Method and device for dredging discharged materials of storage bin

A material silo and material technology, which is applied in packaging, transportation and packaging, containers, etc., can solve problems such as blocking materials, and achieve the effect of increasing fluidity, reducing the probability of arching and sticking to walls, and increasing flow capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

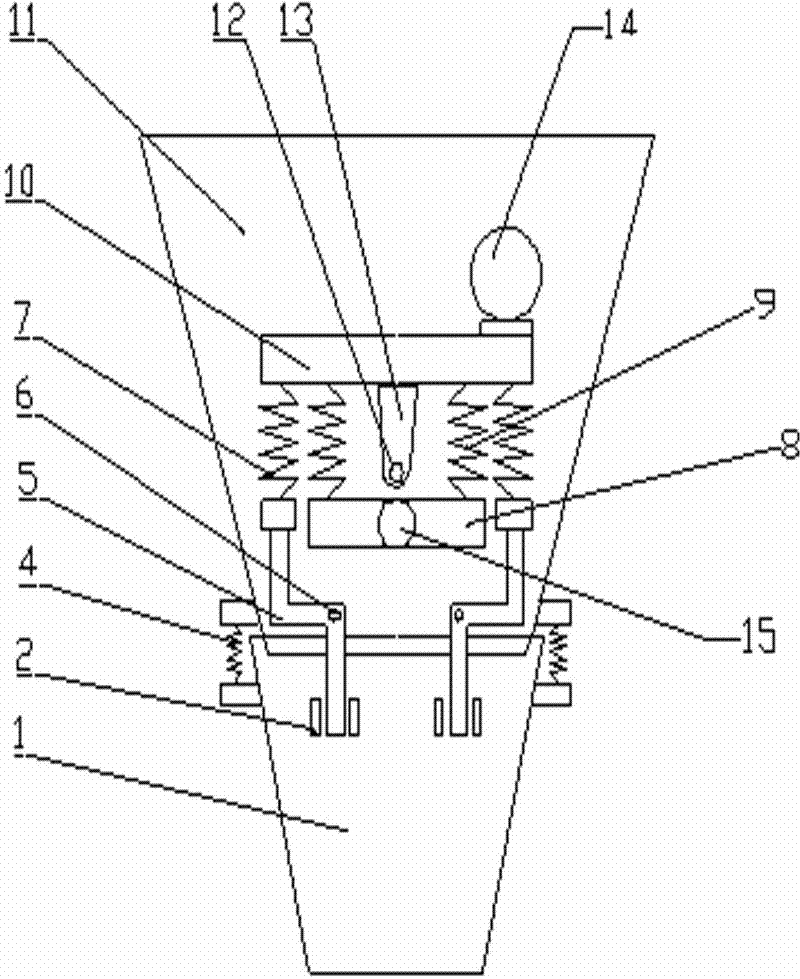

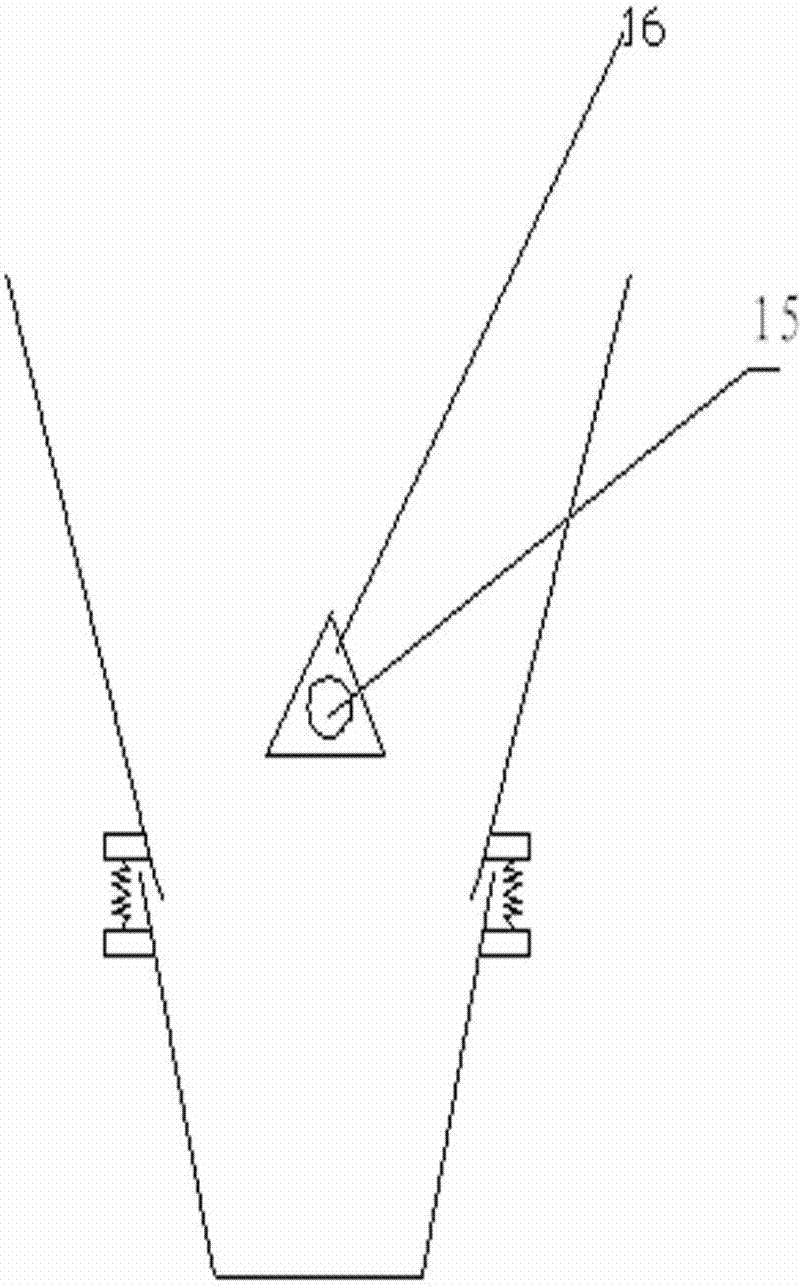

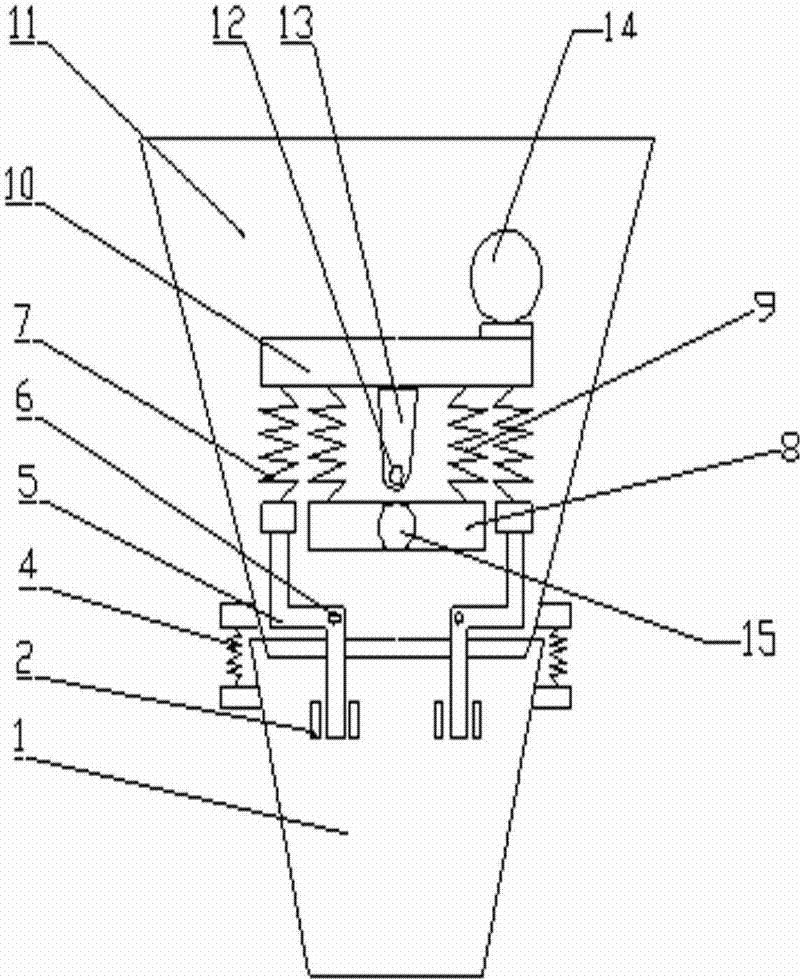

[0031] The structure of the material bin unloading transportation device of the present invention is as follows: figure 1 , figure 2 As shown, it includes a central guide body 16 located in the material bin and a movable hopper 1 connected to the bottom of the material bin 11. The longitudinal section of the central guide body 16 is triangular, and is hinged to the bottom of the material bin 11 by connecting shafts 15 arranged at its two ends. On the bin body above, the movable hopper 1 is connected to the material bin 11 through a flexible hanger 4, and an energy storage and vibration device is installed on the outer side of the material bin. The energy storage and vibration device includes a vibration frame 10, and the rigidity Connect with vibration frame arm 13, vibration frame arm 13 far-ends are hinged on the material warehouse 11 by pivot 12; Vibrator 14 is arranged on the upper right end of vibration frame 10; The shaft 6 is hinged to the material bin 11, wherein one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com