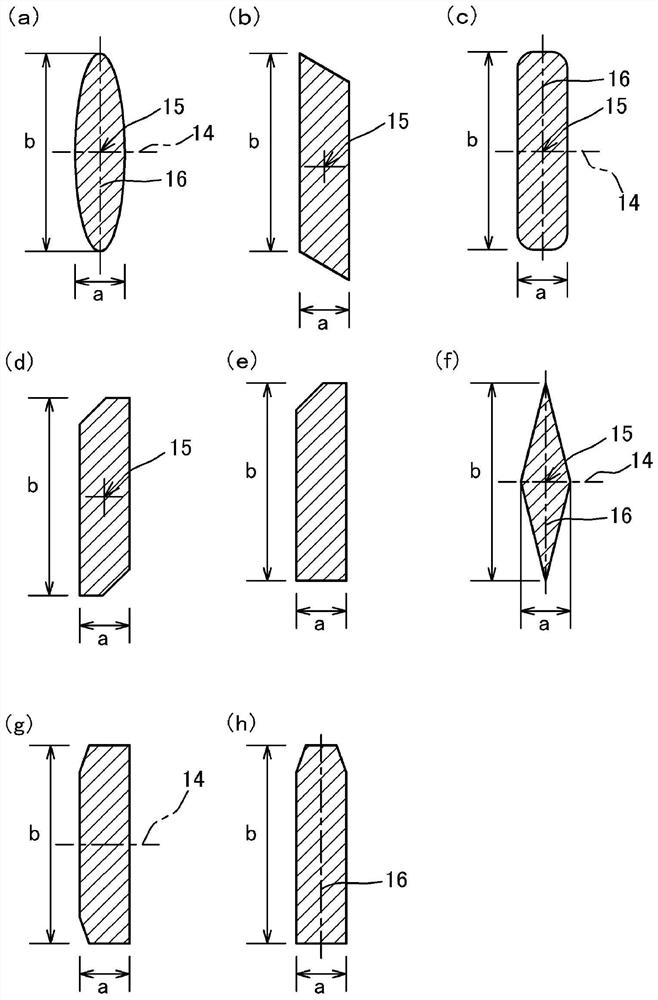

[0057] Such as figure 1 As shown, the coupling shaft 10 of the present invention includes a twisted portion 12 in which a plate-shaped member 11 having a rectangular cross-section 13 is twisted so as to continuously rotate as it advances in the axial direction.

[0058] The cross-sectional shape of the cross-section 13 is a rectangle having a length in the short-side direction and a length in the long-side dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com